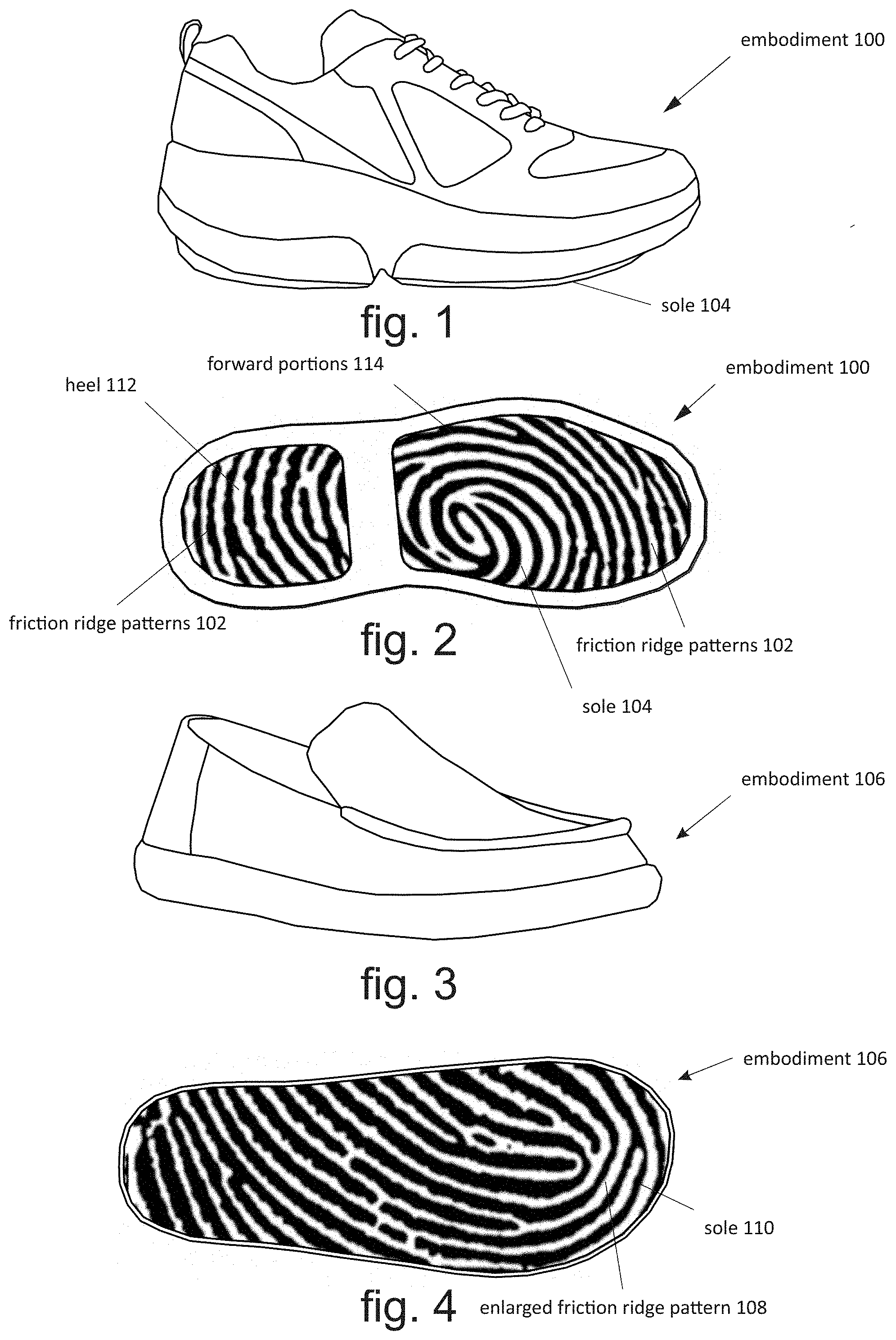

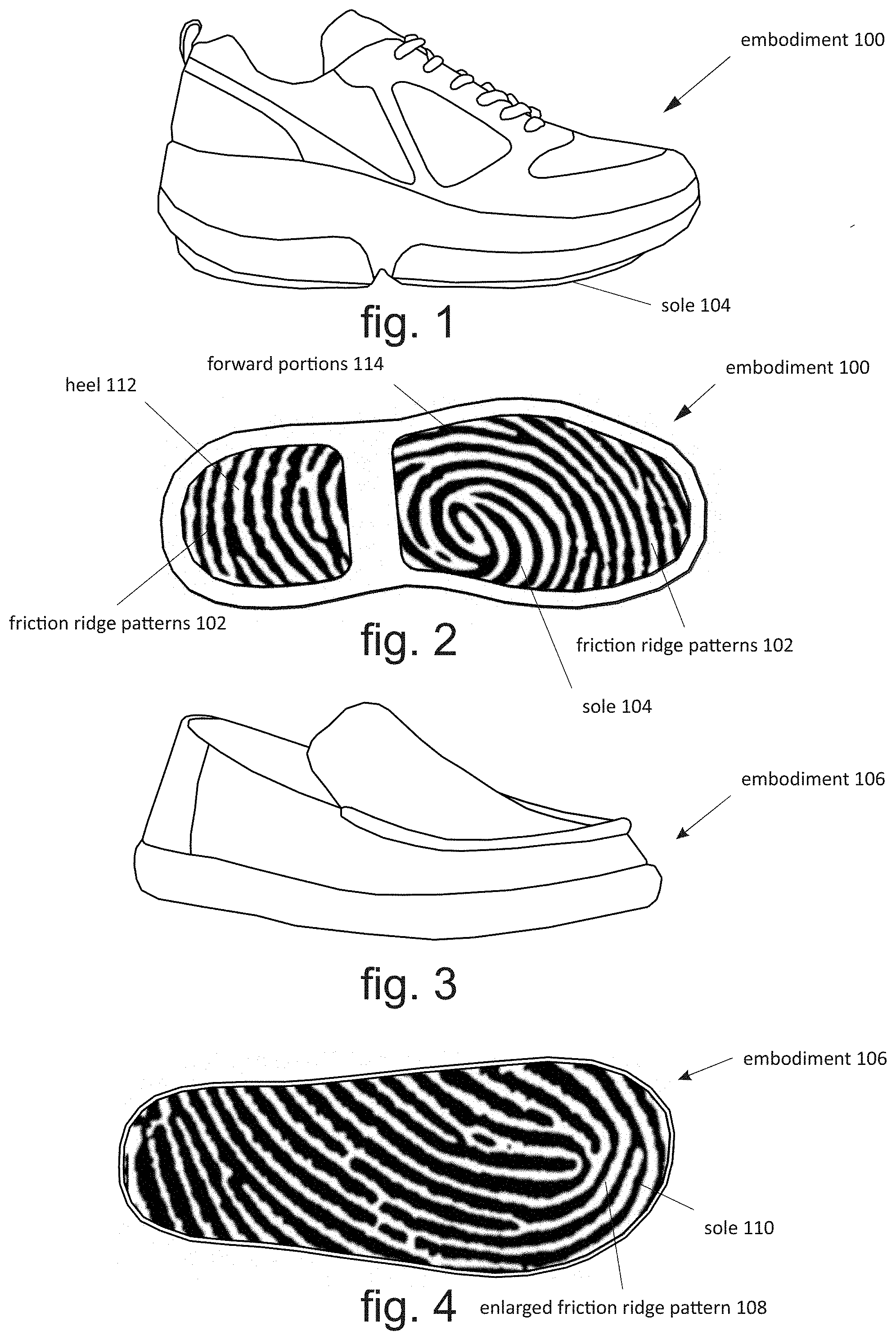

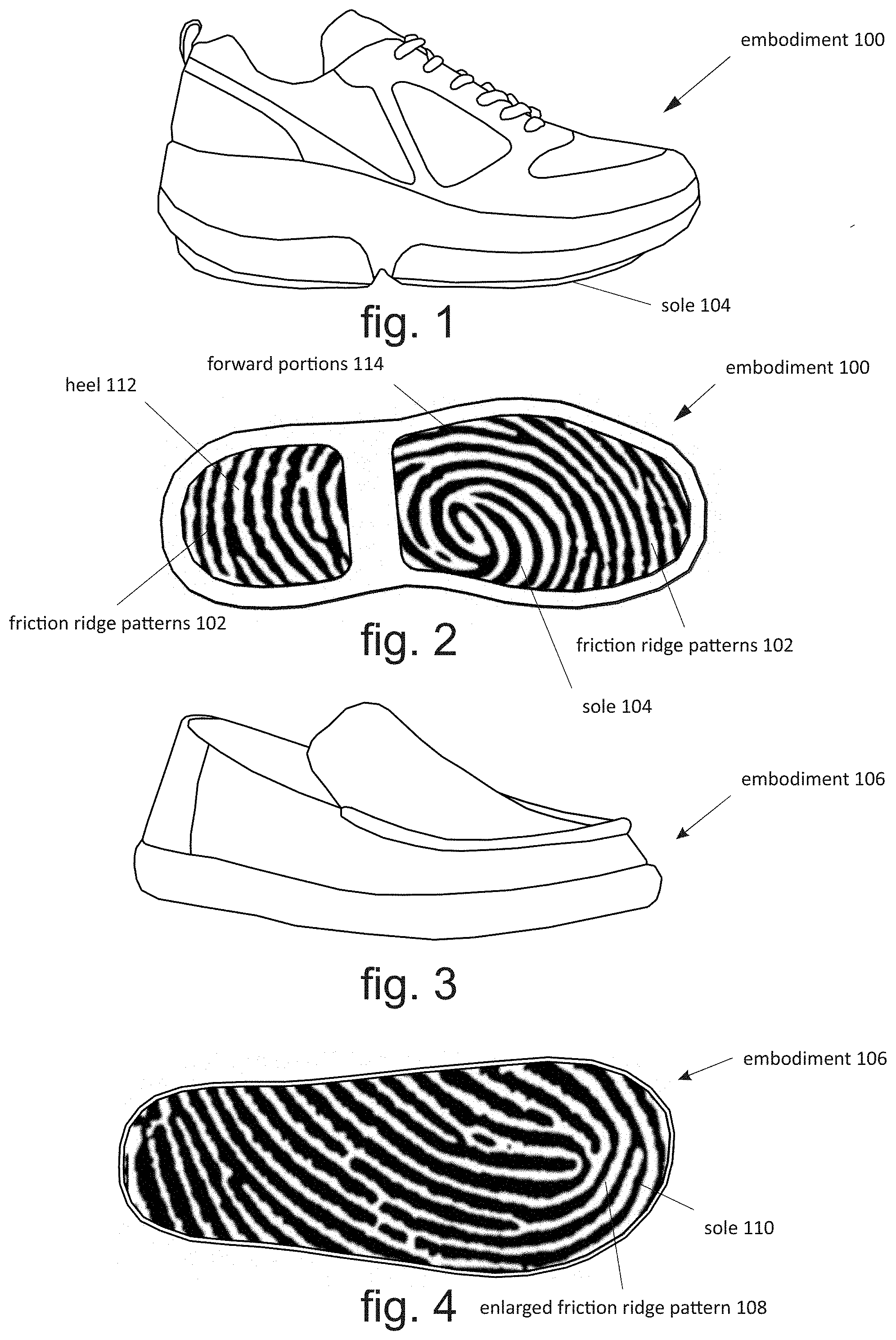

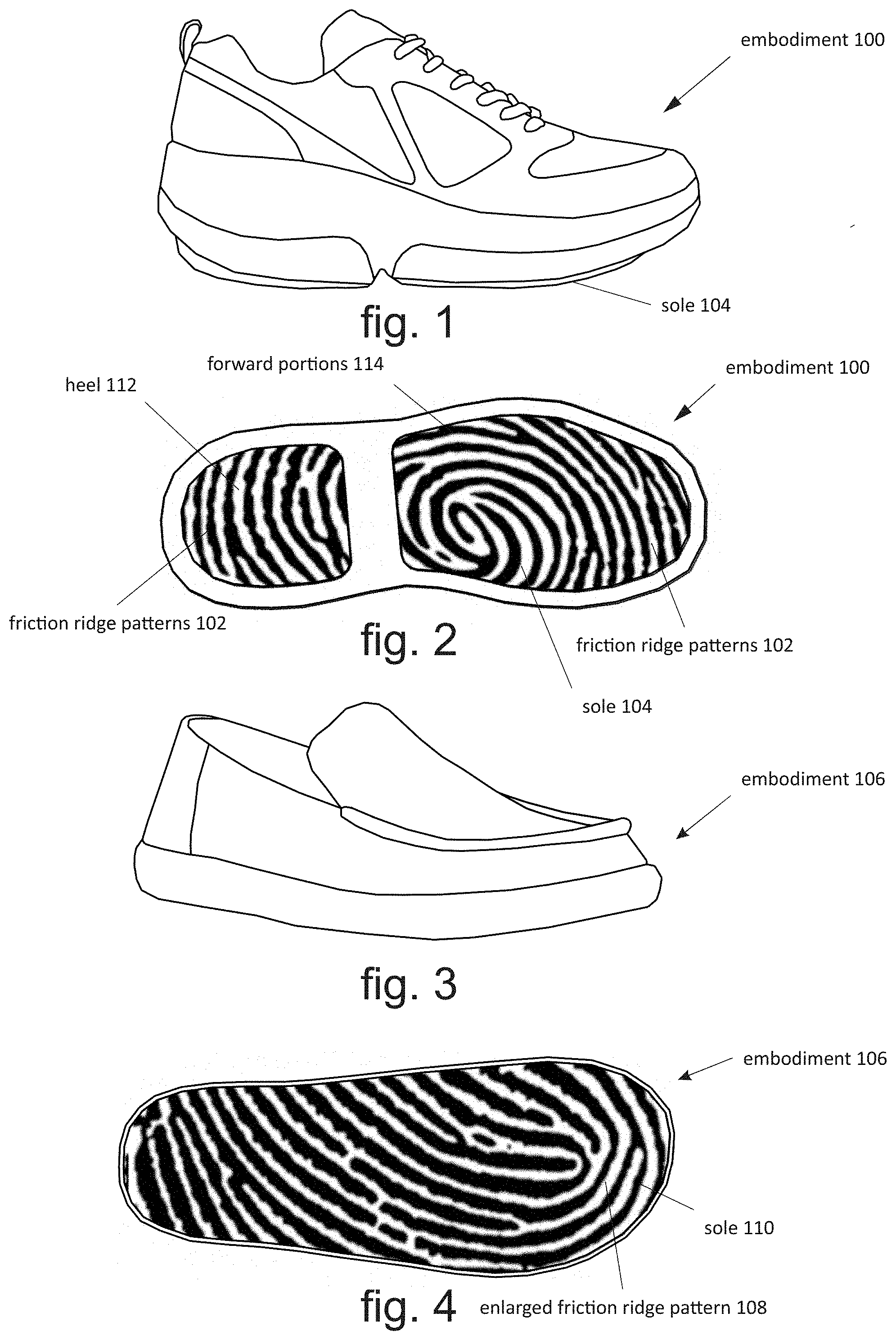

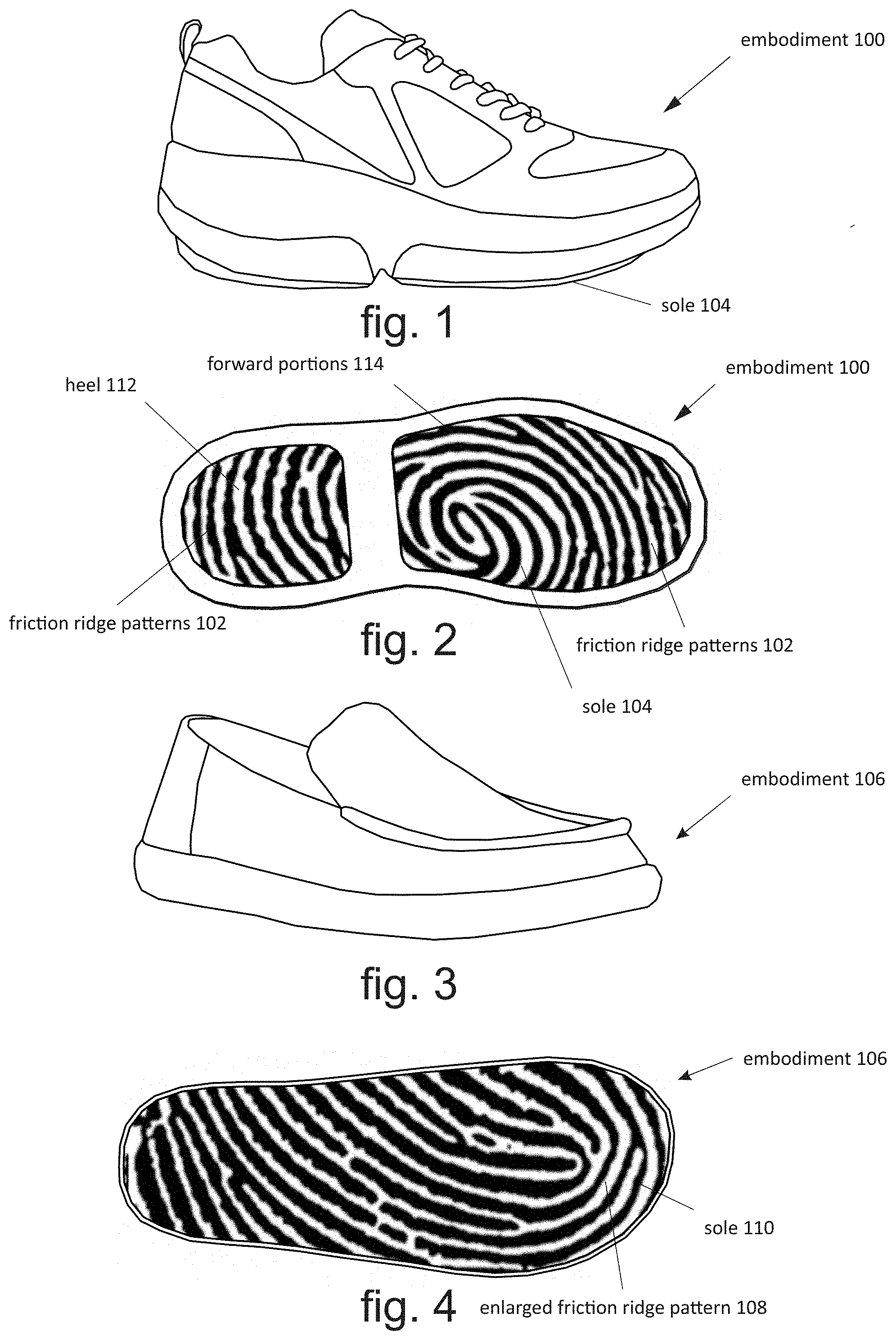

FOOTWEAR UTILIZING FRICTION RIDGE PATTERNS

This application relates generally to the design of human gripping and contact surfaces. Today there are a huge number of celebrity endorsed footwear products. The value of such endorsements has been predicated at least in part on the implication that endorsing celebrity had some influence on, or preference for, the design of the endorsed footwear. It might be useful to make the connection between an endorsing celebrity and the endorsed footwear more intimate, and thus increase the positive influence the endorsing celebrity has on the sales of the endorsed product. Footwear tread design today is generally based on some combination of aesthetics, and measurement and design for specific, limited functional characteristics. By contrast, athletic footwear in particular, and all footwear in general, are subjected to an infinite variety and sequences of only partially predictable forces. In the design of footwear, it might be useful to model gripping surfaces which have evolved in a dynamic gripping/contacting situation. Friction ridges, also referred to as dermal ridges or dermal papillae, which comprise form patterns found on human fingertips, digital inner surfaces, palm surfaces (palmar); and lower toe surfaces, and the soles of feet (plantar), have evolved in dynamic gripping and contacting situations. What Charles Darwin described as “survival of the fittest” is predicated not just on gripping or gaining traction on an object or surface in a static