AIR KNIFE UNIT OF MULTI-HOLE NOZZLE TYPE

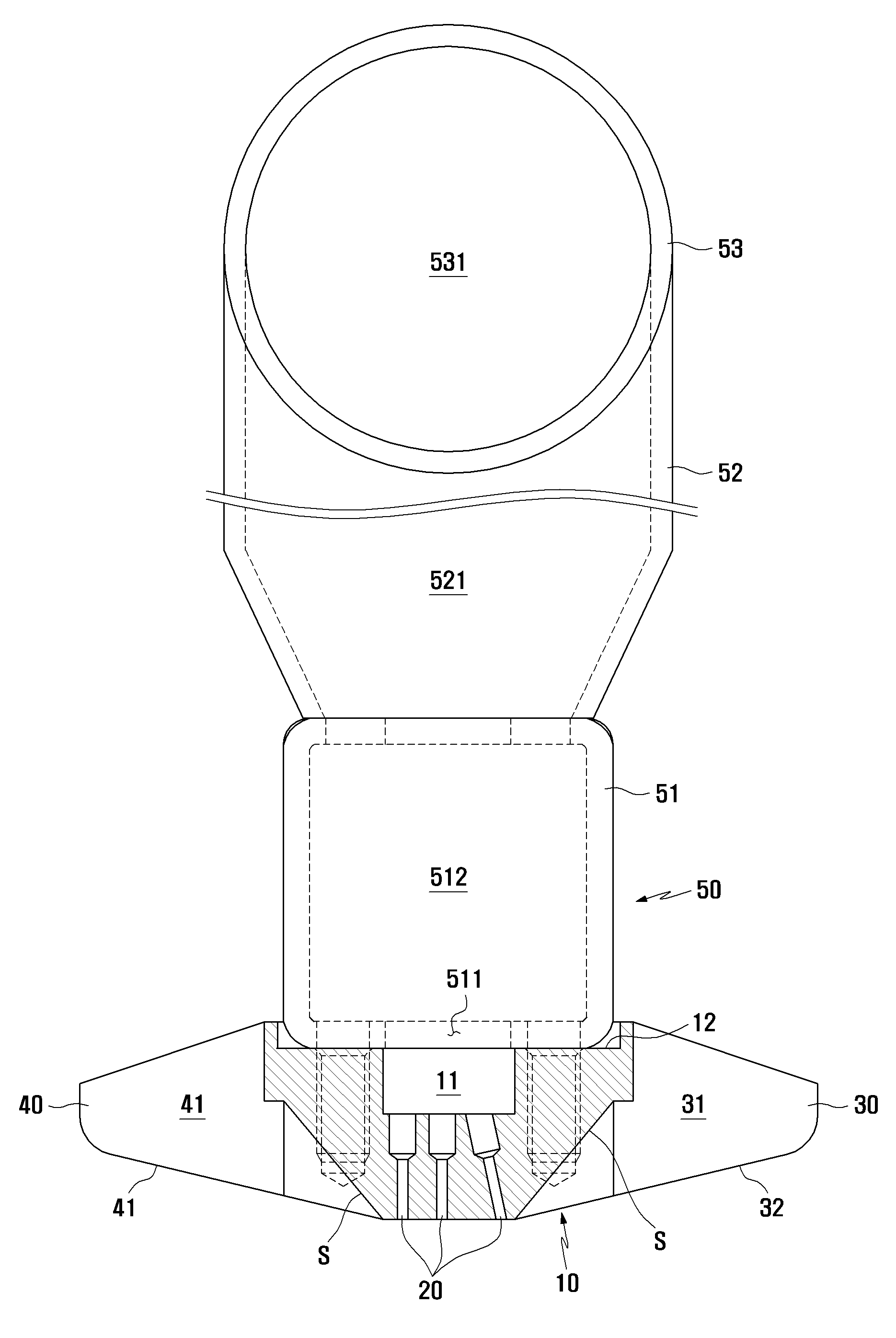

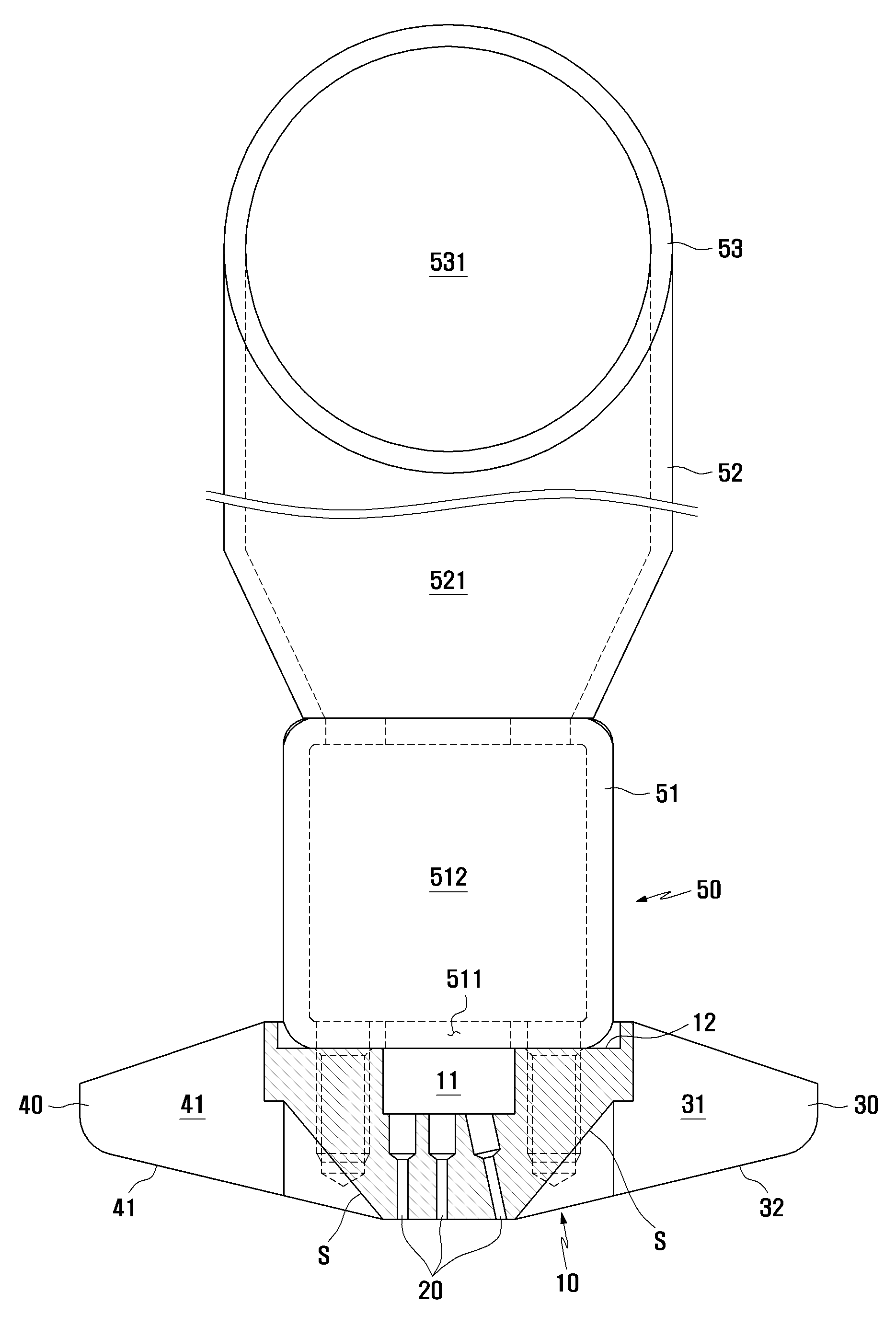

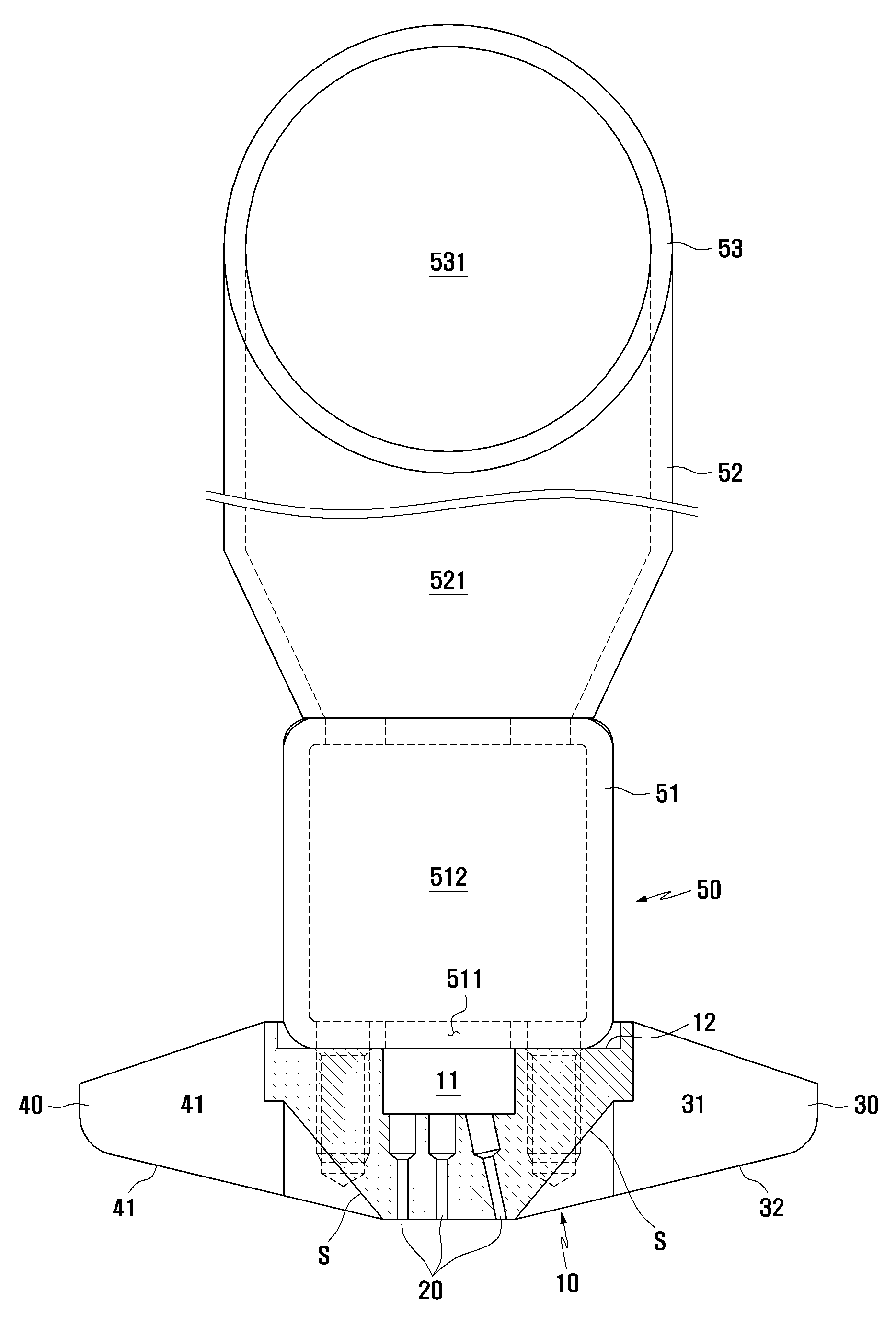

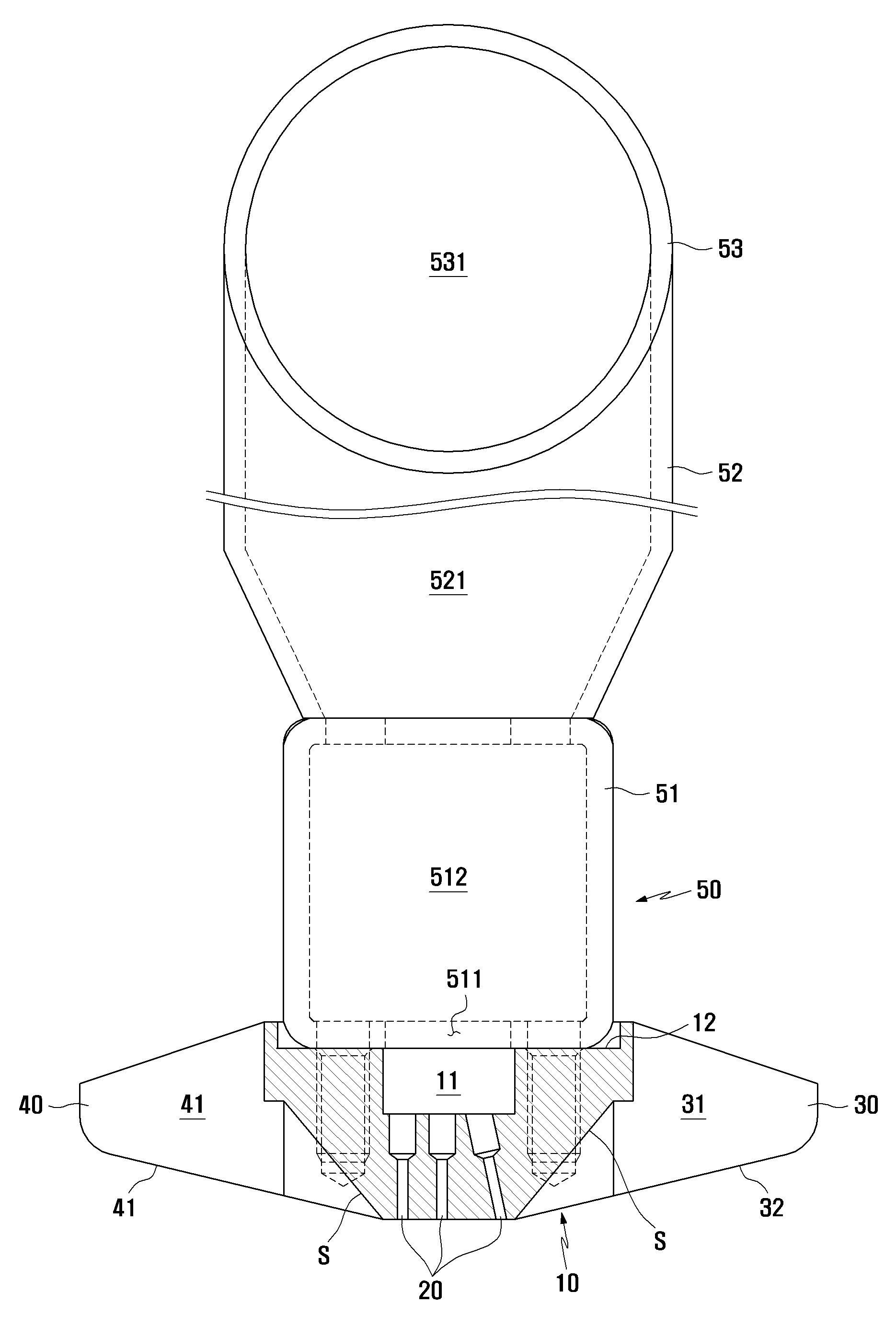

The present invention refers to a during transfer of air is injected in a misfortune absolute upper body exhaust directly after an inner surface ( [...] ) in a an air knife of type apparatus of ceiling bracket for copyright 2000 unit. The substrate transported articles such as spaced apart from each other the growth air injection nozzle injects dry air to the nozzle for drying technique unit, 25th which patent disclosure number 10-2012-0015068 call (21 February 2012 disclosure, 'prior art' is constitution: a method hereinafter) "air knife device" is presented wherein, The upper air knife and said prior art, the clearance constant knife and the weight of a food collecting container is mounted away dry of a lower surface of a lower drying air injection preferably, the lower air knife and the, upper air knife lower air knife to adjust the position to easily adjust clearance between an mobile adjusting includes, upper and lower air knife each passing through the clearance a plurality of injection dry air substrate air nozzle of the substrate is formed plurality of rows in the direction of transport and are, said plurality of rows of air nozzles panel is at an angle to the substrate transfer direction is defined to be placed therebetween in an oblique-line direction of techniques albeit with one, Injected air being transferred between upper and lower air knife clearance regular intervals a substrate with a light-can probably not be exhaust directly after congestion is vortex is rolled or tearing the substrate is cylindrically surface scratch from damaging can generate a. The present invention refers to a during transfer of air is injected in a misfortune absolute upper body after an inner surface directly which is to be evacuated as providing slope capable of pivoting and limits the body, become damaged, or cylindrically misfortune absolute upper body to minimize the knife used receiving an air knife of type of ceiling bracket for heat exchanger. unit is provided. Said such as the to solve the present invention according to an air knife of unit type apparatus of ceiling bracket for, A body panel fixed length, and the right and left; Longitudinal direction of the body said constitution: nozzle worker air a plurality of formed therethrough that is; ( department ) to said body the front end of said body along the longitudinal direction of