TRACK SYSTEM FOR TRACTION OF A VEHICLE

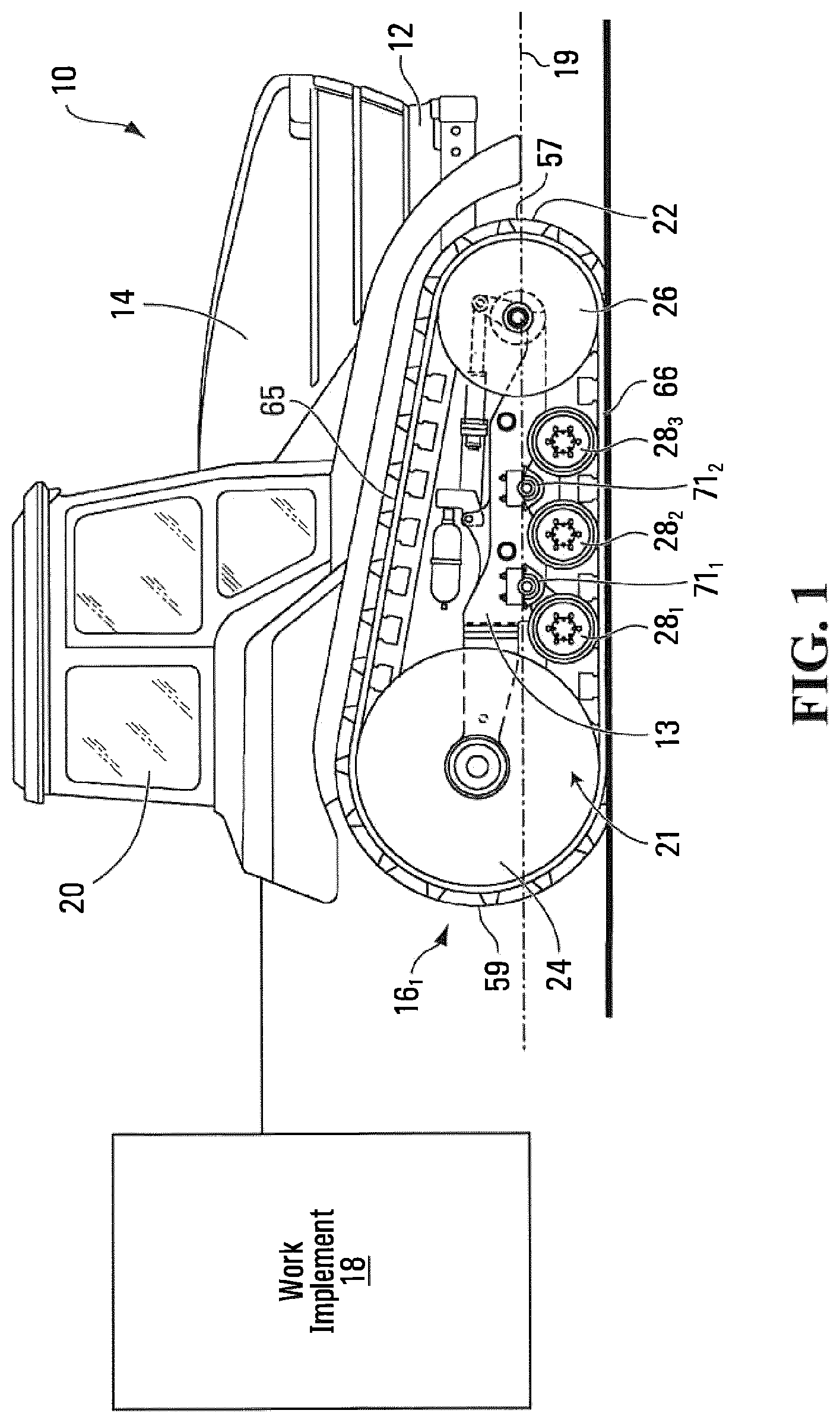

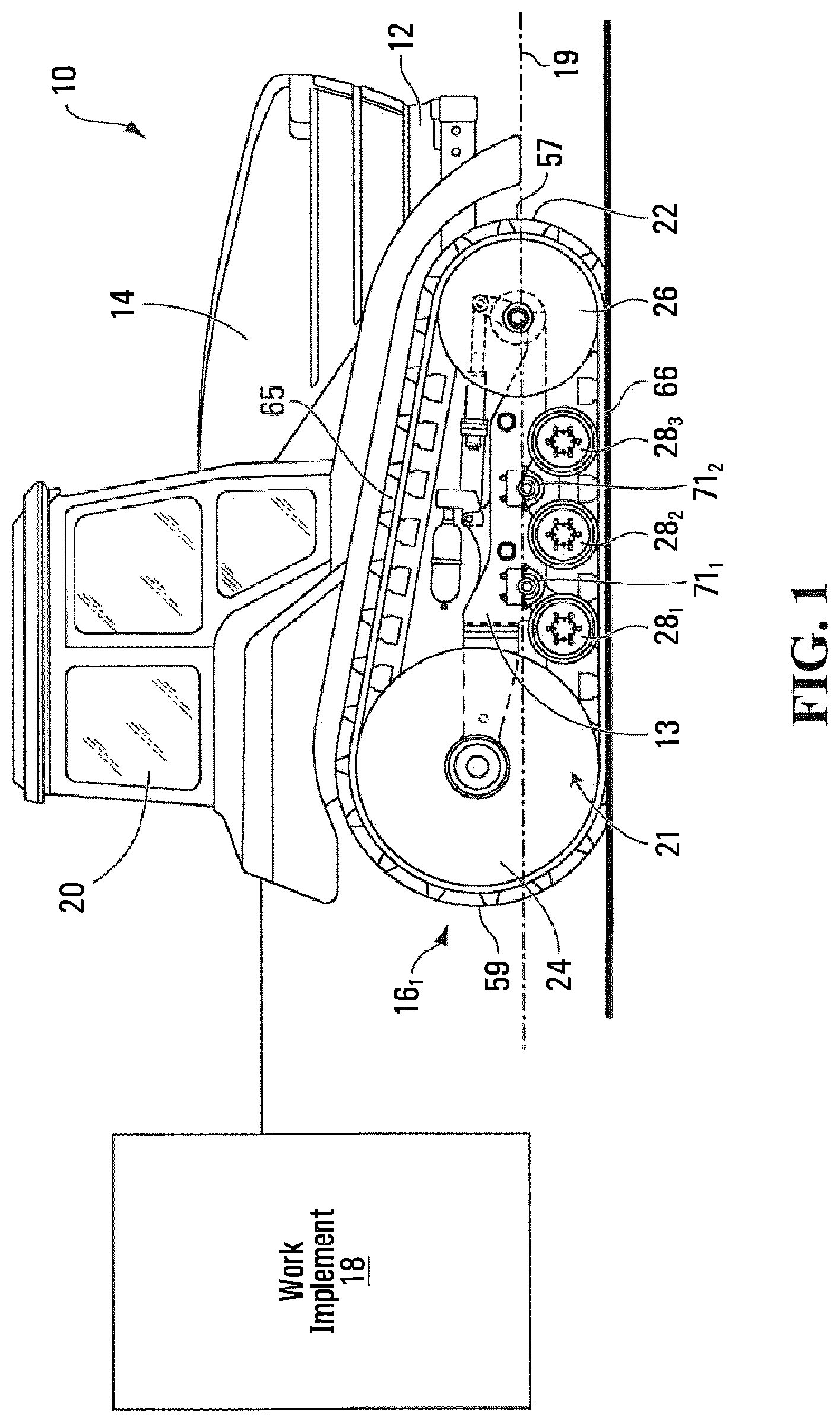

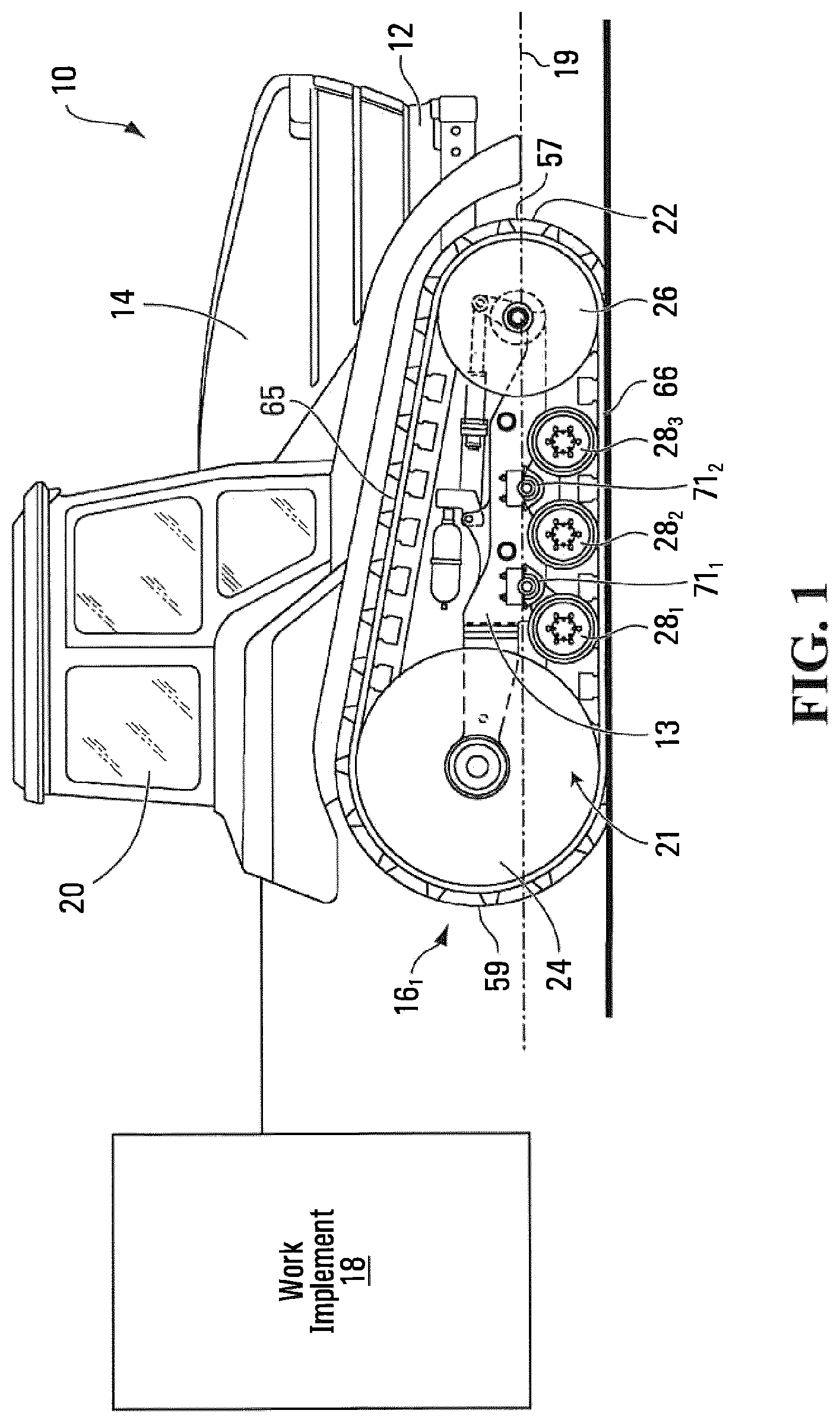

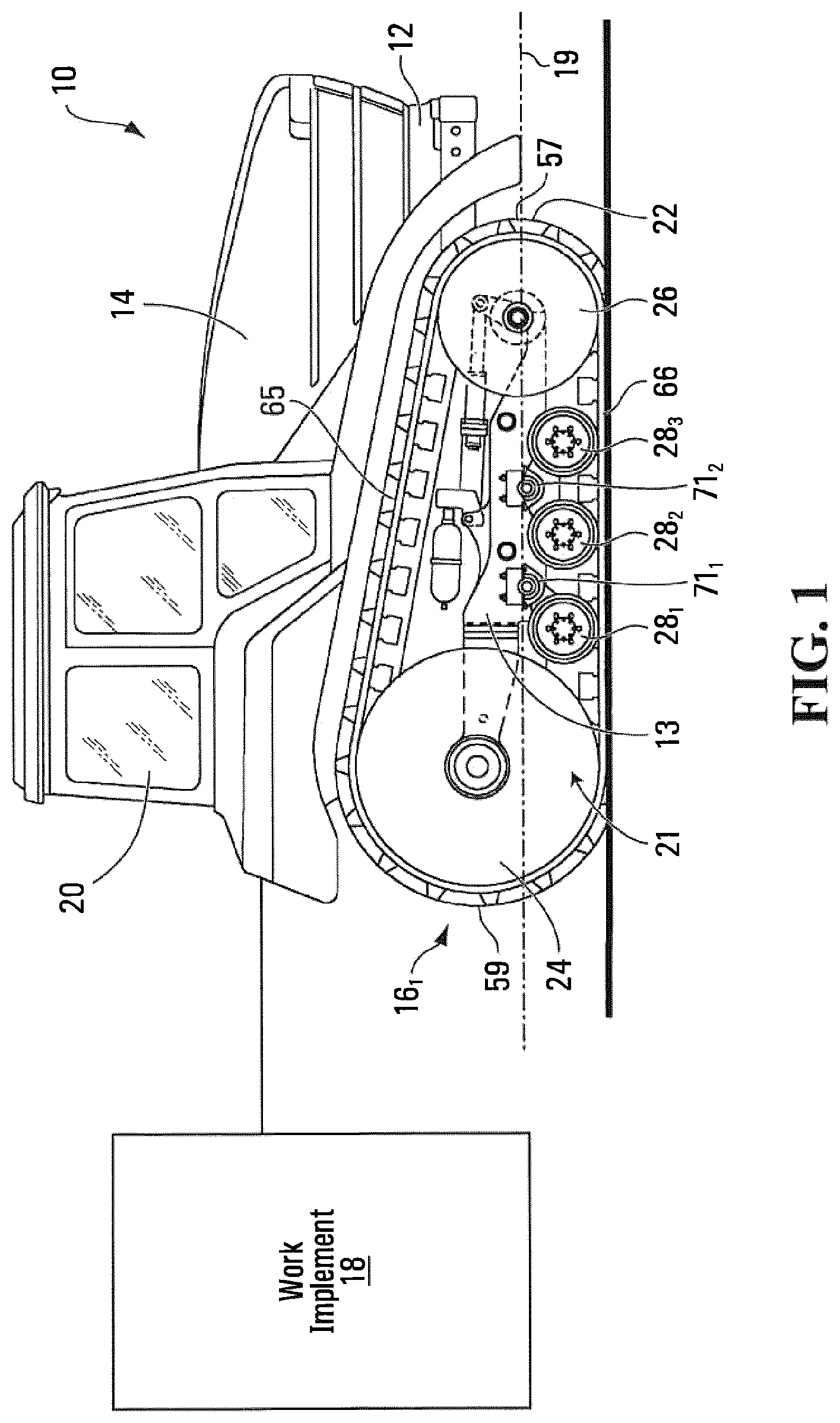

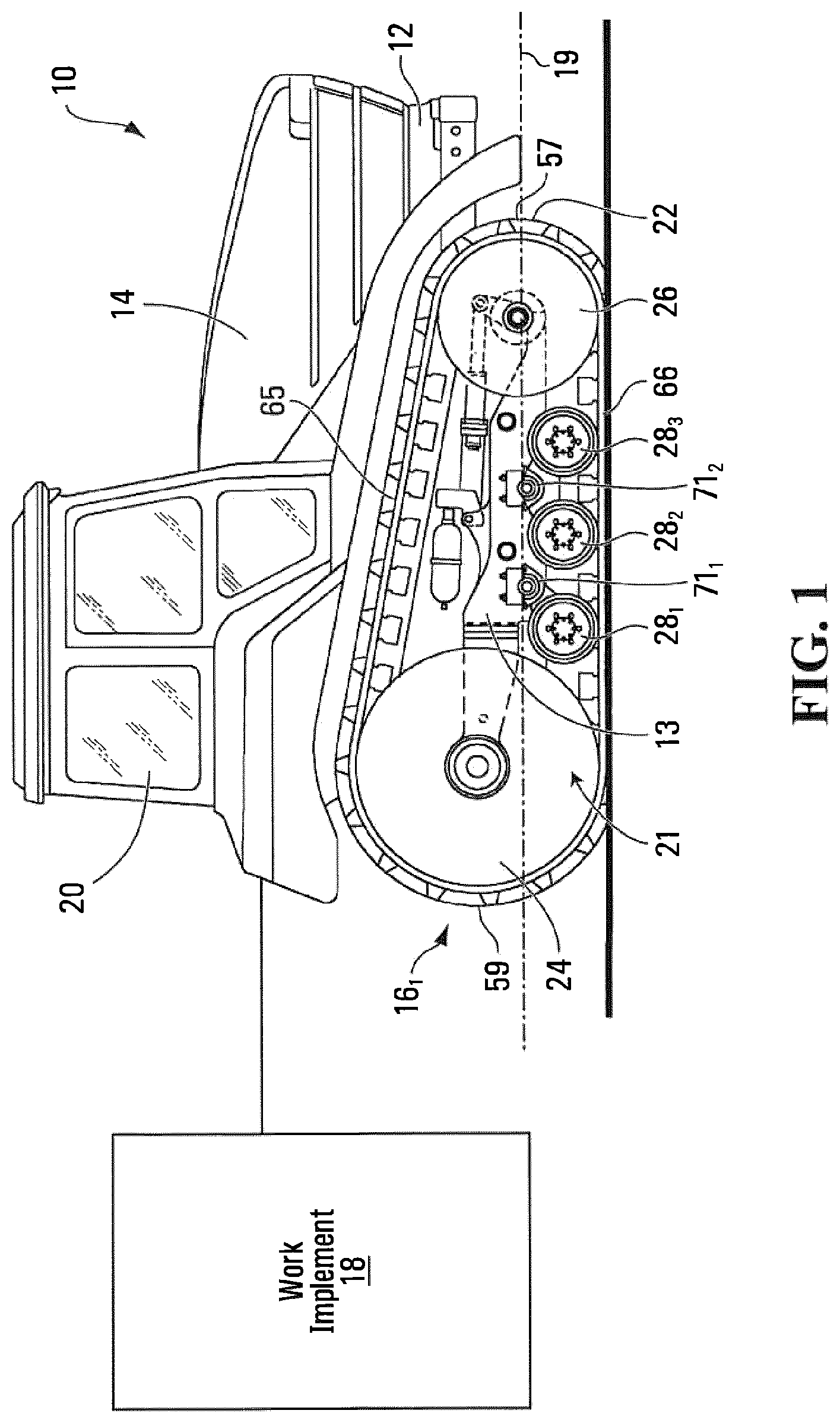

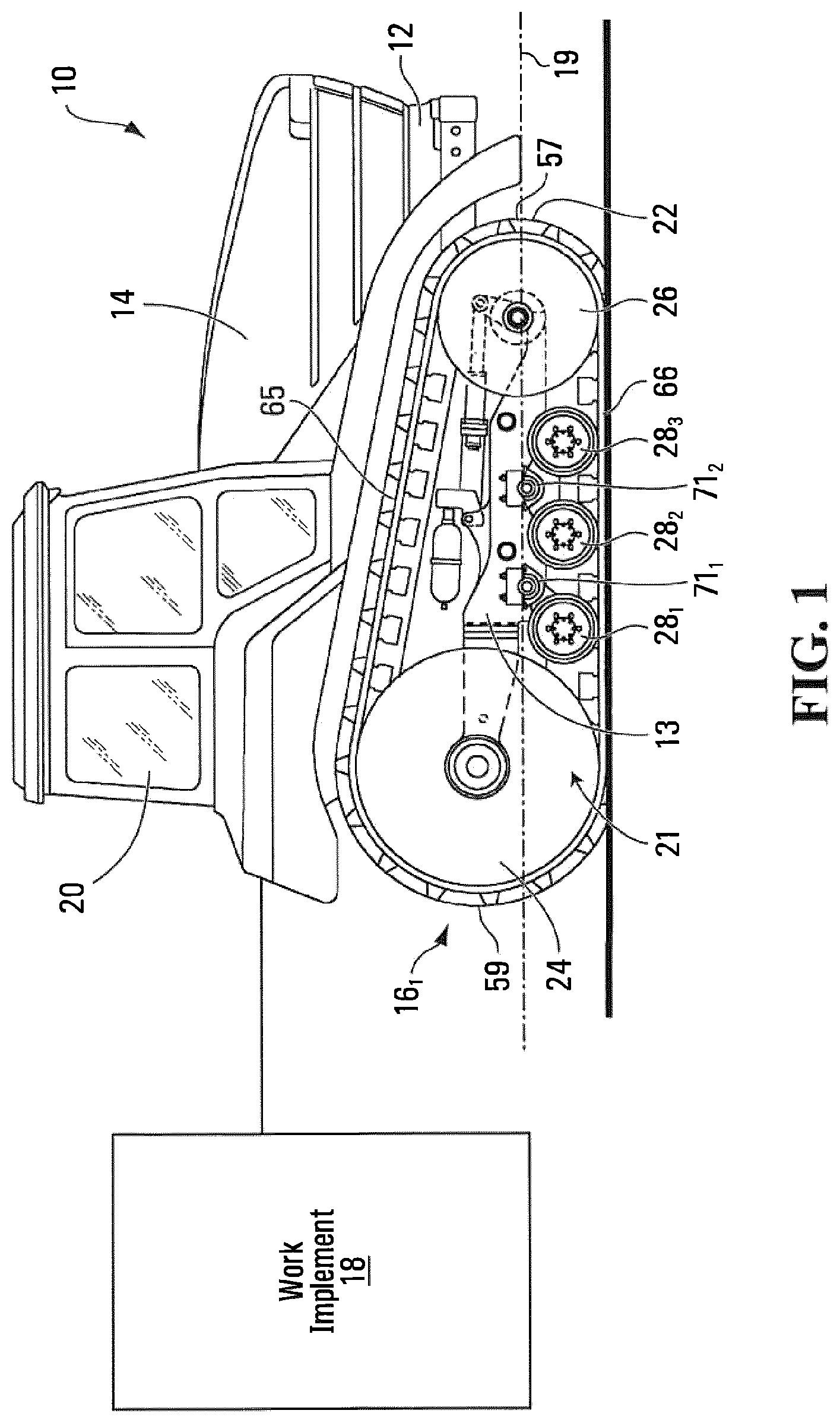

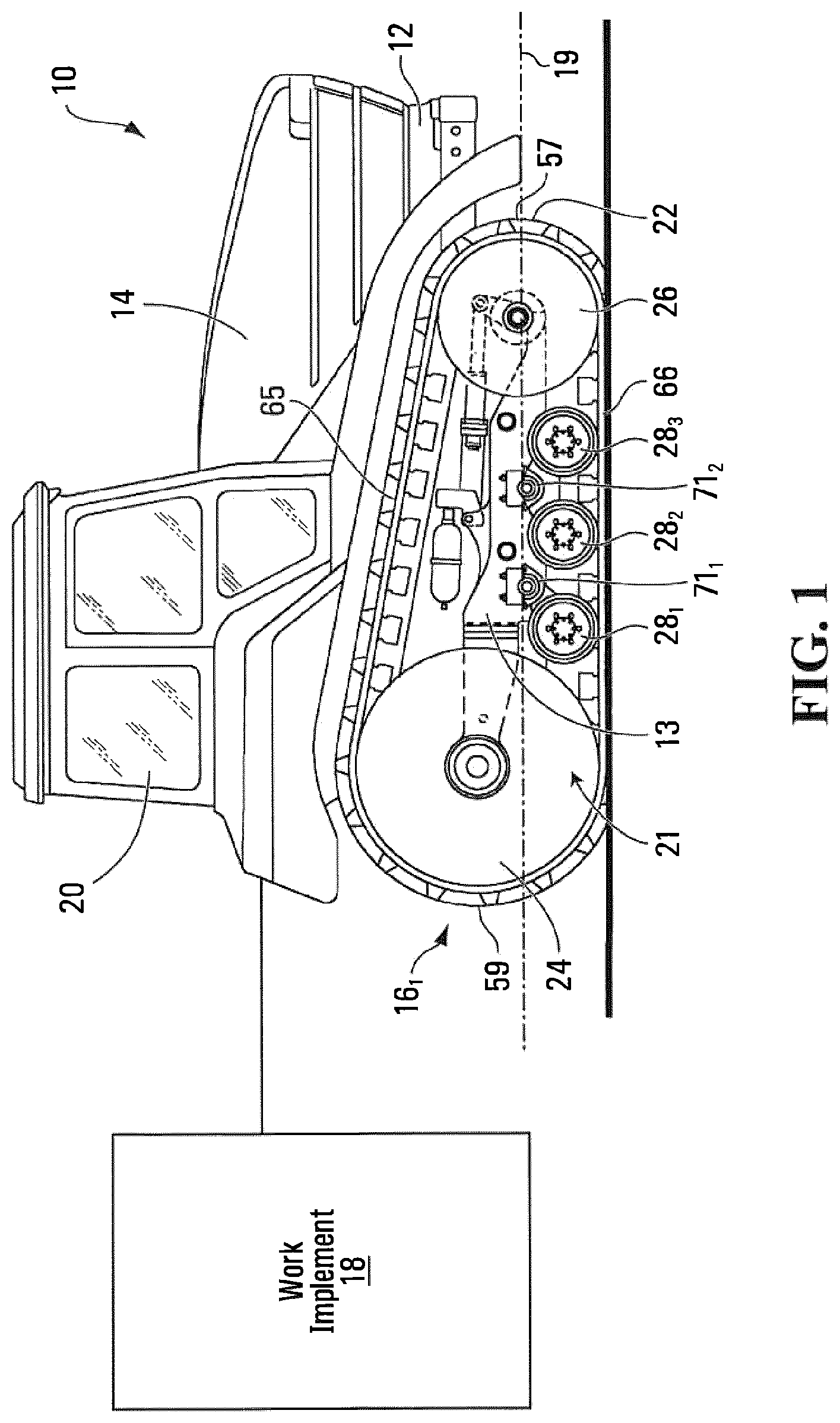

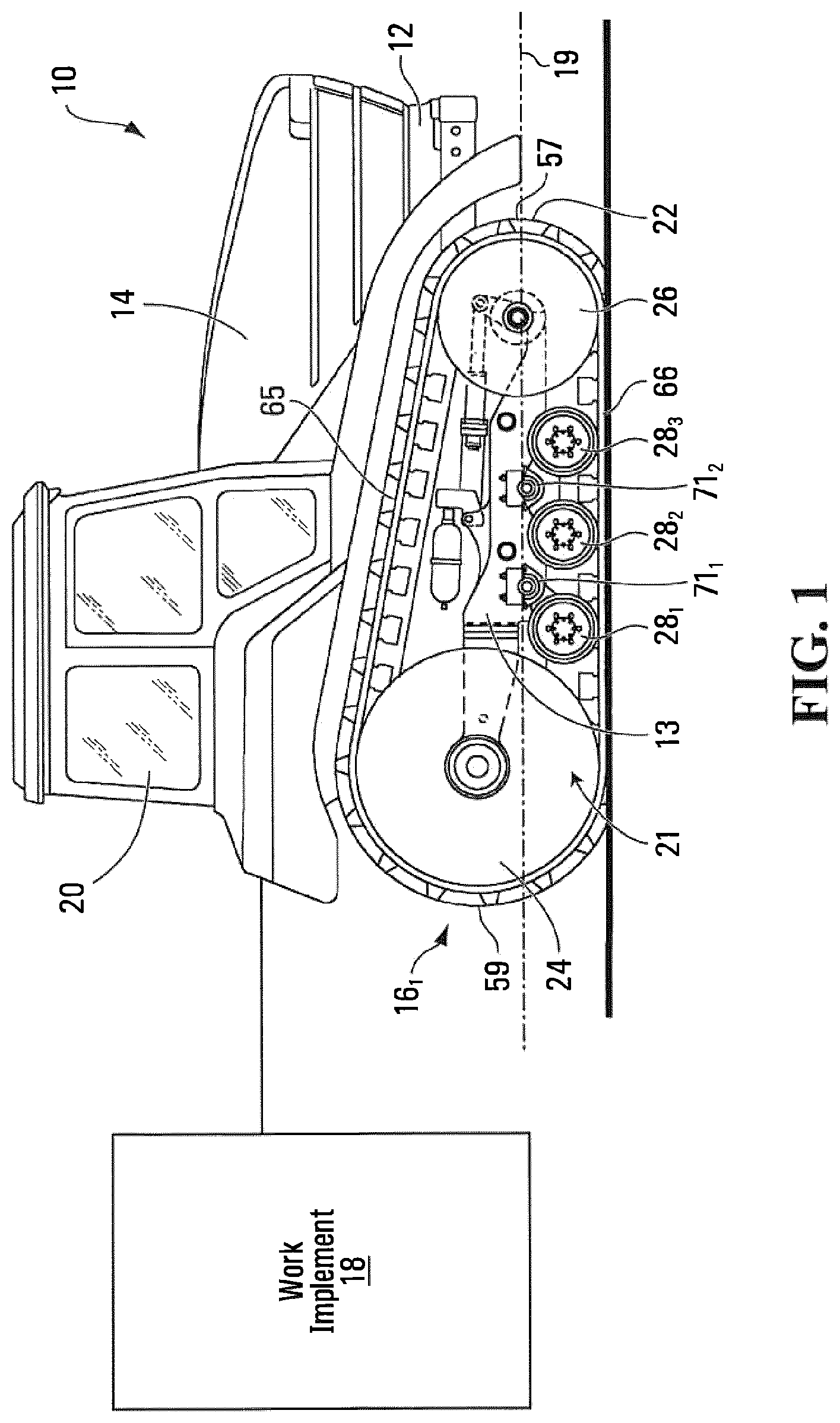

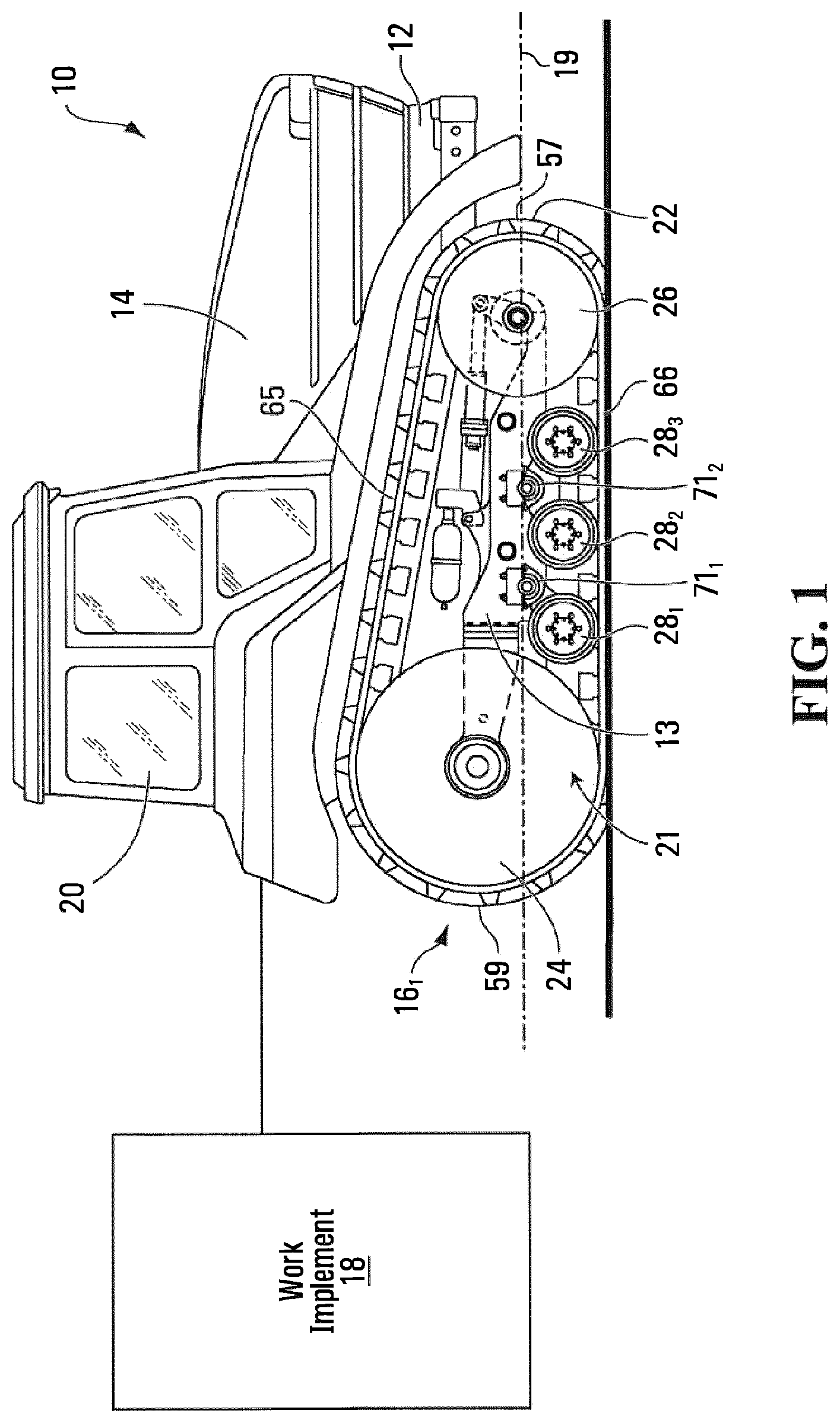

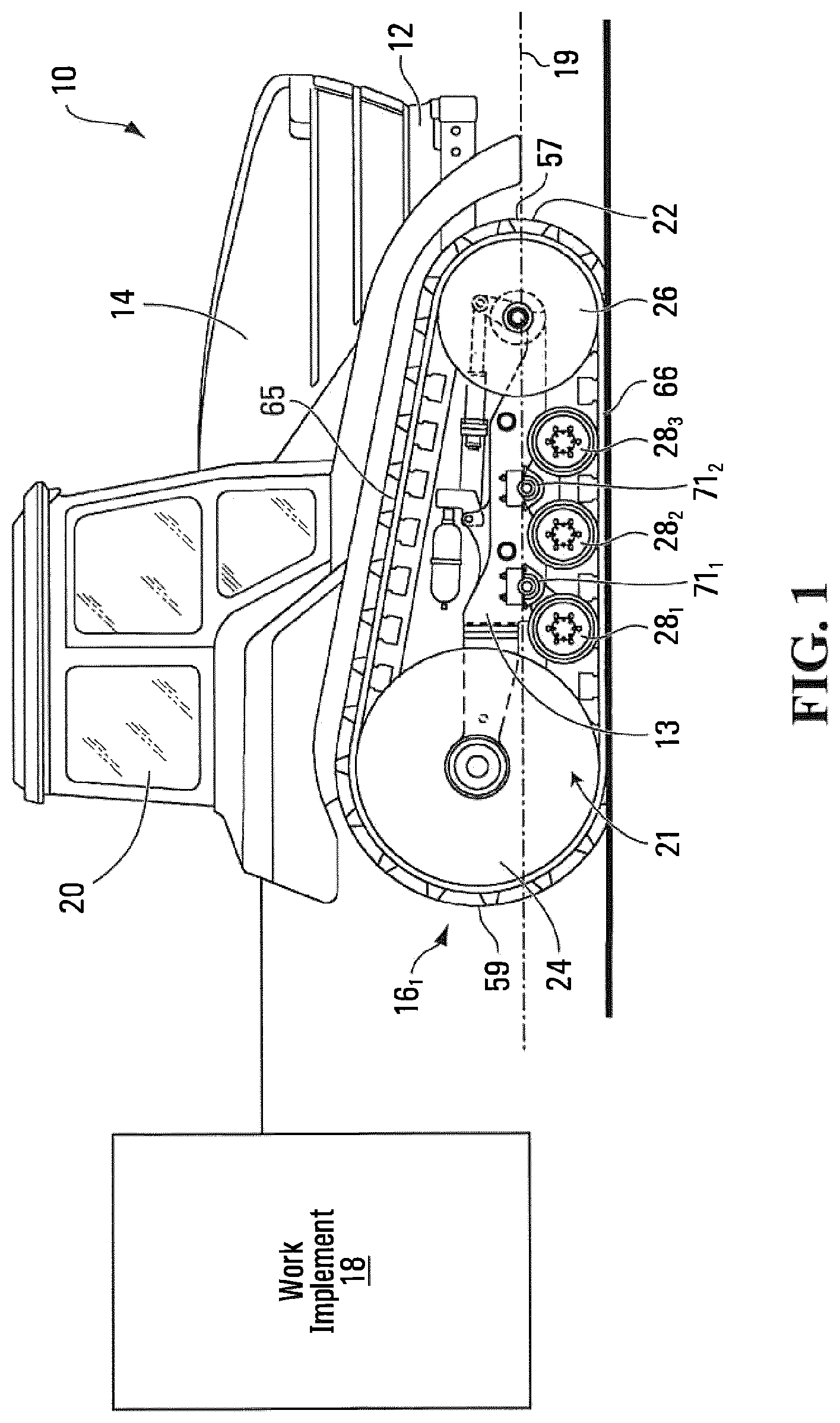

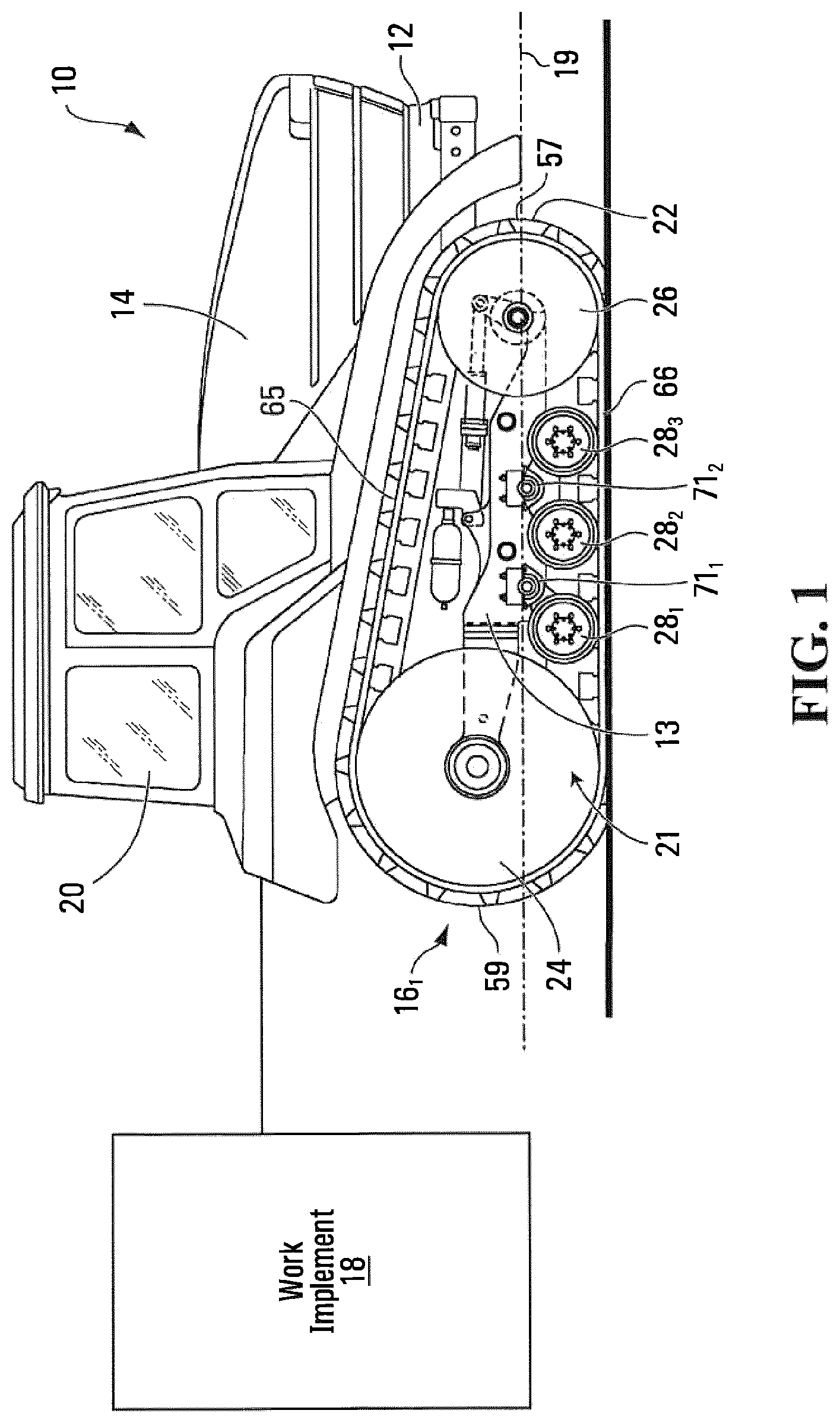

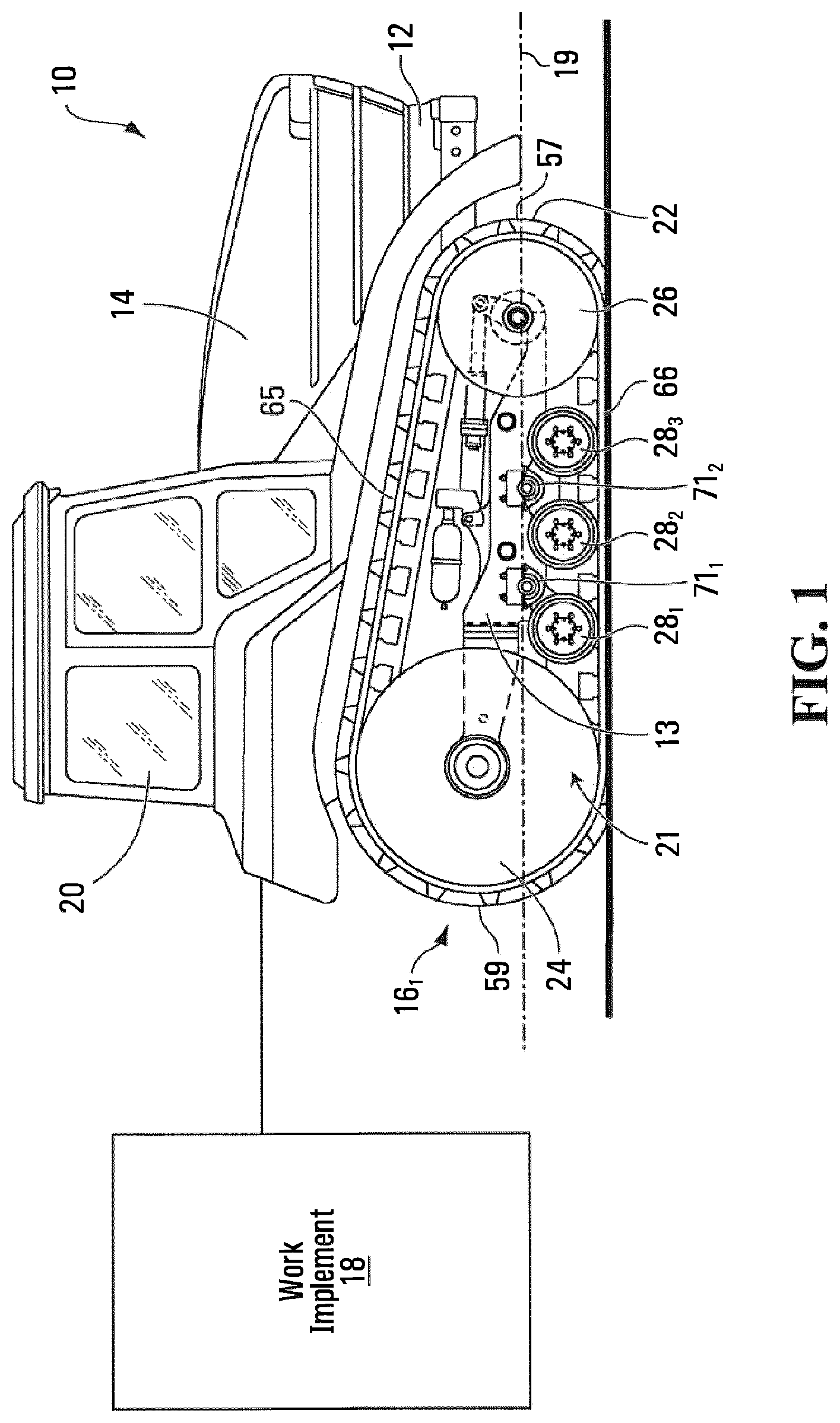

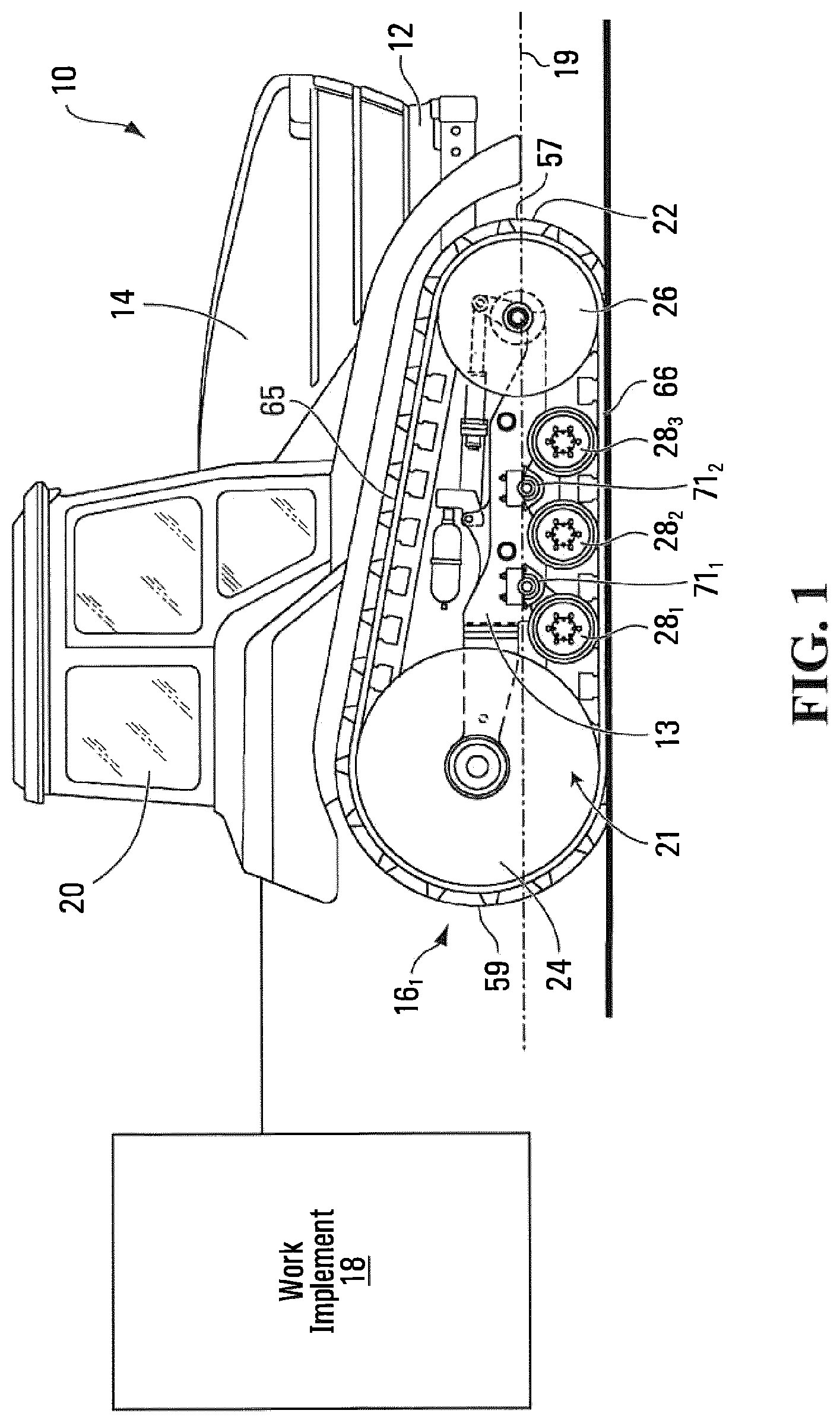

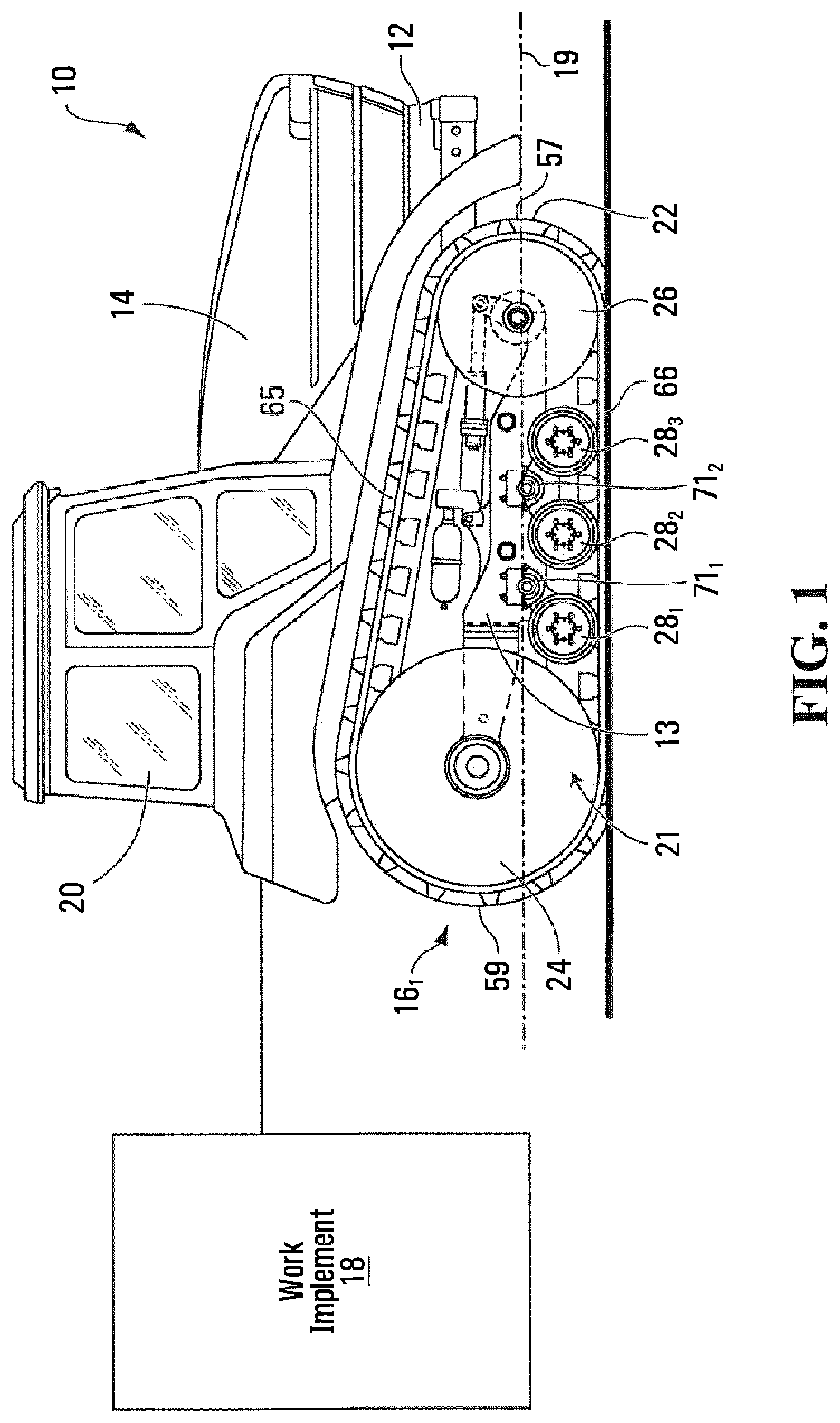

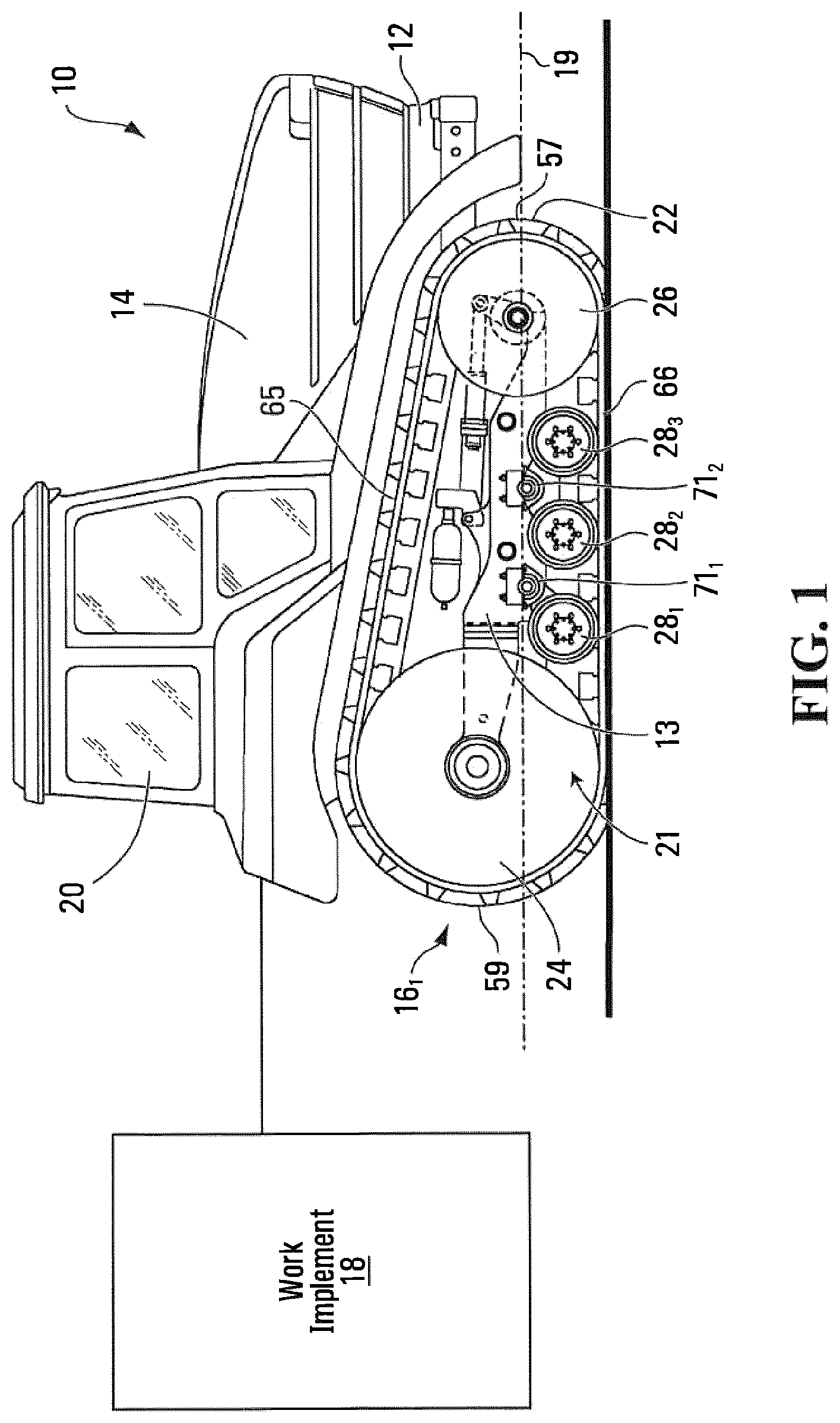

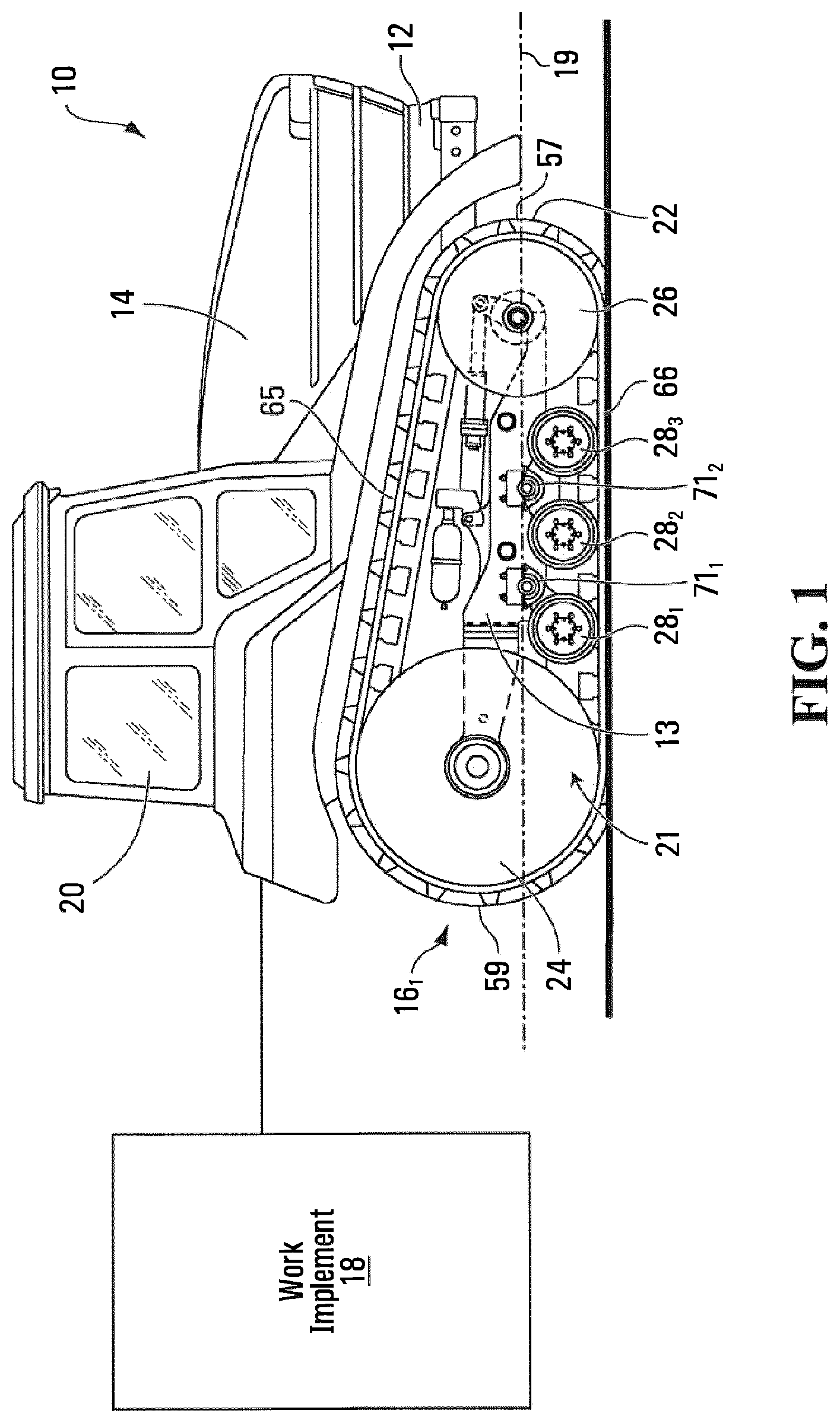

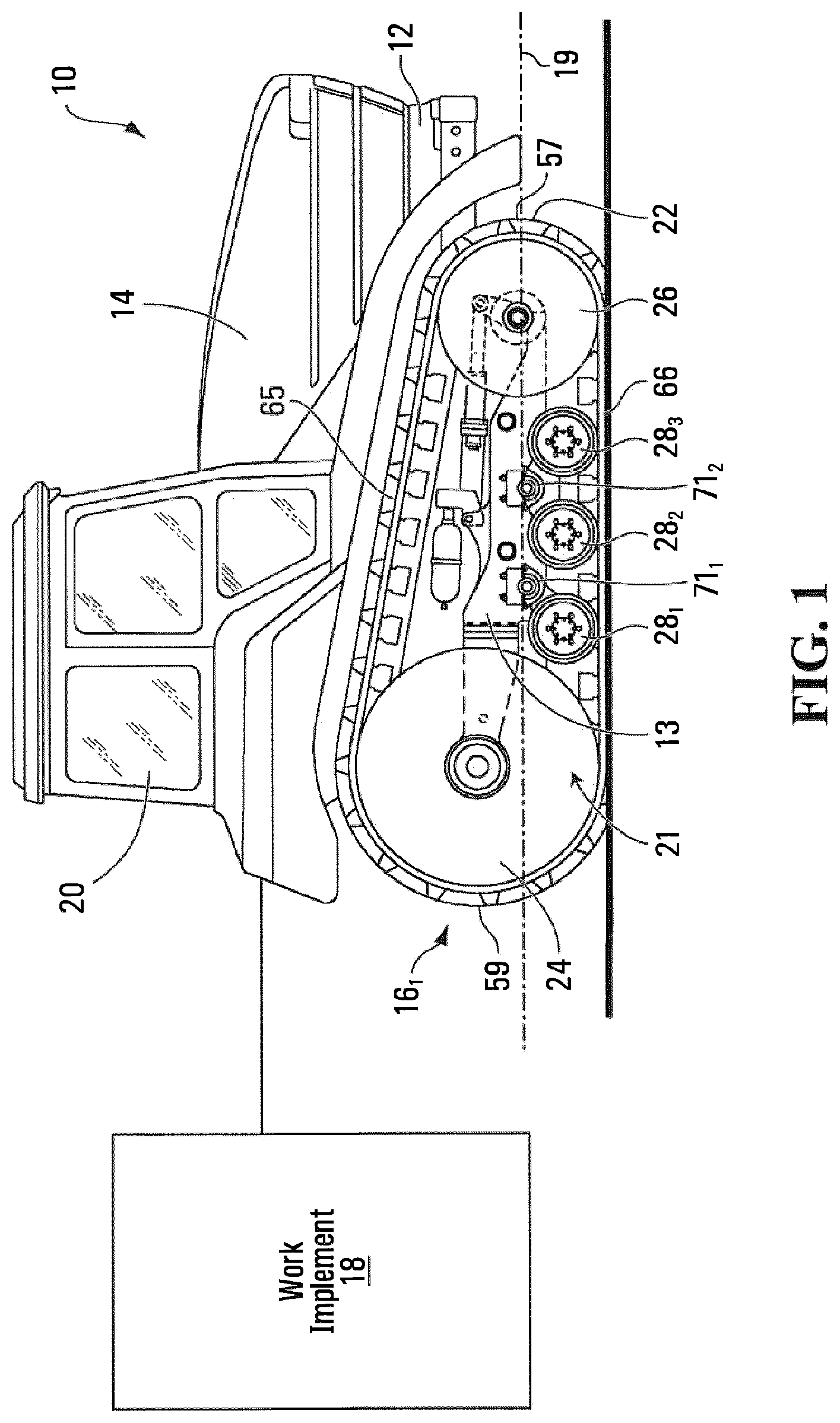

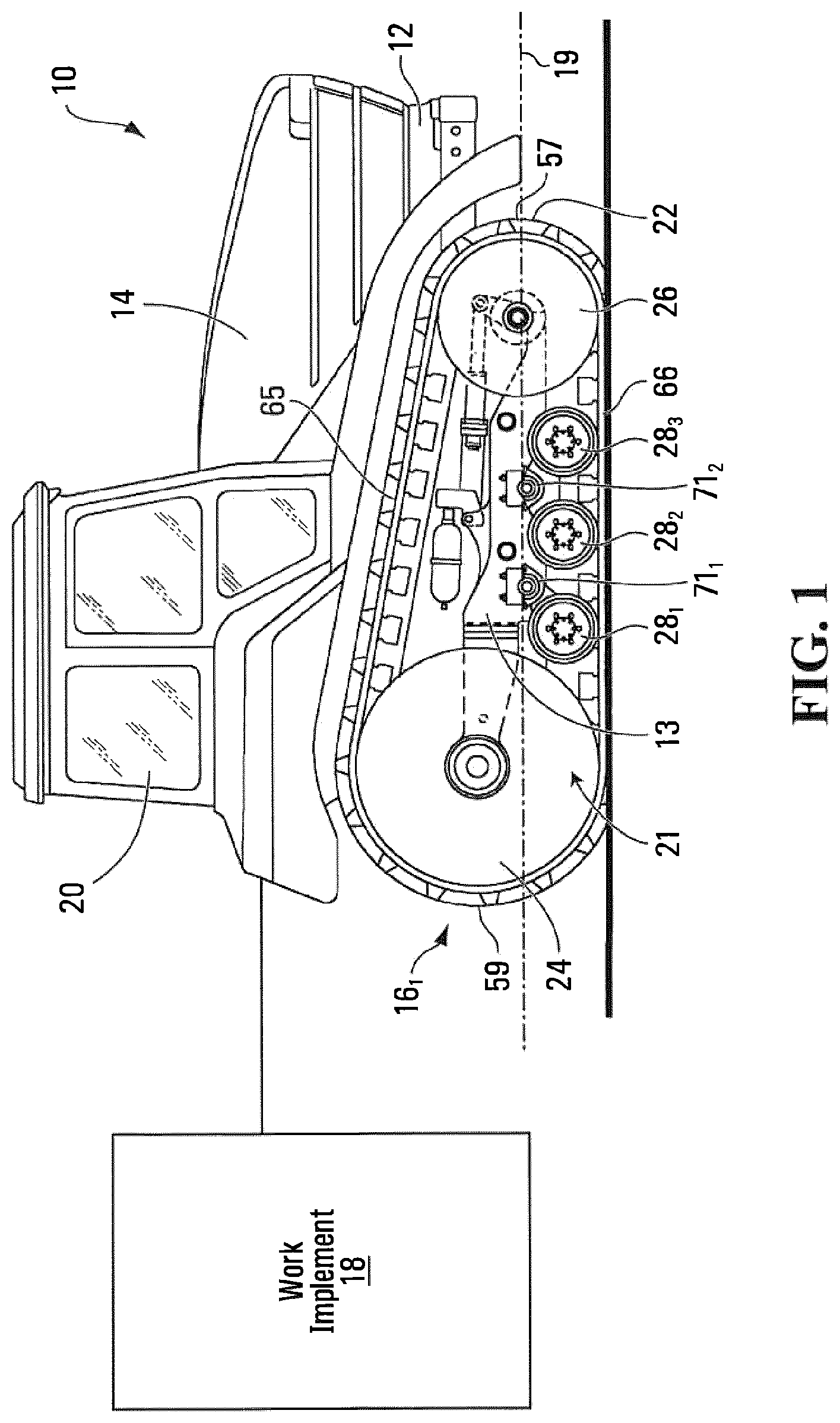

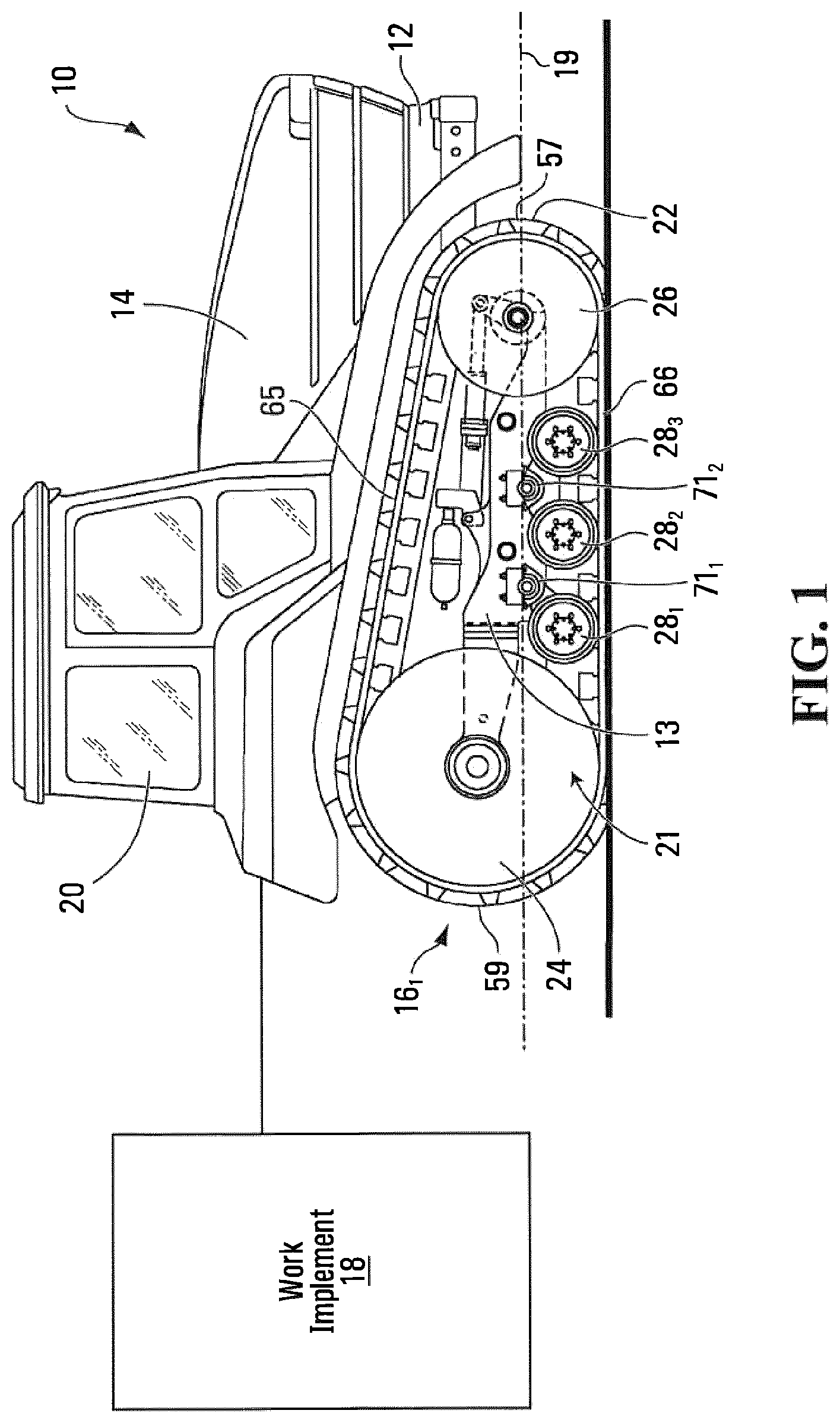

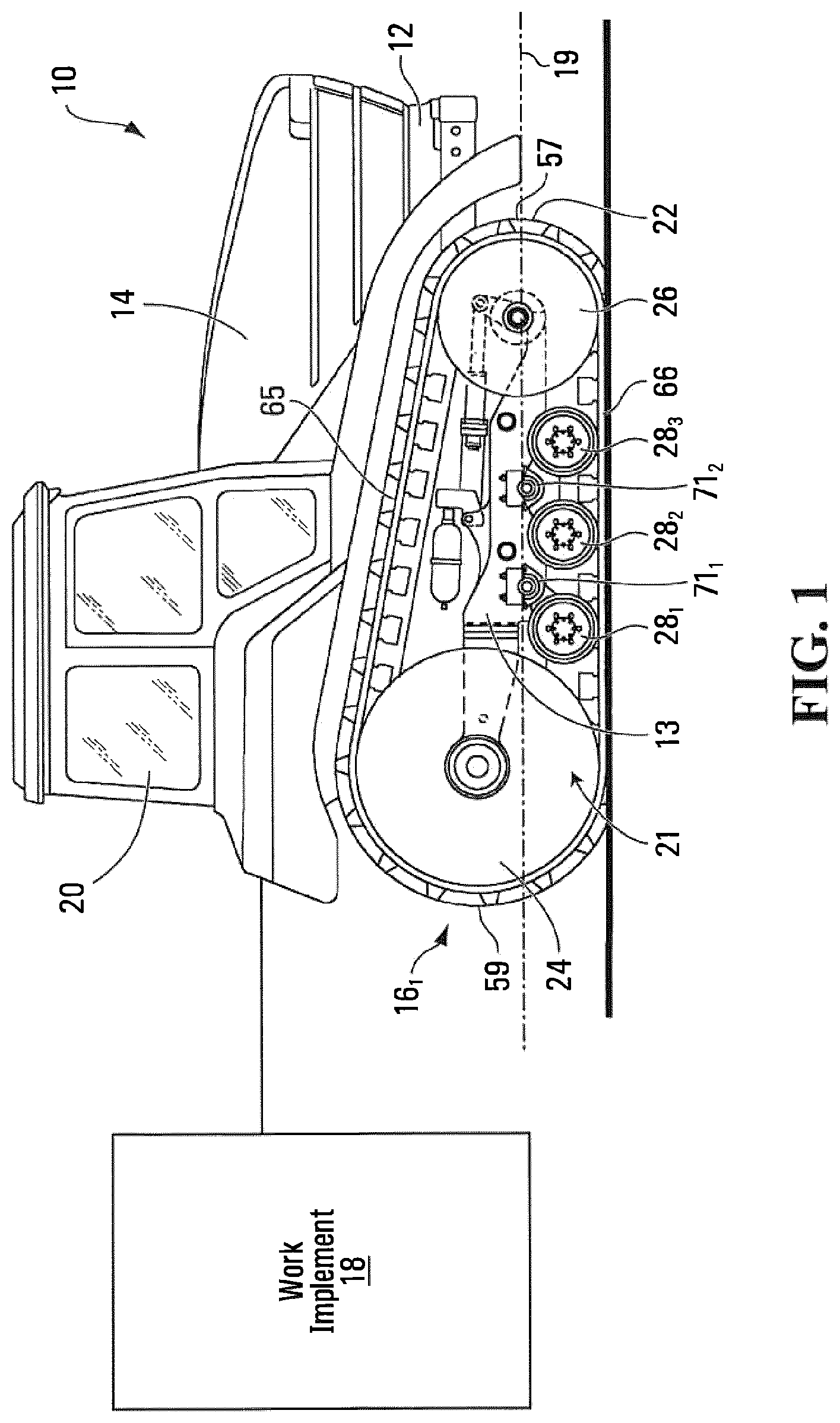

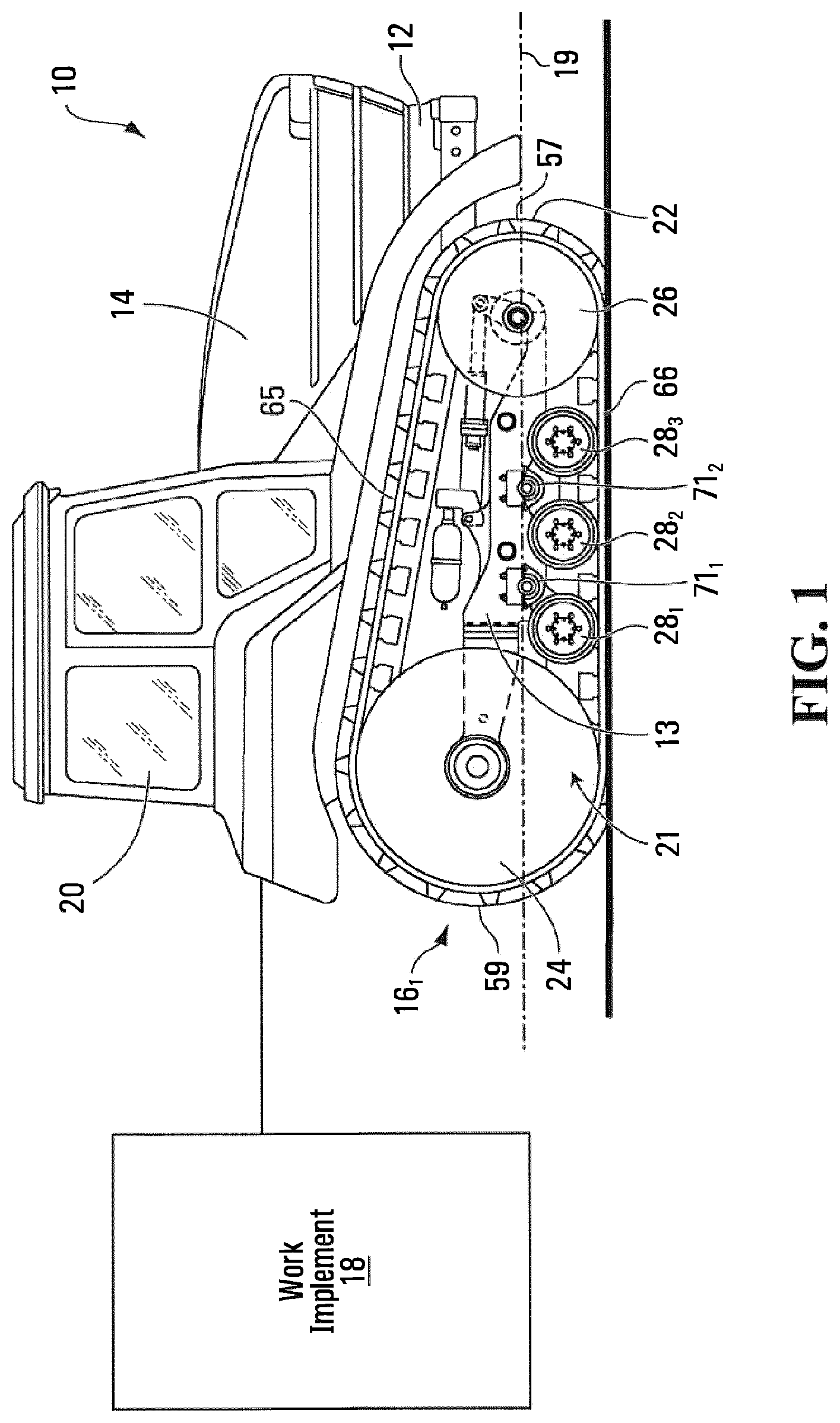

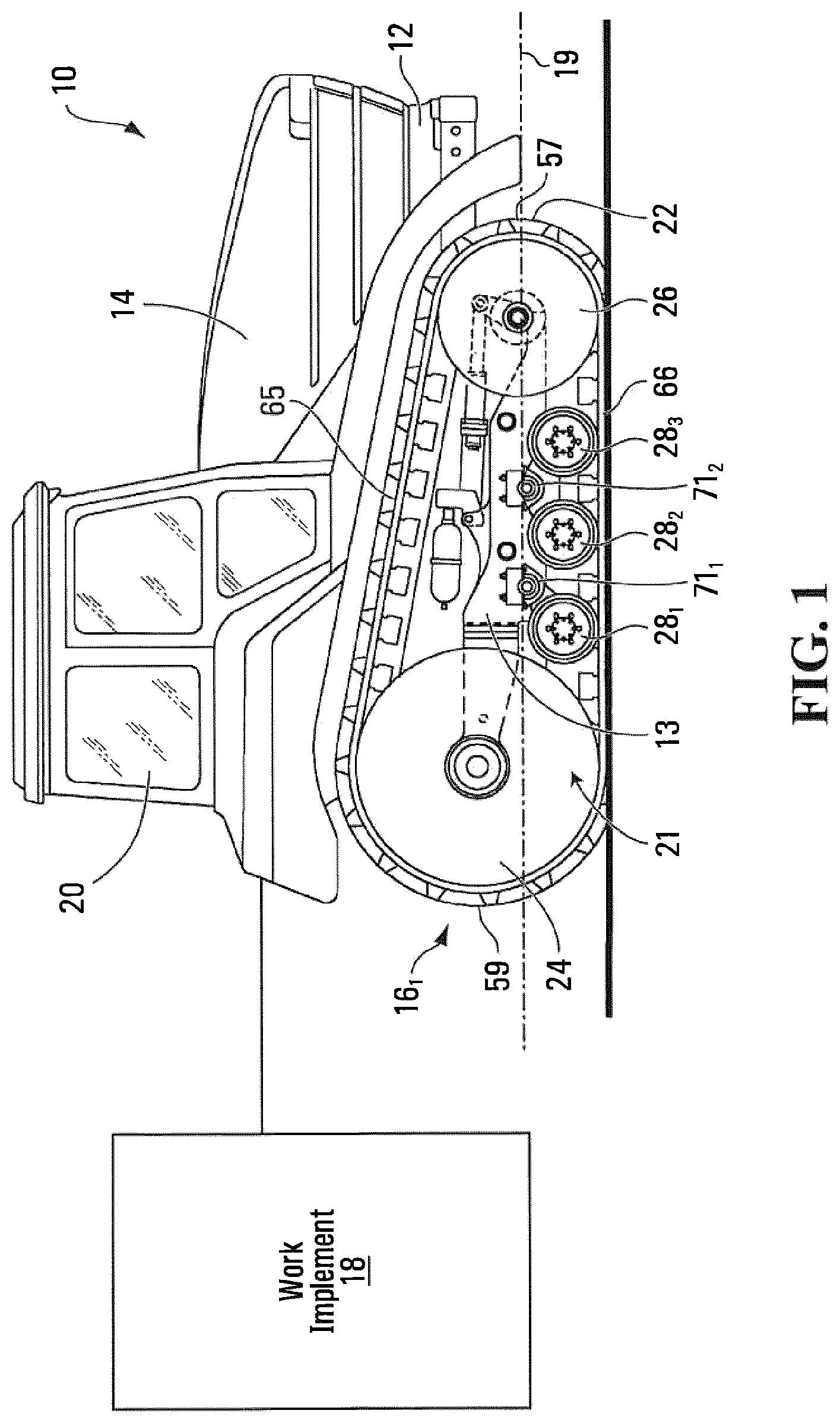

This application claims priority from U.S. Patent Application 62/128,183 filed on Mar. 4, 2015 and hereby incorporated by reference herein. The invention relates to track systems for traction of off-road vehicles such as, for example, agricultural vehicles, industrial vehicles, and military vehicles. Certain off-road vehicles, such as agricultural vehicles (e.g., harvesters, combines, tractors, etc.), industrial vehicles such as construction vehicles (e.g., loaders, bulldozers, excavators, etc.) and forestry vehicles (e.g., feller-bunchers, tree chippers, knuckleboom loaders, etc.), and military vehicles (e.g., combat engineering vehicles (CEVs), etc.) to name a few, may be equipped with elastomeric tracks which enhance their traction and floatation on soft, slippery and/or irregular grounds (e.g., soil, mud, sand, ice, snow, etc.) on which they operate. An elastomeric track comprises a ground-engaging outer side including a plurality of traction projections, sometimes referred to as “traction lugs”, “tread bars” or “tread blocks”, which are distributed in its longitudinal direction to enhance traction on the ground. Deterioration of the traction projections during use may sometimes become significant enough to force replacement of the track even though the track's carcass is still in acceptable condition. For example, the traction projections may sometimes “blowout”, i.e., explode, under repeated loads as heat buildup within them increases their internal temperature such that part of their internal elastomeric material decomposes and generates a volatile product which increases internal pressure until they burst. As another example, the traction projections may wear rapidly in some cases (e.g., due to abrasive or harsh ground conditions). Such deterioration of the traction projections may become more prominent, particularly where there is more roading of the track on hard road surfaces (e.g., in an agricultural vehicle travelling on paved roads between fields or other agricultural sites). This type of track also comprises an inner side which may include a plurality of drive/guide projections, commonly referred to as “drive/guide lugs”, which are spaced apart along its longitudinal direction and used for driving and/or guiding the track around wheels of a vehicle to which the track provides traction. Wear or other deterioration of the drive/guide lugs (e.g., as they come into contact with one or more of the wheels) often also reduces the track's useful life. For these and other reasons, there is a need to improve elastomeric tracks for traction of vehicles and components of such tracks. According to an aspect of the invention, there is provided a track for traction of a vehicle. The track is mountable around a plurality of wheels that comprises a drive wheel for driving the track. The track is elastomeric to flex around the wheels. The track comprises: an inner surface for facing the wheels; a ground-engaging outer surface for engaging the ground; and a plurality of traction projections projecting from the ground-engaging outer surface and distributed in a longitudinal direction of the track. Each traction projection of the plurality of traction projections comprises a first material and a second material disposed inwardly of the first material. A blowout resistance of the second material is greater than a blowout resistance of the first material. According to another aspect of the invention, there is provided a track for traction of a vehicle. The track is mountable around a plurality of wheels that comprises a drive wheel for driving the track. The track is elastomeric to flex around the wheels. The track comprises: an inner surface for facing the wheels; a ground-engaging outer surface for engaging the ground; and a plurality of traction projections projecting from the ground-engaging outer surface and distributed in a longitudinal direction of the track. Each traction projection of the plurality of traction projections has a blowout time of at least 15 minutes under ASTM D-623 (method A) conditions. According to another aspect of the invention, there is provided a method of making a track for traction of a vehicle. The track is mountable around a plurality of wheels that comprises a drive wheel for driving the track. The track is elastomeric to flex around the wheels. The method comprises forming a body of the track. The body comprises an inner surface for facing the wheels and a ground-engaging outer surface for engaging the ground. The method comprises forming a plurality of traction projections projecting from the ground-engaging outer surface and distributed in a longitudinal direction of the track. Each traction projection of the plurality of traction projections comprises a first material and a second material disposed inwardly of the first material. A blowout resistance of the second material is greater than a blowout resistance of the first material. According to another aspect of the invention, there is provided a method of making a track for traction of a vehicle. The track is mountable around a plurality of wheels that comprises a drive wheel for driving the track. The track is elastomeric to flex around the wheels. The method comprises forming a body of the track. The body comprises an inner surface for facing the wheels and a ground-engaging outer surface for engaging the ground. The method comprises forming a plurality of traction projections projecting from the ground-engaging outer surface and distributed in a longitudinal direction of the track. Each traction projection of the plurality of traction projections has a blowout time of at least 15 minutes under ASTM D-623 (Method A) conditions. According to another aspect of the invention, there is provided a system for protecting a track providing traction to a vehicle. The track is mounted around a plurality of wheels that comprises a drive wheel for driving the track. The track is elastomeric to flex around the wheels. The track comprises: an inner surface for facing the wheels; a ground-engaging outer surface for engaging the ground; and a plurality of traction projections projecting from the ground-engaging outer surface and distributed in a longitudinal direction of the track. The system comprises: a sensor for monitoring the track; and a processing apparatus connected to the sensor and configured to issue a signal regarding a potential occurrence of blowout of at least one of the traction projections. These and other aspects of the invention will now become apparent to those of ordinary skill in the art upon review of the following description of embodiments of the invention in conjunction with the accompanying drawings. A detailed description of embodiments of the invention is provided below, by way of example only, with reference to the accompanying drawings, in which: It is to be expressly understood that the description and drawings are only for the purpose of illustrating certain embodiments of the invention and are an aid for understanding. They are not intended to be a definition of the limits of the invention. The agricultural vehicle 10 comprises a frame 12 supporting a prime mover 14, a pair of track systems 161, 162(which can be referred to as “undercarriages”), and an operator cabin 20, which enable an operator to move the agricultural vehicle 10 on the ground to perform agricultural work possibly using a work implement 18. The prime mover 14 provides motive power to move the agricultural vehicle 10. For example, the prime mover 14 may comprise an internal combustion engine and/or one or more other types of motors (e.g., electric motors, etc.) for generating motive power to move the agricultural vehicle 10. The prime mover 14 is in a driving relationship with each of the track systems 161, 162. That is, power derived from the prime mover 14 is transmitted to the track systems 161, 162via a powertrain of the agricultural vehicle 10. The work implement 18 is used to perform agricultural work. For example, in some embodiments, the work implement 18 may be a combine head, a cutter, a scraper, a tiller, or any other type of agricultural work implement. The operator cabin 20 is where the operator sits and controls the agricultural vehicle 10. More particularly, the operator cabin 20 comprises a user interface including a set of controls that allow the operator to steer the agricultural vehicle 10 on the ground and operate the work implement 18. The track systems 161, 162engage the ground to propel the agricultural vehicle 10. Each track system 16icomprises a track-engaging assembly 21 and a track 22 disposed around the track-engaging assembly 21. In this embodiment, the track-engaging assembly 21 comprises a plurality of wheels which, in this example, includes a drive wheel 24 and a plurality of idler wheels that includes a front idler wheel 26 and a plurality of roller wheels 281-286. The track system 16ialso comprises a frame 13 which supports various components of the track system 16i, including the roller wheels 281-286. The track system 16ihas a longitudinal direction and a first longitudinal end 57 and a second longitudinal end 59 that define a length of the track system 16i. The track system 16ihas a widthwise direction and a width that is defined by a width of the track 22. The track system 16ialso has a height direction that is normal to its longitudinal direction and its widthwise direction. The track 22 engages the ground to provide traction to the agricultural vehicle 10. In this embodiment, certain parts of the track 22 are designed to enhance their resistance to deterioration during use, including their resistance to blowout, as further discussed later. A length of the track 22 allows the track 22 to be mounted around the track-engaging assembly 21. In view of its closed configuration without ends that allows it to be disposed and moved around the track-engaging assembly 21, the track 22 can be referred to as an “endless” track. With additional reference to The track 22 is elastomeric, i.e., comprises elastomeric material, to be flexible around the track-engaging assembly 21. The elastomeric material of the track 22 can include any polymeric material with suitable elasticity. In this embodiment, the elastomeric material of the track 22 includes rubber. Various rubber compounds may be used and, in some cases, different rubber compounds may be present in different areas of the track 22. In other embodiments, the elastomeric material of the track 22 may include another elastomer in addition to or instead of rubber (e.g., polyurethane elastomer). More particularly, the track 22 comprises an endless body 36 underlying its inner side 45 and ground-engaging outer side 47. In view of its underlying nature, the body 36 will be referred to as a “carcass”. The carcass 36 is elastomeric in that it comprises elastomeric material 38 which allows the carcass 36 to elastically change in shape and thus the track 22 to flex as it is in motion around the track-engaging assembly 21. The carcass 36 comprises an inner surface 32 and a ground-engaging outer surface 31 that are opposite one another. In this embodiment, the carcass 36 comprises a plurality of reinforcements embedded in its elastomeric material 38. These reinforcements can take on various forms. For example, in this embodiment, the carcass 36 comprises a layer of reinforcing cables 371-37Mthat are adjacent to one another and extend generally in the longitudinal direction of the track 22 to enhance strength in tension of the track 22 along its longitudinal direction. In this case, each of the reinforcing cables 371-37Mis a cord including a plurality of strands (e.g., textile fibers or metallic wires). In other cases, each of the reinforcing cables 371-37Mmay be another type of cable and may be made of any material suitably flexible along the cable's longitudinal axis (e.g., fibers or wires of metal, plastic or composite material). As another example, in this embodiment, the carcass 36 comprises a layer of reinforcing fabric 43. The reinforcing fabric 43 comprises thin pliable material made usually by weaving, felting, knitting, interlacing, or otherwise crossing natural or synthetic elongated fabric elements, such as fibers, filaments, strands and/or others, such that some elongated fabric elements extend transversally to the longitudinal direction of the track 22 to have a reinforcing effect in a transversal direction of the track 22. For instance, the reinforcing fabric 43 may comprise a ply of reinforcing woven fibers (e.g., nylon fibers or other synthetic fibers). The carcass 36 has a thickness Tc, measured from its inner surface 32 to its ground-engaging outer surface 31, which is relatively large in this embodiment. For example, in some embodiments, the thickness Tcof the carcass 36 may be at least than 20 mm, in some cases at least 25 mm, in some cases at least 30 mm, in some cases at least 35 mm, and in some cases even more (e.g., 40 mm or more). The thickness Tcof the carcass 36 may have any other suitable value in other embodiments. The carcass 36 may be molded into shape in a molding process during which the rubber 38 is cured. For example, in this embodiment, a mold may be used to consolidate layers of rubber providing the rubber 38 of the carcass 36, the reinforcing cables 371-37Mand the layer of reinforcing fabric 43. In this embodiment, the endless track 22 is a one-piece “jointless” track such that the carcass 36 is a one-piece jointless carcass. In other embodiments, the endless track 22 may be a “jointed” track (i.e., having at least one joint connecting adjacent parts of the track 22) such that the carcass 36 is a jointed carcass (i.e., which has adjacent parts connected by the at least one joint). For example, in some embodiments, the track 22 may comprise a plurality of track sections interconnected to one another at a plurality of joints, in which case each of these track sections includes a respective part of the carcass 36. In other embodiments, the endless track 22 may be a one-piece track that can be closed like a belt with connectors at both of its longitudinal ends to form a joint. The inner side 45 of the endless track 22 comprises an inner surface 55 of the carcass 36 and a plurality of inner wheel-contacting projections 481-48Nthat project from the inner surface 55 and are positioned to contact at least some of the wheels 24, 26, 281-286to do at least one of driving (i.e., imparting motion to) the track 22 and guiding the track 22. The wheel-contacting projections 481-48Ncan be referred to as “wheel-contacting lugs”. Furthermore, since each of them is used to do at least one of driving the track 22 and guiding the track 22, the wheel-contacting lugs 481-48Ncan be referred to as “drive/guide projections” or “drive/guide lugs”. In some examples of implementation, a drive/guide lug 48imay interact with the drive wheel 24 to drive the track 22, in which case the drive/guide lug 48iis a drive lug. In other examples of implementation, a drive/guide lug 48imay interact with the idler wheel 26 and/or the roller wheels 281-286to guide the track 22 to maintain proper track alignment and prevent de-tracking without being used to drive the track 22, in which case the drive/guide lug 48iis a guide lug. In yet other examples of implementation, a drive/guide lug 48imay both (i) interact with the drive wheel 24 to drive the track and (ii) interact with the idler wheel 26 and/or the roller wheels 281-286to guide the track 22 to maintain proper track alignment and prevent de-tracking, in which case the drive/guide lug 48iis both a drive lug and a guide lug. In this embodiment, the drive/guide lugs 481-48Ninteract with the drive wheel 24 in order to cause the track 22 to be driven, and also interact with the idler wheel 26 and the roller wheels 281-286in order to guide the track 22 as it is driven by the drive wheel 24 to maintain proper track alignment and prevent de-tracking. The drive/guide lugs 481-48Nare thus used to both drive the track 22 and guide the track 22 in this embodiment. In this example of implementation, the drive/guide lugs 481-48Nare arranged in a single row disposed longitudinally along the inner side 45 of the track 22. The drive/guide lugs 481-48Nmay be arranged in other manners in other examples of implementation (e.g., in a plurality of rows that are spaced apart along the widthwise direction of the track 22). In this embodiment, each drive/guide lug 48iis an elastomeric drive/guide lug in that it comprises elastomeric material 67. The elastomeric material 67 can be any polymeric material with suitable elasticity. More particularly, in this embodiment, the elastomeric material 67 includes rubber. Various rubber compounds may be used and, in some cases, different rubber compounds may be present in different areas of the drive/guide lug 48i. In other embodiments, the elastomeric material 67 may include another elastomer in addition to or instead of rubber (e.g., polyurethane elastomer). The drive/guide lugs 481-48Nmay be provided on the inner side 45 in various ways. For example, in this embodiment, the drive/guide lugs 481-48Nare provided on the inner side 45 by being molded with the carcass 36. The ground-engaging outer side 47 comprises a ground-engaging outer surface 75 of the carcass 36 and a tread pattern 40 to enhance traction on the ground. The tread pattern 40 comprises a plurality of traction projections 581-58Tprojecting from the ground-engaging outer surface 75, spaced apart in the longitudinal direction of the endless track 22 and engaging the ground to enhance traction. The traction projections 581-58Tmay be referred to as “tread projections” or “traction lugs”. The traction lugs 581-58Tmay have any suitable shape. In this embodiment, each of the traction lugs 581-58Thas an elongated shape and is angled, i.e., defines an oblique angle θ (i.e., an angle that is not a right angle or a multiple of a right angle), relative to the longitudinal direction of the track 22. The traction lugs 581-58Tmay have various other shapes in other examples (e.g., curved shapes, shapes with straight parts and curved parts, etc.). As shown in In this embodiment, each traction lug 58iis an elastomeric traction lug in that it comprises elastomeric material 41. The elastomeric material 41 can be any polymeric material with suitable elasticity. More particularly, in this embodiment, the elastomeric material 41 includes rubber. Various rubber compounds may be used and, in some cases, different rubber compounds may be present in different areas of the traction lug 58i. In other embodiments, the elastomeric material 41 may include another elastomer in addition to or instead of rubber (e.g., polyurethane elastomer). The traction lugs 581-58Tmay be provided on the ground-engaging outer side 27 in various ways. For example, in this embodiment, the traction lugs 581-58Tare provided on the ground-engaging outer side 27 by being molded with the carcass 36. The track 22 may be constructed in various other manners in other embodiments. For example, in some embodiments, the track 22 may have recesses or holes that interact with the drive wheel 24 in order to cause the track 22 to be driven (e.g., in which case the drive/guide lugs 481-48Nmay be used only to guide the track 22 without being used to drive the track 22, i.e., they may be “guide lugs” only), and/or the ground-engaging outer side 47 of the track 22 may comprise various patterns of traction lugs. The drive wheel 24 is rotatable by power derived from the prime mover 14 to drive the track 22. That is, power generated by the prime mover 14 and delivered over the powertrain of the agricultural vehicle 10 can rotate a driven axle, which causes rotation of the drive wheel 24, which in turn imparts motion to the track 22. With additional reference to The drive wheel 24 may be configured in various other ways in other embodiments. For example, in other embodiments, the drive wheel 24 may not have any side discs such as the side discs 501, 502. As another example, in other embodiments, instead of being drive bars, the drive members 521-52Bmay be drive teeth that are distributed circumferentially along the drive wheel 24 or any other type of drive members. As another example, in embodiments where the track 22 comprises recesses or holes, the drive wheel 24 may have teeth that enter these recesses or holes in order to drive the track 22. As yet another example, in some embodiments, the drive wheel 24 may frictionally engage the inner side 45 of the track 22 in order to frictionally drive the track 22 (i.e., the drive wheel 24 and the track 22 may implement a “friction drive” system). The front idler wheel 26 and the roller wheels 281-286are not driven by power supplied by the prime mover 14, but are rather used to do at least one of supporting part of the weight of the agricultural vehicle 10 on the ground via the track 22, guiding the track 22 as it is driven by the drive wheel 24, and tensioning the track 22. More particularly, in this embodiment, the front idler wheel 26 is a leading idler wheel which maintains the track 22 in tension and helps to support part of the weight of the agricultural vehicle 10 on the ground via the track 22. As shown in The traction lugs 581-58Tcan be designed to enhance their resistance to deterioration during use. Notably, in this embodiment, a blowout resistance of each traction lug 58ican be enhanced to prevent or at least reduce a potential for blowout of the traction lug 58iunder repeated loads which may induce heat buildup within it. Also, a wear resistance of the traction lug 58imay be enhanced such that the traction lug 58iwears less rapidly. This enhanced resistance to deterioration of the traction lugs 581-58Tmay be particularly useful in situations where the track 22 experiences significant roading on hard road surfaces, such as, for example, when the agricultural vehicle 10 travels on paved roads between fields or other agricultural sites. More particularly, in this embodiment, the blowout resistance of a traction lug 58iis greater than a threshold. A test may be performed to measure the blowout resistance of the traction lug 58i. For example, with additional reference to For instance, in some embodiments, the test may be a standard test. In some cases, the blowout resistance of the traction lug 58imay be measured under ASTM D-623 (Method A) conditions (e.g., sample dimensions, load, frequency and deformation specified by ASTM D-623). For example, according to ASTM D-623 (Method A), a sample of the traction lug 58iof specified dimensions (i.e., a diameter of 17.8+/−0.1 mm and a height of 25+/−0.15 mm) can be taken from the traction lug 58i, subjected to a specified preload (i.e., 110 lbs), conditioned at a specified temperature (i.e., 100° C.) for a specified period of time (i.e., 25 minutes), and repeatedly compressed by causing a specified deformation (e.g., compression) (i.e., 0.250 inches in amplitude) at a specified frequency (i.e., 30 Hz) in order to measure one or more parameters indicative of the blowout resistance of the traction lug 58i. This may be performed using a Goodrich flexometer. Various parameters may be measured during the test to assess the blowout resistance of the traction lug 58i. For example: