FEMORAL PROSTHESIS CERAMIQUE/CERAMIQUE OF SMALL DIAMETER

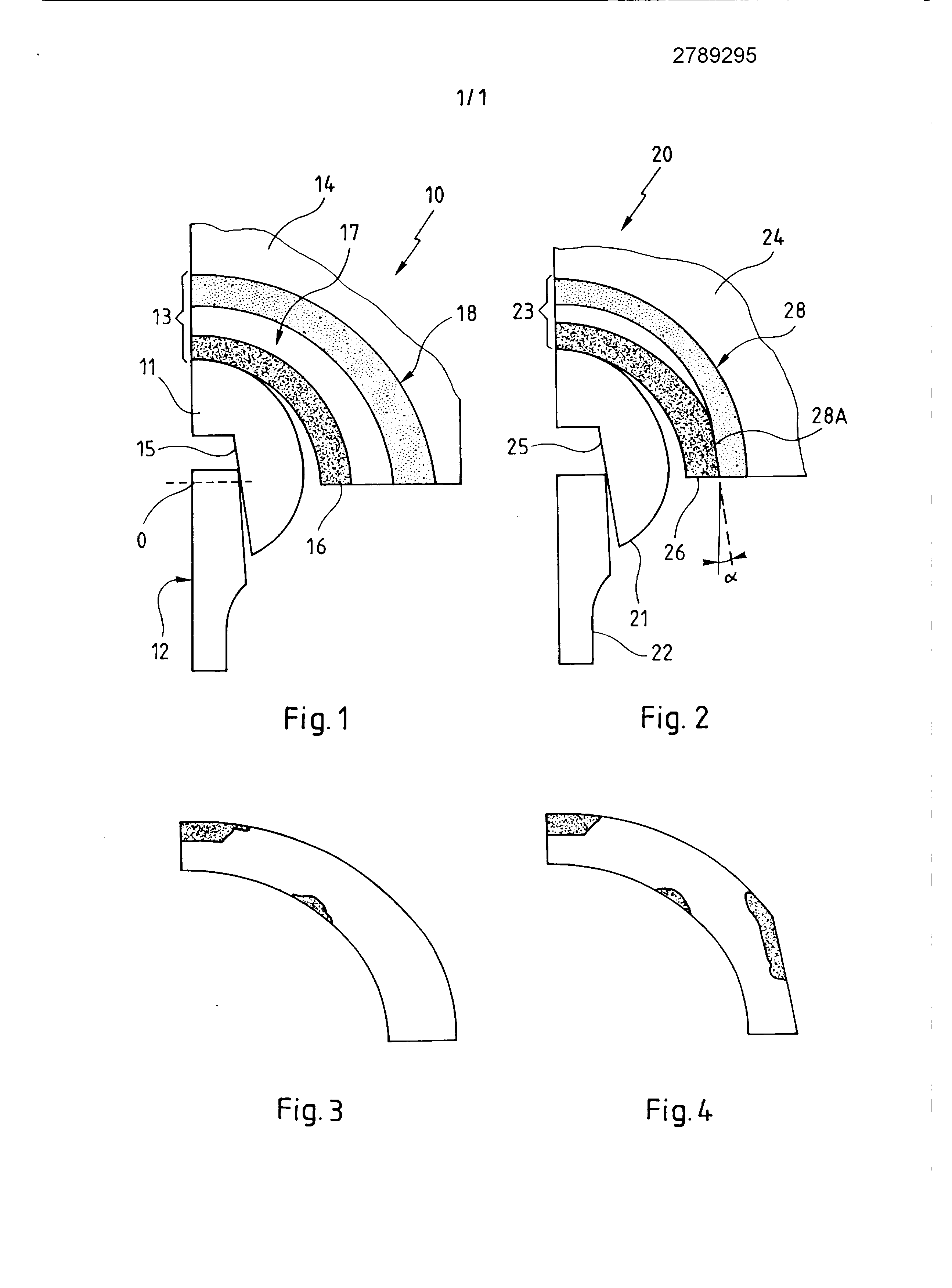

A femoral prosthesis small diameter. As known, a femoral prosthesis comprises: -a head for being engaged on a rod integral with a femur, a cup-and intended to be secured to the user's pelvis, and having a cavity for receiving for rotation friction movement of the femoral head. The invention relates to a femoral prosthesis, comprising a femoral head on the one hand and a cup on the other hand, which the combination can be performed in a spherical surface of the order of 22.22 mm, while achieving a breaking strength at least equal to 46 kN. One femoral prosthesis having a femoral head adapted to be fitted on a femoral stem designed to be joined to a femur of a patient, and a cup intended to be fixed to the basin of the patient, the head being mounted so as to be able to slide in rotation in a cavity to the interior of the well, the femoral head being at least in its outer portion made of a ceramic material and having a spherical outer surface of diameter substantially equal to 22 mm, and the cup being at least in its inner part made of a ceramic material and having a spherical inner surface of diameter substantially equal to 22 mm. According to provisions of the invention, advantageously combined: -the diameter of the head is substantially equal to 22.22 mm. -the diameter of the inner surface of the cup is greater than that of the external surface of the femoral head. -the femoral head has at least 95% of zirconia. -the zirconia is tetragonal zirconia polycrystalline yttria stabilized. -the head has a density of at least 98% of the theoretical maximum density and is produced by sintering high isostatic pressure. -zirconia has an average grain size at most equal to one micron. -zirconia has a flexural modulus greater than 920 MPa 3-points. -the inner diameter of the cavity of the head is between 7 and 16 mm. -the cup includes a ceramic insert within an exterior cover for. In a first possible option, the insert is secured to the outer cap by one intermediate cap, which is advantageously made of polyethylene. In a second possible option, the ceramic insert is a force fit in the outer cap, by conical fitting. The conical sleeve preferably has tapered between 4° and 25 ; it is for example about 20°. The material of which the cup is formed at least in its inner portion is advantageously alumina. However, other ceramics are possible, in particular from the oxides. In practice the materials used are materials grade biomedical, conforming to the standards in force, whether zirconia or alumina. The materials used are in effect materials known per se, to as isolated, in the field of prosthetics or implants. Preferably, the head cooperates with a femoral stem type 12/14, with a conical portion bounded by circles extreme diameters of the order of 12 and 14 mm respectively. This cooperation is advantageously according to the teachings of the document W098/14141. Objects, features and advantages of the invention arise from the description given below, opposite of the attached drawing on which: -figure 1 is a schematic view in half axial section, of a femoral prosthesis according to a first embodiment of the invention, -figure 2 is a half-axial view of another femoral prosthesis according to a second embodiment of the invention, figure 3-shows in isolation a half axial sectional view of the insert of Figure 1, and -figure 4 is a view in half axial section of the insert of Figure 2. Figures 1 and 2 represent two embodiments of a femoral prosthesis according to the invention. In the embodiment of Figure 1, the femoral prosthesis, designated by the general reference 10, has a head 11, engaged on a rod 12, and a cup 13 secured to a base schematized in 14. The rod 12 is a femoral stem, in that, at its lower end, it is intended to be force-fitted in the upper end of the femur of a patient to receive such a femoral prosthesis. Such femoral stem is conventionally metal, for example made of titanium alloy, cobalt chrome alloy, or a stainless steel type alloy. The shaft includes, in its upper part a conical portion which fits into a cavity also frustoconical in the head 11 ; the cavity, marked 15, preferably has a taper equal to or very slightly greater than the taper of the upper end of the shank. It is found further that said stem, normally engaged in the cavity 15 of the head 11, does not penetrate to the bottom of the recess, but remains below the bottom. The cup 13, in the example of Figure 1, is formed of 3 layers (but there may be more). The inner surface of the cup, against which rub its outer surface substantially spherical head 11 is provided on an insert 16, of substantially constant thickness. This can be noted in Figure 1 that the internal diameter of the inner surface of the insert 16 is slightly greater than the diameter of the outer surface of the head 11. The insert 16 is itself engaged in one intermediate cap 17, it also thickness, substantially constant. Intermediate The cap 17 is itself engaged within a third part 18, or outer cap, to be secured to the tank 14 of a user. The spherical outer surface of the head 11, and the spherical inner surface of the insert 16, have radii substantially equal to 22 mm (the diameter of the head is preferably substantially equal to 22.22 mm). Furthermore, the head 11 on the one hand and the insert 16 on the other hand are both made of ceramic materials. The intermediate cap 17 is a synthetic material, preferably high density polyethylene (H P E D). The outer cover 18, it is preferably a metal, for example made of titanium alloy. Preferably, the head 11 is made of a zirconia, preferably yttrium stabilized, preferably made by sintering high isostatic pressure. The ceramic insert 16 is, in turn, advantageously made of alumina. Zirconia which the femoral head 11 preferably has the properties of the zirconia sold under the trademark " [...]"® as available from the company NORTON [...]. For the insert 16 of the cup, alumina that is advantageously a material having properties close alumina sold under the trademark® [...] also sold by NORTON [...]. It has been most has surprisingly found that the combination of the mechanical strength of zirconia especially when it is a zirconia type [...], and wear materials minimum torque zirconia (preferably [...] ) and alumina (preferably [...] ) provides an optimal solution for the torques ceramic/ceramic used to perform a femoral prosthesis type shown in Figure 1. In practice, it is possible to easily form the outer cap 18 a complex geometric shape to be chosen according to the needs; it is therefore simply as illustrative that this cap [...] is represented as having a constant thickness at all points. Figure 2 represents a hip prosthesis, schematized in the general reference 20, which includes, as the prosthesis 10 of Figure 1, a head 21, engaged to a femoral stem 22, and friction in a cup 23 secured to a base 24, e.g. constituted by the pelvis of a patient. The indications preceding, data about the femoral stem and of the femoral head are also valid for the femoral prosthesis 20 of Figure 2. In fact, the substantial difference between the femoral prosthesis 20 and above of Figure 1, is that the well has 2 materials only; it ' is no intermediate cap, for example polyethylene. This prosthesis 20, the connection between the insert 26 on the one hand and the outer cover 28 on the other hand is preferably carried out by a press fit of the conical type. Are observed and, on the Figure 2, that, to the difference of Figure 1 wherein the outer surface of the ceramic insert is represented as being spherical, the outer surface of the insert 26 of this figure 2 comprises in the lower part, thus in the direction of the femur, a frustoconical portion flared to the femur. The conical portion, marked 28A, is connected to the rest of the outer surface of the insert 28, which can be spherical. Of course, the outer surface of the insert 16 of Figure 1 has as has just been specified a spherical outer surface; however it may have other forms, including a shape of the type of the outer surface just-described relating to the Figure 2. Furthermore, the femoral head is advantageously made of zircon, preferably type [...], while the ceramic insert 26 is advantageously achieved by alumina, preferably type [...]. These materials, known per se, have surgical qualities and are defined by the standards that they satisfy. Figures 3 and 4 represent, in isolation, the ceramic insert of Figures 1 and 2 respectively. Figures On these dark areas view the locations of these inserts where the tensile stresses are maximum. On Figure 3, a zone of maximum stress is observed at the top of the insert, the outer side. Furthermore, a region of high strain is observed from the inner side of the insert, substantially 45 degrees from the center of the inner surface. On Figure 4,3 is observed large stress regions, in other words, at the top of the insert to the upper side, from the inner side of the insert substantially 45 degrees from the center of the inner surface and the deepest area in which the conical sleeve. An example, insert for a thickness of the order of 4 mm, and an angle of 20 degrees in the case of the conical sleeve, the forces determined can reach 185 MPa at the top, in Figure 4, as it is only of the order of 70 MPa in the region near the conical fitting. The values for the areas figure 2 are located between these extremes. The material selected had one constraint to the flex points -3 600 MPa. The angle of 20 degrees above has about the conical fitting between the ceramic insert and the outer cap can, as appropriate, be increased or decreased within an angular range whose thresholds are advantageously of the order of 4 and 25 degrees. The prosthesis consists of a spherical head fitted to the end of a femoral shank and performing a sliding motion relative to a cavity in a cup fitted in the patient's pelvis. The head, at least in its outer part, is made from a ceramic material comprising at least 95% tetragonal polycrystalline zircon stabilized with yttrium oxide and produced by high-pressure isostatic fritting. The prosthesis consists of a 22 mm diameter spherical head (11) fitted to the end of a femoral shank (12) and performing a sliding motion relative to a cavity in a cup (13) fitted in the patient's pelvis (14). The head, at least in its outer part, is made from a ceramic material comprising at least 95% tetragonal polycrystalline zircon stabilized with yttrium oxide and produced by high-pressure isostatic fritting. The cup has a ceramic lining (16) and an intermediate insert (17). 1. A femoral prosthesis comprising a femoral head (11.21) adapted to be fitted on a femoral stem (12,22) designed to be joined to a femur of a patient, and a cup (13,23) intended to be fixed to the basin of the patient, the head being mounted so as to be able to slide in rotation in a cavity to the interior of the well, the femoral head being at least in its outer portion made of a ceramic material and having a spherical outer surface of diameter substantially equal to 22 mm, and the cup being at least in its inner part made of a ceramic material and having a spherical inner surface of diameter substantially equal to 22 mm. 2. A femoral prosthesis as claimed in claim 1, characterized in that the diameter of the head is substantially equal to 22.22 mm. 3. A femoral prosthesis as claimed in claim 1 or claim 2, characterized in that the diameter of the inner surface of the cup is greater than that of the external surface of the femoral head. 4. Femoral prosthesis as in any of claims 1 to 3, characterized in that the femoral head has at least 95% of zirconia. 5. A femoral prosthesis as claimed in claim 4, characterized in that the zirconia is tetragonal zirconia polycrystalline yttria stabilized. 6. A femoral prosthesis as claimed in claim 4 or claim 5, characterized in that said head has a density of at least 98% of the theoretical maximum density and is produced by sintering high isostatic pressure. 7. Femoral prosthesis as in any of claims 4 to 6, characterized in that the zirconia has an average grain size at most equal to one micron. 8. Femoral prosthesis as in any of claims 4 to 7, characterized in that the zirconia has a flexural modulus greater than 920 MPa 3-points. 9. Femoral prosthesis as in any of claims 1 to 8, characterized in that the inner diameter of the cavity of the head is between about 16 mm and 7. 10. Femoral prosthesis as in any of claims 1 to 9, characterized in that the cup includes a ceramic insert within an exterior cover for. 11. A femoral prosthesis as claimed in claim 10, characterized in that the insert (16) is secured to the outer cap (18) by one intermediate cap (17). 12. A femoral prosthesis as claimed in claim 11, characterized in that said intermediate cap (17) is made of polyethylene. 13. A femoral prosthesis as claimed in claim 10, characterized in that the ceramic insert (26) is engaged in the outer cap (28), by conical fitting. 14. A femoral prosthesis as claimed in claim 13, characterized in that the conical sleeve has a taper of between 4° and 25°. 15. A femoral prosthesis as claimed in claim 14, characterized in that a taper of about 20°. 16. Femoral prosthesis as in any of claims 1 to 15, characterized in that the material of which the cup is formed at least in its inner portion is an alumina.