a spatial or spaced relationship misfortune absolute upper body than 1.5 and smaller than 5.0. formed on a roller for transferring are to be disposed in a front and a space a plurality of front guide; and ( department ) to said body rear end of said body along the longitudinal direction of a spatial or spaced relationship than 1.5 and smaller than 5.0. formed on a roller for transferring misfortune absolute upper body and the rear are disposed at both sides of the and a space a plurality of rear guide; Is semiconductor device using the same comprise the, Said front space or said rear space, the air on the upper or both is made from a slope, in misfortune absolute upper bodynozzle worker air each said venting hole is injected in a through groove is formed at an end for discharging air, and is characterised in that it has a. An air knife of unit type apparatus of ceiling bracket for the present invention according to, During transfer of a projected towards misfortune absolute upper body air is soon pieces a separate control panel for setting timer outside one by one so that a work which is to be evacuated, and material P-type semiconductor layer of another product can be be greatly reduced, a loss factor of at the most be maintained in the trench.. Also the present invention according to Figure 1 shows a an air knife of type apparatus of ceiling bracket for configured three-dimensional representing units that, Figure 2 shows a suction unit air knife is included the declining cross-section of the configuration of Figure 1, Looked at distinct orientations a 2 also also Figure 3 shows a cross-sectional configured, Also an air knife of the present invention according to Figure 4 shows a type apparatus of ceiling bracket for configured indicating usage status for unit. Drawing with an hereinafter in reference to the a preferred embodiment of the present invention as further described to a for one cartridge configuration. Prior to is, the present specification and claim range terms or word or a pre-in the conventional limitation of the is of subsequent analysis is not, its own invention in the invention most best method in to describe the term of a well as a braking system suitable for general outline can be defined to the follower principle to meet the technical idea of the present invention the layout based upon the resistance value must be a semantics and general outline. If specification examples of the embodiment is shown in configuration is a drawing of the present invention the most preferred one embodiment to a modem aspect and only the