Method for Processing Oil Crops with Rhodotorula

The disclosure relates to a method for processing oil crops with Soybean is an important crop for grain and oil in the world and about 85% of global soybean yield is used for oil pressing, so it is the main global source of vegetable oil and protein feed. Existing soybean processing technologies for preparing soybean oil and soybean meal mainly extruding soybeans first, pressing oil from the extruded soybeans to obtain the soybean oil, and then drying residues to obtain the soybean meal. The soybean oil pressed from soybeans is an excellent edible oil which has a quite high nutritional value, and it is one of the most common edible oils in daily life of people; and the soybean meal, as a byproduct, that is acquired after pressing oil from the soybeans is huge in yield and is an excellent plant protein source for a culture feed due to its protein content up to 45% or more and reasonable amino acid composition. In terms of soybean oil, at present, with the continuous improvement of the quality of life, consumers have higher and higher requirements on the quality of edible oils. In order to gain the favor of consumers, researchers and manufacturers of edible oils have been trying to add natural functional substances (such as carotenoid, squalene and flavone) into soybean oil to endow the soybean oil with certain bioactivities, so that obtained products, functional oils, not only have higher market competitiveness, but also have an improved additional value. However, those natural functional substances require a process of production, extraction and preparation; thus, such oil products have a defect of long technological process in production or natural functional substance products need to be purchased for addition at a high cost. In terms of soybean meal, researchers and manufacturers of feed often carry out microbial fermentation of bean meal to further improve the quality of the bean meal. However, the fermented bean meal needs a plurality of links of water adding and material mixing, raw material sterilizing, inoculating and fermenting and drying; thus, although the quality of the bean meal is improved, the production cost is greatly increased, which is an important problem to be solved for a feed and culture industry that needs to strictly control cost. In order to solve the aforementioned problems, the disclosure provides a method for fermentation processing of soybean extruded powder or other oil crop powder with Technical scheme of the disclosure is as follows: The disclosure provides a method for processing oil crops with The oil crop powder includes one or more of soybean extruded powder, soybean powder, peanut powder, rapeseed powder, castor powder and sesame powder. In one embodiment of the disclosure, the fermentation medium includes, by mass, the oil crop powder, 35-45% of a total mass of the fermentation medium and the water, 55-65% of the total mass of the fermentation medium. In one embodiment of the disclosure, the fermentation medium includes the oil crop powder 40% of the total mass of the fermentation medium and the water, 60% of the total mass of the fermentation medium. In one embodiment of the disclosure, conditions for the solid state fermentation include a temperature of 25-30° C. and a time of 3-6 d. In one embodiment of the disclosure, conditions for the solid state fermentation include a temperature of 30° C. and a time of 4 d. In one embodiment of the disclosure, inoculating the In one embodiment of the disclosure, the In one embodiment of the disclosure, the In one embodiment of the disclosure, the fermentation medium includes the soybean extruded powder and the water. The disclosure further provides oil and bean meal or other oil crop meal prepared by the method above. The disclosure further provides a product that contains the oil and/or oil meal above or other oil crop meal. In one embodiment of the disclosure, the product is a feed, a food, a drug or a healthcare product. Beneficial effects: (1) The oil prepared by the method has rich carotenoid with its content up to 9.071 μg/g, so it has functions of resisting oxidation, delaying ageing, enhancing immunity and preventing cancers and also has great application prospects in the fields of food, drugs and healthcare products. (2) Existing functional oil is acquired by preparing and extracting nutrients and mixing the oil with various nutrients that have a regulation effect on human health, so it has the defects of complicated process and high cost. In the disclosure, functional oil rich in carotenoid is acquired by directly inoculating the (3) Oil crop