INKJET PRINTER AND PRINTING METHOD

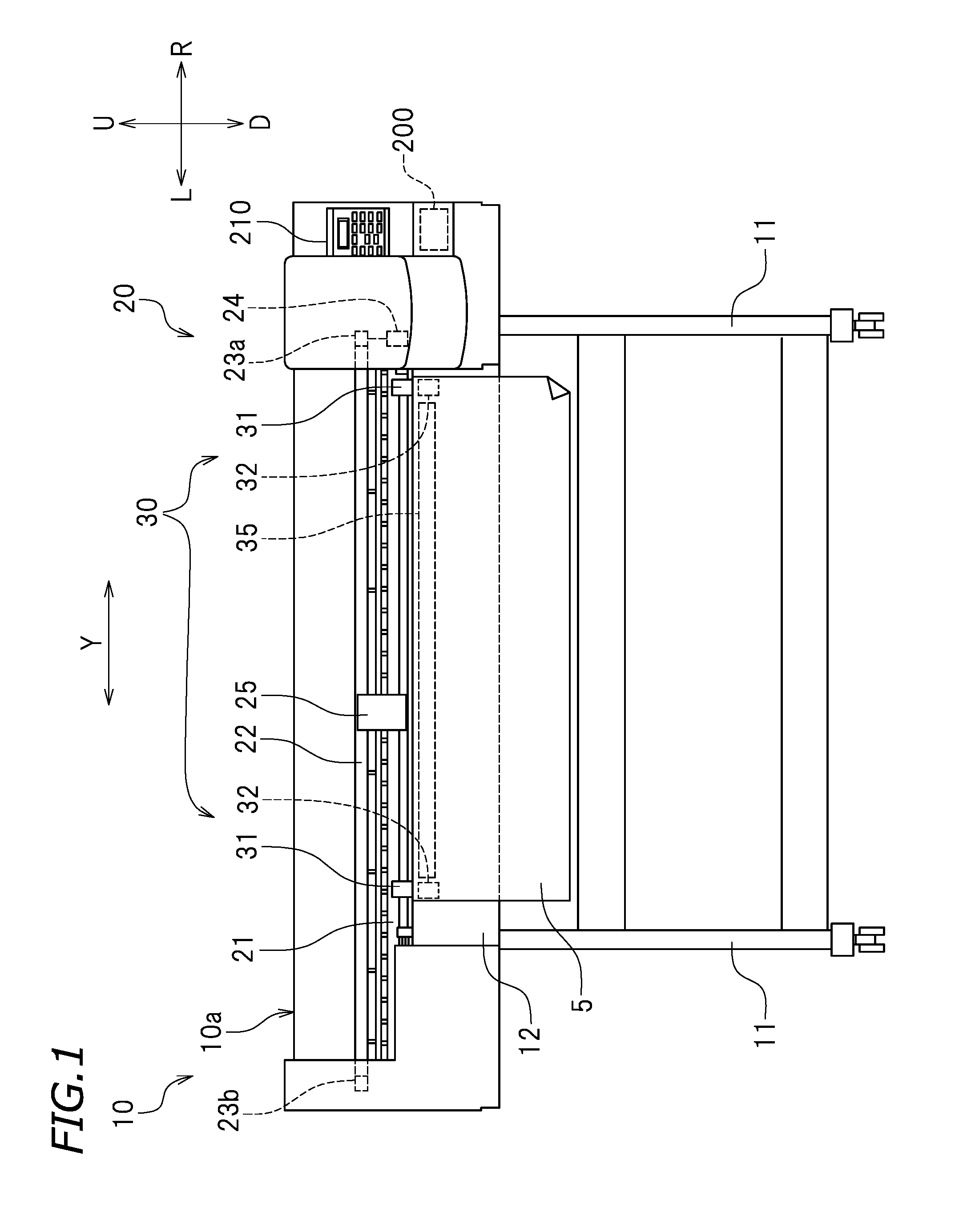

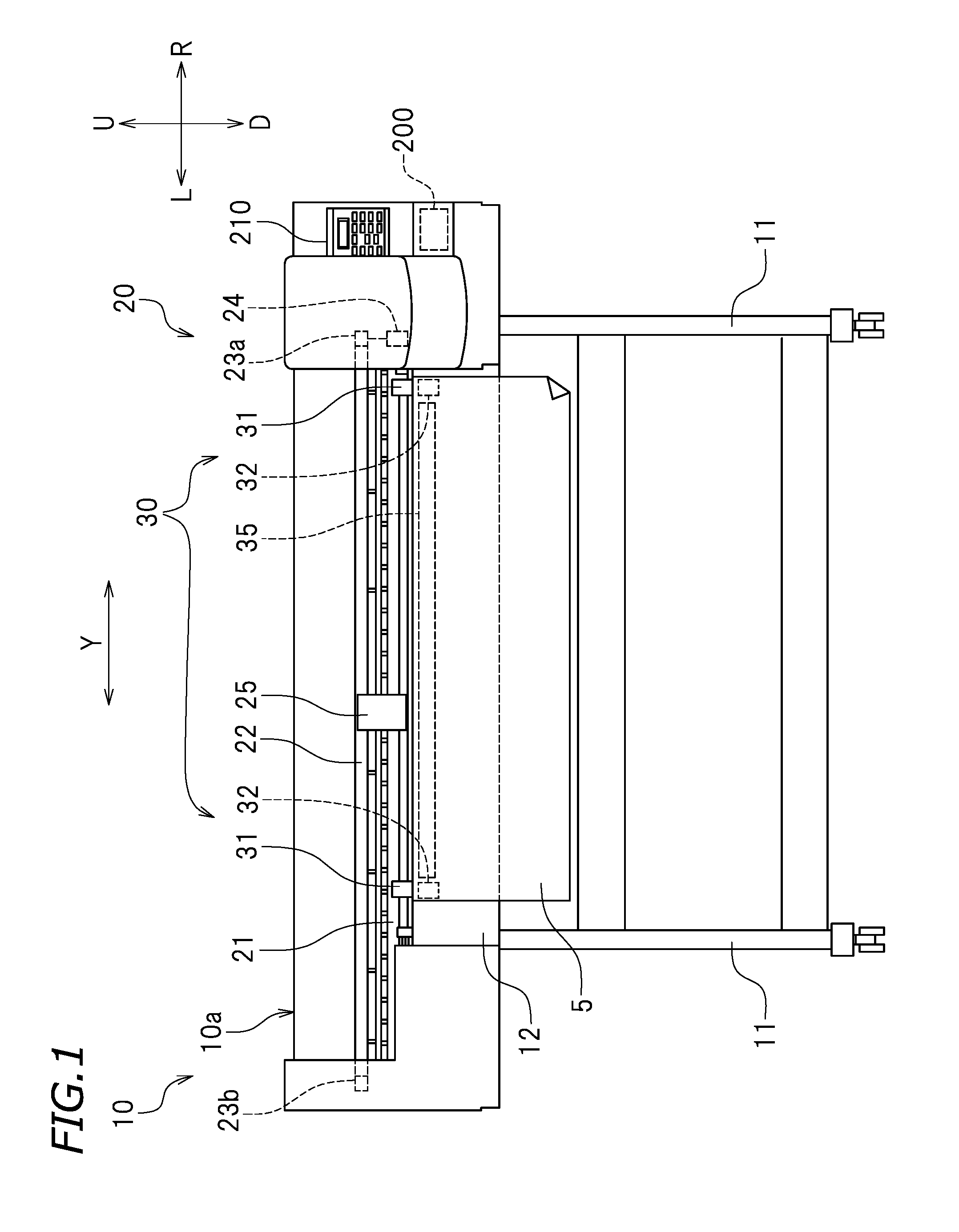

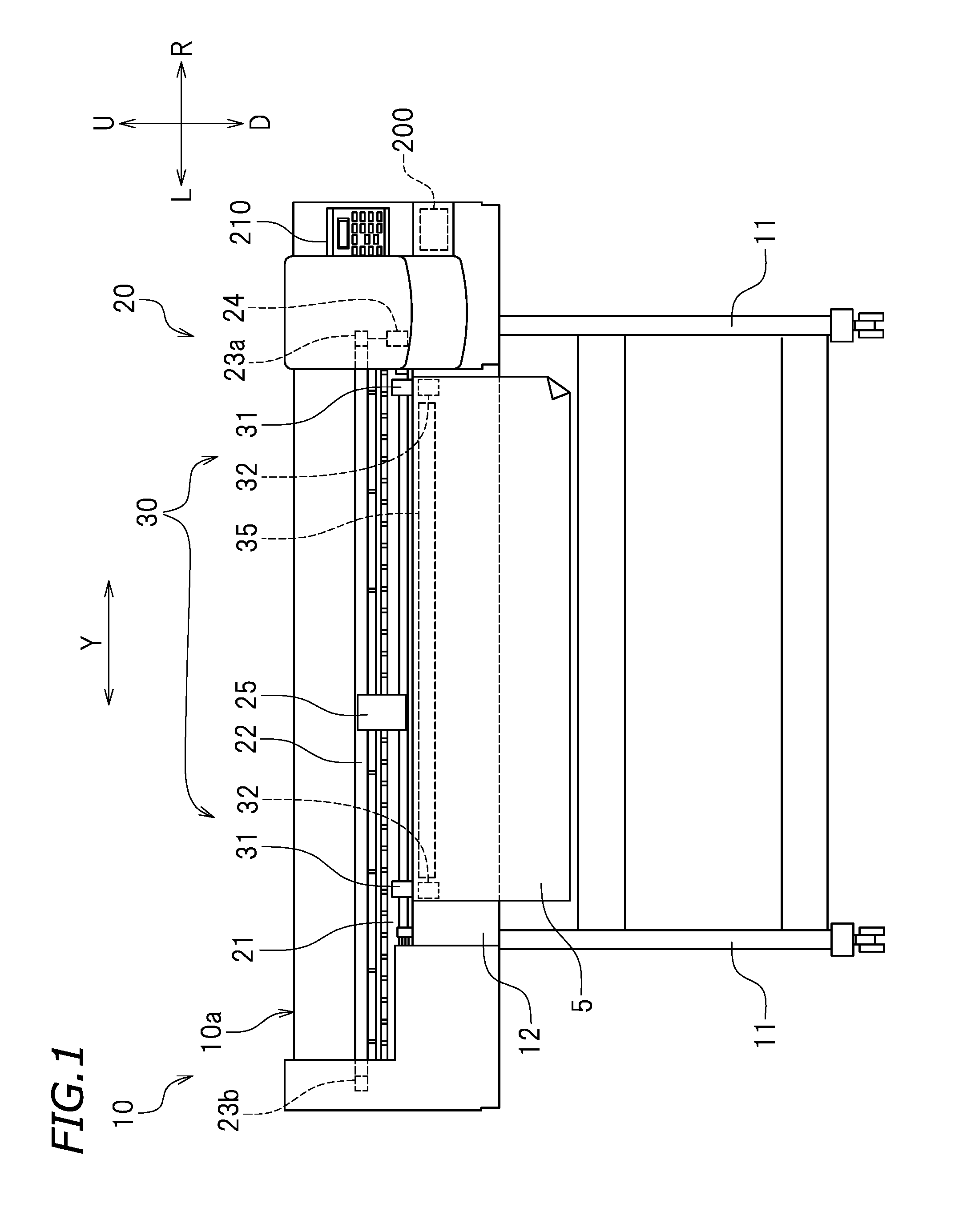

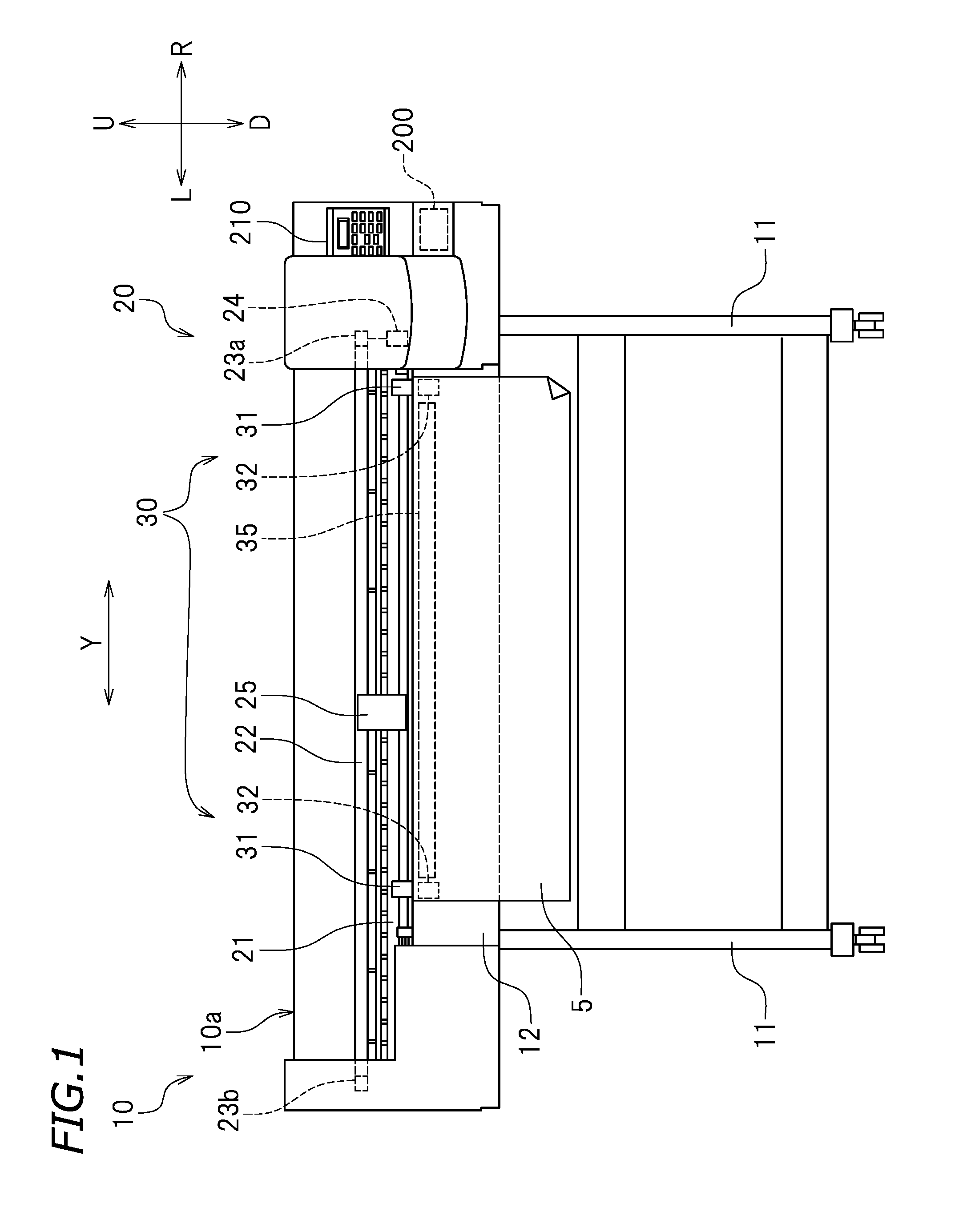

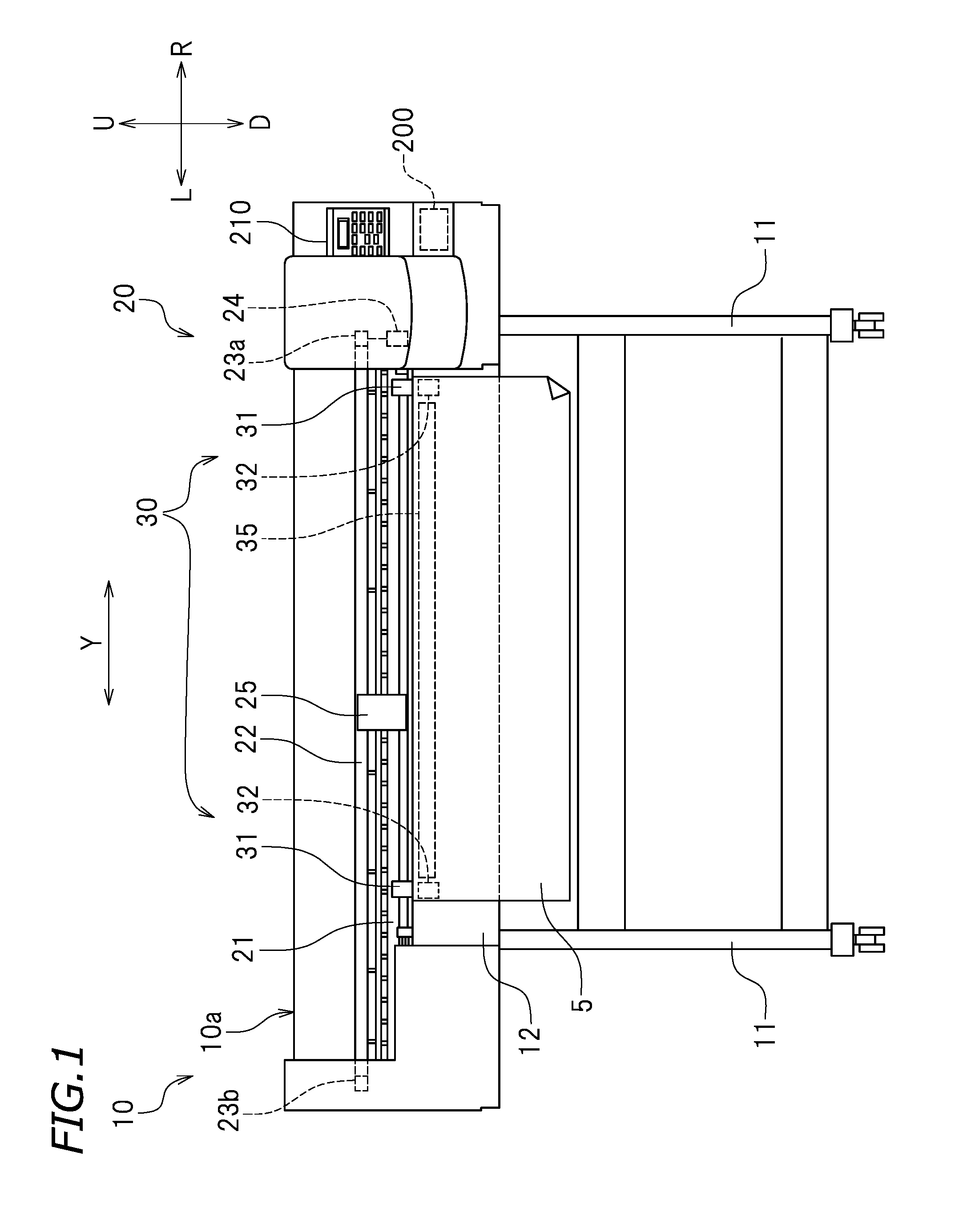

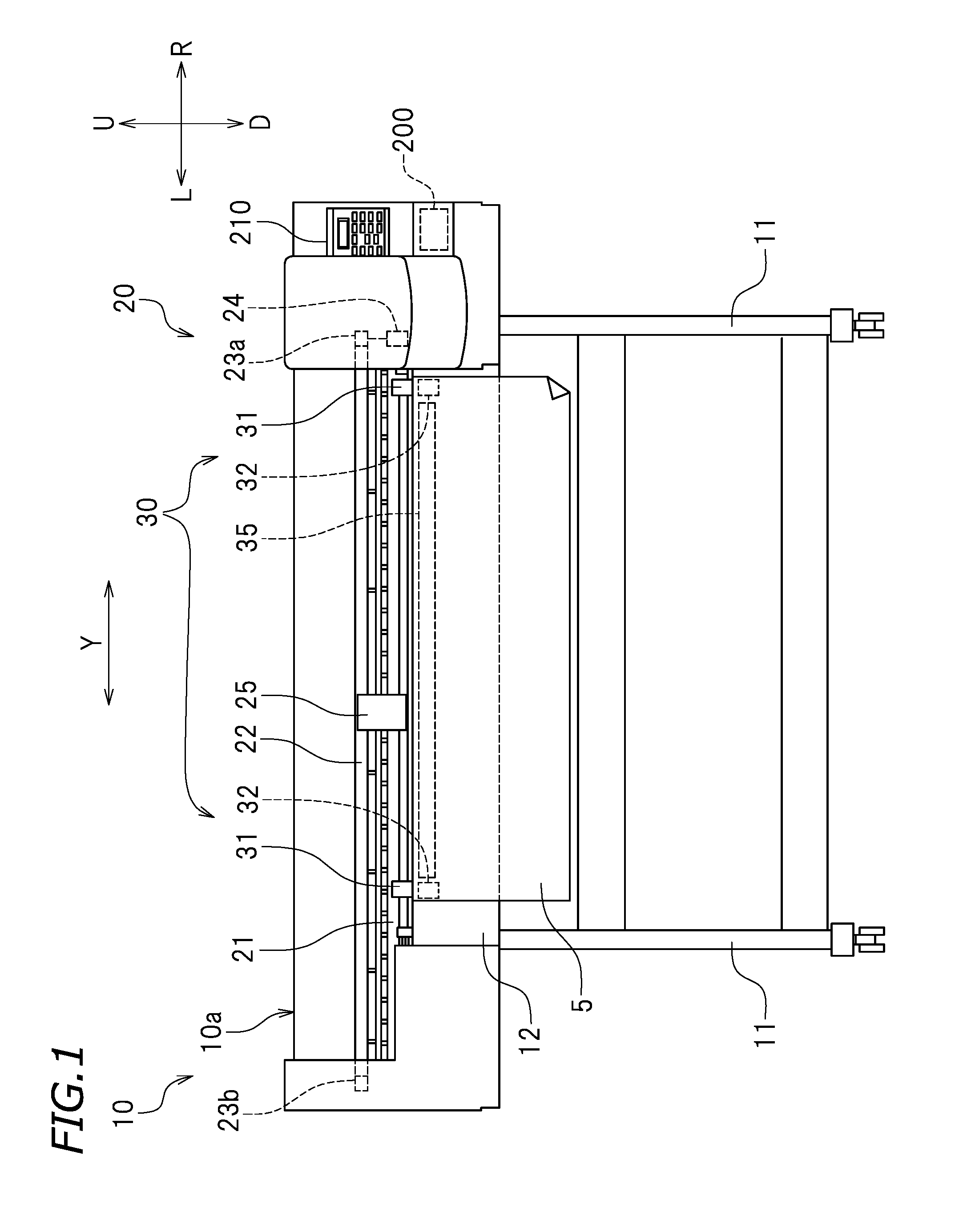

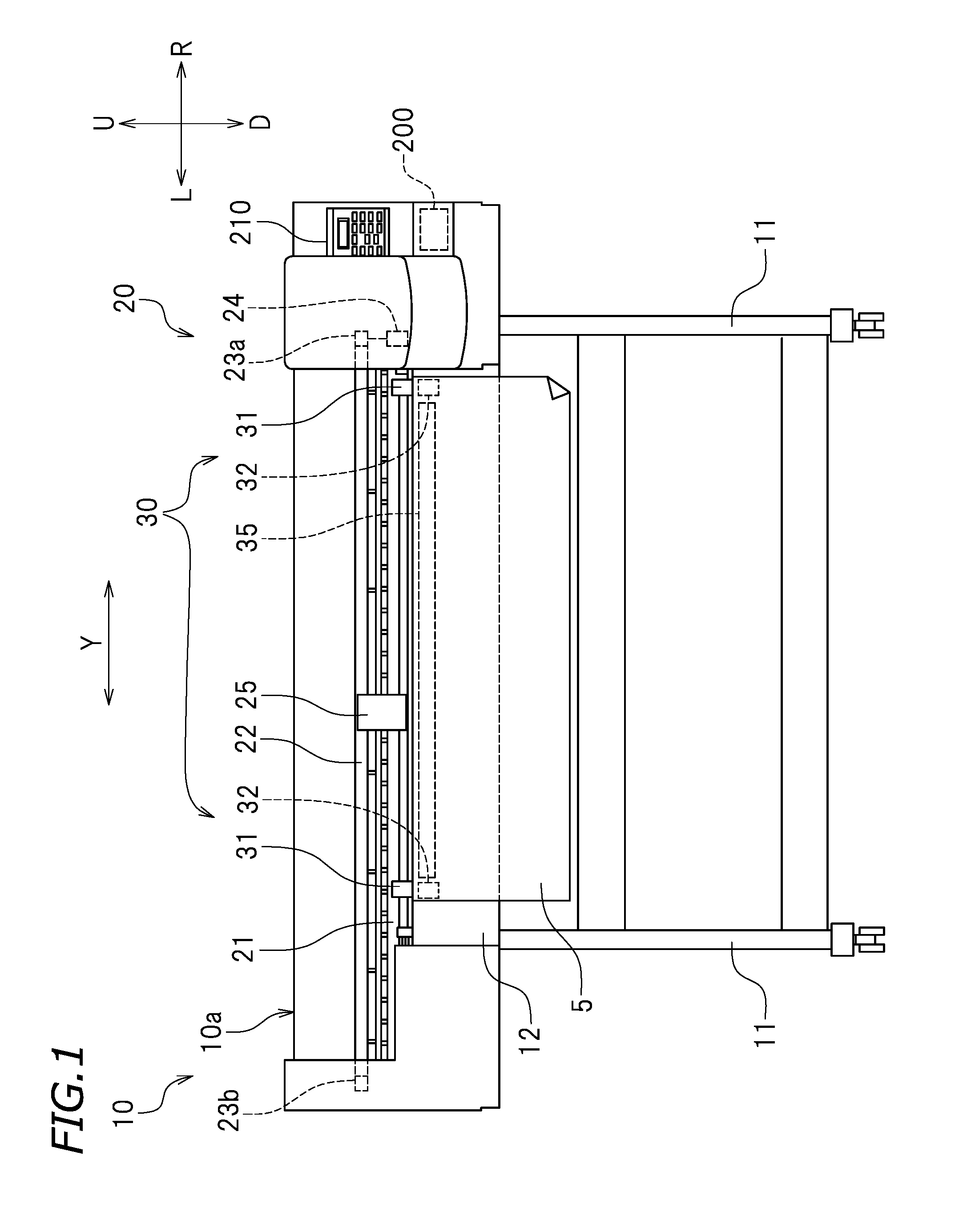

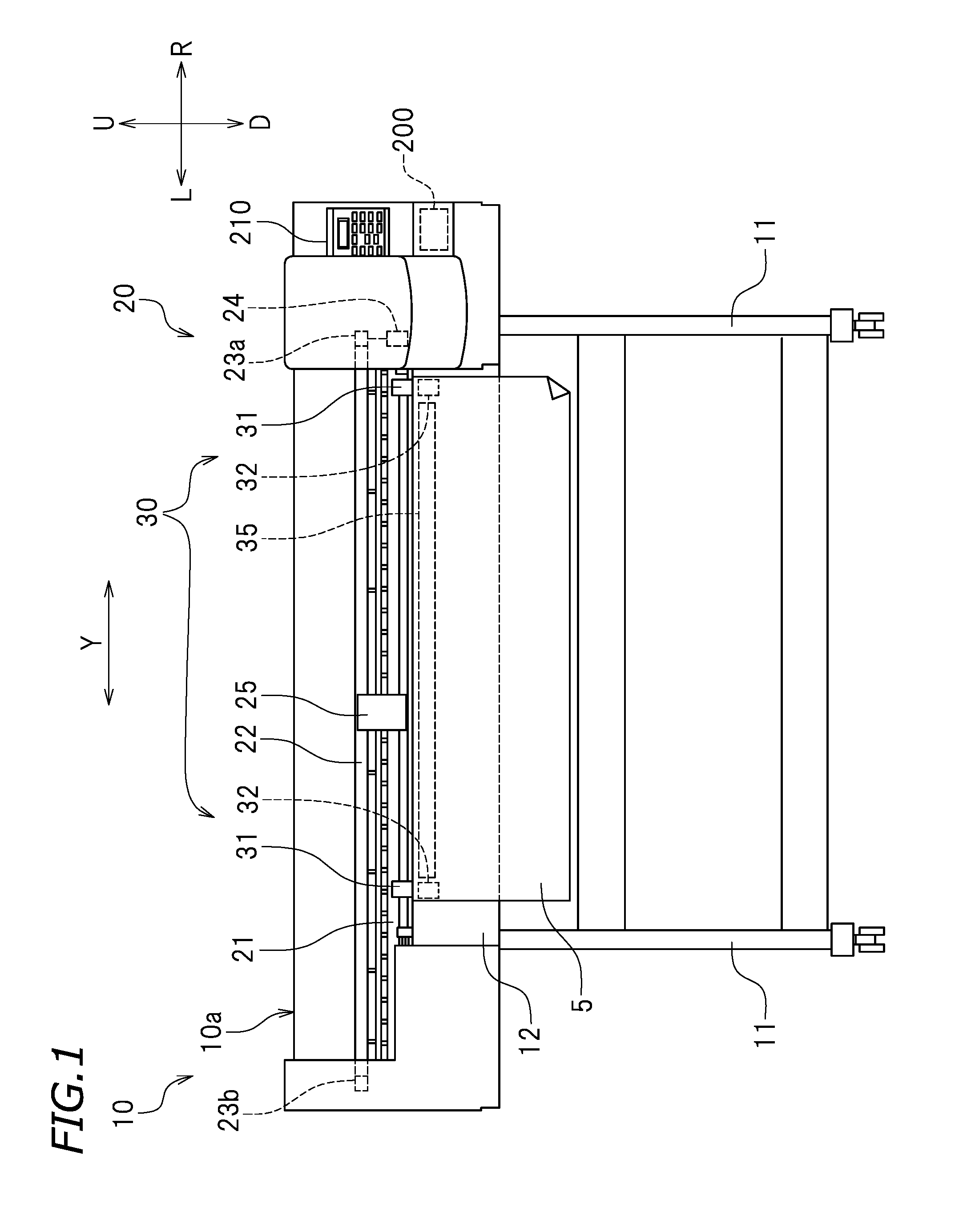

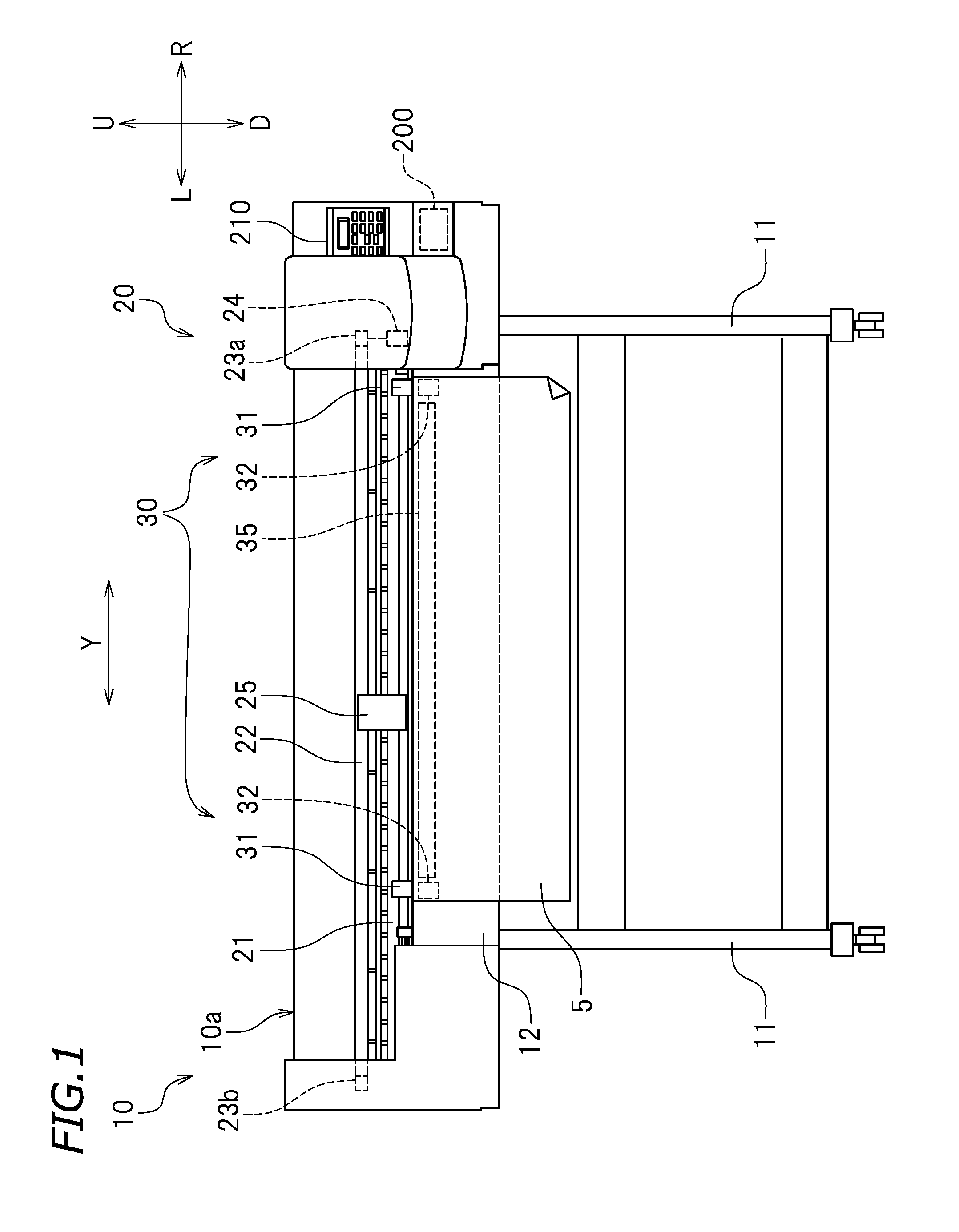

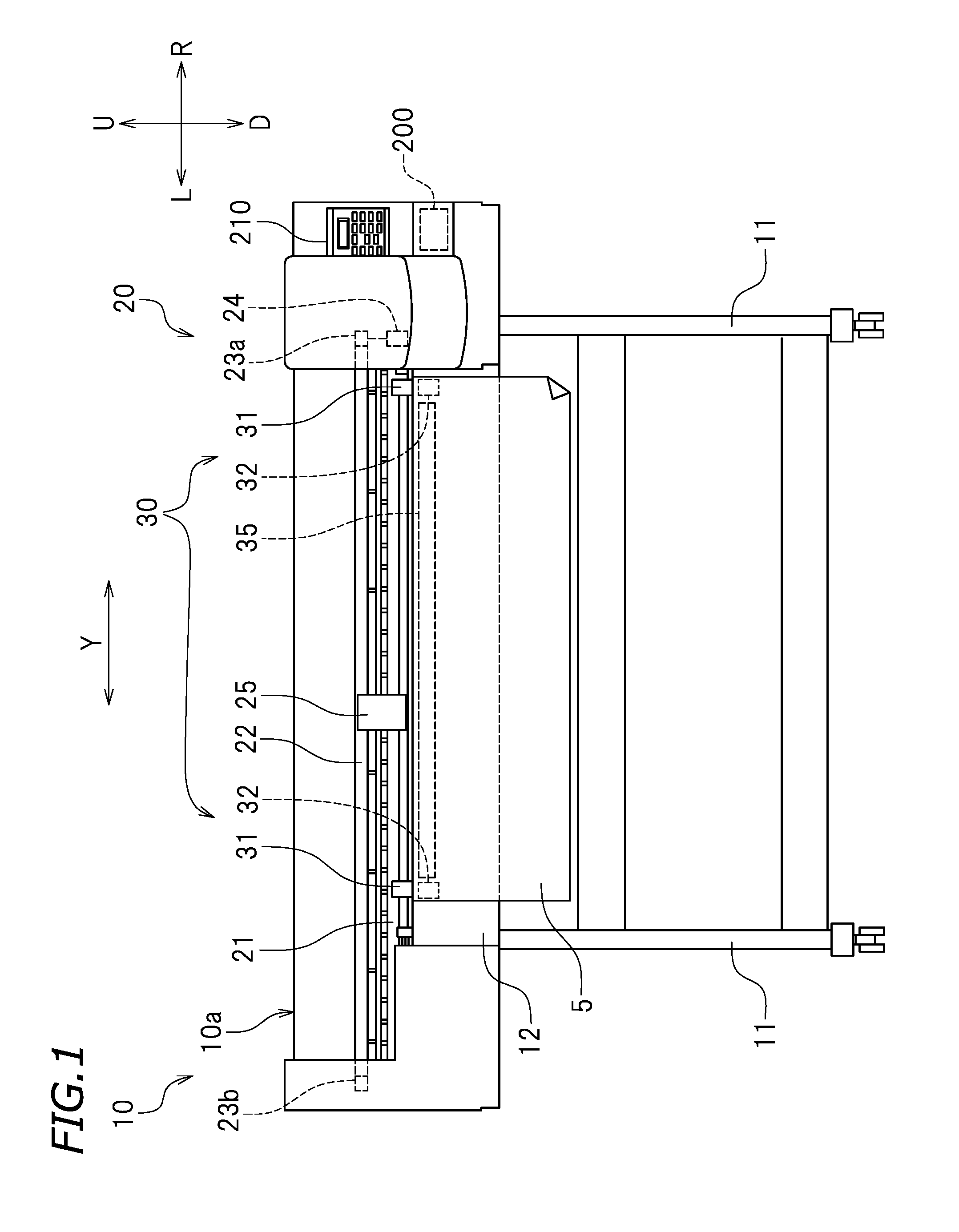

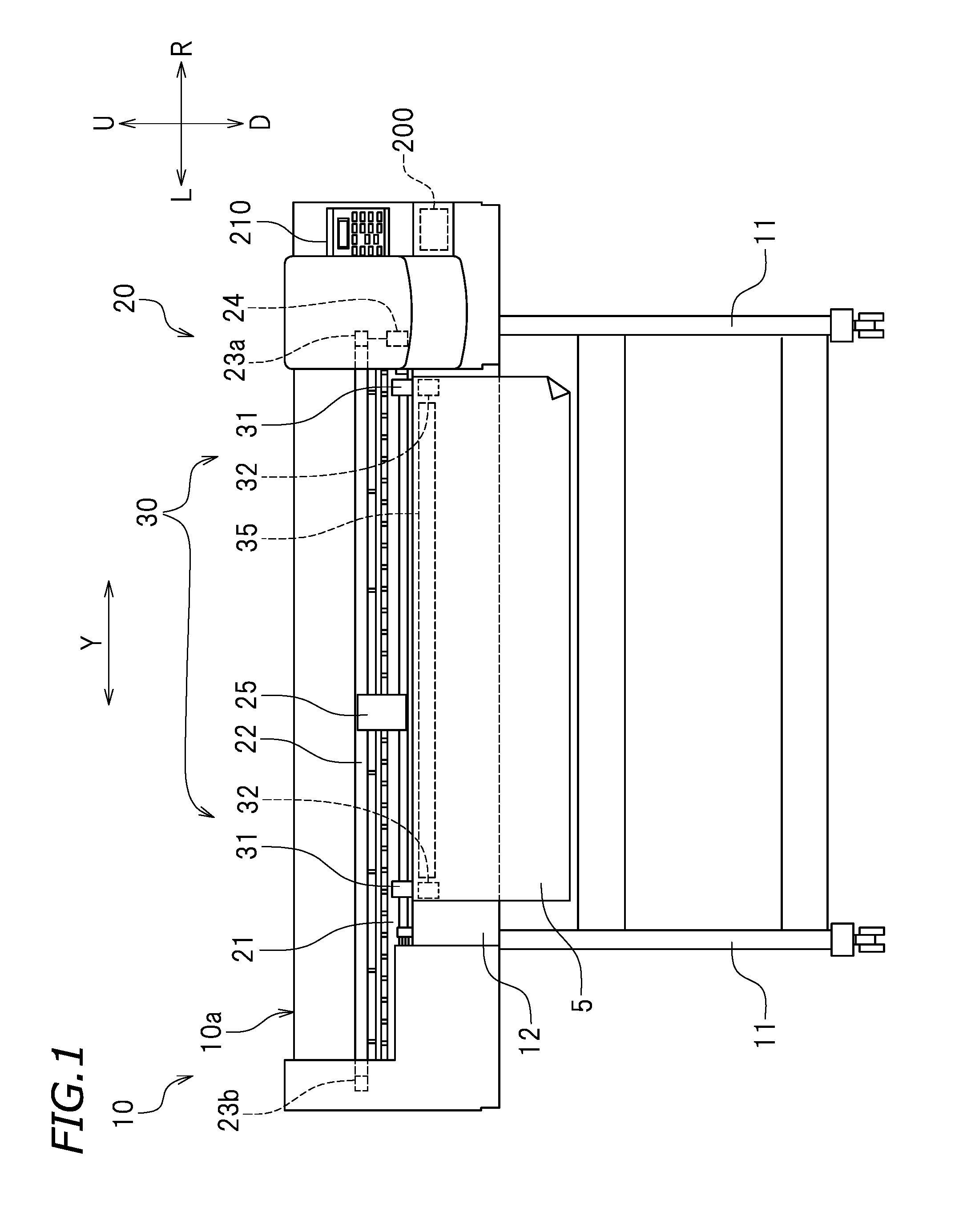

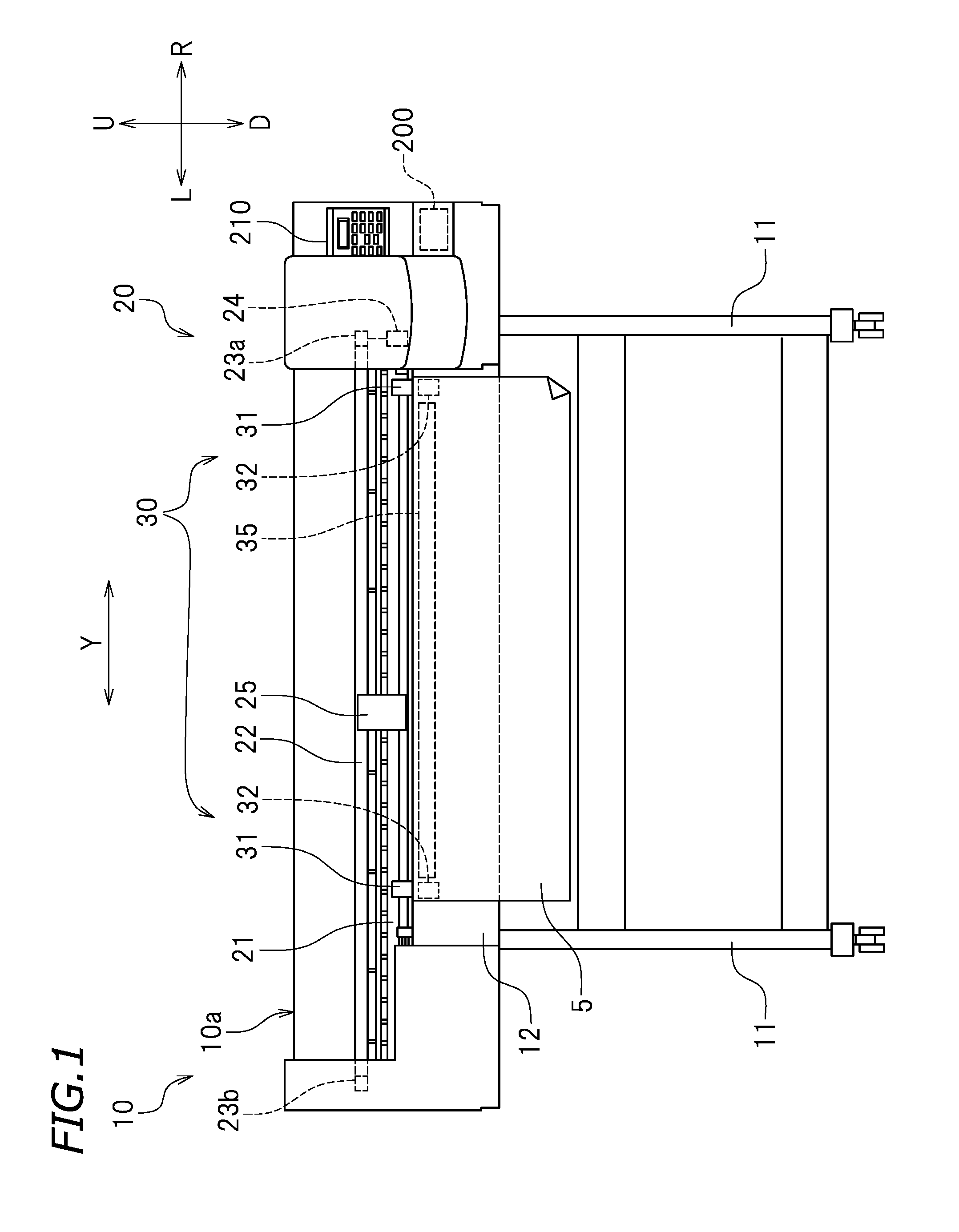

This application claims the benefit of priority to Japanese Patent Application No. 2017-082145 filed on Apr. 18, 2017. The entire contents of this application are hereby incorporated herein by reference. The present invention relates to an inkjet printer and a printing method. Conventionally, an inkjet printer for large format printing that includes a plurality of recording heads arrayed in a direction perpendicular to a scanning direction of a head unit is known. The inkjet printer having such a structure performs printing on a large area of a recording medium within a short time. Japanese Laid-Open Patent Publication No. 2013-67031 discloses an inkjet recording device including nine head units corresponding to nine colors of ink arrayed in the scanning direction. The nine head units each include nine recording heads arrayed in a feeding direction perpendicular to the scanning direction. Some of recording mediums such as cloth, paper, and the like are not white. In the case in which process color ink is directly ejected onto such a non-white recording medium, the real color of the ink may not be provided. According to a technique for dealing with this situation, a recording head ejecting white ink is added to the printer ejecting nine colors of ink as described in Japanese Laid-Open Patent Publication No. 2013-67031, so that the printer provides 10 colors of ink. With this technique, first, the white ink is used to form a white underlying color layer on a surface of the recording medium. After the white ink layer is formed on the recording medium, an image layer of process color ink is formed on the white ink layer. In this manner, a color close to the real color of the ink is printed even on a recording medium that is not white. Usually, the above-described technique provides a sufficiently high level of image quality even on a recording medium that is not white. However, a still higher level of image quality may be desired for some uses of the printed item. In the field of, for example, outdoor advertisements or the like, there is a need for an image giving a strong impression of having depth or massiveness in order to attract more attention. The human sense of vision perceives depth or thickness even on an image formed two-dimensionally. However, often, the conventional printing method does not allow the human sense of vision to sufficiently exert this ability. A reason for this is that the image layer is thin and, thus, the influence of special color ink forming the underlying color layer is not completely eliminated. More specifically, one reason is that the maximum amount of the process color ink that is able to be printed to form the image layer is decreased because there is a limit on the amount of ink that is able to be accepted by the recording medium. Another reason is that the color developing property of the process color ink is decreased by the process color ink being printed on the underlying color layer. For example, in the case in which the special color ink is white ink, the image appears whitish and thus lacks massiveness. In addition, in the case in which the printing is performed in an overlapping manner as described above, the degree of influence of the special color ink varies in accordance with the color of process color ink. As a result, an image having a different color balance from that of the original image may be provided. Preferred embodiments of the present invention provide inkjet printers that print an image with an appearance that has depth or massiveness, and printing methods using such inkjet printers. An inkjet printer according to a preferred embodiment of the present invention includes a plurality of ink heads including a first color ink head, a second color ink head and a second ink ink head (ink head for second ink); a moving mechanism moving the plurality of ink heads and a recording medium with respect to each other; and a controller connected with the plurality of ink heads and the moving mechanism that controls the plurality of ink heads and the moving mechanism. The first color ink head includes a plurality of nozzles through which first ink of a first color is ejected towards the recording medium to form ink dots of the first ink of the first color on the recording medium. The second color ink head includes a plurality of nozzles through which first ink of a second color is ejected towards the recording medium to form ink dots of the first ink of the second color on the recording medium. The second ink ink head includes a plurality of nozzles through which second ink is ejected towards the recording medium to print ink dots of the second ink on the recording medium. The controller includes a first generator, a second generator, a first printing controller, and a second printing controller. The first generator generates, upon receipt of data on the ink dots of the first ink of the first color, a plurality of first dot groups, including a first underlying layer dot group and a first image dot group, of the ink dots of the first ink of the first color. The first generator generates the plurality of first dot groups such that the plurality of first dot groups include all of the ink dots of the first ink of the first color. The second generator generates, upon receipt of data on the ink dots of the first ink of the second color, a plurality of second dot groups, including a second underlying layer dot group and a second image dot group, of the ink dots of the first ink of the second color. The second generator generates the plurality of second dot groups such that the plurality of second dot groups include all of the ink dots of the first ink of the second color. The first printing controller prints a first printing layer, on the recording medium, of at least the ink dots of the first underlying layer dot group, the ink dots of the second underlying layer dot group and the ink dots of the second ink. The second printing controller prints a second printing layer, above or below the first printing layer, of at least the ink dots of the first image dot group and the ink dots of the second image dot group. A printing method according to a preferred embodiment of the present invention is a printing method by which at least first ink of a first color, first ink of a second color and second ink are ejected towards a recording medium to form, on the recording medium, at least ink dots of the first ink of the first color, ink dots of the first ink of the second color and ink dots of the second ink. The printing method includes a first generation step, a second generation step, a first printing step, and a second printing step. In the first generation step, upon receipt of data on the ink dots of the first ink of the first color, a plurality of first dot groups, including a first underlying layer dot group and a first image dot group, are generated of the ink dots of the first ink of the first color. In this step, the plurality of first dot groups are generated so as to include all of the ink dots of the first ink of the first color. In the second generation step, upon receipt of data on the ink dots of the first ink of the second color, a plurality of second dot groups, including a second underlying layer dot group and a second image dot group, are generated of the ink dots of the first ink of the second color. In this step, the plurality of second dot groups are generated so as to include all of the ink dots of the first ink of the second color. In the first printing step, a first printing layer is printed, on the recording medium, of at least the ink dots of the first underlying layer dot group, the ink dots of the second underlying layer dot group and the ink dots of the second ink. In the second printing step, a second printing layer is printed, above or below the first printing layer, of at least the ink dots of the first image dot group and the ink dots of the second image dot group. With the above-described inkjet printer, the second ink and a portion of the first ink (underlying layer dot group) are printed concurrently to provide the “first printing layer”. Above or below the “first printing layer”, another portion of the first ink (image dot group) is printed to provide the “second printing layer”. The first ink is printed to provide the upper layer and the lower layer in an overlapping manner as described above. Therefore, the color developing property of the first ink is inhibited or prevented from being decreased, and an image appearing to be deeper and more massive is provided than by overlapping printing performed by the conventional printer. In addition, with the inkjet printer and the printing method described above, the underlying layer dot group and the image dot group are generated independently for each color of the first ink. Therefore, the image quality is adjustable based on each color of the first ink, and a desired color balance is able to be obtained even by the overlapping printing. With the inkjet printer and the printing method described above, it is sufficient that the underlying layer dot group and the image dot group are generated independently for each of at least two colors of the first ink. For example, the underlying layer dot group and the image dot group may be generated independently for each of seven colors of process color ink as in a general printer. The sum of the underlying layer dot group and the image dot group does not need to be 100% of the ink dots, and may exceed 100%. The above and other elements, features, steps, characteristics and advantages of the present invention will become more apparent from the following detailed description of the preferred embodiments with reference to the attached drawings. Hereinafter, preferred embodiments of inkjet printers according to the present invention will be described with reference to the drawings. The preferred embodiments described below are not intended to specifically limit the present invention. Components and portions that have the same functions will be denoted by the same reference signs, and overlapping descriptions will be omitted or simplified. In the following description, a direction from an inkjet printer towards a user facing a front surface of the inkjet printer is referred to as “forward”, and a direction distanced from the user is referred to as “rearward”. In the drawings, letter Y refers to a scanning direction, and letter X refers to a feeding direction perpendicular or substantially perpendicular to the scanning direction. In the drawings, letters F, Rr, L, R, U and D respectively refer to “front”, “rear”, “left”, “right”, and “down”. These directions are also based on the user facing the front surface of the inkjet printer. It should be noted that these directions are provided merely for the sake of convenience, and do not limit the manner of installation of the inkjet printer in any way. The expression that one component is “above” (or “below”) another component may refer to a state in which the one component is above (or below) the another component while being in direct contact with the another component, as well as a state in which the one component is above (or below) the another component with another component provided between the one component and the another component. The recording medium 5 is a target on which an image is to be printed. There is no specific limitation on the type of the recording medium 5. The recording medium 5 may be, for example, paper, such as plain paper, printing paper for an inkjet printer, or other suitable paper. The recording medium 5 may be a transparent sheet made of a resin, glass or other suitable material. The recording medium 5 may be a sheet made of a metal material, rubber or other suitable material. In the present preferred embodiment, the recording medium 5 is preferably a transparent sheet, for example. As shown in A platen 12 is located below the carriage 25. The platen 12 extends in the scanning direction Y. The recording medium 5 is placed on the platen 12. Pinch rollers 31 pressing the recording medium 5 from above are provided above the platen 12. The pinch rollers 31 are located to the rear of the carriage 25. The platen is provided with grit rollers 32. The grit rollers 32 are located below the pinch rollers 31. The grit rollers 32 are located at a position facing the pinch rollers 31. The grit rollers 32 are coupled with a feed motor 33 (see In the present preferred embodiment, the special color ink head 110 ejects special color ink that changes the color tone or the design of a color image. The special color ink is an example of “second ink”. In this example, the special color ink head 110 ejects white ink. The color tone of the special color ink is not limited to white. The “special color ink” preferably includes ink other than the process color ink, such as C ink, M ink, Y ink, K ink or other suitable color ink, for example, metallic ink, such as silver ink, gold ink or other suitable metallic ink, and transparent ink, for example. In the present preferred embodiment, one special color ink head is preferably provided. The number of the special color ink head(s) is not limited to one. For example, two or more special color ink heads may be provided. There is no limitation on the color tone of the special color ink. The special color ink head 110 may eject, for example, metallic ink, such as silver ink, gold ink or other suitable metallic ink, or transparent ink. As shown in In the special color ink head 110, the eight sub ink heads 110 The first process color ink head 40 through the seventh first process color ink head 100 each eject process color ink usable to produce a color image. The process color ink is an example of “first ink”. In the present preferred embodiment, the first process color ink head 40 ejects cyan ink. The second process color ink head 50 ejects magenta ink. The third process color ink head 60 ejects yellow ink. The fourth process color ink head 70 ejects black ink. The fifth process color ink head 80 ejects gray ink. The sixth process color ink head 90 ejects light cyan ink. The seventh process color ink head 100 ejects light magenta ink. The number of the process color ink heads is not limited to seven. There is no limitation on the color tone of the process color ink. As shown in In the first process color ink head 40, the sub ink heads 40 The second process color ink head 50 through the seventh process color ink head 100 preferably have the same or substantially the same structure as that of the first process color ink head 40. Specifically, the second process color ink head 50 includes eight sub ink heads 50 The first process color ink head 40 through the seventh process color ink head 100 and the special color ink head 110 each include actuators provided therein. More specifically, the first process color ink head 40 includes first process color actuators (see The first process color ink head 40 through the seventh process color ink head 100 and the special color ink head 110 are each in communication with an ink cartridge (not shown) via an ink supply path (not shown). The ink cartridge is preferably detachably located at, for example, a right end of the printer main body 10 As shown in As shown in There is no specific limitation on the structure of the controller 200. The controller 200 is preferably, for example, a microcomputer. There is no specific limitation on the hardware structure of the microcomputer. The microcomputer preferably includes, for example, an interface (I/F) receiving printing data or other data from an external device, such as a host computer or other suitable device, a central processing unit (CPU) executing a command of a control program, a ROM (read only memory) including, stored thereon, the program executable by the CPU, a RAM (random access memory) usable as a working area in which the program is developed, and a storage, such as a memory or other suitable storage that stores the above-described program and various types of data. The controller 200 does not need to be provided inside the printer main body 10 The mode selector 201 is usable to select a printing mode. In the present preferred embodiment, the printing mode is classified into “normal printing” and “overlapping printing”. The “overlapping printing” is classified into “first overlapping printing” and “second overlapping printing”. According to the “first overlapping printing”, an underlying color layer is provided as a lower layer of the special color ink and a portion of the process color ink, and then an image layer is provided as an upper layer of a portion of the process color ink. According to the “second overlapping printing”, an image layer is provided as a lower layer of a portion of the process color ink, and then an underlying color layer is provided as an upper layer of the special color ink and a portion of the process color ink. The “first overlapping printing” and the “second overlapping printing” will be described in detail below. When the “first overlapping printing” mode is selected, the mode selector 201 instructs the first printing controller 203 Upon receipt of data on ink dots of the various colors of process color ink, the generator 202 generates a plurality of “underlying layer dot groups” and a plurality of “image dot groups” of the ink dots of the process color ink. The generator 202 is divided into portions respectively corresponding to the process color ink heads. The first generator 202 The printing controller 203 controls the printing operation. The printing controller 203 is connected with the carriage motor 24, the feed motor 33, and the actuators 43 through 113 respectively provided in the ink heads 40 through 110. The printing controller 203 controls these components to perform printing. The printing controller 203 controls the temperature of the heater 35 to promote the drying of the ink after the ejection. In the printing controller 203, the first printing controller 203 In the printing controller 203, the second printing controller 203 When the “normal printing” is selected by the mode selector 201, the third printing controller 203 The ratio setter 204 sets the ratio of the “underlying layer dot group” and the ratio of the “image dot group” with respect to the entirety of the ink dots of each color of process color ink. The process of generating each of the “underlying layer dot groups” and each of the “image dot groups” based on the ratios set by the ratio setter 204 may preferably be performed automatically based on preset generation conditions. Alternatively, the work may be performed in accordance with the generation conditions input by the operator. In the printer 10 in the present preferred embodiment, the process of generating each of the “underlying layer dot groups” and each of the “image dot groups” is preferably performed in accordance with the generation conditions input by the operator. The ratio setter 204 issues, to the generator 202, an instruction on the ratios of the “underlying layer dot group” and the “image dot group” with respect to the entirety of the ink dots of each color of process color ink, as generation conditions under which the “underlying layer dot group” and the “image dot group” are to be generated of the ink dots of each color of process color ink. The instruction is provided independently for each color of process color ink. The ratio setter 204 includes the first ratio setter 204 The ratio input portion 205 is used to input the ratios of the “underlying layer dot group” and the “image dot group” with respect to the entirety of the ink dots of each color of process color ink. The ratio input portion 205 includes interfaces to which the ratios may be input. The ratios may be input independently for each color of process color ink. The ratio input portion 205 includes the first ratio input portion 205 According to the “normal printing”, one layer is printed on the recording medium 5. For the “normal printing”, only the process color ink is used. In the “normal printing”, the entirety of the ink dots of each color of process color ink is printed. The “normal printing” is performed as follows. The third printing controller 203 In the overlapping printing modes including the “first overlapping printing” mode and the “second overlapping printing” mode, an underlying color layer and an image layer are provided in an overlapping manner on the recording medium 5. In the case in which the recording medium 5 is not white as in the present preferred embodiment (in the present preferred embodiment, the recording medium 5 is transparent), such overlapping printing is often performed on a recording medium. Often, the process color ink ejected directly onto a recording medium that is not white does not develop the real color thereof. Therefore, first, a white ink layer is printed on the recording medium, and then, an image is printed on the white ink layer. In this manner, a color close to the real color of the ink is printed even on a recording medium that is not white. The overlapping printing is also performed in a case other than the above-described case. For example, a special color ink layer of transparent ink, metallic ink or other suitable ink may be provided above or below the image, so that a specific visual effect is provided. In the case in which the recording medium 5 is a transparent sheet as in the present preferred embodiment, the overlapping printing is performed primarily to provide the image with an underlying color (in the present preferred embodiment, white). To provide a printed item, a printing surface of which is to be viewed, the special color ink layer is provided below the image. For providing a printed item, a surface opposite to the printing surface of which is to be viewed, the special color ink layer is provided above the image. For the overlapping printing, there are requirements for a higher image quality. In the field of, for example, outdoor advertisements, there is a need for an image giving a strong impression of having depth or massiveness in order to attract more attention. However, often, the conventional printing method does not sufficiently fulfill such a need. A reason for this is that the image layer is thin and, thus, the influence of special color ink defining the underlying color layer is not completely eliminated. More specifically, one reason is that the maximum amount of the process color ink that is able to be printed to define the image layer is decreased because there is a limit on the amount of ink that is able to be accepted by the recording medium. Another reason is that the color developing property of the process color ink is decreased by the process color ink being printed on the underlying color layer. For example, in the case in which the special color ink is white ink as in the present preferred embodiment, the image appears whitish and, thus, lacks depth or massiveness. In the case in which the printing is performed in an overlapping manner, the degree of influence of the special color ink varies in accordance with the color of the process color ink. As a result, an image having a different color balance from that of the original image may be provided. In order to deal with such a situation, the controller 200 in the present preferred embodiment includes the generator 202, the first printing controller 203 As described above, the printer 10 according to the present preferred embodiment prints the underlying color and a portion of the image concurrently as the “first printing layer”. Namely, the underlying color layer is printed with a portion of the image being mixed therein. With this arrangement, the color developing property of the process color ink is inhibited or prevented from being decreased, and a color close to the real color of the process color ink is provided. Therefore, the printer 10 according to the present preferred embodiment provides an image appearing to be deeper and more massive than by overlapping printing performed by the conventional printer. In addition, the printer 10 according to the present preferred embodiment generates the “underlying layer dot group” and the “image dot group” independently for each of the plurality of colors of process color ink. Therefore, the image quality is adjustable based on each color of process color ink, and a desired color balance is obtained even by the overlapping printing. In the case in which the recording medium is transparent, the image of the printed item provided by the printer 10 in the present preferred embodiment is visually recognizable also from the side of the underlying color layer. In the case in which the printing is performed on a transparent recording medium with the conventional overlapping printing, the level of the light blocking property of the underlying color layer is increased in order to provide a clear image. Namely, the underlying color layer is preferably thick or has a high density. However, in the state in which the level of the light blocking property of the underlying color layer is increased, the image is not visually recognizable from the side of the underlying color layer. This may cause a problem in position alignment in, for example, a bonding process in which a plurality of recording mediums need to be positionally aligned. The printer 10 according to the present preferred embodiment provides a printed item allowing the image to be visually recognizable from the side of the underlying color layer while the level of the light blocking property of the underlying color layer is maintained high. Hereinafter, a process of generating each of the “underlying layer dot groups” and each of the “image dot groups” and a process of “overlapping printing” performed by the printer 10 according to the present preferred embodiment will be described. First, a process of generating the “underlying layer dot group” and the “image dot group” of the ink dots of each color of process color ink will be described. As shown in To each of the input boxes B1 through B7, the operator may input a numerical value as the “underlying layer printing ratio”. The “underlying layer printing ratio” is a ratio of the “underlying layer dot group” with respect to the entirety of the ink dots of each color of process color ink. Namely, the “underlying layer printing ratio” is the ratio of the image to be printed concurrently with the underlying color layer. As described above, in the present preferred embodiment, the sum of the ratios of the “underlying layer dot group” and the “image dot group” of each color of process color ink is 100% with respect to the entirety of the ink dots of the process color ink. The expression that the generator 202 in the present preferred embodiment “generates” the “underlying layer dot group” and the “image dot group” of the ink dots of each color of process color ink substantially indicates that the ink dots of the process color ink is “divided”. Therefore, once the underlying layer printing ratio is input to each of the interfaces shown in In the process of generating the “underlying layer dot group”, the ink dots belonging to the “underlying layer dot group” are randomly extracted from all of the ink dots of the corresponding color of process color ink. In the case in which, for example, the underlying printing ratio is about 25%, for example, the number of ink dots corresponding to about 25% of all of the ink dots of the corresponding color of process color ink is extracted randomly. Since the number of the ink dots included in the image is very large, a situation in which the ink dots are extracted from a particular region does not occur easily. Therefore, a dot pattern similar to the pattern of the original image, except that the printing density is lower, is extracted for each color of process color ink. As described above, the ratio input portion 205 allows the settings of the ratios of the “underlying layer dot group” and the “image dot group” with respect to the ink dots of each color of process color ink. Such settings allow the printing image quality in a finished state to be precisely adjusted. Based on the knowledge of the inventor of preferred embodiments of the present invention, it is preferred that the “underlying layer dot group” of each color of process color ink is set to about 0.5% or higher and lower than about 50%, for example. More preferably, the ratio is about 10% to about 20%, for example. After the printing mode and the printing ratio are set as described above, the overlapping printing is performed. Hereinafter, a printing process under the printing conditions shown in In As shown in The process color ink other than the light magenta ink is ejected in substantially the same manner as the light magenta ink. This will be described more specifically. At the point in time shown in In the “second overlapping printing”, the upper layer and the lower layer are opposite to those of the “first overlapping printing”. In the “second overlapping printing”, the “second printing layer” is provided as the lower layer, and the “first printing layer” is provided as the upper layer. In the “second overlapping printing”, the order in which the “first printing layer” and the “second printing layer” are provided is opposite at the same positions on the recording medium 5. In the “second overlapping printing”, each color of process color ink of the “image dot group” is ejected from the nozzles of the sub ink heads on the upstream side, and each color of process color ink and the special color ink of the “underlying layer dot group” are ejected from the nozzles of the sub ink heads on the downstream side. As described above, the printer 10 according to the present preferred embodiment generates the “underlying layer dot group” and the “image dot group” of the ink dots of each color of process color ink, and prints the “first printing layer” of the ink dots of the “image dot groups” of the plurality of colors of process color ink and the ink dots of the special color ink. The printer 10 further prints the “second printing layer” of the ink dots of the “image dot groups” of the plurality of colors of process color ink, above or below the “first printing layer”. A portion of the image is mixed in the underlying color layer, and another portion of the image is printed as overlapping the underlying color layer. In this manner, the image provided even by the overlapping printing is able to appear to be three-dimensional. The printer 10 according to the present preferred embodiment provides an image that appears to be deeper and more massive than by the overlapping printing performed using the conventional printer. In addition, the printer 10 according to the present preferred embodiment generates the “underlying layer dot group” and the “image dot group” independently for each color of process color ink. Therefore, the image quality is adjusted based on each color of process color ink, and a desired color balance is obtained even by the overlapping printing. The controller 200 in the present preferred embodiment includes the ratio setter 204 setting the ratios of the “underlying layer dot group” and the “image dot group” with respect to the entirety of the ink dots of each color of process color ink. The generator 202 generates the “underlying layer dot group” and the “image dot group” such that the ratios thereof with respect to the entirety of each color of process color ink are the same or substantially the same as the ratios set by the ratio setter 204. The ratio setter 204 sets the ratios, so that the quality of the resultant printed image is adjusted based on each color of process color ink. To the ratio input portion 205, the ratios of the “underlying layer dot group” and the “image dot group” with respect to the entirety of the ink dots of each color of process color ink are input. Each of the ratio setters 204 The ratio of the “underlying layer dot group” of each color of process color ink with respect to the entirety of the ink dots is preferably set to about 0.5% or higher and lower than about 50%, for example. In the case in which the ratio is set to about 0.5% or higher and lower than about 50%, for example, the effect of causing the resultant image to appear to have depth and massiveness is provided. The ratio is more preferably about 10% to about 20%, for example. The printer 10 according to the present preferred embodiment includes the mode selector 201. The mode selector 201 allows either one of the “first overlapping printing” and the “second overlapping printing” to be selected as a mode of overlapping printing. The “first overlapping printing” is a printing mode of providing the “first printing layer” as the lower layer and providing the “second printing layer” as the upper layer. The “second overlapping printing” is a printing mode of providing the “second printing layer” as the lower layer and providing the “first printing layer” as the upper layer. Since the mode selector 201 is included, the printer 10 according to the present preferred embodiment is usable for either the “first overlapping printing” or the “second printing layer”. As described above, the printer 10 according to the present preferred embodiment includes the interfaces to which the operator may input the printing mode and the printing ratios. The printer 10 does not need to include the interfaces. For example, the printing data may include the printing mode and the printing ratios, so that the printing mode and the printing ratios are automatically set. The interfaces do not need to be in the layout shown in In the present preferred embodiment, the printing process of a one pass mode has been described, by which after printing is performed for one pass, the recording medium 5 is moved in the feeding direction X by the same length as the length by which the printing has been performed. The printing mode is not limited to the one pass mode. Another usable printing mode is, for example, interlace printing (overlapping printing), by which after printing is performed for one pass, the recording medium 5 is moved by a predetermined distance that is shorter than the length by which the printing has been performed, so that an image is provided by performing printing for a plurality of passes. In preferred embodiment 2 of the present invention, the ratios of the “underlying layer dot group” and the “image dot group” of each color of process color ink are automatically determined by the ratio setter 204. Therefore, the printer 10 according to preferred embodiment 2 is different from the printer according to preferred embodiment 1 with respect to the specifications of the ratio setter 204. In addition, the printer 10 according to preferred embodiment 2 does not include the ratio input portion 205. Except for these points, the printer 10 according to preferred embodiment 2 preferably is the same or substantially the same as the printer 1 according preferred embodiment 1. In the description of preferred embodiment 2, the components that are same as those of preferred embodiment 1 will be denoted by the same reference signs, and overlapping descriptions will be omitted or simplified. This is also applicable to preferred embodiment 3. The ratio setter 204 according to the present preferred embodiment includes a matrix corresponding to the colors of process color ink and the types of the recording medium. More specifically, the “underlying layer printing ratio” is preset for each of colors of process color ink and each of the types of recording medium in the matrix. The matrix as shown in Process color ink having a low color developing property is low in the ink concentration. Process color ink having a low ink concentration has a low ratio (e.g., % by weight) of color material in the ink. Therefore, the underlying layer printing ratio is preferably set to be higher as the ratio of the color material in the process color ink is lower, and the underlying layer printing ratio is preferably set to be lower as the ratio of the color material in the process color ink is higher. Among the various colors of process color ink in the present preferred embodiment, the light cyan ink and the light magenta ink have a low color developing property. Process color ink having a low color developing property (low ink concentration) is relatively inconspicuous when being ejected as being mixed in the special color ink. Therefore, it is preferable to mix a relatively large amount of such process color ink when such process color ink is used to print concurrently with the special color ink. The printer 10 according to the present preferred embodiment ejects the process color ink having a low color developing property at a higher underlying layer printing ratio than that of the process color ink having a high color developing property. Namely, a larger amount of process color ink having a low color developing property is ejected for the “first printing layer”. As a result, an image appearing to have massiveness is able to be printed. Process color ink having a high brightness is of a bright color. Among the various colors of process color ink in the present preferred embodiment, yellow ink has a high brightness. Process color ink having a high brightness is also relatively inconspicuous when being ejected as being mixed in the special color ink. Therefore, it is preferable to mix a relatively large amount of such process color ink when such process color ink is used to print concurrently with the special color ink. The printer 10 according to the present preferred embodiment ejects the process color ink having a high brightness at a higher underlying layer printing ratio than that of the process color ink having a low brightness. Namely, a larger amount of process color ink having a high brightness is ejected for the “first printing layer”. As a result, an image appearing to have massiveness is able to be printed. The wettability of the process color ink for the recording medium varies in accordance with the combination of the process color ink and the recording medium. Process color ink having a low wettability for a certain type of recording medium 5 does not expand very much when landing on the recording medium 5. Regarding the recording mediums A, B and C shown in As described above, the ratio setter 204 in preferred embodiment 2 automatically sets the underlying layer printing ratio of each color of process color ink based on the color developing property, the brightness and the wettability for the recording medium of the process color ink. It should be noted that the ratio setter 204 may include interfaces by which the color of ink to be ejected from each of the first process color ink head 40 through the seventh process color ink head 100, and the type of recording medium, may be set. In a modification of preferred embodiment 2, the method of setting the underlying layer printing ratios may preferably be selected from an “automatic mode” and a “manual mode”. In the “automatic mode”, the ratio setter 204 automatically sets the underlying layer printing ratios as in preferred embodiment 2. In the “manual mode”, the operator inputs the underlying layer printing ratios to the ratio input portion 205 as in preferred embodiment 1. In this modification, the underlying layer printing ratios may be set in either the “automatic mode” or the “manual mode” selected by the operator. In preferred embodiment 3 of the present invention, the printer 10 is configured such that the ink dots of the special color ink and the ink dots of the “underlying layer dot groups” each have an adjustable dot size. In the present preferred embodiment, the ink dots of different colors of ink may have different sizes from each other. The size input portion 207 includes a first process color size input portion 207 The first process color size controller 206 In many cases, image data includes size data on the three ink dot sizes of S, M and L beforehand. In the size data, the S-sized ink dots, the M-sized ink dots, and the L-size ink dots are included in a mixed state. The size data is changed using the first process color size input portion 207 The printer 10 according to the present preferred embodiment includes the size controller 206 adjusting the dot size of the ink to be ejected from each of the ink heads and the size input portion 207, to which the dot size of the “underlying layer dot group” of each color of process color ink and the dot size of the special color ink, may be input. Thus, the printer 10 according to the present preferred embodiment further improves the degree of freedom in adjusting the quality of the printed image. In the case in which, for example, the dot size of each of the “underlying layer dot groups” is adjusted to be smaller than the dot size of the special color ink, the image mixed in the underlying color layer is able to appear to be natural in a finished state. By contrast, in the case in which the dot size of each of the “underlying layer dot groups” is adjusted to be larger than the dot size of the special color ink, the image mixed in the underlying color layer is able to appear conspicuous and present a stronger visual effect. The size input portion 207 in the interfaces does not need to be in the configuration shown in Some preferred embodiments of the present invention have been described. The above-described preferred embodiments are merely examples, and the technology disclosed herein may be provided and performed in any of various configurations and arrangements. In the above-described preferred embodiments, the sum of the ratios of the “underlying layer dot group” and the “image dot group” is preferably 100% of the entirety of the ink dots of each color of process color ink. Alternatively, there may be ink dots that are included in both of the “underlying layer dot group” and the “image dot group”, so that the sum of the ratios of the two groups may exceed 100% with respect to the entirety of the ink dots of the process color ink. In an image printed in this case, such overlapping ink dots are able to make the image clearer than the image in the case in which the sum of the ratios is 100%. In the case in which the overlapping printing is performed such that the final ink amount exceeds 100% of the ink dots of the process color ink, the range of colors that may be represented by the same printer using the same colors of ink (color gamut) is extended. Based on the knowledge of the inventor of preferred embodiments of the present invention, preferred overlapping printing is performed in the case in which, for example, about 10% to about 20% of the ink dots of each color of process color ink is assigned to the “underlying layer dot group” and about 100% of the ink dots of each color of process color ink is assigned to the “image dot group”. According to the “overlapping printing” in the above-described preferred embodiments, two layers, namely, a lower layer and an upper layer, are preferably provided in an overlapping state. Alternatively, three or more layers may be provided in an overlapping state. For example, three layers of an underlying color layer, an image layer, and a top coat may be provided in an overlapping state. In this case, the top coat may be made of, for example, transparent ink. In the case in which three or more layers are generated in an overlapping state, three or more dot groups may be generated of the ink dots of each color of the process color ink, not only the “underlying layer dot group” and the “image dot group”. In preferred embodiment 3 described above, the controller 200 includes the size input portion 207 to control the dot size of the ink. The size control may not be performed based on an input to the size input portion 207. For example, the dot sizes may be automatically selected by the size controller 206. Alternatively, the dot sizes of the “underlying layer dot groups” of all of the colors of process color ink and the special color ink may be set to be the same or substantially the same size. In the case in which the dot sizes of the “underlying layer dot groups” of all of the colors of process color ink and the special color ink are set to be the same or substantially the same size, the image processing is simpler and the control is easier. In the printer 10 according to preferred embodiment 3, in which the dot size of the ink to be ejected from each ink head is selected from the predefined sizes, the smallest size among the available sizes may be selected as the dot size of the “underlying layer dot group” of each color of process color ink and the dot size of the special color ink. In the case in which the dot size of the “underlying layer dot group” of each color of process color ink and the dot size of the special color ink are set to be the smallest size, the printed image is expected to appear to be natural. In the above-described preferred embodiments, the ink dots belonging to each of the “underlying layer dot groups” are extracted randomly. The extraction method is not limited to this. For example, some statistical technique may be used for the extraction. In the above-described preferred embodiments, the process color ink heads 40 through 100 and the special color ink head 110 each preferably include a plurality of sub ink heads, and the sub ink heads are located in a staggered arrangement in two lines in the corresponding ink head. The positional arrangement of the sub ink heads in each ink head is not limited to the above-described arrangement. The sub ink heads may be arrayed as shown in, for example, In the preferred embodiment shown in In the preferred embodiment shown in As shown in The region E1 shown in In the case of the “second overlapping printing”, the nozzles on the upstream side and the nozzles on the downstream side are opposite to those in the “first overlapping printing”. More specifically, in the “second overlapping printing”, the nozzles 101 of the seventh process color upstream nozzle array 102 In the case in which an odd number of sub ink heads are provided in an ink head and, thus, the sub ink heads are not equally divided into two, one of the sub ink heads may not be used, for example. The sub ink head not to be used may be the sub ink head located at the end on the upstream side X1, or on the downstream side X2, in the feeding direction X among the sub ink heads included in the ink head. Alternatively, the nozzles in the sub ink head through which the border line, equally dividing the nozzle array into two in the feeding direction X, passes may be divided by the border line into two, namely, into the nozzle(s) on the upstream side X1 and the nozzle(s) on the downstream side X2. The ink heads in the carriage 25 may be disposed in a different positional arrangement. For example, in the carriage 25, the process color ink heads and the special color ink head may be located as being offset in the feeding direction X. In the case in which the process color ink heads and the special color ink head are located as being completely offset in the feeding direction X, the nozzle array in each ink head are not divided into the upstream nozzle array and the downstream nozzle array. In this case, all of the nozzles in the ink head are usable. In the case in which the process color ink heads and the special color ink head are located as being partially offset in the feeding direction X, the number of the usable nozzles are smaller than in the case in which the ink heads are located as being completely offset, but the carriage 25 may be made more compact. Alternatively, the process color ink heads and the special color ink head may be mounted on, and may be movable by, different carriages. Still alternatively, the printing of the “first printing layer” and the printing of the “second printing layer” may be performed in completely different steps. In the above-described preferred embodiments, the ink is preferably ejected by a piezo-driving system of changing the volume of the pressure chamber by the displacement of the piezoelectric element. Alternatively, the printer in a preferred embodiment of the present invention may use, for example, any of continuous systems including such as a binary deflection system, a continuous deflection system and other suitable systems, or any of on-demand systems including a thermal system and other systems. There is no limitation on the ink ejection system of the technology disclosed herein. In the above-described preferred embodiments, the carriage 25 moves in the scanning direction Y whereas the recording medium 5 moves in the feeding direction X. The printer in a preferred embodiment of the present invention is not limited to such a system. The movement of the carriage 25 and the recording medium 5 are relative, and either one of the carriage 25 and the recording medium 5 may be moved in the scanning direction Y or the feeding direction X. For example, the recording medium 5 may be unmovable whereas the carriage 25 may be movable in both of the scanning direction X and the feeding direction X. Alternatively, both of the carriage 25 and the recording medium 5 may be movable in both of the directions. The technology disclosed herein is applicable to any of various types of inkjet printer. The technology disclosed herein is applicable to a roll-to-roll printer of feeding the roll recording medium 5 described in the above-described preferred embodiments, or to a flat bed inkjet printer. The printer 10 is not limited to a printer that is independently usable, and may be a printer that is combinable with another device. For example, the printer 10 may be incorporated into another device. While preferred embodiments of the present invention have been described above, it is to be understood that variations and modifications will be apparent to those skilled in the art without departing from the scope and spirit of the present invention. The scope of the present invention, therefore, is to be determined solely by the following claims. The terms and expressions used herein are for description purposes only and are not to be interpreted in a limited sense. These terms and expressions should be recognized as not excluding any equivalents to the elements shown and described herein and as allowing any modification encompassed in the scope of the claims. The present invention may be embodied in many various configurations. This disclosure should be regarded as providing preferred embodiments of the principles of the present invention. These preferred embodiments are provided with the understanding that they are not intended to limit the present invention to the preferred embodiments described in the specification and/or shown in the drawings. The present invention is not limited to the preferred embodiments and modifications described herein. The present invention encompasses any of preferred embodiments including equivalent elements, modifications, deletions, combinations, improvements, and/or alterations which may be recognized by a person of ordinary skill in the art based on the disclosure. The elements of each claim should be interpreted broadly based on the terms used in the claim, and should not be limited to any of the preferred embodiments described in this specification or used during the prosecution of the present application. An inkjet printer ejects a first ink including multiple colors and a second ink. A controller generates dot groups including an underlying layer dot group and an image dot group from ink dots of the first ink of each of the colors. The dot groups of each of the colors include all of the ink dots of the corresponding color. The controller forms a first printing layer of at least the ink dots of the underlying layer dot group of each of the colors and ink dots of the second ink. The controller forms a second printing layer of at least the ink dots of the image dot group of each of the colors. 1. An inkjet printer, comprising:

a plurality of ink heads including:

a first color ink head including a plurality of nozzles through which a first ink of a first color is ejected towards a recording medium to form ink dots of the first ink of the first color on the recording medium; a second color ink head including a plurality of nozzles through which a first ink of a second color is ejected towards the recording medium to form ink dots of the first ink of the second color on the recording medium; and a second ink ink head including a plurality of nozzles through which a second ink is ejected towards the recording medium to form ink dots of the second ink on the recording medium; a moving mechanism to move the plurality of ink heads and the recording medium with respect to each other; and a controller connected with the plurality of ink heads and the moving mechanism to control the plurality of ink heads and the moving mechanism; wherein the controller includes:

a first generator to generate, upon receipt of data on the ink dots of the first ink of the first color, a plurality of first dot groups, including a first underlying layer dot group and a first image dot group, of the ink dots of the first ink of the first color; a second generator to generate, upon receipt of data on the ink dots of the first ink of the second color, a plurality of second dot groups, including a second underlying layer dot group and a second image dot group, of the ink dots of the first ink of the second color; a first printing controller to form a first printing layer, on the recording medium, of at least the ink dots of the first underlying layer dot group, the ink dots of the second underlying layer dot group, and the ink dots of the second ink; and a second printing controller to form a second printing layer, above or below the first printing layer, of at least the ink dots of the first image dot group and the ink dots of the second image dot group; wherein the first generator generates the plurality of first dot groups such that the plurality of first dot groups include all of the ink dots of the first ink of the first color; and the second generator generates the plurality of second dot groups such that the plurality of second dot groups include all of the ink dots of the first ink of the second color. 2. The inkjet printer according to the first ink of the first color is a first process color ink; the first ink of the second color is a second process color ink different from the first process color ink; and the second ink is a special color ink. 3. The inkjet printer according to the controller includes:

a first ratio setter to set a ratio of the ink dots of each of the plurality of first dot groups with respect to the ink dots of the first ink of the first color; and a second ratio setter to set a ratio of the ink dots of each of the plurality of second dot groups with respect to the ink dots of the first ink of the second color; wherein the first generator generates each of the plurality of first dot groups such that the ratio of each of the plurality of first dot groups with respect to the ink dots of the first ink of the first color is the same or substantially the same as the ratio set by the first ratio setter; and the second generator generates each of the plurality of second dot groups such that the ratio of each of the plurality of second dot groups with respect to the ink dots of the first ink of the second color is the same or substantially the same as the ratio set by the second ratio setter. 4. The inkjet printer according to the first ink of the first color has a first color developing property; the first ink of the second color has a second color developing property different from the first color developing property; and the first ratio setter and the second ratio setter:

in a case in which the first color developing property is lower than the second color developing property, set the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color to be higher than the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color; and in a case in which the second color developing property is lower than the first color developing property, set the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color to be higher than the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color. 5. The inkjet printer according to the first ink of the first color includes a color material at a first ratio; the first ink of the second color includes a color material at a second ratio different from the first ratio; and the first ratio setter and the second ratio setter:

in a case in which the first ratio is lower than the second ratio, set the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color to be higher than the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color; and in a case in which the second ratio is lower than the first ratio, set the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color to be higher than the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color. 6. The inkjet printer according to the first ink of the first color has a first brightness; the first ink of the second color has a second brightness different from the first brightness; and the first ratio setter and the second ratio setter:

in a case in which the first brightness is higher than the second brightness, set the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color to be higher than the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color; and in a case in which the second brightness is higher than the first brightness, set the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color to be higher than the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color. 7. The inkjet printer according to the first ink of the first color has a first wettability for the recording medium; the first ink of the second color has a second wettability diffferent from the first wettability for the recording medium; and the first ratio setter and the second ratio setter:

in a case in which the first wettability is lower than the second wettability, set the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color to be higher than the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color; and in a case in which the second wettability is lower than the first wettability, set the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color to be higher than the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color. 8. The inkjet printer according to the controller includes:

a first ratio input portion to which the ratio of each of the plurality of first dot groups with respect to the ink dots of the first ink of the first color is input; and a second ratio input portion to which the ratio of each of the plurality of second dot groups with respect to the ink dots of the first ink of the second color is input; the first ratio setter sets the ratio of each of the plurality of first dot groups with respect to the ink dots of the first ink of the first color to the ratio input to the first ratio input portion; and the second ratio setter sets the ratio of each of the plurality of second dot groups with respect to the ink dots of the first ink of the second color to the ratio input to the second ratio input portion. 9. The inkjet printer according to the first ratio setter sets the ratio of the first underlying layer dot group with respect to the ink dots of the first ink of the first color to about 0.5% or higher and lower than about 50%; and the second ratio setter sets the ratio of the second underlying layer dot group with respect to the ink dots of the first ink of the second color to about 0.5% or higher and lower than about 50%. 10. The inkjet printer according to 11. The inkjet printer according to the first color ink head includes first color actuators causing the first ink of the first color to be ejected from the nozzles; the second color ink head includes second color actuators causing the first ink of the second color to be ejected from the nozzles; the second ink ink head includes a second ink actuators causing the second ink to be ejected from the nozzles; and the controller includes:

a first color size controller to control the first color actuators such that a dot size of the first underlying layer dot group is a first size; a second color size controller to control the second color actuators such that a dot size of the second underlying layer dot group is a second size; and a second ink size controller to control the second ink actuators such that a dot size of the second ink is a third size. 12. The inkjet printer according to 13. The inkjet printer according to the first color size controller, the second color size controller, and the second ink size controller each select a dot size from a plurality of predefined dot sizes; and the first size, the second size, and the third size are smallest among the plurality of predefined dot sizes. 14. The inkjet printer according to a first color size input portion connected with the first color size controller, the first size being input to the first color size input portion; a second color size input portion connected with the second color size controller, the second size being input to the second color size input portion; and a second ink size input portion connected with the second ink size controller, the third size being input to the second ink size input portion. 15. The inkjet printer according to the moving mechanism includes a feeding mechanism feeding the recording medium; the first color ink head, the second color ink head, and the second ink ink head are located side by side in a scanning direction perpendicular or substantially perpendicular to a feeding direction in which the recording medium is fed; the first color ink head includes:

a first color upstream nozzle array including a portion of the plurality of nozzles arrayed in the feeding direction; and a first color downstream nozzle array including another portion of the plurality of nozzles arrayed in the feeding direction, the first color downstream nozzle array being located downstream with respect to the first color upstream nozzle array in the feeding direction; the second color ink head includes:

a second color upstream nozzle array including a portion of the plurality of nozzles arrayed in the feeding direction; and a second color downstream nozzle array including another portion of the plurality of nozzles arrayed in the feeding direction, the second color downstream nozzle array being located downstream with respect to the second color upstream nozzle array in the feeding direction; the second ink ink head includes;

a second ink upstream nozzle array including a portion of the plurality of nozzles arrayed in the feeding direction; and a second ink downstream nozzle array including another portion of the plurality of nozzles arrayed in the feeding direction, the second ink downstream nozzle array being located downstream with respect to the second ink upstream nozzle array in the feeding direction; the first printing controller:

in a case in which the first printing layer is to be provided below the second printing layer, causes the nozzles of the first color upstream nozzle array to eject the first ink of the first color that provides the first underlying layer dot group, causes the nozzles of the second color upstream nozzle array to eject the first ink of the second color that forms the second underlying layer dot group, and causes the nozzles of the second ink upstream nozzle array to eject the second ink, to provide the first printing layer; and in a case in which the first printing layer is to be provided above the second printing layer, causes the nozzles of the first color downstream nozzle array to eject the first ink of the first color that forms the first underlying layer dot group, causes the nozzles of the second color downstream nozzle array to eject the first ink of the second color forms the second underlying layer dot group, and causes the nozzles of the second ink downstream nozzle array to eject the second ink, to form the first printing layer; and the second printing controller:

in a case in which the first printing layer is to be formed below the second printing layer, causes the nozzles of the first color downstream nozzle array to eject the first ink of the first color that forms the first image dot group, and causes the nozzles of the second color downstream nozzle array to eject the first ink of the second color that forms the second image dot group, to form the second printing layer; and in a case in which the first printing layer is to be formed above the second printing layer, causes the nozzles of the first color upstream nozzle array to eject the first ink of the first color that forms the first image dot group, and causes the nozzles of the second color upstream nozzle array to eject the first ink of the second color that forms the second image dot group, to form the second printing layer. 16. A printing method by which at least a first ink of a first color, a first ink of a second color, and a second ink are ejected toward a recording medium to form, on the recording medium, at least ink dots of the first ink of the first color, ink dots of the first ink of the second color, and ink dots of the second ink, the printing method comprising:

a first generation step of generating, upon receipt of data on the ink dots of the first ink of the first color, a plurality of first dot groups, including a first underlying layer dot group and a first image dot group, of the ink dots of the first ink of the first color; a second generation step generating, upon receipt of data on the ink dots of the first ink of the second color, a plurality of second dot groups, including a second underlying layer dot group and a second image dot group, of the ink dots of the first ink of the second color; a first printing step of forming a first printing layer, on the recording medium, of at least the ink dots of the first underlying layer dot group, the ink dots of the second underlying layer dot group and the ink dots of the second ink; and a second printing step of forming a second printing layer, above or below the first printing layer, of at least the ink dots of the first image dot group and the ink dots of the second image dot group; wherein in the first generation step, the plurality of first dot groups are generated so as to include all of the ink dots of the first ink of the first color; and in the second generation step, the plurality of second dot groups are generated so as to include all of the ink dots of the first ink of the second color. 17. The printing method according to the first ink of the first color is a first process color ink; the first ink of the second color is a second process color ink different from the first process color ink; and the second ink is a special color ink.CROSS REFERENCE TO RELATED APPLICATIONS

BACKGROUND OF THE INVENTION

1. Field of the Invention

2. Description of the Related Art

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

Preferred Embodiment 1

Preferred Embodiment 2

Preferred Embodiment 3