Process of purification of polluting residues and installation for its implementation.

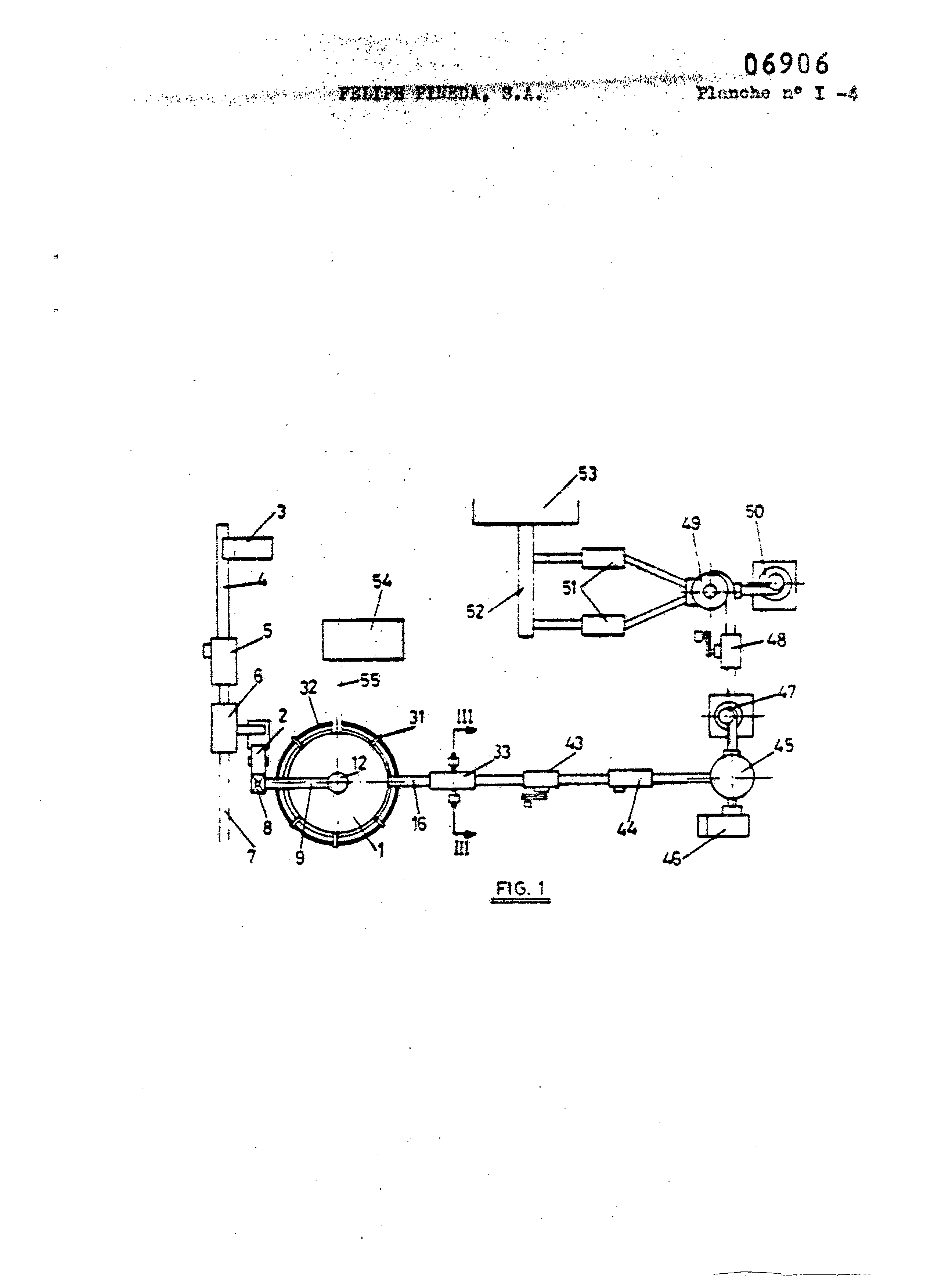

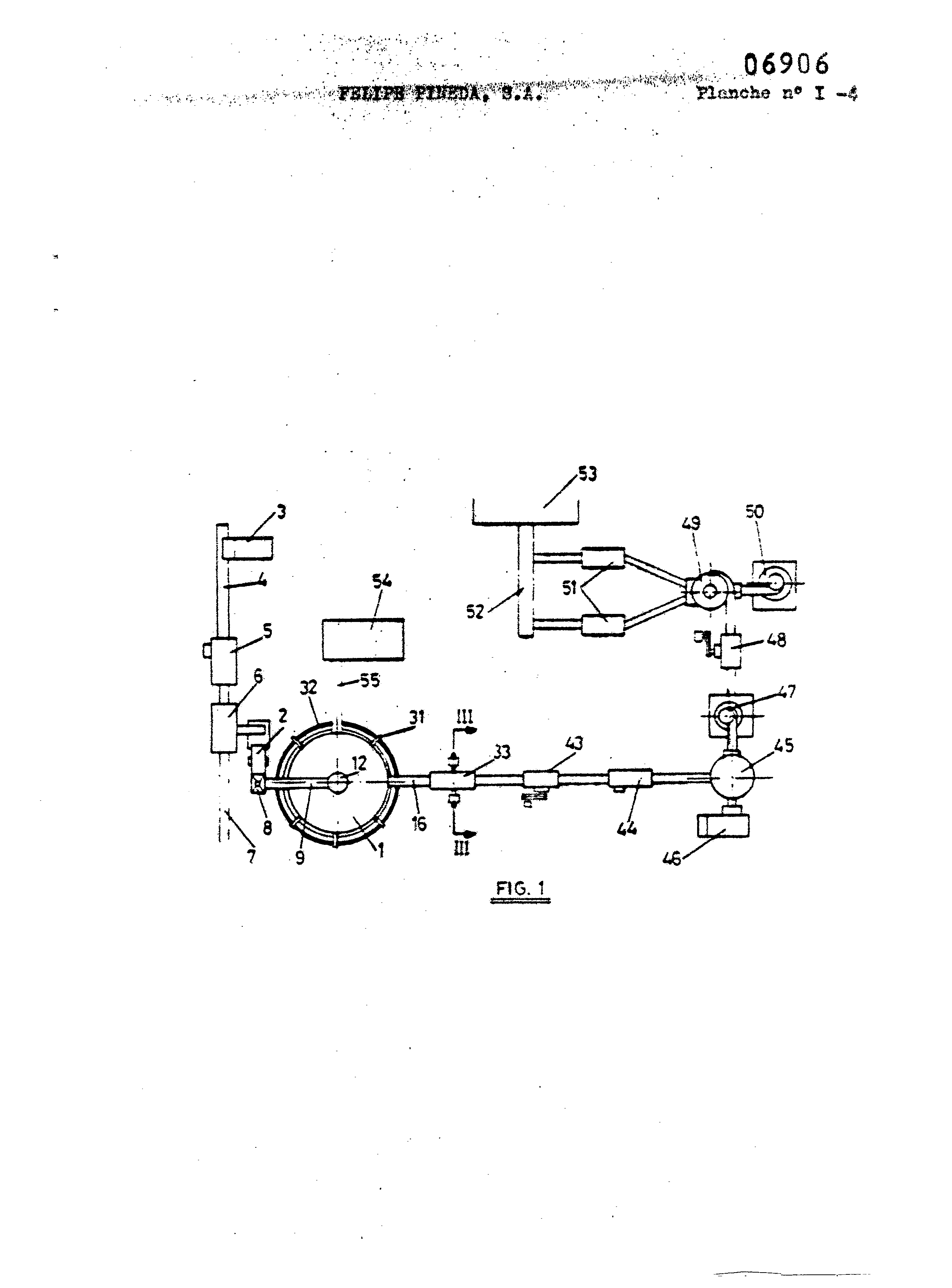

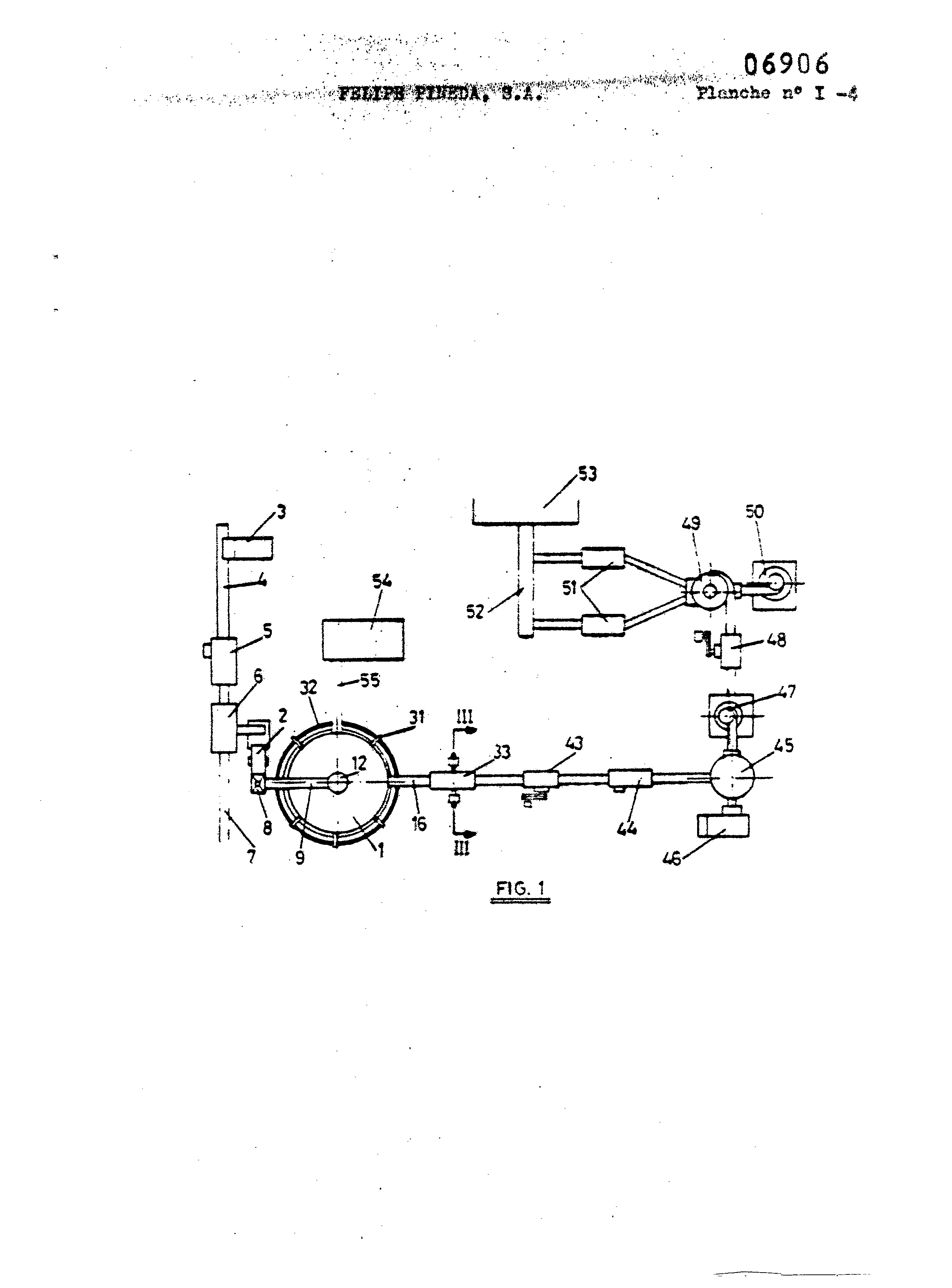

•·ν· ·· - -. - Method of purification. - pollutant residues and installation worked The present invention provides, a method of cleaning semiconductor nanoparticles, pollutant residues or contaminants, especially to clean waste gas, liquid and pasty * # as well as setup for carrying. implementing said - method. , •.. " - "•- ' The invention relates, more particuliereaent ', is a method of windings and " plant for R pollutants, - by employing a biological filter of organic nature, with which the purification is accomplished residues and in The. purified. systems heretofore known ion which may be grouped into two types; those that limit * AIs tùër action of a ^ physical separation of constituents which * cytopathy due part to be scrubbed and product, and b) those in which, in addition to forming this separation, there is a biochemical process for transforming the product to be purified.< Among the systems of the first type agenda such quotas, can include all filtration systems, in which the filter media is unalterable and can, for example, be a porous mass,, such as sand, as well as physical separation systems,, tejls that electrostatic separators.. Among the systems of the second type, there can be mentioned the systems of waste-water treatment, in which exist a fermentation process and a phase separation by decantation, capable combirer in conjunction with a filtration phase *. In the phase dî settling, there remains as residual sludge, whose el the IIR that heat exchanger constitutes to date a large problem ., '••••" [) years all. case, earlier, whatever the process adopted, was only recoups treating the product to be purified and is consequently obtientw, the solids, liquid and gaseous substances that enter constituting said the pro * -V. has should, which cannot be used in practice, The para illeurs # AGEs are the high cost of maintenance and conventional sewage treatment facilities in II was offered that ## is avoided in many cases thereof, after the aêae toto svoir mounted *, with consequent deterioration of the POIs R. AIs place enviléronnant cooked by the déverseaent residues without the toto svoir11 previously subjected th any a purification treatment. For the purpose of 1 - ^ * Pick ion is to realize a method corresponding station installation CD, which allow the purification of - pollutant residues; soaking pit using a biological filter, 15 consisting of a bracket or aasse filter of organic nature, which is etched biologiqueasnt and transforcé during opera ' action of filtration of the purifying th residue, the latter being luiaême attacked, and transformed biologiquesent, such that in the assembly, the end of the th *, we get a product with mental 20 EB by the filter medium. ransforaé and the residue pollutant or contaminant cleaned, said end product is favorably usable as a fuel. In this way, with the method of the invention, is carried out, not only the purification of pollutant residues, but|* 5 also obtains a solid product which may be used and that, th alone, it is to say for its high value ccmbustibi ", in that the installation becomes cost-effective. Waste contaminants to be purified can be of natutgâteuse #, for example from the industries, 11 - 30 nature quide,>ARs example (urine) originated in stock farms the swine, cattle and other, or blen pasty nature, corm can be the case with the waste sludge wastewater purifying it. It is another object of the invention is to provide a prey supplied th1 - a plant for residues PolI - luants, by which; the liquid products, once purified, ' are eliminated as they are in the form of liquids or as -; vapor without producing bad smells nor pollution still another object of the invention is to provide a method for purifying a Iin of pollution, in which a fuel gas that we could use.. , ' The above objects and others which will be readily apparent from the following, are reached according to 1' invention by a method comprising passing the residues to be purified, nature gas, liquid or pasty, through a biological filter, the filter medium which is composed of a mass of organic origin at different stages or types of composting. The mass-qnï ^ constitutes the filter medium may consist of vegetable residues, e.g. residues from wood or forest, or still refuse, or mixtures of refuse or waste from wood. This capability provides the method of the invention a large value, by allowing the use and disposal of garbage from urban centers, which constitute auiourd ' poses a large problem. In this case, the method of 1' Pick ion may be applied for single objective, with the removal of the refuse, further enabling an end product and being adapted to have use as a fuel. Distinct fermentation conditions are initiated in the filtering support by cultures of microorganisms, such as bacteria, fungi and other, previously prepared, so that they are resistant to pollutant residues to be treated * As can be appreciated, the microorganisms that cause and maintain the fermentation, must be resistant to the medium in which they are to live and must further be capable of producing the decomposition and the purification desdifes residues. Therefore, it is necessary to pre-culturing the ITS micro orcanisms deed, so that takes place their suitability to medium in which there is developing. Once having obtained microorganisms, resistant 11 may occur depending on the ^ time that the strains, in; the method of 11 invention for a determined type of residue polluted&Tg degenerate and become unusable for X ' operation on the filter. In this case, it is requires renewal of 1' seed. The microorganisms used can be susceptible to complete decomposition of the pollutant residues and the mass mistletoe defines a support. F. it thirty them into solid products, be used as fuel "to liquid products harmless * who can be removed at a liquid or gaseous state, and in products * gaseous fuels or non polluting" "•- * The medium comprises, according to the invention, three consecutive fermentation among which, in the first ' and the third, occur the aerobic fermentation, whereas in the second anaerobic fermentation takes place. ; ' - To maintain substantially constant the boundaries between the three fermentation conditions, as well as activate said fermentation in each state, is set in the presence of oxygen, moisture and temperature in each of said conditions. In the first and third conditions, is introduced toto âir atmospheric, for providing aerobic fermentation, whereas in the second state, is extracted gasses and liquids, all measures contributing, further, temperatures are maintained. The first and third fermentation conditions further serve as filters for the gas and liquid that can form in the second stage, by ensuring that their release can occur without bad smell " The gas that are retrieved directly from the second fermentation step and which are those that can produce malodor, contain large percentages of combustible gasses, so that they can be fed to a chamber for combustion or operation, after having been duly processed " The mass which constitutes the support filter continuously renewing due passed gradually from the - Toto prwrëir•. '; 'Itfrfc' - - derifairaentation at second étof?% al-ai, AA-three the:: - - ℮ itaï of fermenting, D.; * where the O "- the X * extract" batches transformed, at said third state fcefme "céuftii"&tvec resided the scrubbed, meanwhile, the mass filter -? new is found; n. a-cluite beginning at endometrial ;. *. RAI - state fermentation,>* thine, that performs this year prsseasas Cor; ;. do. Its m CWR 12 > e - 2 4c ' L.F. the I 1 is performed reneuveemen fc-•TMs cuppa? t-filter, gold. added the residue pollutant to be purified, which AEP read introduced into said fésisentafcion * state - of-or still ., in the second state fermentation. The speed-renewal - of the support'support'.fût-as joined to residues to be purified, must be clean to assacer-a '-a' total dénospcsition, such waste and maintaining the " living conditions for bacteria in the. three conditions. fermentation. To maintain the presence of oxygen in the sppcoorLées in first and third conditions of-to-Carmentalion, it may evacuate - gas and the communicating ' directly with the atmosphere. As is. can understand it, ., . between ' the. similarly tones of the filter media.. which correspond to the three 'conditions, of - fermenting, there is' of PeoPles intermediate transition, in which gradually changed conditions, between the values that correspond to the conditions -' Haltropheâ.' By extracting the product from the second liquid - state fermentation, in, part in vapor form, together with the hair in gas products in-said-a-tone service, and in part. form-liquid by gravity-or - suction. Could carry; out the three steps - farmentation together or separately according to, inter alia, environmental conditions, the characteristics of the residue to be cleaned, the nature of the filter media, the cleaning speed desired and the like. Thus, there can be three statuses fermentation together in a common tank, wherein the first and the-third-in-state of ferment ion to occupy the end zones of said réservoir,-to-a-'tandis -, that the second state occupies the central - portion. thereof. Preferably, the three conditions are distributed vertically, - the first state ^ - ^ - ;: ·;··: ;;·; · '•e and the top being troisièse being ' lower * of - eèt Te manner, 1 * removal; the euppprt - F. iltraiitréaiïi eA. - residues' lost, can be effected by gravity, by adding a nouvelI® suncoct mass. filter part for sucking Laura tank and ISS residues to be purified in step most appropriate. In the case of d * gas cleaning, by the Exe ^ ETP>;; these: - thereof. may be introdui TSs; in the second ' a-êtai ;. of. $otet irons.|is, ' with. - tequéV the first and " ^ trpisiess: etafs -: rCS afcvde ^;: filter cleaner. for the gas which penetrate Onpeufc also implement the three state fermentation in separate tanks. In a first tank, occurs during the first state of aerobic fermentation, from which ' changes' toto riservoir mâsse filter in a second, the takes place the anaerobic fermentation, for passing finally said isasse-in in third tank for the third, state of aerobic fermentation. Adding residues, the extraction of gax and liquids, the setting conditions. fermentation and the like are brought to-.oeuvredéjàexposée as above. Finally, there is opportunity to put 13; en.' work of venting the first state fermentation and the commencement of the second state, - by passing the filter medium consecutively joined to residues - has be purified into: a reservoir or is then completes the second and third fermentation conditions. The QA can even be achieved with three jetproof fermentation conditions in the open air. A joggled * LED further aspect present invention, following completion of the distinct fermentation steps, or at least part of them, is carried out with the separation of foreign matter, such as stones, metal objects, glasses and the like that could accompany the material comprising the filter media or be included in the residue be purified. Separating said body after the three ^ fermentation repair or parts - they, ' stakeholders " n granî srsr.tig */ therein, especially when the support. filter: AST testing consisting, c * 5t * l fessai; or hand tee ballast. 1, perse desdes.or-hard FSO - if ' milk qusqus.éüb Cup; tone-to-litions, the SHâtièr " - which constitutes Ta-;.' carrier f. ii.ifeî AN prshînt % 5 - 3 * -? - iâsejrêgéâiquerrent rats under high - of - petiter-to-'n * -; :' laughed, had ρ· ·℮. -. be reeKe ' teottédtgréfle - / -; 3V ' TD: I - Uï|Trl.-to-subscribes: ' enjoying: here in energy,, so, that-a TES - ohfetTnoa "eéb ·. g GT To - gvevsnfe" T-. 'separate perse ettb-to-isqe' a-'.ou " by difference, of dB ' uu.irê * . - ℮℮ ;℮℮ is 1' - will expose hereinafter. A - times - that the. carrier " - filter.tM®. sAL - pollutant residues purchase '. - jetproof érsntss - a tiff. passed.;âa ' farsantttkm and, after separation method to Ala " .body - of -. foreign, the product is subjected, to a - Da are-pulping process. -, - cAT-FFEs opera T-ion are provided facilities' by-a-tees - conditi on-s-in-a-which is the produit,-to-racilecent disaggregated the under the aifet * fermentations. - - said ., triturated product ■■aside from R of the product triturated and * dried, obtainable also, before - the - côbfonBS T-ion. briquette, . " n.; powdery product, finely ' divided,, which may be I-RIS cyle of £ivantageusemenc as fuel.... the injectable. ... Commeb il-to-.-been; indicated.' hereinafter dessas .,, the -. three. steps of fermentation RTO part of them are luxuriating ., out in a tank of a storage-a preferably cylindrical, vertical-axis, whose.;: " the- . base·-to-θΐΐ-party ' - opening at its lower portion and the apex or upper # - - is: . firm ' Sajis said reservoir, is introduit,-by a minings. input. in its closed top, the-material which constitutes the filtering medium * the residue. e relatively high ion, such as plastic bags, bottles and other.. According to the invention, the reservoir is supported by brackets could support feet external, which lie around the tank at separate points radially relative thereto. Below the tank is disposed a substructure for supporting the filter media, the tank wall which does not extend to the base defining between them an annular opening, through which a radial worm, which can move angularly along the length of said opening. The seat support is provided with a central opening, which serves as an outlet port, which is located inferiorly connected a pneumatic suction extraction duct. The worm is supported by its inner end on a pivot bracket, mounted in the central portion of the outlet port of the product. By its outer end, the said worm is connected to an actuation mechanism, for causing rotation thereof and its angular displacement. Under these conditions, the screw passes through the filtering mass, in the part in which it protrudes beyond the lower edge of the tank by resting on the underlying support. The rotation of the worm results in movement of the filtering mass toward the central port output device, provided in the underbody support, from which said mass is drawn through the discharge line. At the same time, the angular displacement of the worm that runs through the entire substructure supporting, by driving constantly front with a filtering mass which is driven to the central exit opening. In case the worm screw encounters in its angle advance excessive resistance, the driving torque of the actuating mechanism that causes said angle advance is less than a predetermined value, such that when the resistance to said advance is greater than the given value, said mechanism slips, the worm being in this case only the drive rotation so that it does not cease. moving the material toward the orifice For- Also manner according to the invention, the reservoir is provided with a series this tabes - vertical, in addition to the aforementioned central conduit, tubes penetrating leedits, equal to the said central duct, the upper lid for closing the reservoir, but reaching only heights corresponding to distinct conditions. A set-their characteristics.. the tubes which extend up to the conditions correspondant'correspondant' with-to-a-aerobic fermentation, serve the input dêdê.l ' SIRs lesdlts conditions. On the contrary, the tubes which reach the height corresponding to the fermentation amêrèMe, - serve, - to the gas outlet and vapors. Lesàifcstubes.-to-enable - adjust of the presence of oxygen and th © tempera tare weight - steps, distinct. A part of. ducts Also, the - ducts. aforesaid perviennent - up to the anaerobic fermentation zone, may be closed at their ends. I imetior -, -;The IQ|" the R;; L-UcoXlecte<3' - liquids, which may be retrieved periodically by suction. The individual tubes are provided with block valves and radial holes, located at different heights in the region of ferment-ion to which they benzoylacetanilide dir igent * In the extraction duct is mounted a separation chamber of heavy particles, such as stones, metal objects, pieces of glass and the like. All organic materials which compose the filter media, joined at residue purified, after being passed through the three fermentation steps, density are quite smaller than the particles and objects that may enter said organic materials, whether as particles and objects mineral or organic inclusions which, due to their size, have not been collapse under the effect of the fermentation. The above separator, exploits this density difference for the removal of said particles and objects. In accordance with 1 * invention, the separator is formed by a chamber below the air extraction duct, in communication with said conduit. In this chamber is a worm, actuated by the corresponding motor, disposed horizontally between two walls of said chamber. O ^ TREs, thence chamber opens laterally into a downwardly inclined conduit, which opens out into the outside bottom it. The mission of the worm is agitate the material that falls from the discharge line and displace it towards the inclined conduit. The open lower end of said inclined conduit is provided with a block valve that can be calibrated. The excess pressure in the discharge line, causes occurs through the inclined conduit, an air inlet toward said extraction duct, variable according to the opening of the valve. This air flow drives again the particles less heavy to the conduit described above. By adjusting the block valve of the lower end of the inclined conduit, can vary the amount of air flowing into the discharge line, so that the drive force of said air is sufficient, the n tsour send to the pipe-entities for pulling the particles less heavy, corresponding to the organic product, fermented, while the heavier particles fall to the lower end•said tube, from which they are discharged to the outside. With said system,, may be, simply and reliably, effect the removal of objects and heavy particles or unavoidable, such as soil, stones, crystals, and other metal objects. The extraction pipe may emerge, beyond the separation chamber, in a hopper portion of which the product is transported, also by 1' through a pneumatic line, crusher in which takes place reducing the size of particles " this operation is facilitated by the absence of foreign bodies, separated by the screen and the separation chamber, and by the conditions under which are the material after fermentation, said material being then readily repulpable. The output of the mill by a conduit transporting the product to a screen, wherein separate the particles of larger size, then passing to a cyclone, from which it is obtained a powdered product, which # by its characteristics, can be used as fuel injected, and a product of larger particles, which pass in a brr iquetteuse, charged conformation solid compact body, easily manipulâtlesj usable as solid fuels. Other features and advantages of the invention shall become apparent from the following detailed description of an example of a plant for carrying out the method, illustrative, but none at all limiting, reference to the accompanying drawings, in which ii figure 1 represents a plan view schematic of one possible form of embodiment of the installation of the invention; figure figure 3 is a cross-sectional view is provided year of th figure 4 is a sectional view along the line VI-VI of Figure 3. The installation shown in, figures is constituted such that all three conditions of fermentation are implemented in the same tank, although as mentioned above, lesdlts fermentation conditions can be implemented separately, in separate storage containers, and that even the first and at least a portion of or all of said second conditions may be done in the open air, the mass which composes the filter media forming clusters of convenient height, in which. the entry of air into the aerobic fermentation conditions and the output of the MFR of the anaerobic fermentation, can be performed by the aforementioned cluster tubes inserted into appropriate depths. In EE-case, further added in the clusters mentioned, waste contaminants to be purified in the fermentation step the most suitable. As can be seen in Figure 1, the installation comprises a cylindrical tank 1, vertical-axis, within which consists in carrying out the three steps or fermentation conditions, material-feeding of organic origin which constitutes the filter media is performed by a bucket elevator 2, although it may also be performed by another system of any elevation. The material of organic origin, from a storage area, is poured into a doser 1, from which starts a conveyor belt 4 for powering the crusher 5. Using the metering device 3, by adjusting the amount of material entering the mill 5, so that it does not occur of obstructions in the latter. Said mill 5 is provided to produce a grinding or milling is sufficient to break large objects. For example, in the case where the material of organic origin originates, totally or partially, refuse, this invention finds the mill to cause fragmentation of the refuse bags, boxes, bottles and the like. From the crusher 5, the product is sent to a screen diu separator 6, are seulsrvant removed the objects of large dimensiao - * - kind of. plastic, metal, crystal and the like. a TES in separate objects come out - 7, while the rest of the product 'is poured onto 1' elevator. 2. said elevator can emerge into - a chamber 8, where ' it passes, by way of the conduit 9, within the reservoir 1. As shown best in Figure 2, the reservoir 1 comprises a cylindrical wall 10, which is constituted by or covered - internally by a non - of the etchable or deteriorated under the effect-to-'de fermentation, and an upper lid closure. 11, ' while at its lower base, said tank is opened. On the cover 11 there is mounted a soild © receiving '-of the material, such as a cyclone 12, until which reaches the supply line 9. The tank 1 is mounted on brackets. or external supporting legs 13. Below the tank is disposed a basement 14, for example a ' basement concrete or iron, which is slightly separated from the free lower edge of the wall of the tank 10 *. In - the central portion of the floorpan 14 is arranged an outlet 15, from which a line ' extraction pneumatic -■16, . extending radialèsent outside * Has 1 'tank interior there is mounted a' central vertical tube 1? suspended, for example, by tie rods 18, said tube extending from the top of a point above the level or 'a-'hauteur peak-to-which is reached by-the - filter media, and. - inferiorly emerging above the outlet 15.' .the L'end. upper, the tube 17 may be provided with a cap 13 which. prevents admission of the. material from the cyclonic - 12. - Cetube may 'include, throughout its length, openings 20, superiorly protected - 2 - 1 by detectors, which' for preventing the entry-material of the filter medium and serve for the suction of gas and vapors which are generated in each ' fermentation steps. For the operation of said gas beam, it is then provided vertical conduits 22 extraction which open through the cover 11 and sputtering start from the region 26 corresponding to the state or step fermentate ion of tee. . - - - i-. '. as already mentioned above, between the three conditions, transition areas exist, but to simplify this disclosure, were represented three areas where said conditions occur, separated by the lines 23 and 24, 25 the upper region corresponding to the first state fermentation, aerobic, whereas the area - intermediate 26 corresponds to the second state fermentation #, anaerobic, etet.que'-to-area, lower 2? corresponds to said third state fermentation, also aerobic. For I * entry of air into the areas 25 and The £etween the lower edge of the wall 10 of the tank 14 and the subframe, is mounted radialesieht a worm 29 for transporting the mass of the filter that pre. feel at the end of the third state fermentation 27, towards the central exit opening 15 the worm 29 e © is externally actuated by a motor unit 30 and bears with its inner end on a pivot bracket 31. The motor unit 30 is mounted, by means of wheels or any other system, juice a raceway 32, mounted between the supporting feet * 13 of the tank 14 and the subframe. Said group Mo TEAR messages is; moves on the track, so as to impart to the a-vis,'s-ans. ' worm 29, and posting of a-.plus This purpose} can be obtained, for example, by the system ., - bearing group nctcur " F. -; - fsççn that the inner support 31 of the screw without In drive * - extracting ' 16. fig. 1 *■" there is mounted a particle separator. heavy 33 consisting coasse seen in Figure 4 and SAL -3the R by. each chamber 34 disposed under said ' - line. Ls *■•cossssmicatioa - and with it through 1■'■opening, / 35, whose "a may adjust the passage using the valve .36"' . In the chamber 34 is fitted a screw without FISs - :.. horizontal. 37 "'that follows a path that is transverse, to - the a-to-'Conduite 16" and is actuated by the power plant. 3RD. the confined - 34 opens "in a lower conduit 39 inclined -" - - which is open at its end YR laughers. 40 '*/ juice' which is mounted an adjustable valve 41." for example by X ' via the mechanism 42. . - In the same hose 16 "fig. 1" downstream of the particle separator 33 "found disposed-one fan 43 * whose inlet - is performed through said conduit 16, from" the I ' port fig. 2 sortie.-to-15 *.. . - - - This suction creates a vacuum in said conduit that has a function to eatralnerla.-to-.jaafciete moved by the worm gear 29 and dress the orifice 15" * - of Sn. addition * 'said suction causes an input: the air. *'d' to -: through. the conduit 17 and the opening created by #. the " worm itself during its operation, in 'avoiding-to-a-.'.ainsi - the airflow produced which could cause obstructions to the outlet 15 * l 'suction produced-to-a-'dans the conduit 17 is formed with the air inlet will occur, the upper cyclone * 12. At the same time, in its reference to Figures 3 and 4 * the 'vacuum pressure in the pipe 16-effective to provide an air inlet through the L .' port 40, the intensity of which depends on the degree of opening of the " valve 41. •■■. · ·■■; . 1 δ The ' ^ the TIER th entealliée Pal■am - ie. line 18 falls-d-years the chamber 34 > une.-times - the valve ' 36 open ;® ., AEG screw. without, end 37 agitates these products - - at the same time that elxe therein.-las systems moves in the windscreen -.. except tilted channel 39. The " L-rulethe R vessel RTUs that this the valve 41 so that current in toto dîair-to-complements. penetrates through the orifice 40' - again drives:iês; partiçîiles. ins for ώο. heavy to the conduit 16 -, for tracking is $; in the denser particles # tandieque - heavy, such - that stones ": metal objects". glasses, and the like, fall on the valve 41# of or they are discharged to the outside by-.l'ouverture/ihtenaitrente thereof. The duct 16 opens out " after the fan 4, 3, in ' a. mill. 44jthe R ;: desiiné th; : '; fragiaenter fermented product made to the' ^ gràeuloséteiedésitéèy this operation being facilitated by consistency.; ' reduced of-particles after the fermentation. '. The - material - triturated may subsequently transitioned into. screen, and then has a chambredeséchage45, into the furnace 46 which can combust ., per-.exemple." a part of. residues, previously separate * ïlïl.y; should hold. the account. fact-that the degree. * d.: ; moisture " of: - the. this material. time is very short " by. following:; of: l-.' removal of: steam under - temperature - which ' -. - prevails, in the grounded during the distinct states de-fermenting. ;. /. -1 The dried product can. then be stored in a silo.. 47, "to departing which ion in the extract" - via a transpOrtear tire having a fan 48, and■sent. to, α α ^. cyclonic. As can be appreciated, the facility can be supplemented by silos at the locations where it is desirable to i arrange - create orf.; .: d inter-POCs rg - "1 . This can.; '. i: - s providing two parallel tanks rsoae * I-controlled by the charging equipment and estracfclcs. Near the reservoir L is formed on the deposition The tube. 22 or parts had, fig. 2, may extend along an inclined portion thereof downwardly # YES ART poured-in the wall 10 of the tank " - for the outlet by gravity liquids produced in the sound 26 anaerobic fermentation. "In a different manner" iésdifcs tubes may be closed at their lower end to collect the uncooked liquids, then being extracted. by suction. It will be understood 1 * invest indispensable The specification discloses a method and installation for purifying waste. A tank (1) is fed with the waste and with a biological filter substrate, both of which are fermented within the tank. Pipes and ducts (17, 28) supply air to an upper aerobic fermentation region and to a lower aerobic fermentation region, and ducts (22) remove gaseous and liquid products from a middle anaerobic fermentation region. The fermentation products are removed by a sweeping worm (29) and sucked by a fan (43) through a separator (33) in which heavy particles fall out (through 40) but lighter ones are retained by the suction. The product is triturated (44) and may be dried (45, 46) and made into briquettes (51) for use as fuel. ;.!. Method to 'épar O T-ion of pollutant residues, in sartiscïlier, for purifying waste gas,, liquids and péteiMS * characterized' by. the fact that it comprises passing the re - * sidus to traders on a biological filter, compound these fermentations are being adjusted ' by introducing air addition first and third conditions and the L.V. w, X-pulling, imposition RBM and liquids of the second state,: 'for, maintaining the height of each state and the conditions of temperature, -'d' moisture within boundaries that activate the process-of; feraen T h ion which, in proeé - -; bafflement at renouvellensentthe R the trochlear mass which composes the filter medium, by taking out the mass, and the solid products. décosposée non-. harmful formed parts - /. residues, -. driven ' by said massei to. làlà .fin due: third; dedifferentiated state fermenting, while introduced ^ has; fresh mass, at, the beginning of the first. state. fermentation,-to-to-go manner. that the, mass. and: the - residues to removed above. pass. gradually by, . the; conditions dîstinctsermentation of f, the. speed. . renewal; being own confectioneries ensure the total decomposition residues and the conditions of maintaining AE life: microorganisms' in all three conditions, fermentation prevailing in the filter medium. ■: 2 i; -. 5roeédé according the, paragraph * characterized in that. the SAL - residues introduced to '-treating dansile first.■cooking state, . : . ; 3. Dédé.selon image display apparatus' the, paragi * eB hr. ^ * 'vVr' 1, characterized by the fact that■introduces the residues to be treated in the second state fermentation, ■• . .' - 4. Method according; lambdag - paragraph 1# characterized in that the first and third, fermentation conditions have1 direct gas outlets: in 1' atmosphere. -." 5. Method according! "characterized by the fact - that fly off the gas extracted from the second state" if step. fermentation, in, a chamber this ooabasfcion, '* rívetted of OA - OA is treated for subsequent combustion. 6. Method according its^1®ssspïSs■the I, . characterized ' by the fact that between the areas corresponding if "tri fermentation exist of•intermediate zones' transition" in which varied © regressiveaeat conditions between the values corresponding lock adjacent boundary conditions. 7. The method according to the I# characterized by the fact that the n l * o retrieves the( liquid product of the second state fermentation "verified to be® sôud pit vapors, reunite with the gas from said-state" ATs - partly in liquid form " by gravity or suction. a method according the I * 9. Method according % characterized by the fact that a set worked the tri - de. prefermentation in separate tanks " 10. The method of claim 1 ., characterized by the fact that with-minus the first 11. Method according/lg - except for charging or - reservoir." and an extractor products. solid non-hazardous " resulting from; the. /.. - fermentâtion, characterized. the fact that the tank is open to Uî SSs its base 'lower " in ** descsuc of' which. ■ΐ β - is disposed.069 Μ■ a substructure 13. The bars gauge-to-.gr installation according to 12, characterized in that the reservoir is supported by brackets (13) external abutment, which lie around the tank U-), radiaiement separated therefrom by a variable mechanism into the'd ' AC-T-I-ionneaervt worm, below said tank being provided with biased (14) supporting the filter media, separated from the wall of said tank (40) of a height sufficient for the passage of the screw (29) endless, in the central portion of said base (14) being provided for a port (15) central exit * 14. Installation according to 1" 13, characterized by the fact that the worm. {291 is pressed, because its inner end, on a swivel bracket (31) mounted in the central portion of the port {15) of crimped, between the opening and the mouth of said central vertical pipe, without obstructing the fall, the product, while by its outer end, said " worm (29) is linked with a aetiormœeîît, confectioneries for cause rotation and angle advancement of said screw, the engine torque which is generated by the angle advance being lower T a given value, so that when the resistance confectioneries said advance is greater than a certain limit, the worm described only rotational motion * 15. Installation according ^ paragraphs. 14, characterized by the fact that the mechanism of actionnenenb of the worm (29) is arranged outside the support understructure, said mechanism resting, by 1' through a rolling element, a track that surrounds said underframe, and movable along said track by driving said auger (291. '^' 16. Installation according: 1e ^ raplie SAR