meal such as bean meal, peanut meal and rapeseed meal prepared by the method of the disclosure also has rich carotenoid with its content up to 8.062 μg/g, so it has certain functions of resisting oxidation, delaying ageing, enhancing immunity and preventing cancers and has great application prospects in preparation of high quality feed. (4) Existing manufactures of feed often sterilize oil crops subjected to oil pressing and ferment the sterilized oil crops and various kinds of bacteria to obtain a fermented bean meal feed, as a result, sterilizing, fermenting and other additional processes are added to processing of the feed, which greatly increases the cost of the feed. In the disclosure, the oil crop meal is acquired by directly inoculating the (5) Manufacturers of feed usually add a large quantity of antibiotics to feed to reduce the survival rate of bred animals, and undoubtedly, a lot of antibiotics will be left in bodies of the bred animals, resulting in potential hazards to health food sanitation and safety. In the disclosure, the oil crop meal with rich carotenoid and functions of resisting oxidation, delaying ageing, enhancing immunity and preventing cancers is acquired by directly inoculating the The disclosure is further described in conjunction with Examples as follows. A medium involved in following Examples is as follows: A YPD seed medium (m/v): peptone 2%, yeast 1% and glucose 2%. Detection methods involved in following Examples are as follows: Analysis of functional oil and oil crop meal: 1. Extraction A solid state fermented product is dried at 50° C. until a water content reaches 5-10%; the dried fermented product and n-hexane are mixed at a mass ratio of 1:30, soaked and stirred for 24 h; suction filtration is performed and a filtrate is taken; and the filtrate is rotary evaporated at 50° C. by a rotary evaporator to obtain the functional oil and oil crop meal. 2. Measurement of type and content of fatty acid in functional oil 50 mg of the acquired functional oil is taken and added to 2 mL of a 0.5 mol/L NaOH—CH3OH solution; the mixture is saponified in a water bath for 30 min at 65° C., cooled to room temperature, and 2 mL of a 14% BF3—CH3OH solution is added; the mixture is saponified in a water bath for 30 min at 65° C., cooled to room temperature, and 5 mL of n-hexane is added to oscillate for 3-4 min to extract fatty acid methyl ester; a little of anhydrous Na2SO4 is added for dewatering treatment; centrifuging is performed for 5 min at 10,000 r/min; an upper layer organic phase is taken to pass through a 0.22 μm organic film for use; a 0.2 mg/mL nonadecanoic acid methylester solution (with n-hexane as a solvent) is added to a solution subjected to methyl esterification and film passing at a volume ratio of 1:1 to serve as an internal standard; and the content of the fatty acid in the extract is measured by a GC-MS. 3. Extraction and content measurement of carotenoid in functional oil (1) 0.5 g of functional oil is accurately weighed and added into a 10 mL brown glass volumetric flask, reaches a constant volume with dichloromethane and is shaken up, and its OD value is measured at a light absorption wavelength of 450 nm and is substituted into a standard curve to calculate the content of the carotenoid. (2) the standard curve of the content of the carotenoid is formulated: a 0.2 mg/mL β-carotene standard solution is prepared, 0, 0.1, 0.2, 0.4, 0.8, 1.6, 3.2 and 6.4 mL of β-carotene standard solutions are sucked correspondingly to reach a constant volume 10 mL with dichloromethane, their OD values are measured at a light absorption wavelength of 450 nm, and a standard product curve is drawn. 4. Extraction and content measurement of carotenoid in oil crop meal 500 mg of oil crop meal is accurately weighed and put into a brown flask, 5 mL of acetone is added for ultrasonic treatment for 2 h, and the flask is taken out and shaken up every 20 min; the solution is centrifuged for 10 min at 10,000 rpm after ultrasonic treatment, and a supernate is taken; and the content of the carotenoid in the oil crop meal is measured by the measurement method for the content of the carotenoid in the functional oil. Detection method of cell concentration: 1 mL of a seed solution of The cell number in each mL=(cell number counted by blood counting chamber/80)×400×10000×dilution ratio. Specific steps are as follows: (1) a strain of (2) 80 mL of the YPD seed medium is taken and put into a 250 mL conical flask (sterilized for 20 min at 115° C.) and 200 pi of the activated fluid obtained in step (1) is inoculated into the YPD seed medium for culturing for 2 d at a temperature of 