situation, but rather on adapting and having a balance between gripping and contacting many, many different objects and surfaces, in an infinite variety and sequence of situations. Due at least in part to the evolutionary development processes involved in the creation of friction ridge patterns, such patterns may ideally enhance the ability of surfaces mimicking friction ridge patterns to grip, gain traction and enhance control when contacting a variety of objects and surfaces in a wide diversity of only partially predictable situations. They may also include such patterns found in analogous locations on various animals, including, but not limited to, primates, apes, great apes, and koalas. They may also include such patterns which are logically derived, based on characteristics of naturally occurring friction ridge patterns. Such patterns may be at 1-to-1 scale, or may be enlarged and/or reduced in scale. Such patterns may also be distorted in various ways, including specifically, but not limited to, squeezing, skewing and/or bending. Such friction ridge patterns may be regularly or irregularly repeated one or more times, on an entire surface, or on one or more portions of a surface. Such friction ridge patterns may be isolated ( And such friction ridges may be placed on smooth surfaces (see Such patterns may comprise regular, partially regular, or irregular mosaic structures (see And such patterns may be employed generally across lower footwear surfaces (as non-limiting and non-exhausted examples, Products employing such friction ridge patterns may be of conventional construction, utilizing conventional materials and fabrication techniques; or they may employ construction and materials specifically