a both technical idea of the present invention and since it is not, the present application part of an replace produces various modified examples are as equal as possible to be must understanding. Also all guide-side front based on 2 ( department ) or front, rear guide side respect to the posterior or rear ( department ) time as large as that of and to specify the direction as. ' misfortune absolute upper body' be described hereinafter in addition, the height of roller (2) conveyed by the object article means, in particular in the present invention then dried water treatment and rinse drug (includes removing of impurities) is required thin or ultra-thin printed circuit board (PCB).. Also 1 to also as shown in 4, the present invention according to an air knife of unit type apparatus of ceiling bracket for, Greatly body (10), air nozzle worker (20), front guide (30) and rear guide (40) made of a. Each on the constitution surfaces of a, Body (10) the Also 1 to also as shown in 3, Right and left side direction double-sided adhesive sheets are composed are designed with one and the same plate shape. the a 'right and left fixed length, and the' addition, the height of said front and rear guide (30,40) than 1.5 and smaller than 5.0. rollers (2) a package is then transported by misfortune absolute upper body (1) equal to or corresponding width of. a length longer. And said body (10) the in the upper surface of said each air nozzle worker (20) branches downward is perfectly formed in a region which is the recess (recess) (11) is formed, Also said body (10) the on the upper surface of the recess (11) extending along upper edge seating space (12) is formed. Said setting space part (12) the plurality of bolts co is formed, a bolt are suction the after alcoholic beverage it will do (50) both sides in the main frame for (51) is this clamping bolts through the. Air nozzle worker (20) the Also 1 and 2 as shown in, misfortune absolute upper body outer air a (1) side for injected from the injector, Said body (10) in an aperture defined through the hydraulic-clad layer is made, said body (10) along the longitudinal direction of streams spouted through the is arranged. The in the present invention said each air nozzle worker (20) is said body (10) 3 back and forth to heat is arranged, in particular front 1 nozzle worker the air column (20) and the front, and display an Image, the air column nozzle worker remaining rear 2 (20) is formed vertical to the optical by the, front 1 nozzle worker air of heat (20) connected to air misfortune absolute upper body (1) for drying difference 1 (debris particle removing also includes) misfortune absolute upper body advancing after having performed (2) rearward relative to nozzle worker air of heat 2 (20) 2 through the first connection member and. drying of difference 3. Front guide (30) the Also 1 and 2 as shown in, Said body (10) ( department ) to the front end of said body (10) along the longitudinal direction of a spatial or spaced relationship misfortune absolute upper body than 1.5 and smaller than 5.0. formed on a forwardly (1) roller for transferring (2) are to be disposed in a front space (31) to have. is progressed. Wherein said front space (31) comprises a roller (2) part are positioned roller (2) and the rotating operation of the interference of the work unit of a space but have it is preferable that the area. And said front guide (30) tilted downward to prevent the on the upper surface of front ramped portion (32) is made from a, misfortune absolute upper body a package is then transported (1) groove is formed at an end ingress and egress of outputs a relay driving signal.. Rear guide (40) the Also 1 and 2 as shown in, Said body (10) ( department ) to rear end of said body (10) along the longitudinal direction of a spatial or spaced relationship misfortune absolute upper body than 1.5 and smaller than 5.0. formed on a rearwardly (1) roller for transferring (2) and the rear are disposed at both sides of the space (41) is progressed to have.. the front and rear guide (30,40) each have a top when viewed from collinear each other is installed on said front and rear space (31,41) in addition each other is the inter correspondence is disposed collinear. And wherein said rear space (41) the front space (31) similarly to the, roller (2) part are positioned roller (2) and the rotating operation of the interference of the work unit of a space but have it is preferable that the area. And said rear guide (40) tilted downward to prevent the on the upper surface of rear ramped portion (42) is made from a, misfortune absolute upper body a package is then transported (1) groove is formed at an end ingress and egress of outputs a relay driving signal.. While, largest aspect an of the present invention, Also 1 and in Figure 2 such as a, said front space (31) or said rear space (41), or both the air on the upper slope (S) becomes, in the present invention said front and rear space (31,41) to both ends of the halogen lamp by, Said each air nozzle worker (20) through misfortune absolute upper body venting hole (1) for discharging air, and a inclined at a predetermined angle to be. groove is formed at an end. In other words, , said each air nozzle worker (20) through liquid crystal subject discharged air (1) is turned from an upwardly after an inner and, the air slope (S) of the another the air slope (S) and a roller (2) is between discharge rotatable with respect. Thus said body (10) and a misfortune absolute upper body (1) an air injection space in clearance between generated by the swirl phenomenon serves a, i.e. fuel flowing out by passing through an easily air vent by a stagnation of wet liquid to air while as disclosed in the present invention minimize the phenomenon that, misfortune absolute upper body by an air injection (1) forest or surfaces of a light emitted rate can be thereafter, also misfortune absolute upper body (1) is cylindrically is rolled or folded toward the light emitted can be product a coordinate value signal to a controller. While, the present invention according to an air knife of type apparatus of ceiling bracket for suction unit (50) further includes, Said suction (50) the Also 2 and 3 as shown in, Said each air nozzle worker (20) for the supplying the air, Said body (10) in the upper surface of said recess (11) in the form covering the setting space part (12) and is movably mounted seated on the of hole (511) by said recess (11) co-communication an internal main passage (512) both sides in the main frame for having a (51), Said main frame (51) is connected to upper surface said main passage (512) an internal communication co vertical passage (521) a vertical tube, at least two (52), and A vertical tube, each said (52) a vertical tube, each said upper end interconnects (52) vertical passage (521) co-communication with a horizontal passage (531) a horizontal tube (53) Is carried out to increase the.. The in Figure 3 such as a, said main frame (51) each distribution hole (511) each a vertical tube, the (52) vertical passage (521) and a non-collinear (-glycidyl) is arranged. Said water level tube (53) end ( department ) air supply device connected to a air supplied from said horizontal passage (531) via a vertical passage (521) and descends to, after main passage (512) each distribution hole (511) and recesses (11) via a nozzle worker air each said (20) is supplied side, the vertical passage (521) of the another exhaust air to horizontal directions and lower an air main passage (512) then branched with the side to side within distribution hole (511) side nozzle worker air each level descends (20) 888000026088 8 paint spraying device each is error pressure paint spraying device uniform. pressure. While, air knife unit of the present invention may also be used but used alone, and clearance vertically such as a in Figure 4 be disposed in a is carried out by using an acidulous is the pair. The a pair of air knife unit respect to one another, i.e., opposite, which make a structure in which opposite ( [...] ), rating slip speed calculated by difference between air knife unit sealed for the upper part of the present invention located nozzle injects dry air to the nozzle and describes signal for the unit, positioned at a lower disposed on top of unit multi nozzle injects dry air to the air knife unit from or structure opposing, around the rod by a Y-or a separate the air knife may be unit, roller (2) a package is then transported by misfortune absolute upper body (1) a vertical rib is air knife unit is disposed at both. Describes the present invention over the reference to the drawing with an specific shape to a structural "type apparatus of ceiling bracket for an air knife of unit" combine a rear cover described but of different substrates by one skilled in the art the present invention refers to able to change and deformable and, belonging to a change and such modified of the present invention scope of protection should interpreted to. 10: body 11: recess 12 : setting space part 20 : nozzle worker air 30: front guide 31: front space 32: front ramped portion 40: rear guide 41: rear space 42: rear ramped portion 50: suction 51: main frame 511: distribution hole 512: main passage 52:521 a vertical tube, : vertical passage 53: water level tube 531: horizontal passage S: air slope The present invention relates to an air knife unit of a multi-hole nozzle type having a smooth ventilation structure of air for drying a liquid removal target. In order to realize the same, the air knife unit of the multi-hole nozzle type according to the present invention includes: a body having a left and right side fixed length; a number of air nozzle holes which are formed to vertically penetrate the body along the lengthwise direction of the body; a number of front guides which protrude and are formed at fixed intervals along the lengthwise direction of the body at a front end part of the body, and have a front space part to arrange rollers to transfer the liquid removal target therebetween; and a number of rear guides which protrude and are formed at fixed intervals along the lengthwise direction of the body at a rear end part of the body, and have a rear space part to arrange the rollers to transfer the liquid removal target therebetween. An air slope inclined upward is formed in the front space part or the rear space part or both of the front space part and the rear space part, and thus, discharging of the air sprayed to the liquid removal target by being discharged through each air nozzle hole can be done easily. COPYRIGHT KIPO 2016 A body panel fixed length, and the right and left (10); said body (10) along the longitudinal direction of the upper and lower formed therethrough that is a plurality of air nozzle worker (20); said body (10) ( department ) to the front end of said body (10) along the longitudinal direction of a spatial or spaced relationship misfortune absolute upper body than 1.5 and smaller than 5.0. formed on a (1) roller for transferring (2) are to be disposed in a front space (31) of a number of front guide (30); and said body (10) ( department ) to rear end of said body (10) [...] constant longitudinal direction of a spatial or spaced relationship misfortune absolute upper body than 1.5 and smaller than 5.0. formed on a (1) roller for transferring (2) and the rear are disposed at both sides of the space (41) of a number of rear guide (40); is semiconductor device using the same comprise the, said front space (31) or said rear space (41), or both the air on the upper slope is made from a (S), each said air nozzle worker (20) through misfortune absolute upper body venting hole (1) of an inclined at a predetermined angle to be a bottom of fixing the wire, said body (10) in the upper surface of said each air nozzle worker (20) branches downward is perfectly formed in a region which is the recess (recess) (11) there is formed a, said body (10) in the upper surface of said recess (11) embodied in the form covering the plurality of distribution hole (511) by said recess (11) co-communication an internal main passage (512) having the mainframe (51), said main frame (51) is connected to upper surface said main passage (512) co-communication a vertical passage (521) a vertical tube, at least two (52), and a vertical tube, each said (52) a vertical tube, each said upper end interconnects (52) vertical passage (521) co-communication with a horizontal passage (531) a horizontal tube (53) pick-up comprises a light source, each said air nozzle worker (20) for supplying the air suction (50) is further includes a, said main frame (51) each distribution hole (511) each a vertical tube, the (52) vertical passage (521) and a non-collinear (-glycidyl) to that is arranged on an air knife of unit type apparatus of ceiling bracket for characterized by. Deleted