30° C. and a rotating speed of 200 r·min−1 to obtain a seed solution, where a cell concentration in the seed solution is about 9×109 CFU/mL at the moment. (3) 300 g of a fermentation medium is taken and put into a 2500 mL conical flask (sterilized for 30 min at 121° C.), and the seed solution is inoculated into the fermentation medium in accordance with fermentation parameters in Table 1 for solid state fermentation to obtain a fermented product. Oil extraction is performed on the obtained fermented product by the analysis method of the functional oil and oil crop meal to obtain the functional oil and fermented bean meal; and the obtained functional oil and fermented bean meal are analyzed by the analysis method of the functional oil and oil crop meal, and analysis results are shown in Tables 2-4. The blank group is original soybean extruded powder without microbial fermentation. The functional oil obtained by the original soybean extruded powder, group A, group B and group C is shown in FIG. 1, and the functional oil extracted from original extruded soybeans is golden yellow, the functional oil obtained by group A is light orange, the functional oil obtained by group B has a darker color than group A and is reddish orange, and the functional oil obtained by group C has the darkest color and is almost red. It can be known from Table 2 that the functional ingredient carotenoid is added to both the functional oil and bean meal obtained by fermenting the extruded soybeans with the Specific steps are as follows: (1) The same as Example 1. (2) The same as Example 1. (3) Peanuts are put into a hot air circulating oven and dried at 50° C. until a water content reaches 5-10%, then the peanuts are husked, and the husked peanuts are ground into fine peanut powder. (4) The peanut powder replaces soybean extruded powder, and 300 g of a fermentation medium is taken and put into a 2500 mL conical flask (sterilized for 30 min at 121° C.) and a seed solution is inoculated into the fermentation medium in accordance with the fermentation parameters in Table 1 for solid state fermentation to obtain a fermented product. Oil extraction is performed on the obtained fermented product by the analysis method of the functional oil and oil crop meal to obtain the functional oil and fermented bean meal; after the obtained functional oil and fermented bean meal are analyzed by the analysis method of the functional oil and oil crop meal, it is found that the peanut oil and peanut meal both have rich carotenoid; and the presence of the carotenoid endow the oil certain physiological functions, improves the quality of the peanut meal, and comprehensively improves the nutritional values of the oil and peanut meal. Specific steps are as follows: (1) The same as Example 1. (2) The same as Example 1. (3) Rapeseeds are put into a hot air circulating oven and dried at 50° C. until a water content reaches 5-10%, then the rapeseeds are husked, and the husked rapeseeds are ground into fine rapeseed powder. (4) The rapeseed powder replaces soybean extruded powder, and 300 g of a fermentation medium is taken and put into a 2500 mL conical flask (sterilized for 30 min at 121° C.) and a seed solution is inoculated into the fermentation medium in accordance with the fermentation parameters in Table 1 for solid state fermentation to obtain a fermented product. Oil extraction is performed on the obtained fermented product by the analysis method of the functional oil and oil crop meal to obtain the functional oil and fermented bean meal; after the obtained functional oil and fermented bean meal are analyzed by the analysis method of the functional oil and oil crop meal, it is found that the rapeseed oil and rapeseed meal both have rich carotenoid; and the presence of the carotenoid endows the oil certain physiological functions, improves the quality of the rapeseed meal, and comprehensively improves the nutritional values of the oil and rapeseed meal. The disclosure discloses a method for processing oil crops with 1. A method for processing oil crops, comprising the steps of performing solid state fermentation on wherein the oil crop powder comprises one or more of soybean extruded powder, soybean powder, peanut powder, rapeseed powder, castor powder and sesame powder. 2. The method of 3. The method of 4. The method of 5. The method of 6. The method of 7. The method of 8. The method of 9. The method of 10. The method of 11. The method of 12. Oil and/or oil crop meal, prepared by the method of 13. A product that comprises the oil and/or oil crop meal of 14. The product of TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF FIGURES

DETAILED DESCRIPTION

EXAMPLE 1

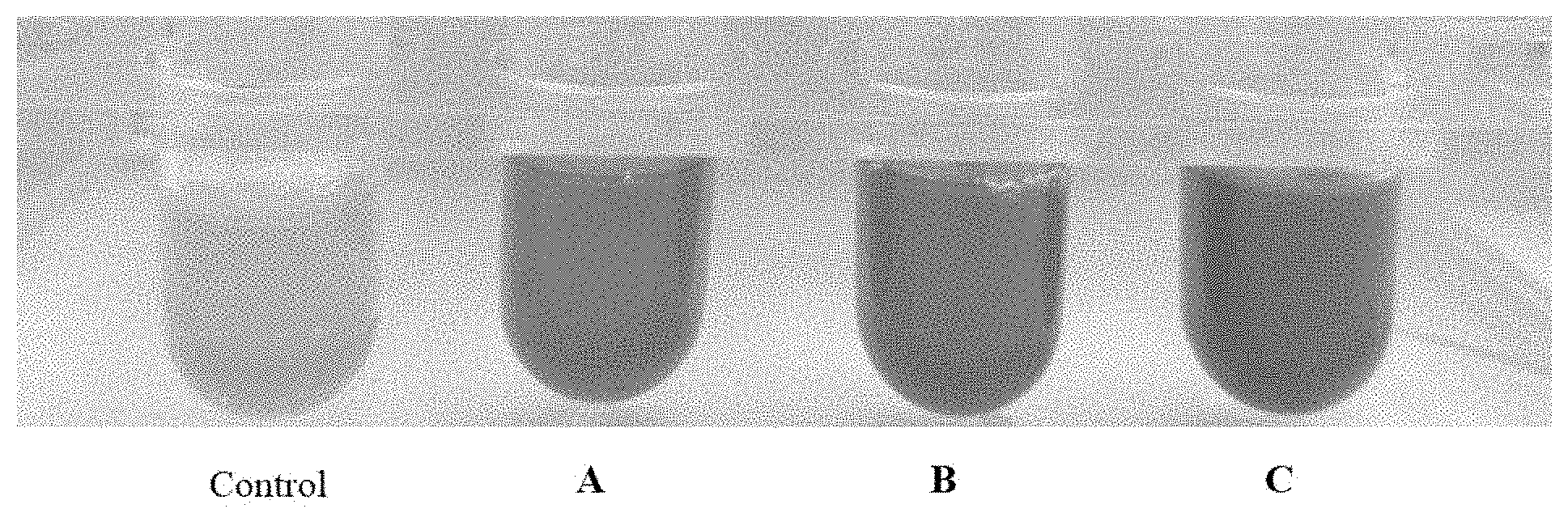

Using Soybean Extruded Powder as Raw Material

Fermentation parameters Inoculum Fermentation Group Strain Size Medium conditions Group A Group 12 mL Soybean extruded powder 120 30° C., 4 d A1 g, water 180 g Group 21 mL Soybean extruded powder 140 25° C., 4 d A2 g, water 160 g Group 13 mL Soybean extruded powder 110 28° C., 6 d A3 g, water 190 g Group B Group 18 mL Soybean extruded powder 120 30° C., 4 d B1 g, water 180 g Group 18 mL Soybean extruded powder 140 25° C., 4 d B2 g, water 160 g Group 16.5 mL Soybean extruded powder 110 28° C., 6 d B3 g, water 190 g Group C Group 18 mL Soybean extruded powder 120 30° C., 4 d C1 g, water 180 g Group 14 mL Soybean extruded powder 140 25° C., 4 d C2 g, water 160 g Group 14 mL Soybean extruded powder 110 28° C., 6 d C3 g, water 190 g Content of carotenoid in functional oil and fermented bean meal Carotenoid Oil (μg/g Bean meal (μg/g Group functional oil) fermented bean meal) Blank Group 7.286 0.623 Group A Group A1 7.513 8.062 Group A2 7.652 7.975 Group A3 7.751 8.059 Group B Group B1 8.462 2.161 Group B2 8.367 2.059 Group B3 8.453 2.112 Group C Group C1 9.071 7.627 Group C2 8.976 7.484 Group C3 9.031 7.575 Type and content of fatty acid in functional oil (mg/g functional oil) Group A Blank Group Group A1 Group A2 Group A3 C14:0 0.305 0.268 0.254 0.276 C16:0 46.976 44.832 45.667 48.492 C16:1 0.406 0.387 0.362 0.435 C18:0 16.803 16.122 16.101 16.556 C18:1 108.598 108.652 107.576 109.112 C18:2 223.761 223.592 221.347 225.379 C18:3 25.015 24.394 23.560 23.673 C20:0 1.515 1.400 1.297 1.378 C20:1 1.0521 1.018 0.984 1.027 C22:0 1.713 1.604 1.542 1.669 SFA/UFA 0.186 0.179 0.183 0.190 Type and content of fatty acid in functional oil (mg/g functional oil) Group B Group C Group Group Group Group Group Group B1 B2 B3 C1 C2 C3 C14:0 0.361 0.314 0.372 0.333 0.320 0.354 C16:0 54.176 52.880 56.076 45.284 44.187 46.583 C16:1 0.589 0.525 0.587 0.541 0.512 0.564 C18:0 19.640 18.352 19.896 16.494 16.087 16.809 C18:1 124.662 121.672 126.176 119.285 118.817 121.304 C18:2 253.395 250.768 254.098 236.165 234.734 236.189 C18:3 28.553 26.125 29.174 25.428 24.126 25.765 C20:0 1.748 1.720 1.759 1.457 1.217 1.468 C20:1 1.207 1.163 1.213 1.113 1.089 1.119 C22:0 2.019 1.986 1.987 1.729 1.703 1.790 SFA/UFA 0.191 0.188 0.195 0.171 0.167 0.174

Note: SFA refers to saturated fatty acid; MUFA refers to monounsaturated fatty acid; PUFA refers to polyunsaturated fatty acid; and UFA refers to unsaturated fatty acid.

EXAMPLE 2

Using Peanut Powder as Raw Material

EXAMPLE 3

Using Rapeseed Powder as Raw Material