adapted to take advantage of such friction ridge patterns. Virtually all or any footwear may advantageously employ such friction ridge patterns. Such patterns may provide advantage at least for functional reasons, such as, by way of non-limiting and non-exhaustive examples, to improve contact and control between the soles of footwear and the surfaces they contact. Such patterns may also provide advantage by providing a direct and easily understood connection between an individual and the footwear such patterns may be on. As a non-limiting and a non-exhaustive example, between a sports celebrity and a shoe the sports celebrity may endorse. Various embodiments will become better understood with regard to the following description, appended claims and accompanying drawings wherein: Each such imprint may be formed into a basically non-contoured sole 128 as shown in Alternatively, each fingerprint-like imprint may be formed into a contoured substructure 130 of its own, such as, as a non-limiting and non-exhausted example, the domed substructures shown in Such contoured structures may overlap (not shown), or be isolated as shown in Likewise, each contoured substructure may be unique, or may be partially or completely identical, or be rotated relative to one another, or be mixed with other similar or dissimilar contoured substructures in any of a variety of useful ways. Further each contoured substructure may be of uniform size, or be of varying sizes. Or one or more friction ridge patterns may be repeated or partially repeated or may be completely dissimilar, including, but not limited to, in size and/or scale, and/or its distortion relative to the origins it's based upon. Or imprinted friction ridge patterns, and/or contoured substructure may be arranged and derived in any other useful ways. Again, each such friction ridge pattern may be unique, or may be duplicated, or may be rotated to any angle, or may be produced at any scale, or may be distorted, or may be a derivative of any other useful organizational or distorting process. Also, the rectangular tiling may be replaced with any other useful organizational structure. As non-limiting and non-exhausted examples, regular patterns of repeating geometric forms may be used, including, but not limited to, triangular, hexagonal, combinations of octagons and squares, tetrahedrons, other singular or combined regular or irregular polygons, irregular polygons, random forms, curved forms, or any other useful geometric structure. The relief of such friction ridges may be of any useful contour or depth. As non-limiting and non-exhausted examples, such ridges may be the same as or greater or lesser in scaled depth than the natural occurring friction ridges from which the imprinted friction ridges are derived. Or the receding or advancing friction ridge sides may be perpendicular, or formed to duplicate the natural structure from which the friction ridges are derived, or be of any other useful form structure. Such randomized patterns, as with virtually all patterns of friction ridges shown herein, might also be segregated into areas exhibiting specific characteristics. As non-limiting and non-exhaustive examples, some areas might have friction ridges imprinted to greater depth to decrease the effects of expected wear. Or some areas might have friction ridges with greater or lesser thickness of sole underneath the friction ridge imprint to convey greater or lesser forces from the shoed foot to the bottom of the friction ridge. Or friction ridges might be segregated in other useful structures. Friction ridge patterns may also be advantageously fabricated into the handles of rackets for: badminton, racquetball, ping-pong, as well as handles for other sports equipment. Likewise, these may be friction ridge patterns of, or derivative of friction ridge patterns of, celebrities, including, but not limited to sports celebrities. Here again, such patterns may help reinforce the value of celebrity endorsements. Any effective arrangement of friction ridge patterns, including those described herein, may be used alone and/or in combination, and/or at any useful scale, and/or at any effective relief contours, and/or utilizing any compatible fabrication technique, to potentially increase the performance of products, and/or to enhance the effectiveness of celebrity endorsements for such products, and/or for other reasons. This is true for any of a wide variety of products, including specifically those described herein. As non-limiting and non-exhausted examples, such products may include: footwear (including footwear for: track, track and cross-country running, marathons, climbing, baseball, basketball, football, track and field, swimming, snorkel and skin diving, tennis, golf, boating, rowing, auto racing, weightlifting, all sports, work, dress and/or leisure wear, gymnastics, hunting, fishing, and other indoor and outdoor activities, etc.); gloves and hand wear for the above activities, as well as handles and gripping surfaces on products including, but not limited to: tennis, badminton, squash, and racquetball rackets; ping-pong paddles; golf clubs, croquet mallets, hockey sticks, yard utensils, including shovels, rakes, trowels, lawnmowers, weed whackers, cythes; power and manual hand tools, automobile steering wheels, aircraft yokes and joysticks, bicycle and motorcycle handle grips, military and sports rifles and pistols; hand grips on weapons such as grenade launchers and surface to air rocket launchers; floor coverings such as tumbling, yoga, and exercise mats, and area and general floor and wall surfaces; hand and foot gripping and contact areas, including those on: gym equipment, eating utensils, automobile and other device control pedals; knives and cutlery; archery bows; appliance and tool handles; bottles, jars and containers; door knobs, stair and other railings; as well as other gripping and contact areas on other products including automobile and other tires, and tractor treads; as well as gripping and contact areas on other products. Footwear, sports equipment, weapons, gloves, vehicle controls, floor surfaces, and vehicle tires three dimensionally imprinted with friction ridge patterns derived from individuals. 1. A method to enhance an individual endorsement of a product comprising the steps of:

recording a friction ridge pattern of an individual endorsing a product, and forming a three dimensional derivation of the recorded friction ridge pattern into the product endorsed by the individual. 2. The method of 3. The method of 4. The method of 5. The method of 6. The method of 7. The structure of 8. The method of 9. The method of 10. An athletic footwear product with versatile performance, comprising:

an upper enclosure configured to surround upper and rear portions of a foot, a sole coupled on its periphery to a lower portion of the upper enclosure, and the sole having a downward directed lower face, and wherein the lower face is three dimensionally imprinted with a friction ridge pattern derived from an individual. 11. The athletic footwear product of 12. The athletic footwear product of 13. The athletic footwear product of 14. A versatile firearm grip, comprising a firearm including a gripping handle portion, wherein the gripping handle portion is three dimensionally imprinted with a friction ridge pattern derived from an individual. 15. The versatile firearm grip of 16. A versatile vehicle control hand interface, comprising vehicle control hand interface gripping surface, disposed on a steering wheel, brake pedal, accelerator pedal, gearshift, or turn direction signal stalk, wherein the hand interface gripping surface is three dimensionally imprinted with a friction ridge pattern derived from an individual. 17. A glove having versatile gripping surfaces, comprising:

a glove, including hand enveloping surfaces comprising gripping areas configured to contact objects being grasped, wherein the gripping areas are three dimensionally imprinted with friction ridge patterns derived from an individual. 18. A vehicle tire with a versatile tread surface, comprising vehicle tire, including a tread surface, wherein the tread surface is three dimensionally imprinted with a friction ridge pattern derived from an individual. 19. A horizontal floor surface, comprising an upward directed foot contacting surface, wherein the upward directed foot contacting surfaces being three dimensionally imprinted with friction ridge patterns derived from an individual. 20. The floor surface of TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION