SOLAR CELL MODULE MANUFACTURING METHOD

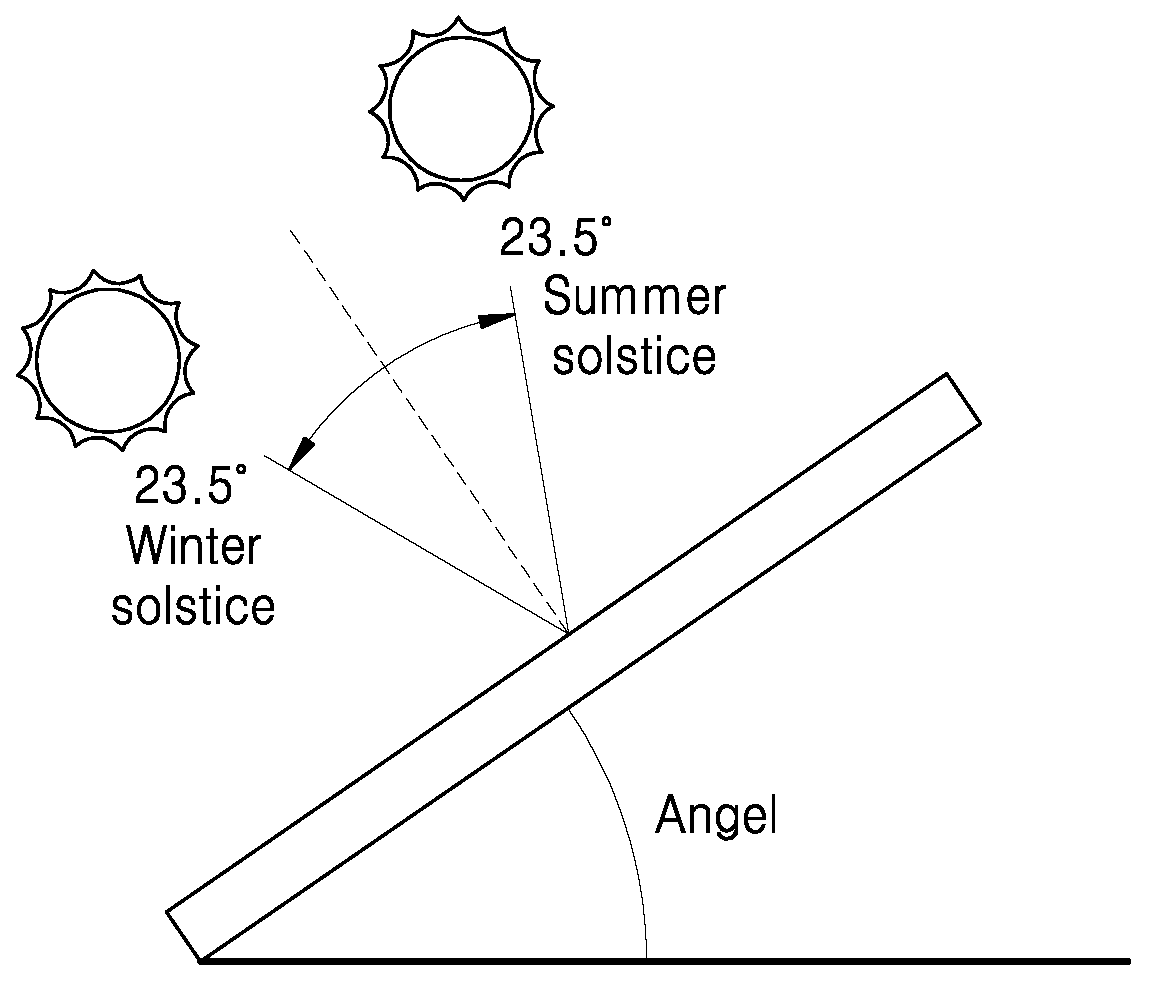

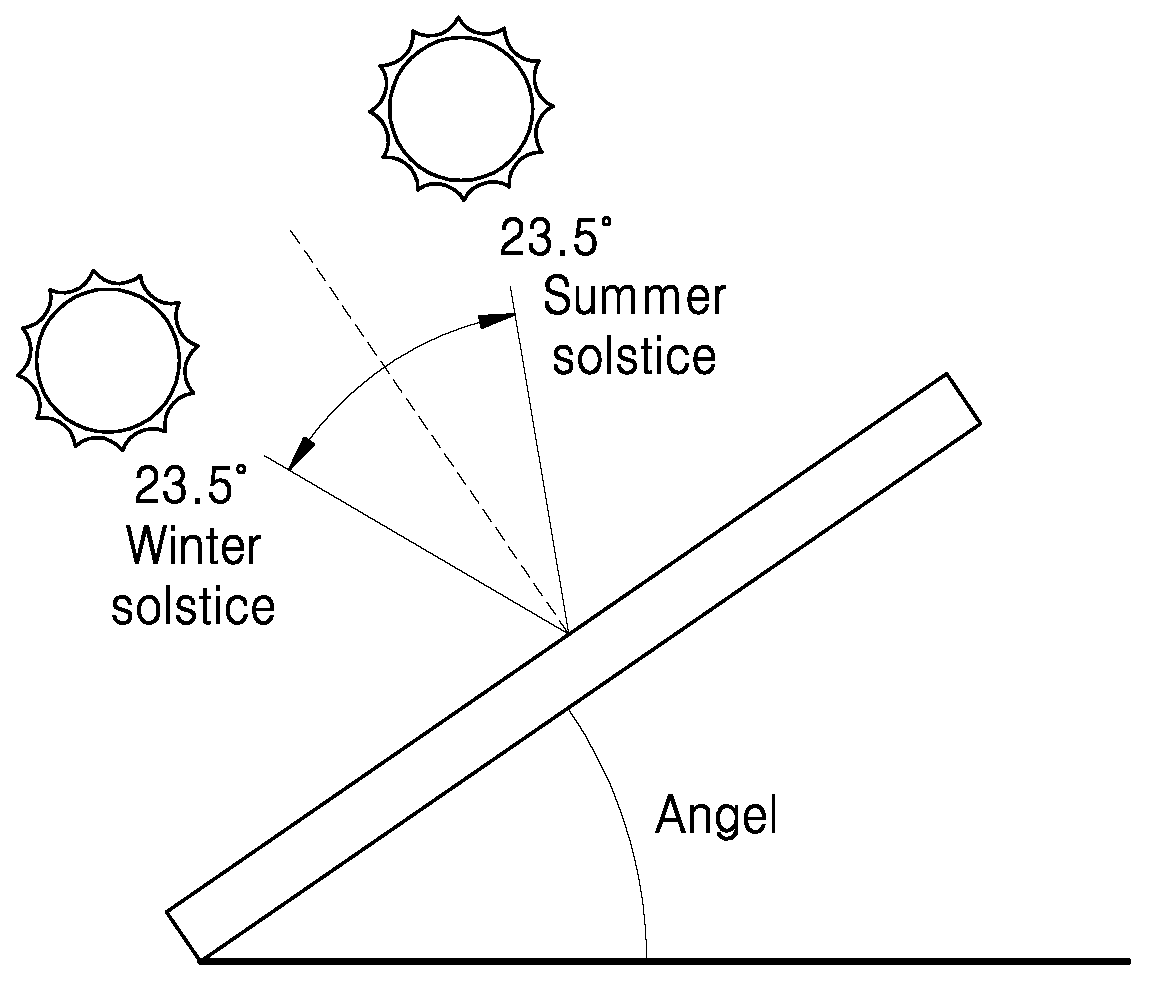

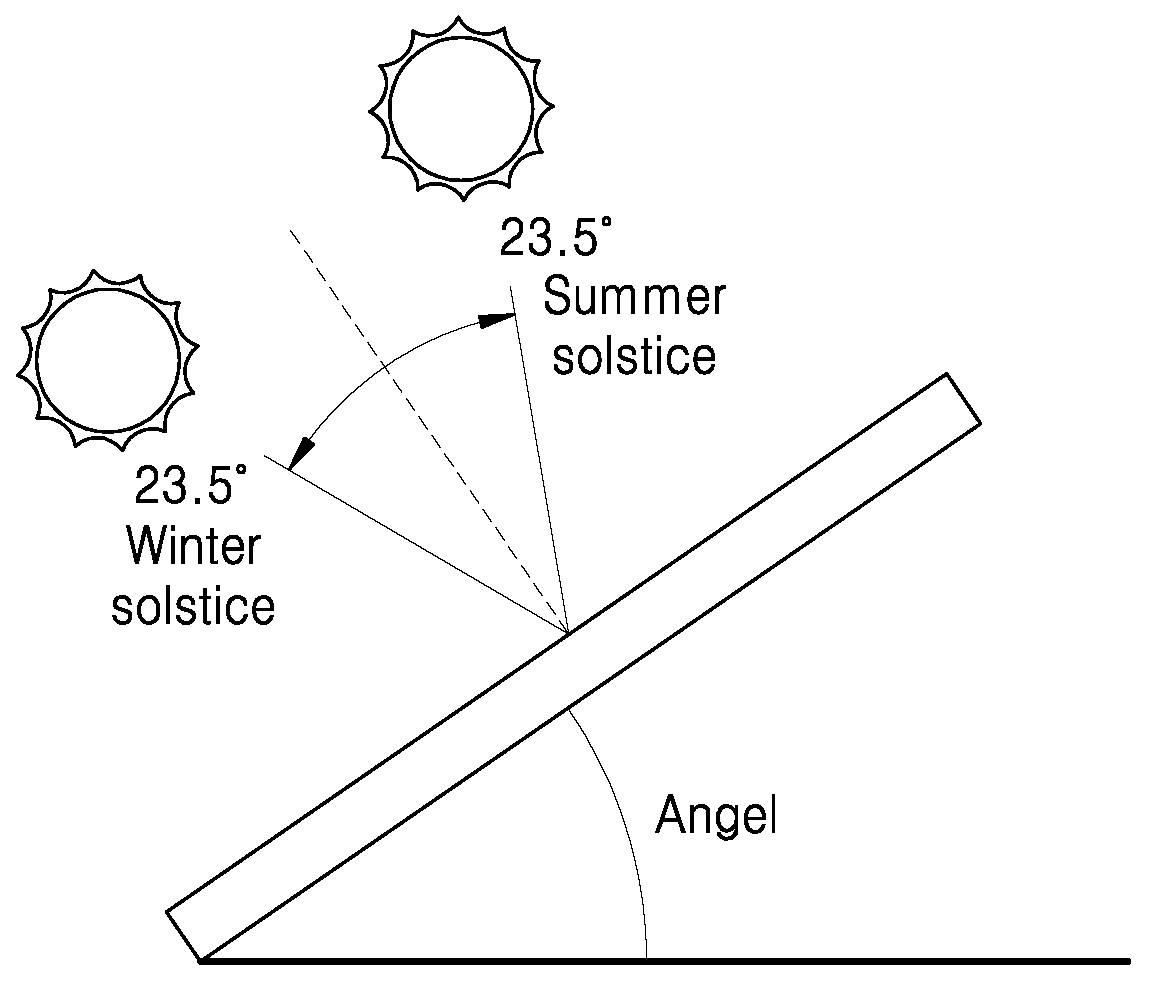

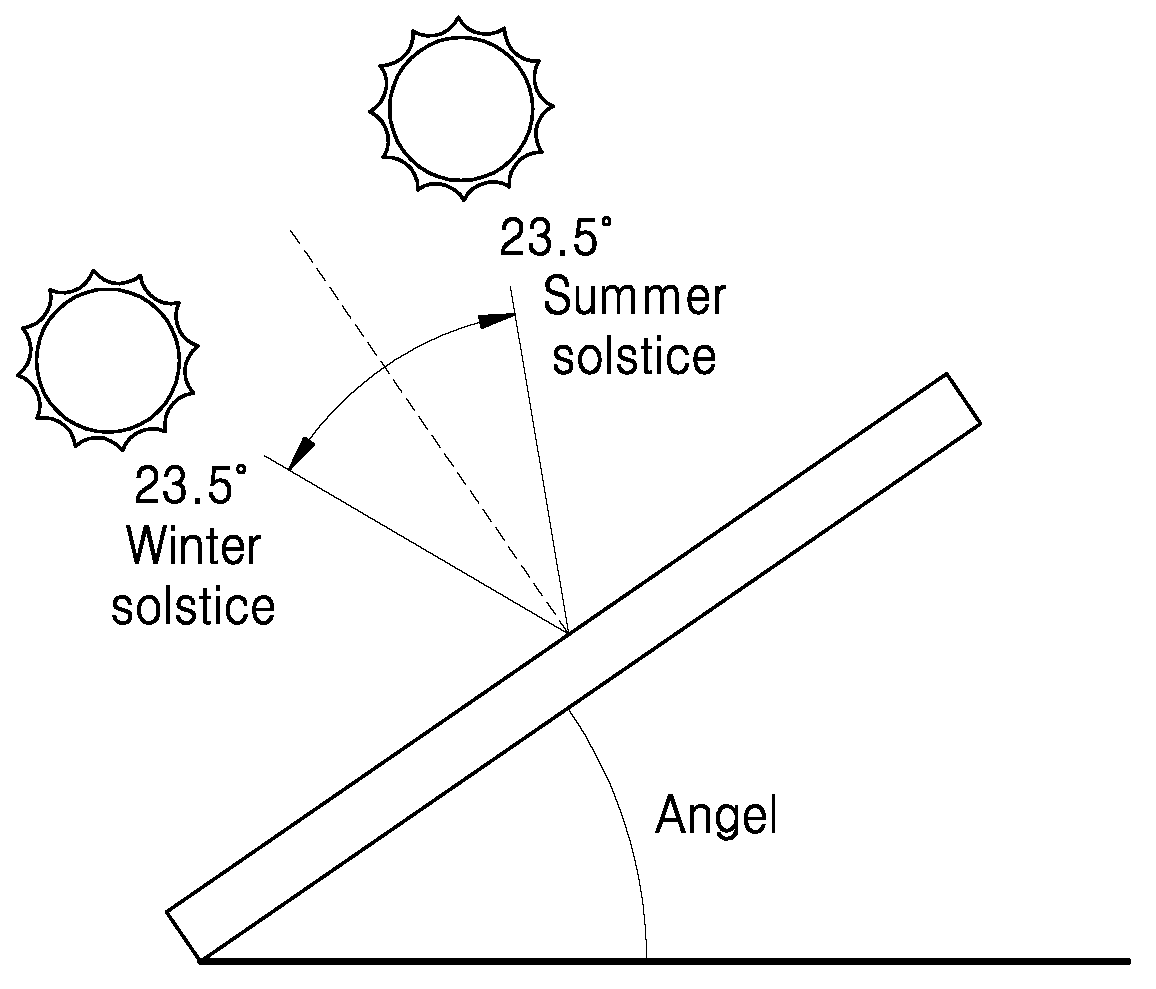

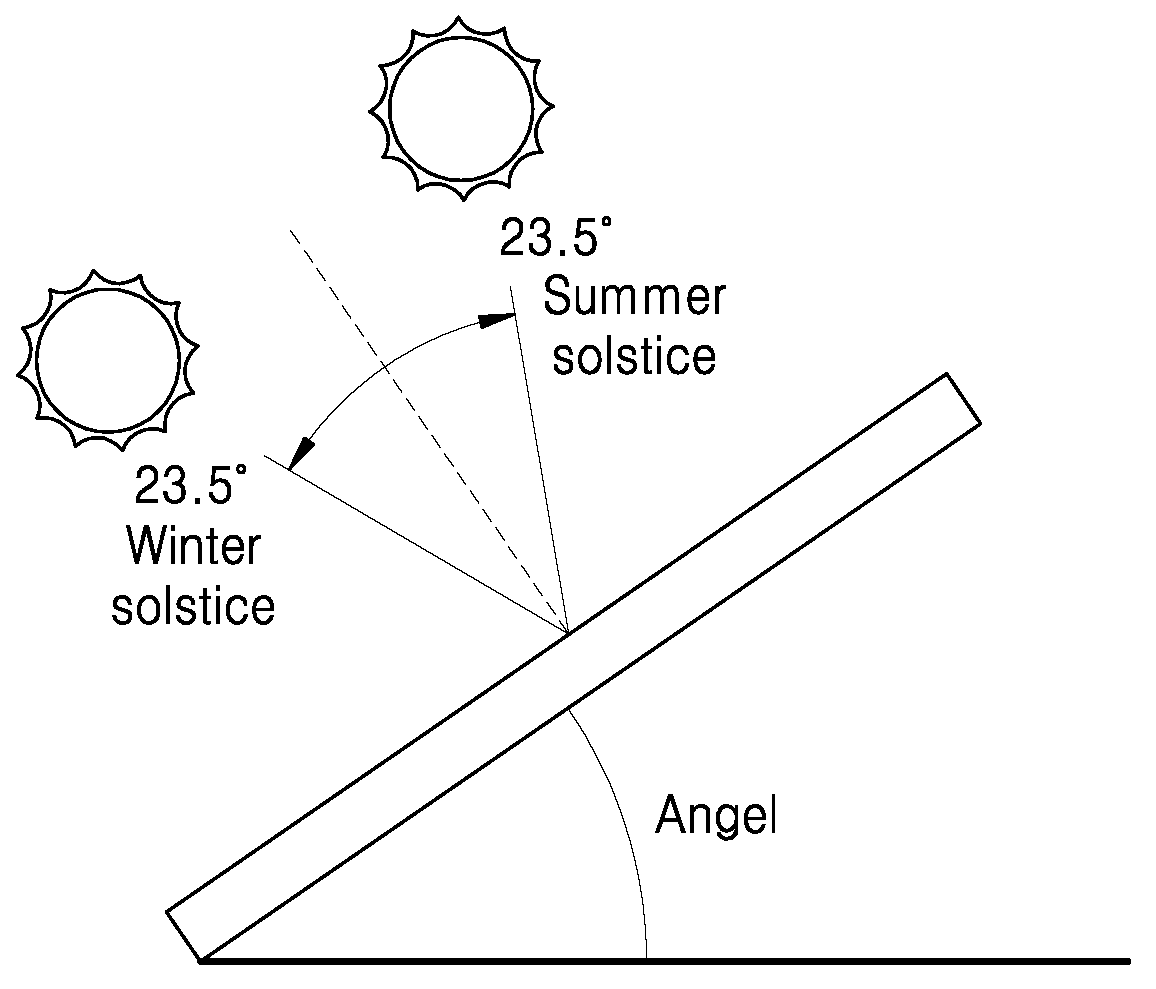

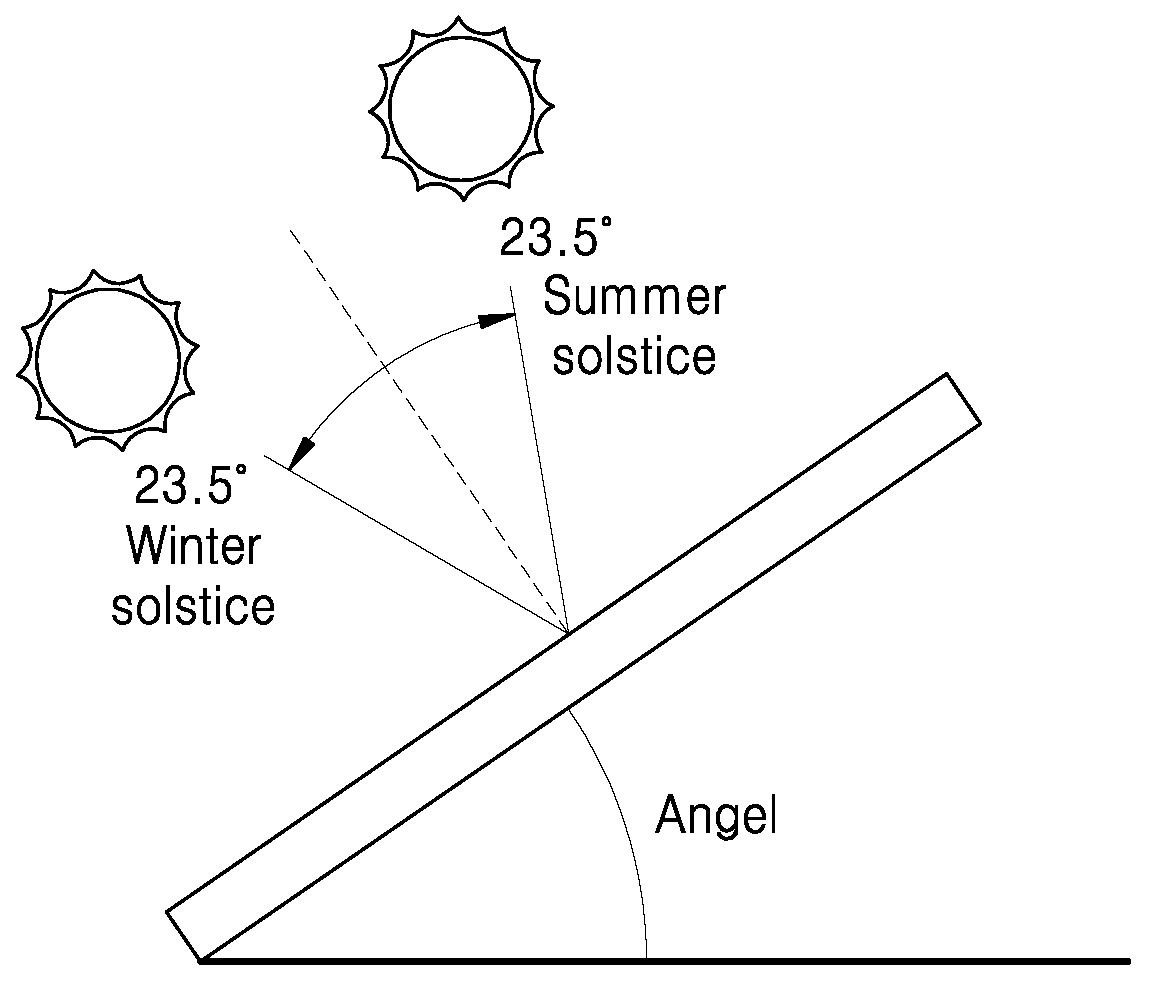

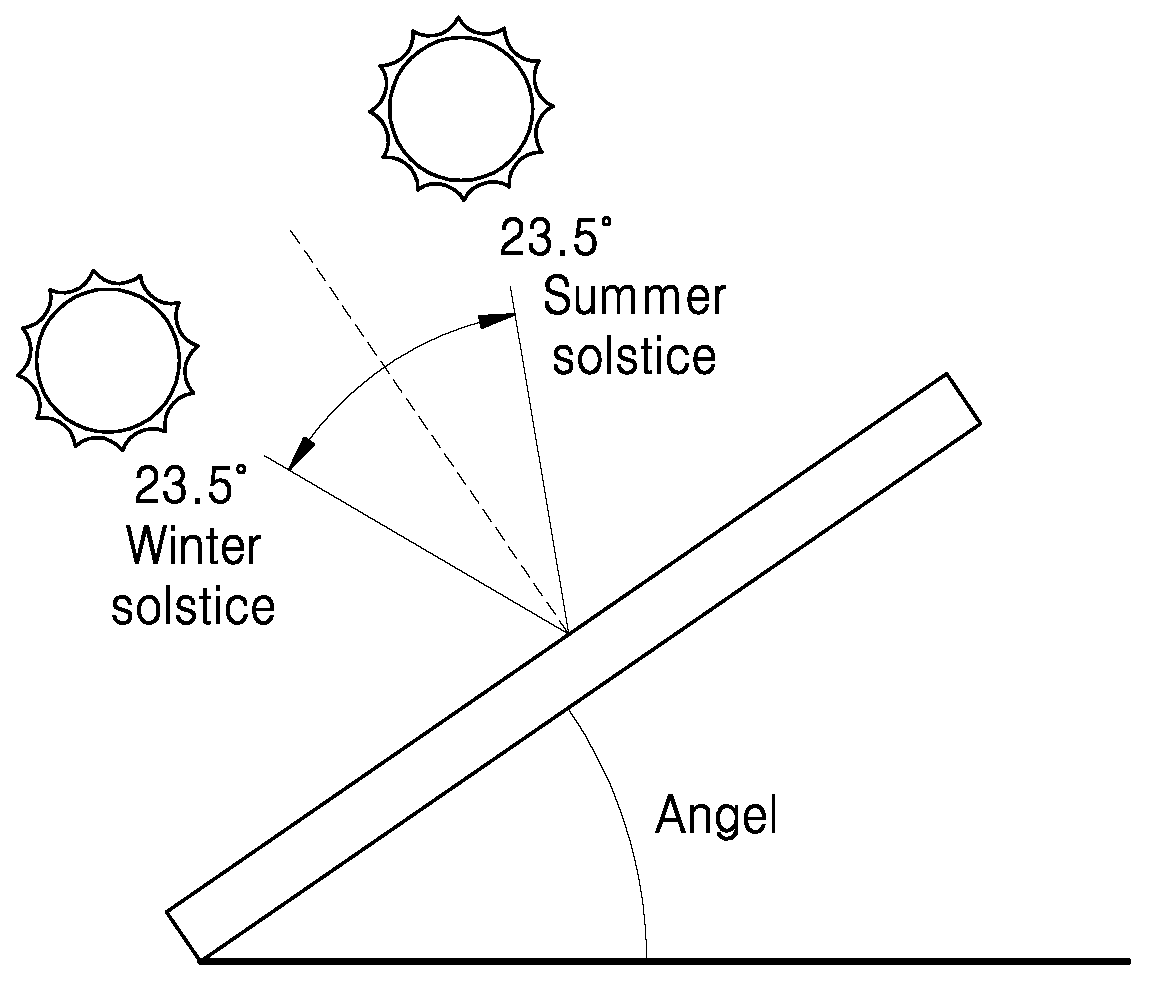

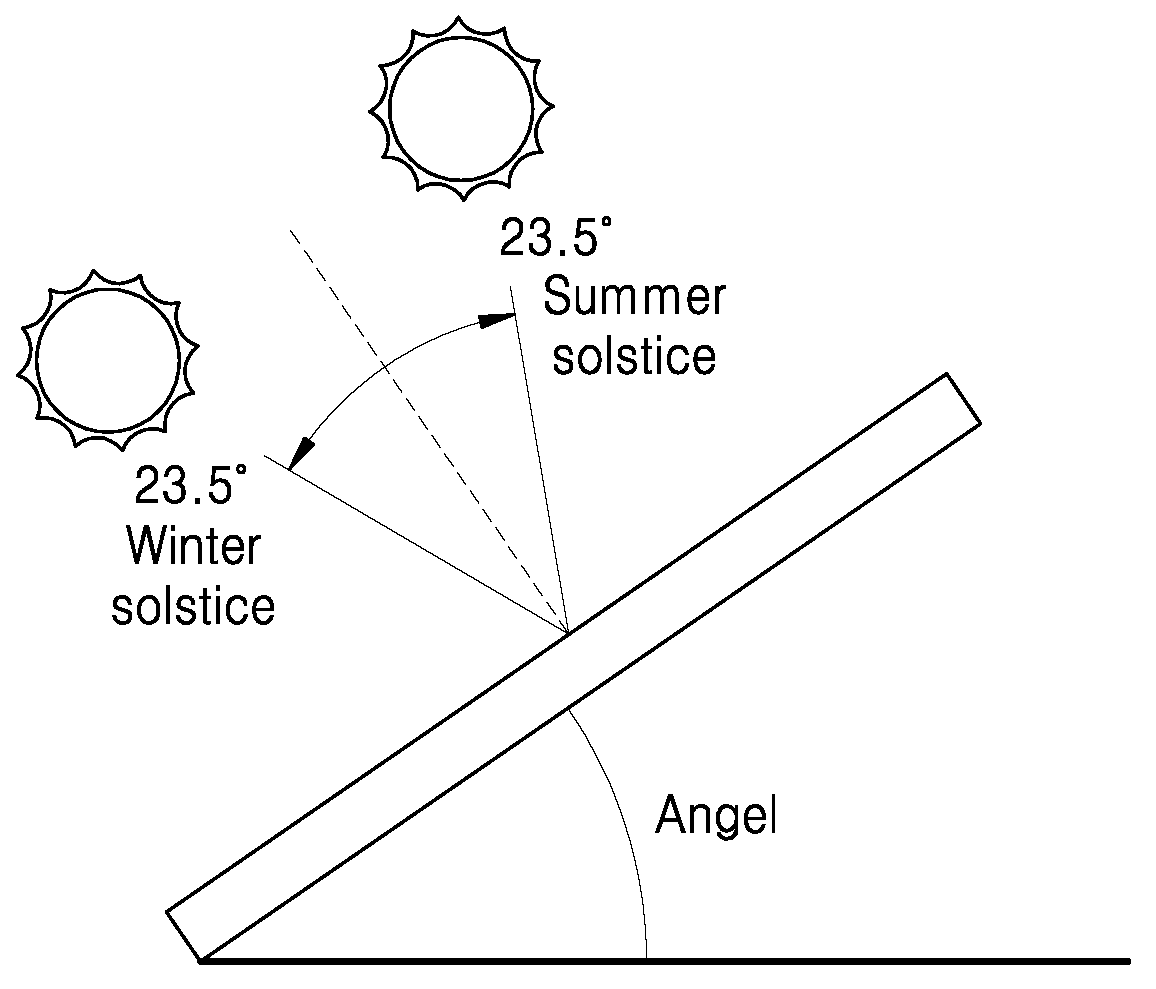

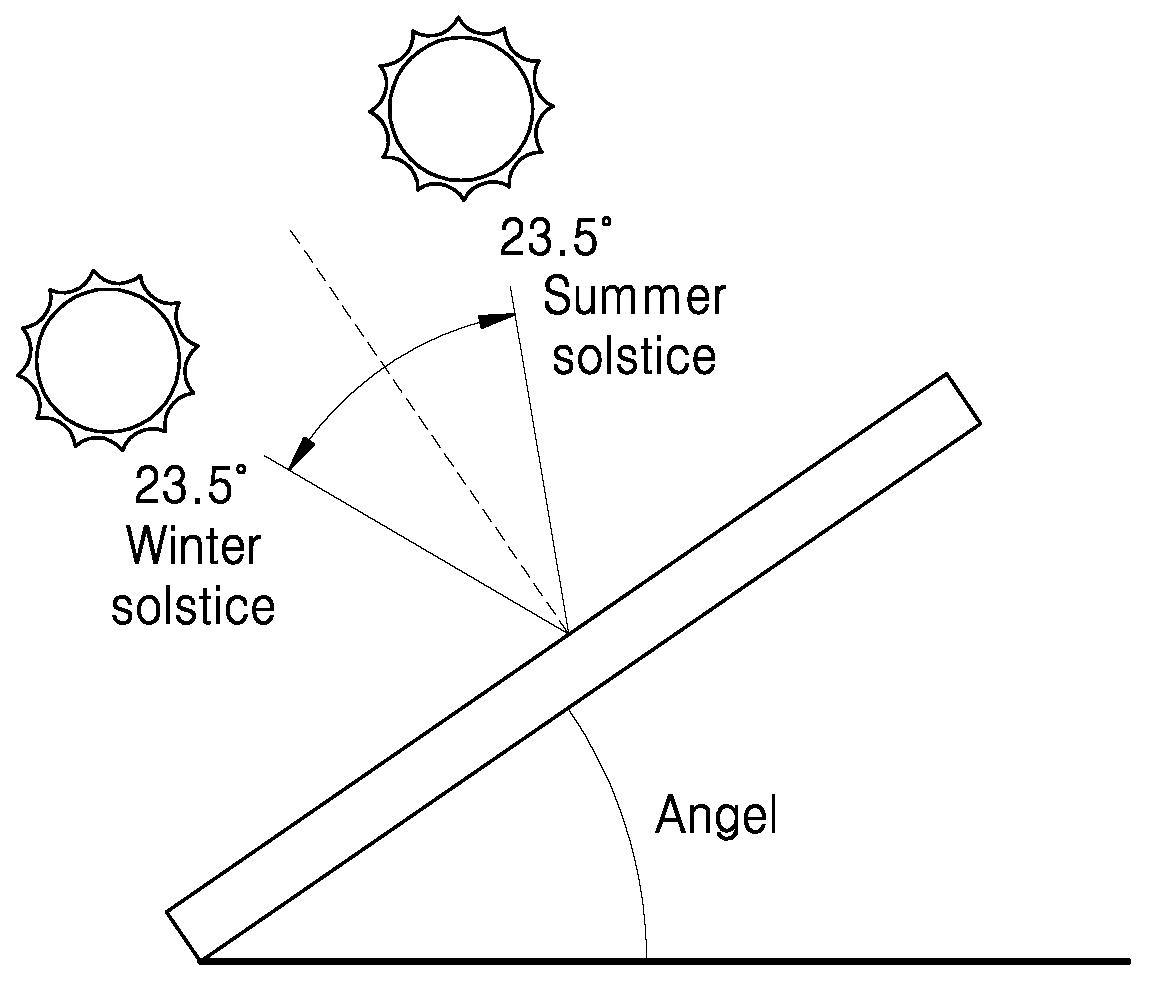

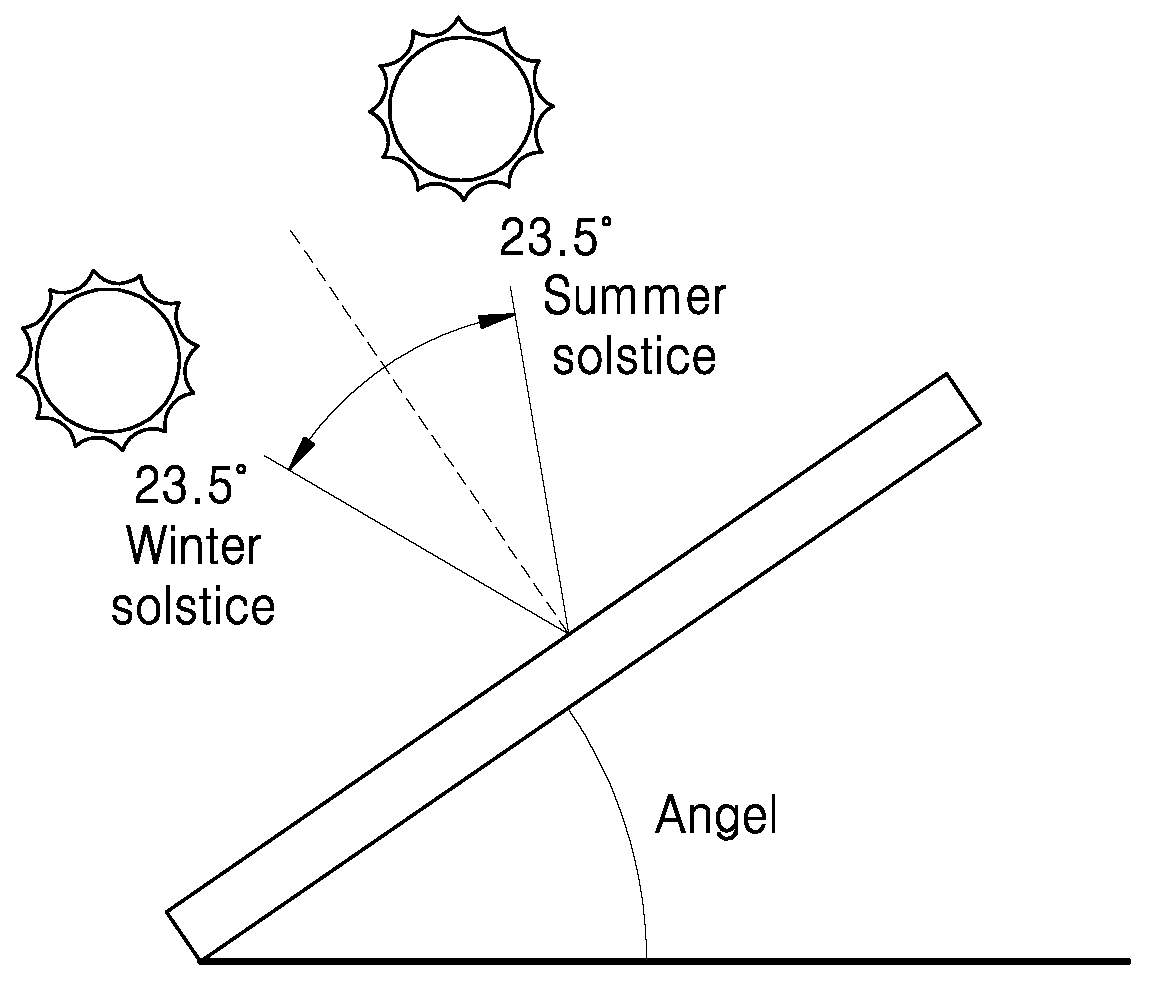

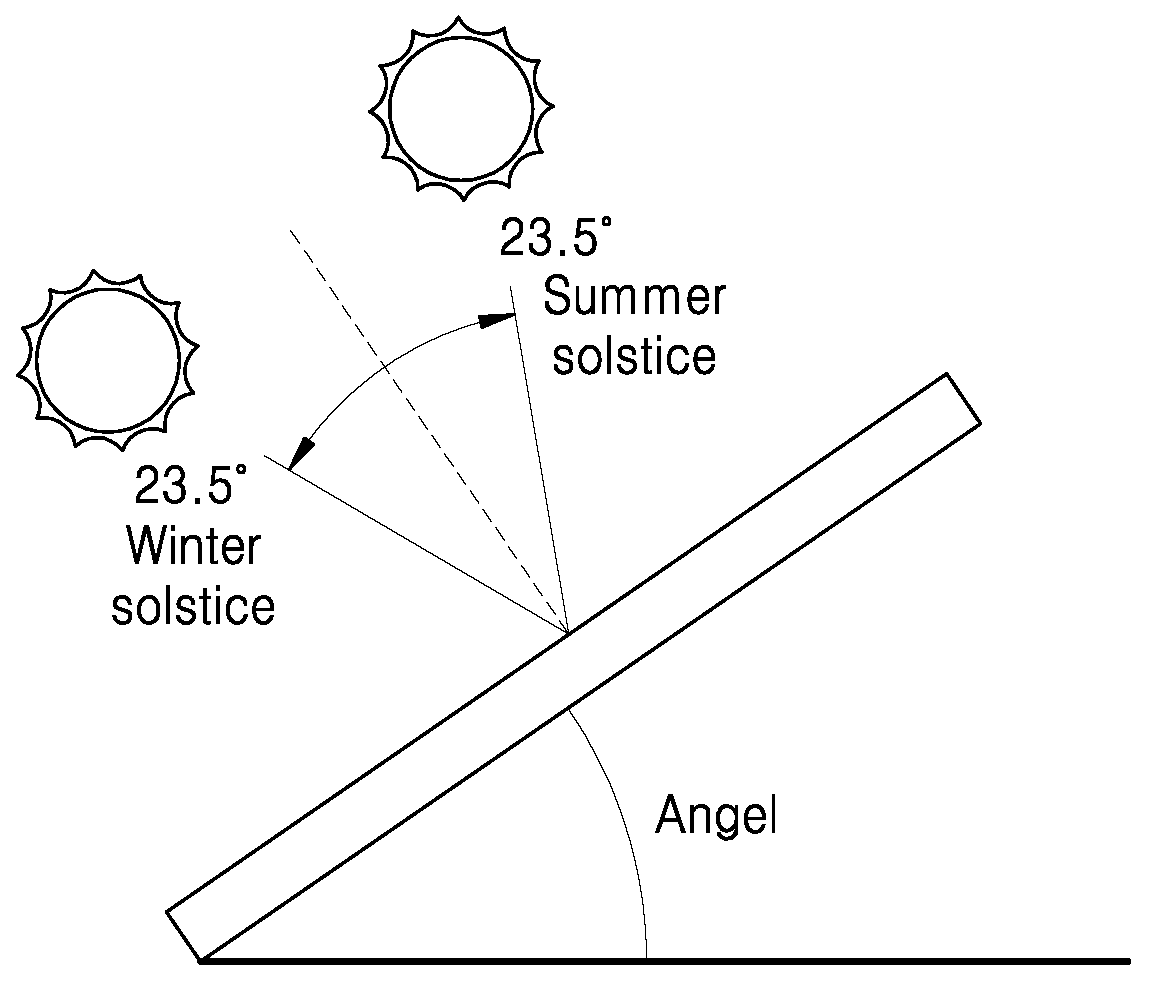

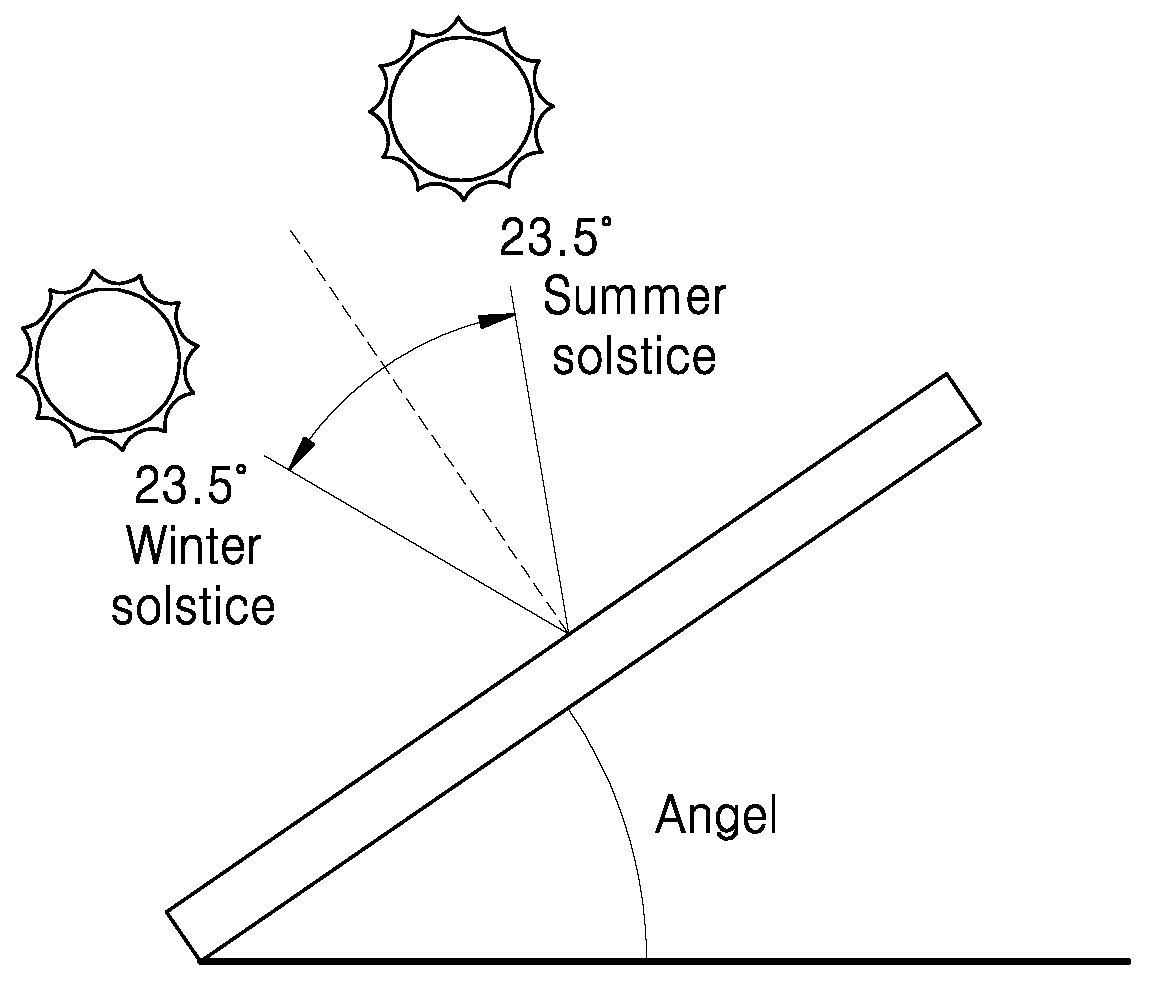

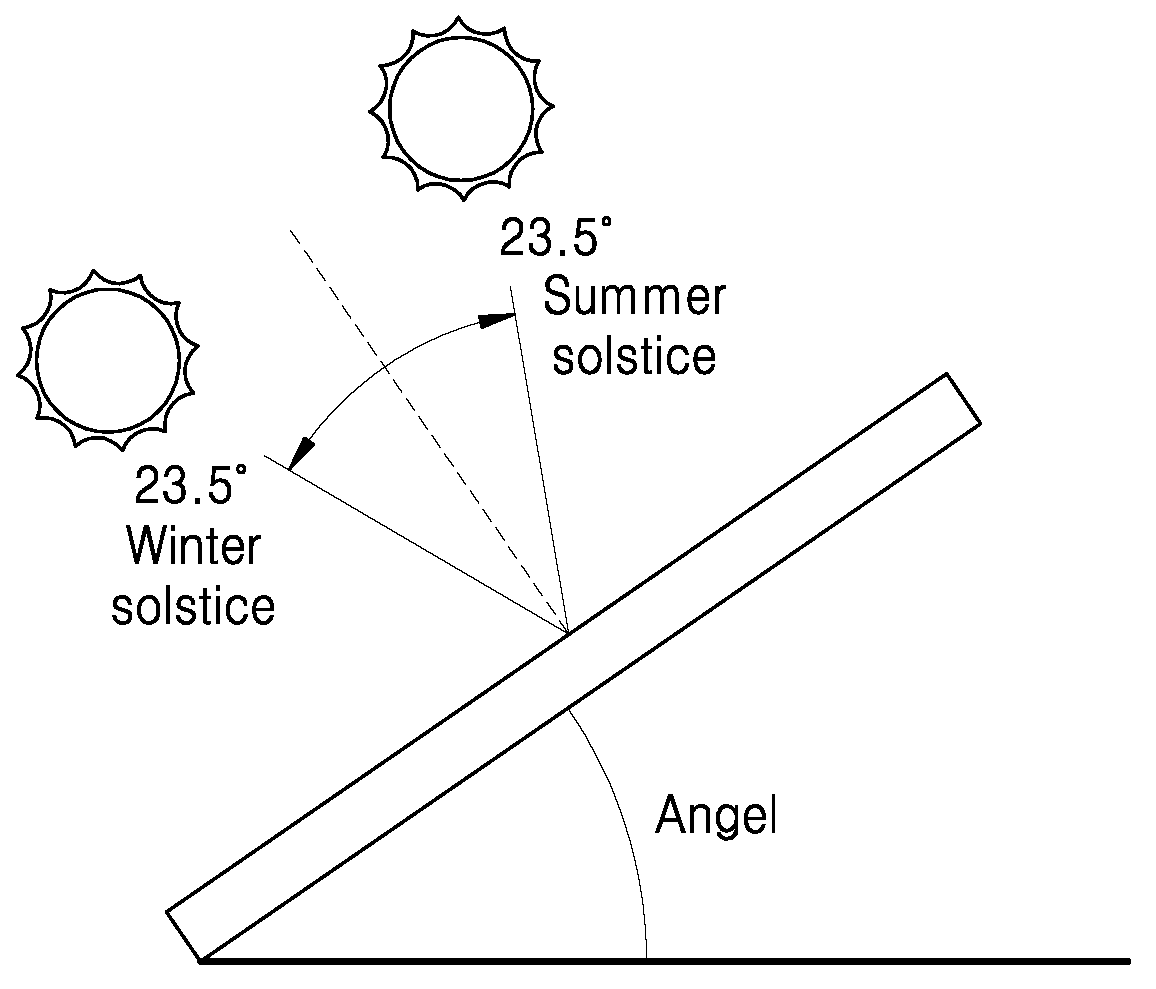

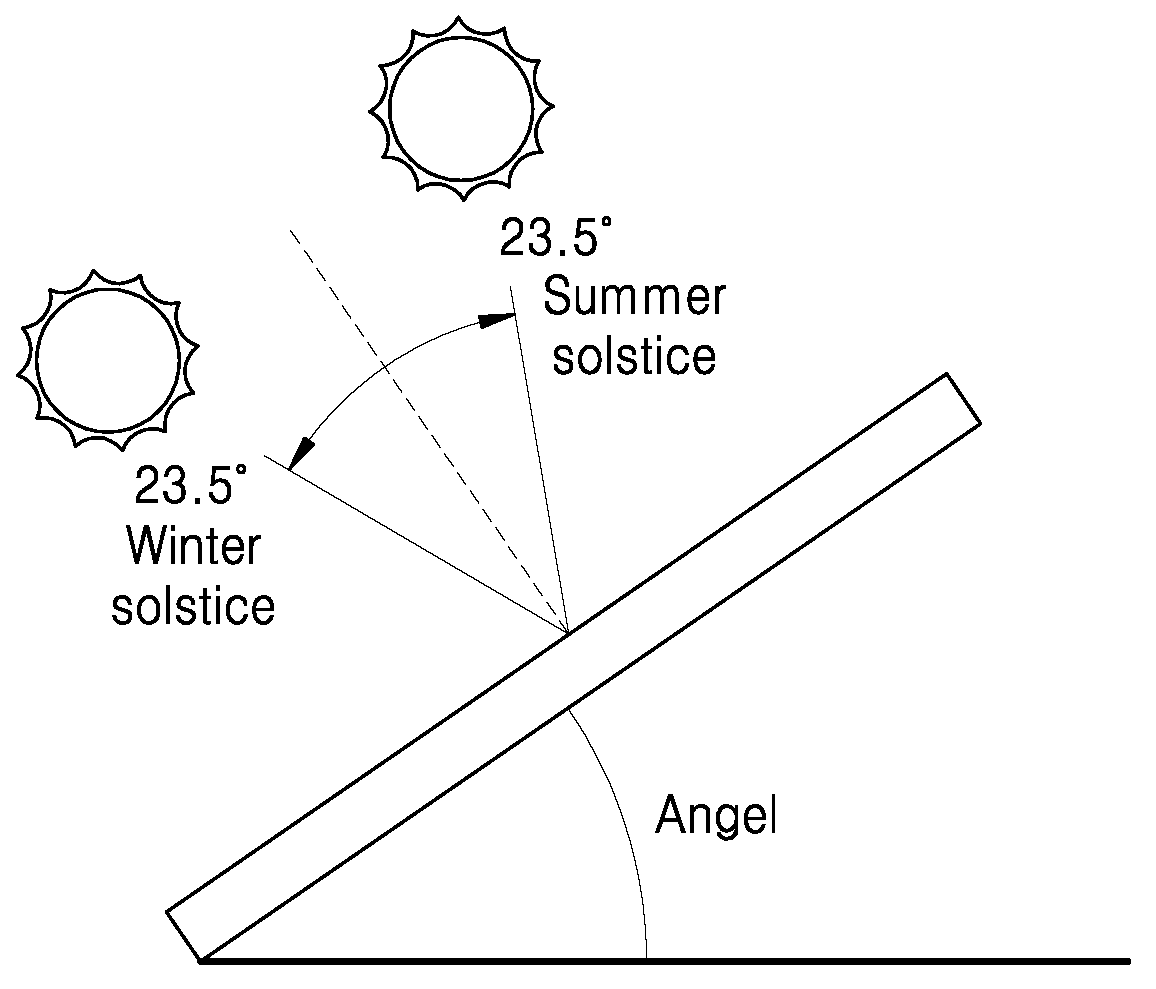

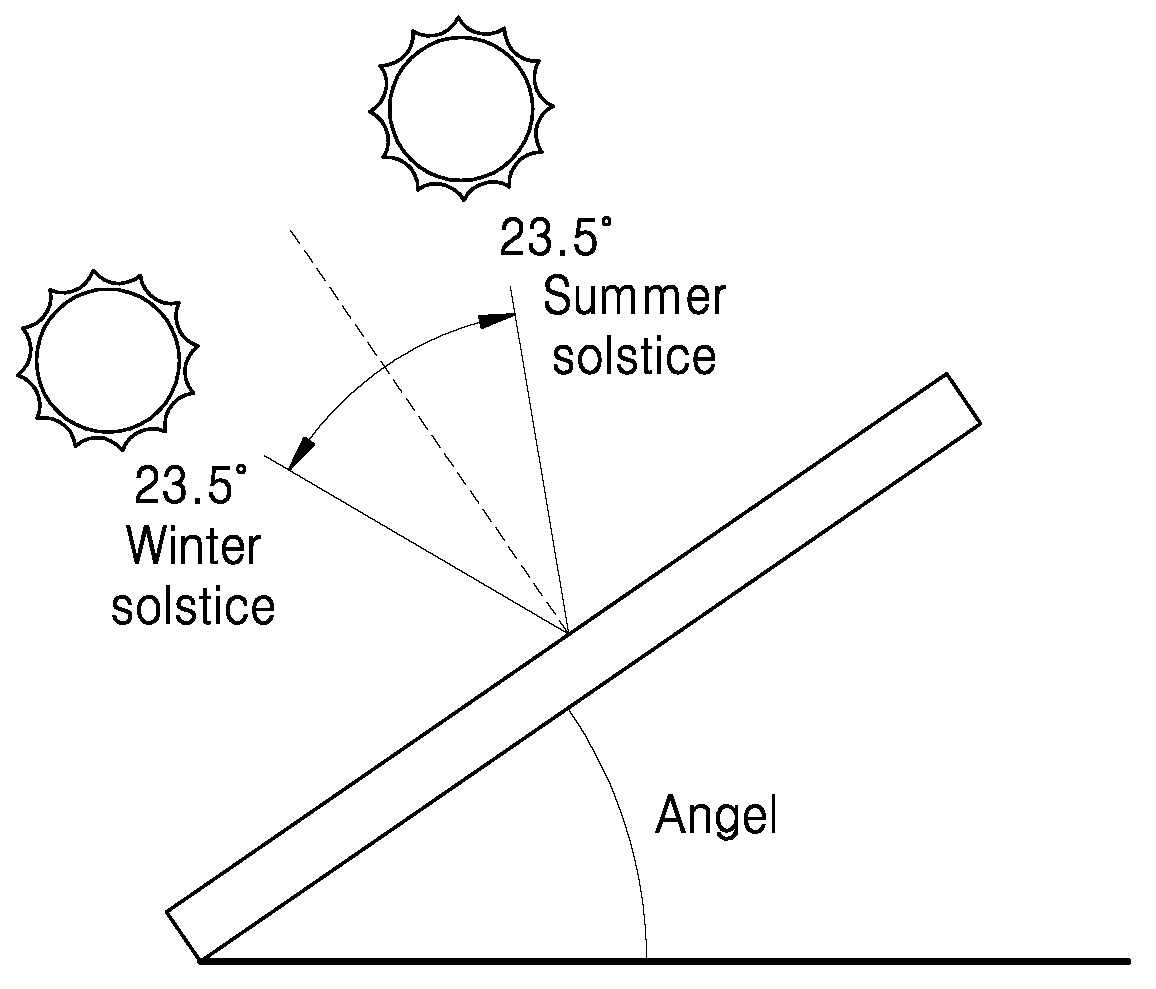

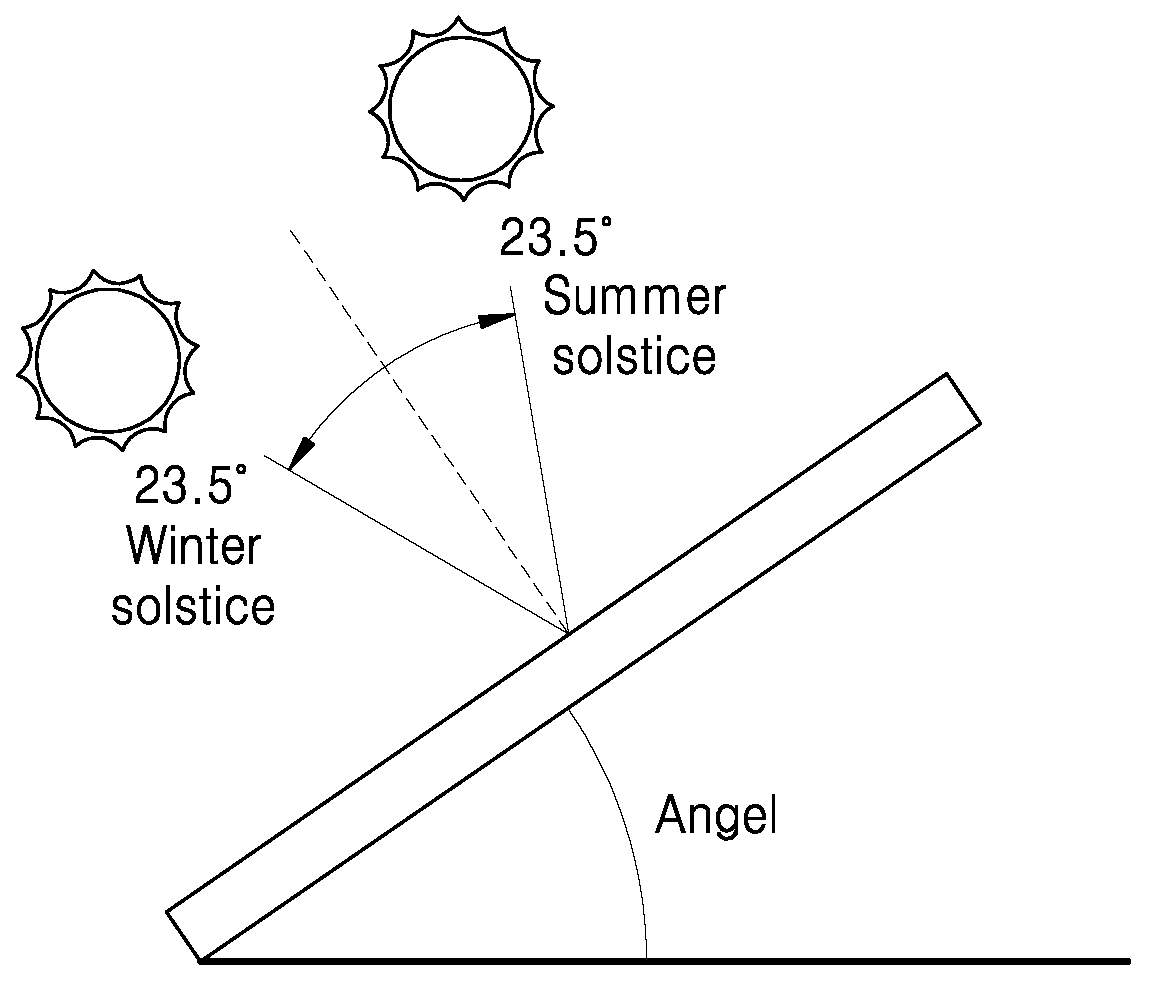

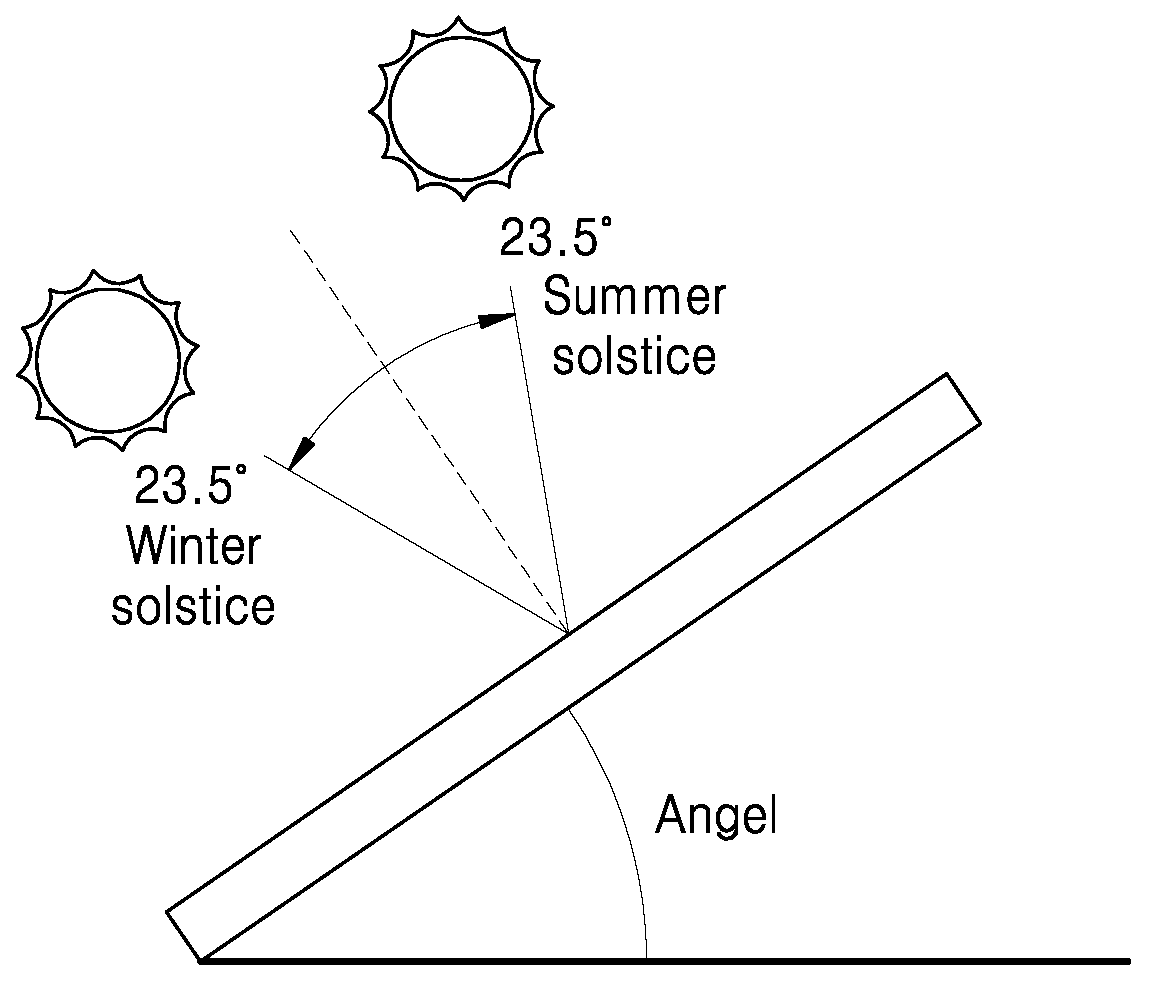

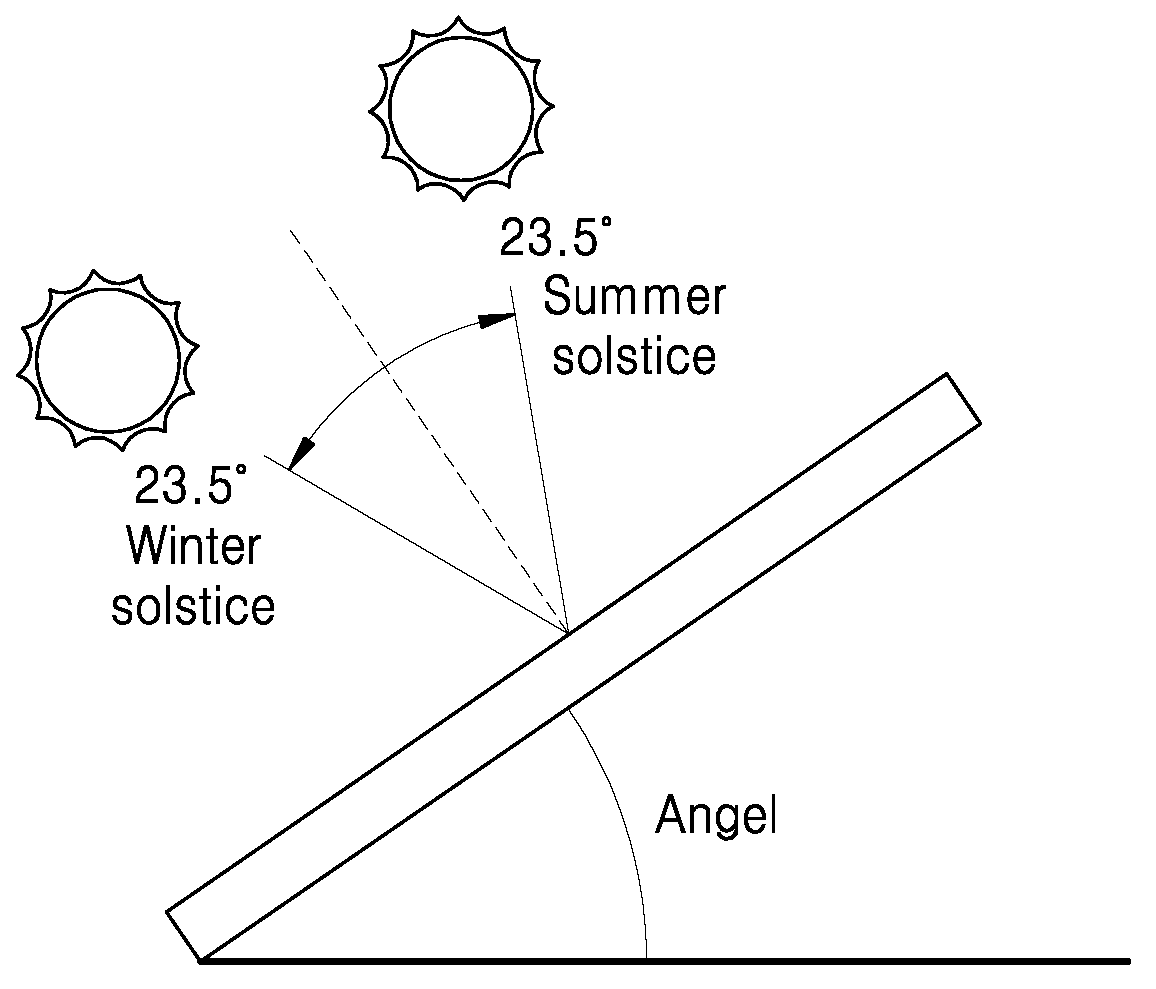

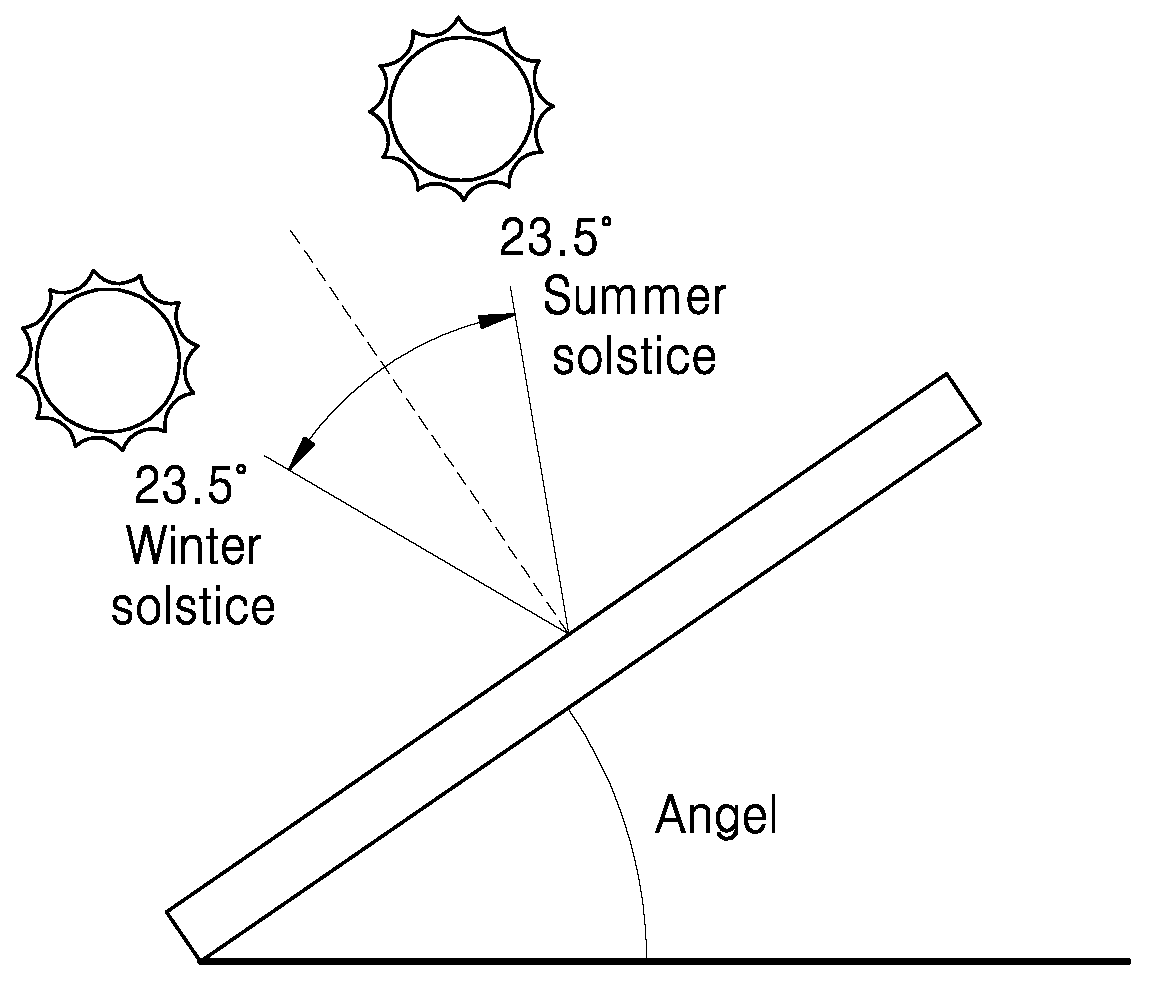

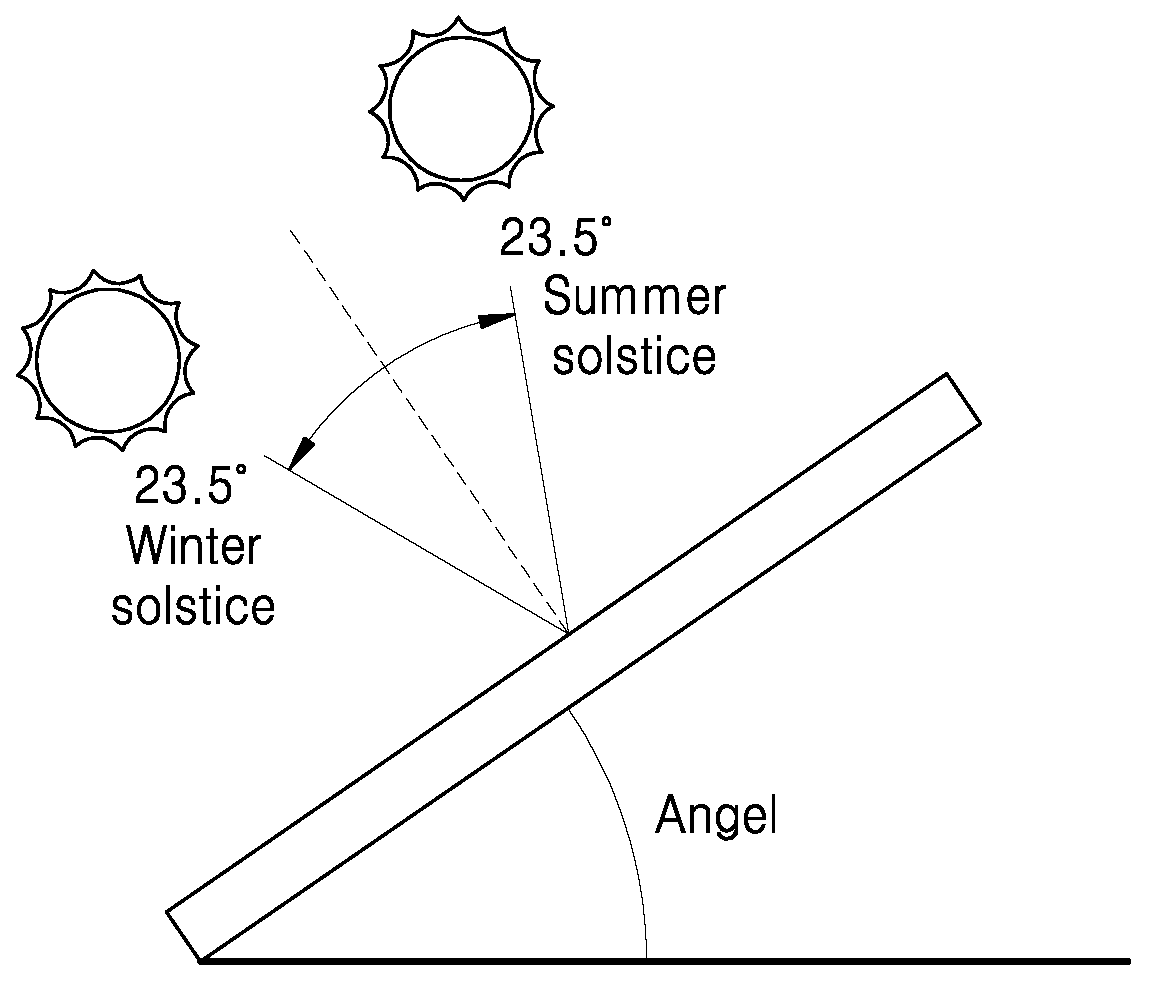

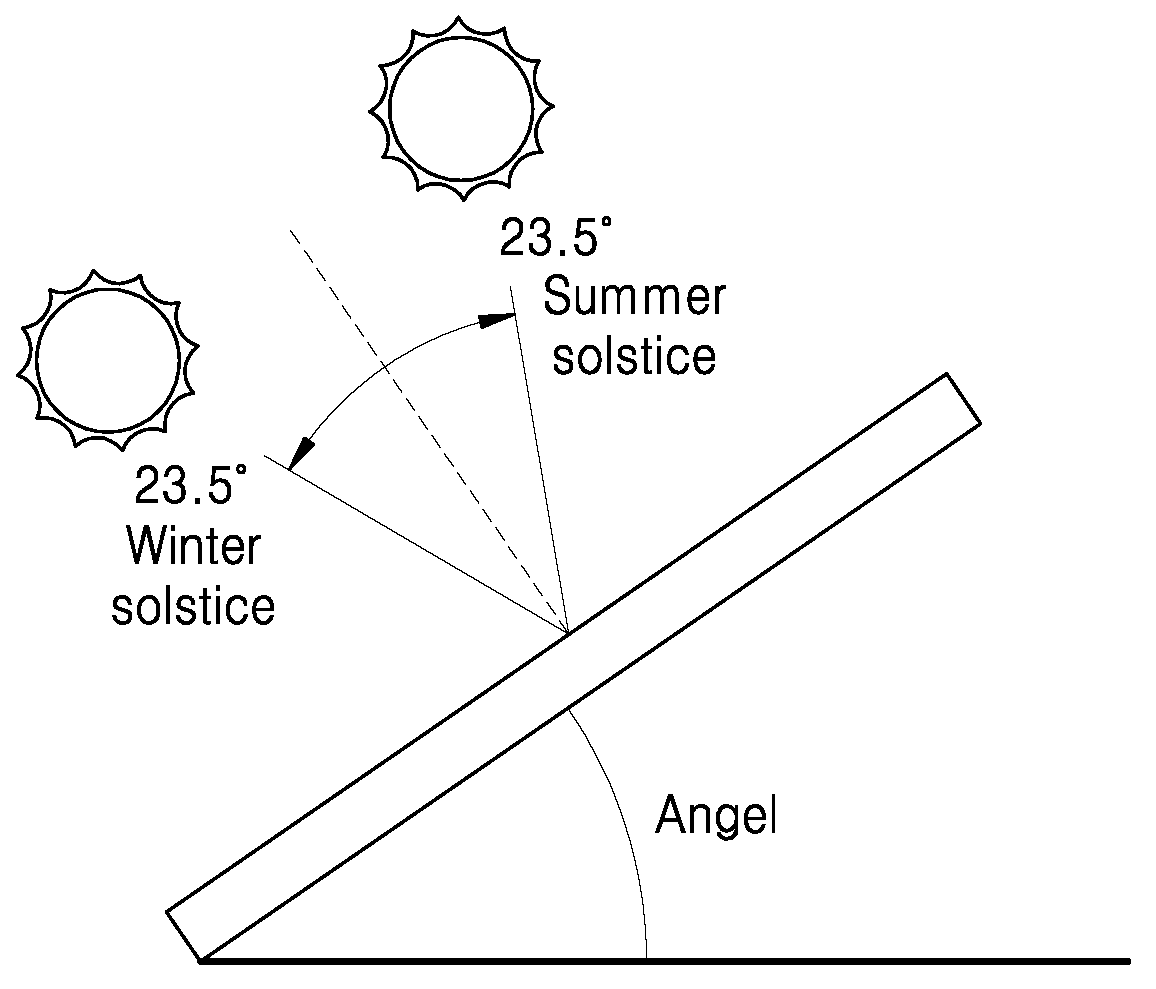

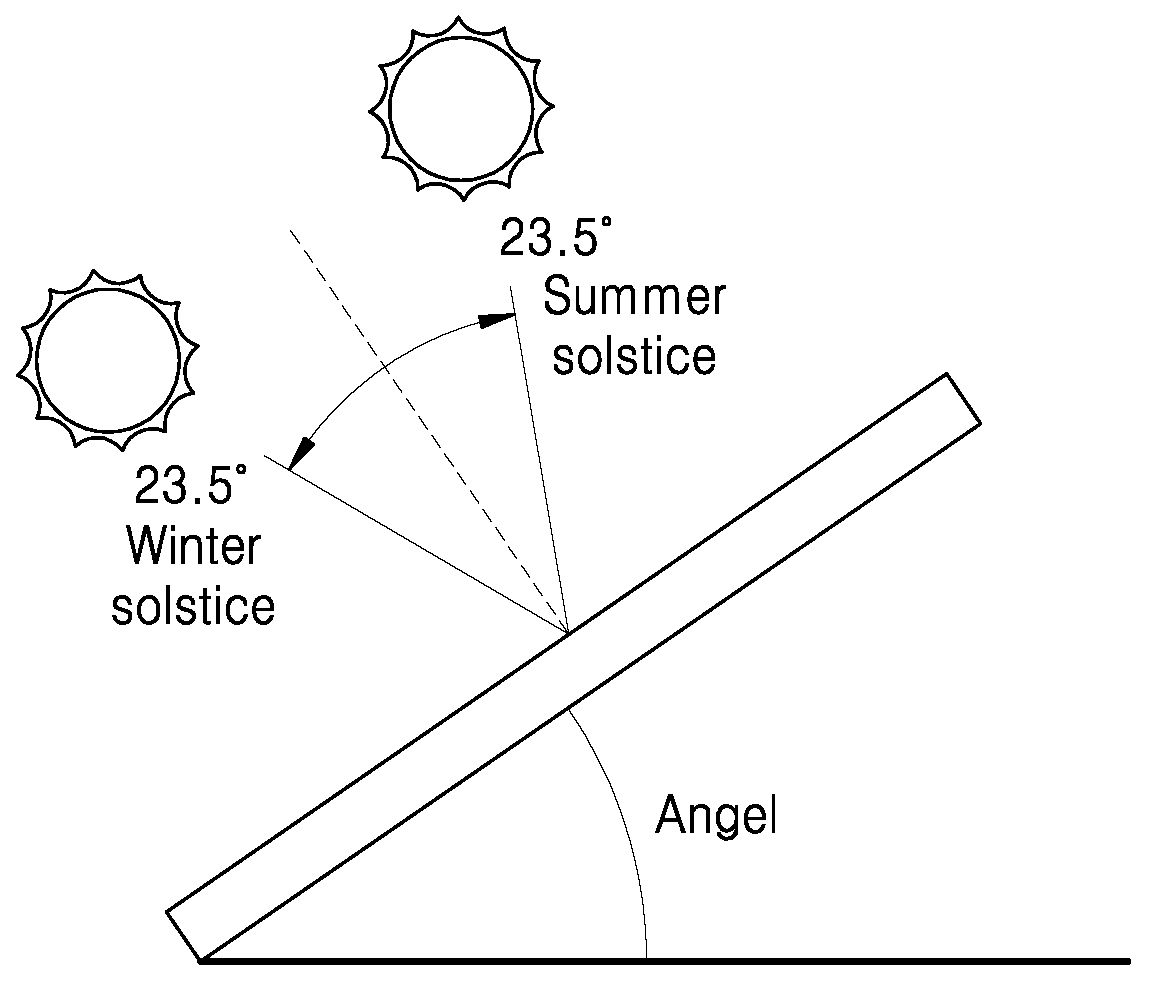

The present invention according to the solar cell module number bath method, number 1 consisting of a concave lens has a variable focal length lens; said number 1 focal distance of the lens disposed solar cell; said lens that is located between the solar cell said number 1 number 2 lens; including a number of the solar cell module as bath method, seasonal picture of the incident angle of sunlight condensing efficiency despite changes to secure solar cell modules which number bath method are disclosed. Of the existing method to replace fossil fuel solar cell can be one of regenerative energy potent device thereby converting energy into electrical energy aspects are disclosed. A solar anti-nothing expands solar energy heating unit being free from moving parts and combustion process which does not easily generate noise such as a harmful byproduct generating powders disclosed. The high reliability of the solar cell module's oldest minimize damage to obtain a long time constant. Despite advantages such costly solar cell module price fixing etc. acting as practical. Solar cell techniques for complications as piano light of one solar cell system are disclosed. The chemical vapor deposition chamber to form a solar cell system light condense therein. Thereby solar cell substrate of the first solar cell than can be relatively expensive lens by using the piano of the entire system can be. 1 also such as, according to the read and write seasonal solar altitude is moving substrate. In the case of our country, summer and winter solar elevation respectively a high degree of difference from the center 23. 5° are disclosed. Aspects of lens surface perpendicular to useful incoming light when a triangle can be created but, if the lens surface with the light obliquely incoming light cannot be effectively as well as if a triangle is equal to some extent also cannot use in solar cells. The solar cell system light in a triangle solar cells solar tracking device to effectively write is generally to 10sup16. Solar tracking device is capable of repairing maintenance must be accompanied however, limited number applied to a small building or the outside it picked area are disclosed. The light tracking device capable without been stationary solar light collection system inside. However such schemes which are a panorama is still low condensing rate are disclosed. The present invention refers to number provided which secures the door in order to solve the aforementioned point, the purpose of the invention is, number 1 consisting of a concave lens has a variable focal length lens; said number 1 focal distance of the lens disposed solar cell; said lens that is located between the solar cell said number 1 number 2 lens; a solar cell module including a bath as method number, seasonal picture of the incident angle of sunlight and secure a condensing efficiency despite changes a number or a reversed F. under public affairs number solar cell modules which bath method. In order to achieve the aforementioned purpose, the present invention according to the solar cell module number bath method, number 1 consisting of a concave lens has a variable focal length lens; said number 1 focal distance of the lens disposed solar cell; said lens that is located between the solar cell said number 1 number 2 lens; wherein, said number 2 lens, said number 1 lens is disposed to said surface of said solar cell is configured to deliver a solar cell having a plurality of descending operation of the right-angled prism watching a predetermined angles each other parallel to the lens are sequentially formed in the longitudinal direction of said solar cell panel configured to be force said number 1 lens, said light reaching said number 1 is a right-angled prism lens have upper surfaces as solar cell module number bath method, (A) said number 2 lens is set width of the upper surface of said right-angled prism steps; (B) said number 2 position of lens steps; and (C) each of said right-angled prism steps the size of angles; wherein, The width of the upper surface of said right-angled prism lens is set said number 2 steps, (-1) said number 2 lens having a plurality of longitudinal direction mutually become the same value reference is provided which involves splitting the reference width; (-2) said respective reference region (-1) apparatus and light incident on said incident angle of said reference values corresponding to the number of the distributed value reference dispersion reference dispersion value equal to the number of steps; The number of summed to both said reference dispersion value (-3) divides the reference derived reference average dispersion obtain; (-4) one end in the longitudinal direction of said number 2 lens light into one end in the longitudinal direction of said number 2 number of positive center incident light lens is divided into positive centers set region, the set region number n, n 1 n second elements at one end in the longitudinal direction into the central position of the second point between the point of second elements n the central position of the other end in the longitudinal direction between the point of location and n + 1 elements into the second elements, the set region number 1 number 2 to the area beneath the end of said number 2 lens longitudinal end; In the incident angle of incident light sequentially number m set region (-5) obtain a dispersion dispersion value settings; Said setting said reference average dispersion value (-6) compares a peak, said dispersion value setting said reference average dispersion value is summed with the summed iteratively summed background set region sequentially if it is less than the entire set region incident angle of incident light dispersion value sum distributed obtain; (-7) said dispersion value derived from the average dispersion value (-6) said sum to said summing section greater than said reference priority set region width of the upper surface of a right-angled prism steps; without using a tool. Preferably, the size of the angles of a right-angled prism each said steps, (C 1) each upper surface of a right-angled prism beam emitted a predetermined first to obtain the average incident angle of incidence; (C 2) selecting each reference a right-angled prism is incident, said each said reference incident light is (c 1) average derived from incident light incident angle closest chamber number step; (C 3) said incident said solar cell to be incident each said reference angle of angles of a right-angled prism [...] intrusiveness said determining; without using a tool. Preferably, said step of determining each of a right-angled prism angle of angles, (C 1) each upper surface of a right-angled prism beam emitted a predetermined first to obtain the average incident angle of incidence; (C 2) selecting each reference a right-angled prism is incident, said each said reference incident light is (c 1) average derived from incident light incident angle closest chamber number step; (C 3) at a front side of a right-angled prism incident said number 2 in the incident reference said total reflection at the descending operation of determining whether or not said reference; and (C 4) said total reflection at the incident of a right-angled prism said reference angle of said beveled of determining whether or not the descending operation of the right-angled prism; wherein, Said step (c 4), Reference incident of a right-angled prism does not totally in descending operation of the formula 1 by determining the angle of said beveled of a right-angled prism and, Said right-angled prism 2 formula if said total reflection at the incident of descending operation of the reference by said angle of angles of a right-angled prism determines. (Type 1) (Type 2) (H: the vertical distance between point number 2 lens refractive light solar L: refractive light at the horizontal distance between the center of number 2 lens solar θp : A right-angled prism of angles θIn : Incident angle of incident light incident on the upper surface of a right-angled prism reference n0 : Refractive index of the external environment np : Refractive index of lens number 2) Preferably, said step (c 3), Θ derived by said type 1p Which fit determined by formula 3 θPc Comparing, in the totally of descending operation of the judges whether or not the incident said reference right-angled prism, said θPc Θ >p When no inspection light is placed, θPc Θ <p When the number of passes is decides which inspection light, said step (c 4), θp Θ <Pc Using said angle of angles of a right-angled prism is filled in said type 1 determines, θp Θ >Pc In an area using said angle of angles of a right-angled prism determines said type 2. (Type 3) According to the present invention, aspects of an altitude is varied depending on the seasonal solar cell made optimal power production in spite condensing efficiency can be ensured. I.e., solar cell number 1 and number 2 lens and refractive lens the exercise collected solar cells, said number 2 to the fourth lens structure having a plurality of prisms solar elevation despite varying solar cell can be collected solar cell power power units are the solar cell. Figure 1 shows a surface representing the difference altitude according to seasonal also are disclosed. Figure 2 shows a indicating also the present invention according to the solar cell module are disclosed. Figure 3 shows a number 1 indicating also the present invention according to the lens of the solar cell module are disclosed. Figure 4 shows a number 1 of the solar cell module indicating the present invention according to the lens by refraction of sunlight also are disclosed. Figure 5 shows a number 1 of the solar cell module also indicating the present invention according to the lens by refraction of sunlight are disclosed. Figure 6 shows a lens of the solar cell module indicating the present invention according to the number 2 also are disclosed. The present invention according to the width of the prism lens 7 to 13 of the solar cell module also indicating drawing number 2 determining method are disclosed. The present invention according to the width of the prism of the lens of the solar cell module 14 to 16 also indicating drawing number 2 determining method are disclosed. Also the present invention according to Figure 17 shows a lens position variable indicating the number 2 of the solar cell module are disclosed. Also the present invention according to Figure 18 shows a of the solar cell module through a right-angled prism reference incident lights, indicating the trajectory of the incident light passing through in a right-angled prism refractive Conference 2 after reference are disclosed. Figure 19 shows a right-angled prism indicating also the present invention according to the trajectory of the incident light passing through the reference of the solar cell module are disclosed. Also the present invention according to Figure 20 shows a of the solar cell module through a right-angled prism reference incident lights, in a right-angled prism 2 1 total reflection of the incident light passing through the reference trajectory after refraction and Conference Conference indicating are disclosed. Figure 21 shows a the present invention according to incident light incident to the lens of the solar cell module indicating the reference number 2 also are disclosed. Figure 22 shows a the present invention according to incident light incident to the lens of the solar cell module indicating the reference number 2 also are disclosed. Hereinafter, with reference to the attached drawing, the present invention according to preferred embodiment is described as follows. The number in the embodiment but is intended tastes. Advantages and features of the present invention, achieve the appended drawing method and an electronic component connected to the reference surface with specifically carry activitycopyright will in the embodiment. However the present invention refers to hereinafter are limited to the disclosure in the embodiment in different but can be implemented in various forms, in the embodiment of the present invention disclosure to only the are completely, to complete the present invention of the invention is provided to a target number for informing a person with skill in the art categories in which ball, defined by category of the present invention refers to claim only disclosed. Throughout the specification the same references refer to the same components. The spatially relative terms "upper", "side" or the like is shown on the drawing as one member or components described hereinafter for correlation with another component or components can be used. Spatially relative term are shown in the drawing direction in use or operation in addition to the outer member including different terms should it will. For example, when a member [...] shown on the drawing, "vertical direction" is "the left-right direction" can be interpreted. The, exemplary terms include both the right and left direction can be a "vertical". Member even can be oriented in another direction, the film substrate can be interpreted according to spatially relative terms. The specification describes in the embodiment for the present invention the term used in which relayed a number that is even endured. In the specification, a plurality type comprises a unit in a single may be phrase will not specially mentioned. Used in specification "(comprises) comprising" and/or "including (comprising)" handle components, steps, operation and/or absence of at least one other component, step, operation and/or absence does not number the presence or addition times. In the absence of other definitions, all terms used in the specification is provided to the present invention (including the techniques and the treatment) is in common sense can be understood to a person with skill in the art to can be used are disclosed. It is apparent that a term generally used in a pre-defined are not specially defined is not ideally or overly interpreted. Each drawing members exaggerated or omitted for descriptive convenience and clarity magnitude or determine the is also shown. In addition each area size or area that reflect the number and size of the components entirely yarns are not correct. In addition, in the embodiment of the present invention in the course of the angle and direction is referred to disclosed is a drawing cache based on the other. In a specification description is given of a construction in the present invention, when the latter has not referred to the reference angle and positional relationship, reference diffuse to the related drawing. Also the present invention according to Figure 2 shows a solar cell (300) module (1) and indicating the drawing, Figure 3 the present invention according to solar cell (300) module (1) of number 1 lens (100) and indicating the drawing, Figure 4 the present invention according to solar cell (300) module (1) of number 1 lens (100) refraction of sunlight and indicating by drawing, Figure 5 the present invention according to solar cell (300) module (1) of number 1 lens (100) by indicating which of sunlight incident drawing, Figure 6 the present invention according to solar cell (300) module (1) of number 2 (200) lens 99900002 62999 indicating and drawing, 7 to 13 also the present invention according to the solar cell (300) module (1) of number 2 lens (200) of prisms (210) determining the width of the drawing indicating which method, 14 to 16 also the present invention according to the solar cell (300) module (1) of number 2 lens (200) of prisms (210) indicating and determining the width of the drawing method, Figure 17 the present invention according to solar cell (300) module (1) of number 2 lens (200) indicating the position of the variable are disclosed. The present invention according to solar cell (300) module (1) the number bath method, number 1 consisting of a concave lens has a variable focal length lens (100); said number 1 lens (100) disposed solar cells have a focal length (300); said solar cell (300) on said number 1 lens (100) that is located between the lens number 2 (200); wherein, said number 2 lens (200) is, said number 1 lens (100) through said light collected through the solar cell (300) is configured to deliver said solar cell (300) having a plurality of right-angled prism surface looking at predetermined angles (210) are sequentially formed in the longitudinal direction of each other parallel to the lens panel said number 1 lens (100) on said solar cell (300) configured to be force, said right-angled prism (210) is said number 1 lens (100) reached at a front top surface (212) having solar cell (300) module (1) to number bath method are disclosed. The present invention according to solar cell (300) the number bath method, said number 2 lens (200) is set said right-angled prism (210) on the top surface (212) width of the steps; each said right-angled prism (210) size of angles of the steps; and said number 2 lens (200) position of the steps; wherein, specifically said number 2 lens (200) is set said right-angled prism (210) on the top surface (212) the width of the steps, said number 2 lens (200) having a plurality of longitudinal direction mutually become the same value reference is provided which involves splitting the reference width; each base region of light incident on said incident angle reference dispersion [...][...] obtain; obtain a dispersion values from the average of said reference average dispersion; said number 2 lens (200) one end in the longitudinal direction of light into said number 2 number of positive center incident light lens (200) is divided into one end in the longitudinal direction of the positive centers set region, the set region number n, n 1 n second elements at one end in the longitudinal direction between the point of the central position of the second location and elements into second elements n n + 1 elements in the longitudinal direction between the point of the central position of the other end to the side of the second location and, the number 1 set region said number 2 lens (200) area between an end of the longitudinal direction of number 2; number m set region sequentially obtain incident angle of incident light dispersed in dispersion value settings; if it is less than said reference average dispersion value sequentially setting said dispersion value is summed with the summed iteratively summed background set region incident angle of incident light dispersion value sum dispersion value is found and the entire set region, said summed dispersion value greater than a reference average dispersion value priority set region said section to said right-angled prism (210) on the top surface (212) width of the steps; without using a tool. The reference 2 also, the present invention according to solar cell module number bath method by solar cell prepared by the number (300) is generally consisting of number 1 or a concave lens having a focal length lens (100); said number 1 lens (100) disposed solar cells have a focal length (300); said solar cell (300) on said number 1 lens (100) that is located between the lens number 2 (200); wherein, the, solar cell (300) in order on a predetermined lens 2 has the structure. Number 1 lens (100) to any scanned consists of a concave lens. Said number 1 lens (100) is scanned in any, simple non-concave lens, as shown in the drawing the top surface (212) which is configured as a planar lower surface such as in the form of a Fresnel lens consisting of a plurality of unevenness can be, not limited therein. The, number 1 lens (100) is symmetrical about a longitudinal center point has left along a longitudinal configuration. I.e., z direction into a slot 3 also shown in width direction, perpendicular x direction lengthwise thereof when the recording layer 2, is symmetrical about a longitudinally central longitudinal C1 can be left. Accordingly, said number 1 lens (100) is as shown in the drawing are made of a plurality of recessed point is formed on the lower surface width extending long in the directions of said plurality of generally parallel longitudinal direction thickness facial constituting a concave lens can be scanned. Such as said first to the fourth configuration, the present invention according to solar cell (300) module (1) of number 1 lens (100) includes a vibration may have configuration. I.e., also 3 as shown as rectangular lens, a concave surface on an lower surface, said concave surface such as uneven configuration for positioning the longitudinal direction is divided into a plurality, said batches that are symmetrical about a longitudinal center extending in the lateral direction thickness has a consists of. Solar cell (300) is said number 1 lens (100) is disposed on lower direction of said number 1 lens (100) focal distance of disposed thereon. Wherein, said surface means facing the direction referred to as unevenness it downward and, by the present invention solar cell (300) module (1) with the orientation of the can be interpreted. On the other hand, as shown in fig. 4, solar cell said number 1 lens (100) to the incidence, maximum of sunlight incidence at 23. And Wednesday 5, the number 1 the lens (100) can be etched undergoes total internal reflection occurs. This light condensing against loss since a, number 1 to prevent total internal reflection lens (100) to minimum can be scanned, number 1 corresponding focal length lens (100) of the width of 1. 9 bail be. Said focal length solar cell (300) to be coated is located. Said number 2 lens (200) includes said number 1 lens (100) on said solar cell (300) between to the lungs. Said number 2 lens (200) includes said number 1 lens (100) through the deflected light is incident upon the lens number 2 (200) bent again to said solar cell (300) configured to incident, the herein invention according to the solar cell (300) module (1) in number 1 lens (100), and number 2 lens (200) is equal to 2 times in 1 made made a total refractive [...] refractive Conference. I.e., amplifying the refracted solar 2 times (300) incident on the substrate. On the other hand, said number 1 lens (100) is the present invention according to solar cell (300) module (1) placed on top of the exercise, solar is first number 1 lens (100) is equal to incident. Said number 1 lens (100) is comprised of a concave lens by the lens said number 1 (100) through the predetermined angle of the refracted solar and spreading to be coated. The, said number 2 lens (200) is, said number 1 lens (100) on said solar cell (300) configured to be force, said number 1 lens (100) looking at a top surface (212) and, said solar cell (300) looking at the lower surface, said upper surface having a plurality of right-angled prism predetermined angles (210) are formed parallel to each other in the longitudinal direction of lens are sequentially formed in said number 1 lens (100) to a scattered light is collected through said light refracting said solar cell (300) that is configured to deliver a construction. I.e., as shown in fig. 6, said number 2 lens (200) is, flat plane top surface (212) and, a plurality of right-angled prism (210) structure by having the upper surface, number 1 lens (100) to said collected light delivered light impinged said solar cell (300) switch substrate. Wherein, each said right-angled prism (210) is said number 2 lens (200) on the top surface (212) a predetermined width is formed and a top face (212) and, said top surface (212) extending downward in a vertical right-angled surface (214), and said perpendicular surface (214) and said upper surface (212) a connection between the descending operation (216) has. In addition, said top surface (212) and said descending operation (216) between predetermined angles formed therein. The reference 2 also, the present invention according to solar cell (300) module (1) is, number 1 lens (100) width (W1), number 2 lens (200) width (W2), number 1 lens (100) on solar cell (300) (L1) distance between, and number 2 lens (200) on solar cell (300) (L2) of the distance between the design elements. In addition, the 6 also reference, specifically number 2 lens (200) includes a right-angled prism (210) on the top surface (212) width of (P), the size of the angles (θ) has a design element. In the present invention, number 1 lens (100) width (W1), number 2 lens (200) width (W2), number 1 lens (100) on solar cell (300) (L1) distance between a focusing effect through the remaining elements in the corresponding achieves. The contemplated overall form, number 1 lens (100) includes a concave lens type and, number 2 lens (200) is referred to as a convex lens type can be. Number 1 lens (100) number 2 a lens (200) is disposed on, number 2 lens (200) by deploying the piston incident to the light incident angle further variance of the object are disclosed. By seasonal number 1 lens (100) which is a maximum value of sun light incident angle difference 47° are disclosed. The, number 1 lens (100) number 2 through sun light incident on the lens is smaller than incident angles at which the maximum value is equal to the difference 47°. Number 2 lens (200) is incident solar cell (300) converge to a point for the purpose designed substrate. Number 2 lens (200) most of the right-angled prism constituting (210) is refracted by solar solar cell (300) to be incident on its compensated, in addition to the usually large refractive angle edge portion relationship is equal to use with total internal reflection. I.e., as above-mentioned said number 2 lens (200) includes said number 2 lens (200) collected light delivered said solar cell (300) accessories to the delivered, said number 2 lens (200) is set right-angled prism (210) a focusing effect that achieves the above construction. Specifically, said lens to a focusing effect can be achieved said number 2 (200) which the predetermined physical layer, said right-angled prism the physical layer (210) constituting a top surface (212) width of (P), and the size of the angles (θ) 2 of elements, and said number 2 lens (200) (L2) is equal to the position of total 3 consisting of design elements. the design variables, the present invention according to solar cell (300) module (1) comprises the following steps made according to its number is equal to oxide. I.e., according to the physical layer, said number 2 lens (200) is set said right-angled prism (210) on the top surface (212) width of the steps; each said right-angled prism (210) size of angles of the steps; and said number 2 lens (200) position of the steps; solar cell according to the present invention according to (300) module (1) number of oxide or combustion chamber. Said number 2 lens (200) is set said right-angled prism (210) on the top surface (212) to the width of the steps by the barrier metals such as disclosed. First, such as lens 7 also said number 2 (200) each other in the longitudinal direction having the same value reference width a plurality of reference is divided into a plurality of hierarchies. Wherein, optionally a multi-reference width as a predefined width at half maximum, considering conventional lens design limits about 0. 1 mm can be defined into and out. Accordingly, said number 2 lens (200) having a plurality of sections reference width longitudinal direction said randomly division as follows. The lens in the second segmentation said number 2 (200) having a predetermined width as makeup partitioning virtual sections, forms can be separate and the like do not. On the other hand, the multi-lens width wherein said number 2 (200) and the longitudinal direction of the motor vehicle is started, the number 2 the lens (200) includes a plurality extend in a longitudinal direction are arranged in parallel and equally above said virtual reference period is equal to the virtual reference section with reference width. On the other hand, the number 1 lens (100) bent in number 2 lens (200) incident ray tracing can be derived using predetermined trajectory of the incident light, the incident angle of incident light at an arbitrary position on any can be obtained. The angle of incidence of incident light can be utilized such as said substantially deriving. Then in dispersion of incident angle of light incident on said reference value reference dispersion value is found other. As above-mentioned said number 1 lens (100) through the refracted solar lens spreading said number 2 (200) on the top surface (212) which is incident, each fixing up an incident solar cell is equal to the reference. Number 1 lens (100) through the deflected by each lens with an angle of incidence of solar eml2 said number 2 (200) which is incident, the solar incident upon them with an angle of incidence is equal to the predetermined reference. The incident angle of sunlight that is incident upon respective reference step in dispersion value obtained is equal to respective reference regions of the reference dispersion values are derived. For example, as shown in the drawing, the reference number 1 (S1, S2, S3, S4) in (R1) 1 - 4 times referred to as solar incident solar once when, said number 1 (R1) in the reference number 1 - number 4 of sunlight incident angle dispersion value (S1, S2, S3, S4) once said number 1 (VE1) once the reference dispersion value derived through which solar, said number 2 (R2) to the reference number 2 in the reference (S5, S6, S7, S8) in 5 - 8 times referred to as solar incident solar once when, said number 2 (R2) to the reference number 2 at the incident angle of sunlight in dispersion value (S5, S6, S7, S8) once said number 5 (VE2) reference dispersion value derived through solar - number 5 to be coated. Then, said reference values from the average of average dispersion value (VT) 2042 obtain a reference dispersion. For example, said number 2 lens (200) of the segmentation step divided by the number of reference region when among N, N reference dispersion value is derived, said N reference dispersion value into said reference average dispersion value (VT) both easily and summed N the derived to be coated. On the other hand, the, as above-mentioned lens number 2 (200) includes a longitudinal symmetrical plates and the ejecting member extend in a longitudinal direction, said number 2 lens (200) longitudinal one end corresponding to said reference average dispersion value in addition deriving a positive center pivotably. Then, said number 2 lens (200) divided into a plurality of set region as follows. the set region, said number 2 lens (200) one end in the longitudinal direction of light into said number 2 number of positive center incident light lens (200) one end in the longitudinal direction of the positive centers one set region is detected, the number n set region, n 1 n second elements at one end in the longitudinal direction into the central position of the second point between the point of second elements n the central position of the other end in the longitudinal direction between the point of location and n + 1 elements into the second elements, said number 2 lens number 1 is set region (200) in an area between the longitudinal end of end system is number 2. Sequentially described, said set region in addition one virtual of an area, the above-mentioned reference said reference average dispersion values are derived and likewise to the virtual set region, said set region in addition set region in said reference average dispersion value a peak incident angle of incident light is provided for virtual area are disclosed. I.e., the diameter of said set region of such which are not used so provided, substantial number 2 lens (200) carry the first plate substantially a right-angled prism (210) on the top surface (212) above the determined width of hypermetropia. The number of said number 2 lens said set region (200) on the top surface (212) to be incident at an incident light equal disclosed. I.e., each said incident light lens based on said number 2 (200) by a plurality of dividing said number 2 lens (200) is the number of divided area setting to activate the incident light. The, as above-mentioned said number 2 lens (200) includes a longitudinally central symmetrical about the lens since said number 2 (200) one end in the longitudinal direction of light into said number 2 number of positive center incident light lens (200) one end in the longitudinal direction of a plurality of set region positive center was less than 1000. Wherein, number 2 lens (200) for receiving the upper end of number 1 set area setting region into a slot, then number 2, number 3. When that total number M M shape of the two settings to set region, the width of one of the second set region n number n set region is determined as follows. As well as, the incident light is incident upon a second area n number n set region are disclosed. The central position of the second location and n n 1 elements at one end in the longitudinal direction between the point of second elements into second elements n the central position of the other end in the longitudinal direction between the point system is second location and n + 1 elements. I.e., each incident light amount at the lower stage between a plurality of set region are disclosed. The, number 1 set region is said number 2 lens (200) in an area between the longitudinal end of end system is number 2. I.e., most side grade separate incident light incident light of the rotation on the front end, the number 2 number 1 set region most side grade said lens (200) at one end which are the ends of the longitudinal are disclosed. Said criteria the respective prescribed width having setting region said number 2 lens (200) to be coated segmented. I.e., as shown in fig. 8, each incident light (A1, A2, A3, A4.) set for each region (S1, S2, S3, S4.) set to be coated. Then, in the region of said each setting on the incident angle of incident light incident dispersion value from substrate. Here, water and to dispersion value referred to as the substrate. Said dispersion value derivation can set said number 2 lens (200) from the center of the lead the most side only of sequentially. Obtain a dispersion setting in at the earliest stages, one set region in the presence of only one incident light of the dispersion value is 0 an output reduced by disclosed. Then, compares said reference average dispersion value derived said setting a peak, said dispersion value setting said reference average dispersion value is summed with the summed iteratively summed background set region sequentially if it is less than the entire set region incident angle of incident light dispersion value sum distributed data so that the average dispersion correction said summed value with a reference dispersion sides of the substrate. The process lens said number 2 (200) from most side only of sequentially combustion chamber. I.e., also such as 9, number 1 set region (A1) setting within the dispersion value setting number 1 distributed data so that said reference average a peak after comparing, setting said number 1 dispersion value if it is less than said reference average dispersion value, (A1) and (A2) said number 1 set region sums up the new one set region number 2 set region equal to the summed area (B1) of the one set area and said number 1 set region and said number 2 in all incident angle of incident light that is incident upon said reference average dispersion value sum distributed data so that compares a peak. The dispersion value is obtained dispersion value in the region of incident light not summed summed summed all target dispersion value remains the same as the incident angle to each other. Then, if it is less than said reference average dispersion value setting said number 2 dispersion value sums up the set region (B1) that the new sum region additionally number 3 is set in a range from the new sum region (B1) setting number 1 number 3 plus unencoded set region all incident angle of incident light dispersion value sum dispersion value compares said reference average dispersion value. I.e., if it is less than average dispersion value summed dispersion value is further summed after ranking set region all relevant area compares a peak average reference dispersion in incident angle. Said sides of the plurality, said summed dispersion value is greater than the reference average dispersion value detouring said priority set region a right-angled prism (210) on the top surface (212) defined by the width of the substrate. I.e., also with reference to the SFC also 11 to 13, such as also 11, number 1 to number 4 (B1) dispersion value of a summed area sums the set region set region number 1 (V1) is less than said reference dispersion value (VT) when summed number 5 is summed with the new number 1 set region (B1 provided 1) further set region sets, a peak average dispersion value of said new number 1 set region (B1 provided 1) summed (VT) compares a reference. The, such as 12 also, the new sum dispersion value is greater than said reference average dispersion value (VT) when (V1 provided 1), such as 13 also, it is a line ranking number 1 to number 4 set region width one a right-angled prism to set region (210) the upper surface of (212) determines the width of the. I.e., B1=P1 (the width of a set region number 1 to number 4) (one a right-angled prism (210) width) I.e., said summed dispersion value larger than the value until said reference average dispersion which sums the set region, said summed dispersion value is greater than the reference average dispersion value one a right-angled prism detouring line ranking set region (210) on the top surface (212) determines the width of the. the one a right-angled prism (210) on the top surface (212) of width is determined. On the other hand, one a right-angled prism (210) on the top surface (212) of width is if it is determined that, from said queue set region sides of the substrate. I.e., e.g. number K - number L is summed one a right-angled prism is set region (210) on the top surface (212) if it is determined that the width of a length of a, then it is a ranking number L + 1 set region from said sides of the right-angled prism ranking (210) on the top surface (212) sequentially deriving a width are disclosed. Accordingly, the predetermined size of the turned in portions having various beam emitted when the angle of incidence of incident angle of incident light is essentially larger than the corresponding partial dispersion value is small vent holes width corresponding with a right-angled prism (210) which is provided with a plurality, another multi-beam emitted within a portion having relatively uniform when the angle of incidence of the incident light of the corresponding partial dispersion value is relatively large incident angle since having a right-angled prism width (210) to be coated provided. Repeating said process each right-angled prism (210) of width is number 2 lens (200) to one side and the center determined in each sequential, by use of a symmetrical lens same number 2 (200) constituting a right-angled prism (210) is equal to a width of design elements is determined. By said process, one a right-angled prism (210) formed a relatively uniform distribution incident angle of incident light bundle. I.e., each right-angled prism (210) beam emitted by having relatively similar angles of incidence for each bundle, each of the prism angles can be determined for thermally processing hereinafter. Then, each said right-angled prism (210) becomes a function of the size of the steps of angles such as disclosed. First, each right-angled prism (210) on the top surface (212) of incident light that is incident upon a predetermined first 2042 obtain average incident angle of incidence. Said process said average incidence at each determined through a right-angled prism (210) so that each said incident light having a predetermined first right-angled prism (210) number of number of derived. Then, each right-angled prism (210) reference incident light is defined in a substrate. Each said incident light is incident light as said reference average incident angle closest, i.e., said angle of incidence derived average number or string having the smallest chamber interposed angle incident light incident light of incident light incident into virtual reference number selected. Then, said reference incident said solar cell (300) to be incident [...] intrusiveness of each said right-angled prism (210) of said determined beam angles. Wherein, number 2 lens (200) on solar cell (300) a determination of the distance between, after setting up the various distance, each distance in the case of beveled to obtain a high intensity of the selected distance through calculated for most can be achieved. This calculation can be performed by predetermined computer or the like. 14 to 16 through a browser-compatible are as same reference also also. In accordance with said, each right-angled prism (210) pulse widths of the determined, sequentially P1, P2, P3 is equal to. Each right-angled prism (210) is equal to the incidence of the incident light. Each right-angled prism (210) average angle of incidence of incident light is obliquely incident on a top surface of each right-angled prism (210) with an angle of incidence average virtual, or string with incident light of SP is equal to a number. Wherein, each right-angled prism (210) P1, P2, P3 with an angle of incidence average each virtual incident light of SP1, SP2, SP3 has. Then, each right-angled prism (210) incident obliquely incident on said SP1, SP2, SP3 attachment to a smallest angle incident light determines reference to derive the incident light. The reference also 15, a right-angled prism (210) has been derived in reference S3 ST1 incident light incident light P1, P2, P3 each reference incident light then even ST2, ST3 been derived. Then, respective reference incident solar cell (300) to each incident at the center of right-angled prism (210) determines angles of. I.e., the angle of the both sidewalls of each variable refraction angles of incident light angles, said determined reference incident solar cell (300) each right-angled prism to be incident to the center portion (210) of determining angles are disclosed. As described above, each right-angled prism (210) in a relatively uniform beam emitted bundle has an optical dispersion value of incidence through only, each right-angled prism (210) for thermally processing of angle decision method of angles can be made hereinafter. The, reference incident solar cell (300) so as to reach the center of the right-angled prism wherein each (210) beam emitted relatively solar cell (300) can reach a long side to be coated. On the other hand, a right-angled prism (210) adjacent to the light emission surface, according to the angle of incidence of descending operation of the right-angled prism in total internal reflection can cause disclosed. I.e., a right-angled prism toward the inner surface of the housing exceeds a threshold within the descending operation of the incident angles at which undergoes total internal reflection, total internal reflection in this case take account of a right-angled prism (210) angle of angles of to determine other. For example, reference degrees below (b), (c), (d) such as, address signal only when the angle of incidence light in less total internal reflection when light refraction can react to form such as (d) taking into account the optical path in the form of beveled determines. I.e., when such as said, the refractive index of the prism beam when passing through the prism cause total internal reflection of the once and twice the angle substrate. <Reference also> Also the present invention according to Figure 18 shows a of the solar cell module through a right-angled prism reference incident lights, in a right-angled prism of the incident light passing through the reference trajectory after drawing indicating which refractive Conference 2, Figure 19 the present invention according to drawing of the incident light of the solar cell module through a right-angled prism reference trajectory and indicating, Figure 20 the present invention according to incident lights of the solar cell module through a right-angled prism reference, in a right-angled prism refraction and total reflection of the incident light passing through the reference trajectory drawing indicating Conference 1 2 Conference after which, the present invention according to incident light incident to the lens 21 and 22 of the solar cell module is also indicating the reference number 2 are disclosed. Also in 18 to 22 also hereinafter by referring to, upon determination of a hole of each angle of angles of a right-angled prism to explain. 1. 2 Conference for spot welding gun the concentrating region (A) said reference degrees such as 18 and also, made a right-angled prism refractive Conference 2 (210) with respect to the, right-angled prism (210) such as a determination of the angles of a method in accordance with the combustion chamber. Reference such as said incident light so as to reach the solar battery each right-angled prism (210) of the angle substrate. Such a right-angled prism (210) for determining the angle of incidence of incident light of a reference variable, number 2 lens (200) on the horizontal distance between the solar cell, and vertical distance, number 2 lens (200) refractive index, the refractive index and an external environment, b determined by the same formula 1 angle of the prism. (Type 1) Wherein, as shown in the variation also 19, H is number 2 lens refractive light (200) and through the vertical distance between solar point, light L is refracted and number 2 lens (200) through the solar point (300) the horizontal distance between the center of are disclosed. θp Angle of the prism which is, n0 The external environment and the refractive index, np The number 2 lens (200) is the index of refraction. Said value is as both constant, number 2 lens (200) on the upper, number 2 lens (200) of the distance between the solar cell on a given optical path determined by tracking the disapproval. Wherein, the value θ printingp Are disclosed. For derivation of the angle of the prism of the SFC by said type 1 principle such as disclosed. First, the relationship between such as refracted through the law of refraction rate for each [...] to be coated. The lens formula 1 - 1 number 2 (200) according to laws of right-angled prism is incident site for [...] quickly type 1 - 2 (210) located at each passing of descending operation of the [...] according to laws of dietary disclosed. n0 Sin θIn =np Sin θ1 (Type 1 - 1) np Sin θ2 =n0 Sin θOut (Type 1 - 2) Wherein, also 18 according to respective angle with reference surface, such as a relational expression is derived. (Type 1 - 3) θ2 =θP1 - Θ1 (Type 1 - 4) Each said type 1 - 2 evaporated on the same, to dietary derived. (Type 1 - 5) The, according to said type 1 - 1, n0 Sin θIn =np Sin θ1 Therefore, θ1 Present the disclosed. (Type 1 - 6) Type 1 - 6 of θ1 Said type 1 to type 1 - 5 is evaporated on the derived. Said such as, H, L, n0 , Np Since all given value, the same θ bp To be coated are derived. 2. Using total internal reflection light region (B) said reference pays 20 and also, (c), (d) such as, 2 times of total reflection surfaces this over with the refractive index of the group in relation to the area, a right-angled prism (210) such as a determination of the angles of a method in accordance with the combustion chamber. Reference such as said incident light so as to reach the solar battery each right-angled prism (210) of the data set angles to each other. Such a right-angled prism (210) determining angles of incidence of incident light reference variables, number 2 lens (200) on the horizontal distance between the solar cell, and vertical distance, number 2 lens (200) refractive index, the refractive index and an external environment, the same prism angle θ erased according to the formulap Is determined. (Type 2) Wherein, said each variable can efined described. I.e., H is number 2 lens refractive light (200) and through the vertical distance between solar point, light L is refracted and number 2 lens (200) through the horizontal distance between the point at which the solar cell are disclosed. On the other hand, number 2 to calibrate the light refractive lens (200) through the points are a right-angled prism (210) of descending operation rather than side with each other. θp Is a right-angled prism (210) and angles of, n0 The external environment and the refractive index, np The number 2 lens (200) is the index of refraction. 3. Total internal reflection of the profile Such as said, type 1 or type 2 by applying a right-angled prism (210) determines the size of the angles of. The, type 1 when subjected to the, right-angled prism (210) which undergoes total internal reflection does not occur in descending operation of when, if type 2 is applied, a right-angled prism (210) undergoes total internal reflection occurs in descending operation of are disclosed. 1 discriminates whether total internal reflection in a manner applying θ angles obtained byp On the critical angles θpc By comparing determines. I.e., θp Θ <Pc When the storing vessel undergoes total internal reflection type 1 is applying substrate. On the contrary, θp Θ >Pc Is generated by the type 2 undergoes total internal reflection when applying substrate. Wherein, θPc As a threshold angles, number 2 lens (200) reference number 2 incident on the incident lens (200) of refracted at the descending operation of the when, refraction angles 90° when the angles are disclosed. I.e., number 2 lens (200) of descending operation of the θ undergoes total in at the time of generatingp Can be called. The constant critical angles, right-angled prism than critical angles (210) if descending operation of the greater angles of undergoes total internal reflection in comparison, type 2 beveled according to determine the other. Wherein, θ is critical anglesPc Is determined according to the formula 3. (Type 3) Principle of derivation of said type 3 for the SFC such as disclosed. Type 1 is used as a critical angles θPc Determines a. Said leaves, a right-angled prism (210) in refraction angles of descending operation of the 90° when there is sin θOut =1 are disclosed. Type 1 exhibited type each sides of the sequentially established dietary for derivation of the process substrate. (Type 3 - 1) (Type 3 - 2) (Type 3 - 3) Wherein, Therefore, after same erased, the sequentially operation such as type 3 derived said to be coated. Said such as type 1 as they are applied, each applied with conventional pressure to the residual type 2, type 1 when subjected to the varied, such as 21 also, number 2 lens (200) when total internal reflection does not occur inside and, if the former is smaller incidence since relatively, number 2 lens (200) located in the central portion of the right-angled prism (210) can be referred to as (M). On the contrary, type 2 even when it is applied, such as 22 also, number 2 lens (200) which undergoes total internal reflection in the interior of the occurrs, since relatively when the angle of incidence, number 2 lens (200) edge of the right-angled prism positioned on one portion (210) can be referred to as (N). According to the present invention, vary in accordance with seasonal solar elevation in spite solar cell (300) secured a condensing efficiency of optimal power production can be made. I.e., solar cell number 1 lens (100) and number 2 lens (200) through the deflected by the solar cell (300) and the array, said number 2 lens (200) is a plurality of prisms (210) to the fourth solar elevation despite varying structure having a solar cell (300) the solar cell and collected solar cell (300) can be power power units are. In the preferred embodiment shown and described but for more, the present invention refers to the use of a specific in the embodiment above-mentioned correspondingly limited to, in the claims claim the subject matter of invention made without deviating from the invention various modifications if any person with skill in the art is provided to embodiment as well as in, these modified embodiment of the present invention are technical idea or will it will separately from the perspective must not. 1: solar cell module 100: number 1 lens 200: number 2 lens 210: a right-angled prism 212: top surface 214: perpendicular surface 216: descending operation of the 300: solar cell According to the present invention, a solar cell module manufacturing method comprises: a first lens made of a concave lens having a predetermined focus distance; a solar cell arranged in the focus distance of the first lens; and a second lens arranged between the solar cell and the first lens. In spite of a change of a season and a change of an incident angle of sunlight, the solar cell module manufacturing method obtains light collection efficiency. COPYRIGHT KIPO 2016 Number 1 consisting of a concave lens has a variable focal length lens; said number 1 focal distance of the lens disposed solar cell; said lens that is located between the solar cell said number 1 number 2 lens; wherein, said number 2 lens, said number 1 lens is disposed to said surface of said solar cell is configured to deliver a solar cell having a plurality of descending operation of the right-angled prism watching a predetermined angles each other parallel to the lens are sequentially formed in the longitudinal direction of said solar cell panel configured to be force said number 1 lens, said light reaching said number 1 is a right-angled prism lens have upper surfaces in solar cell module number bath method, (a) said number 2 lens is set width of the upper surface of said right-angled prism steps; (b) said number 2 position of lens steps; and (c) each of said right-angled prism steps the size of angles; wherein, the width of the upper surface of said alkylene [...] said number 2 is set right-angled prism steps, said number 2 (-1) lens having a plurality of longitudinal direction mutually become the same value is provided which involves splitting the reference width reference; (-2) said respective reference region (-1) apparatus and light incident on said incident angle of said reference values corresponding to the number of the distributed value reference dispersion reference dispersion value equal to the number of steps; the number of said reference dispersion value (-3) divides the summed to derive the reference both obtain a reference average dispersion; (-4) one end in the longitudinal direction of said number 2 lens light into one end in the longitudinal direction of said number 2 number of positive center incident light lens is divided into positive centers set region, the set region number n, n 1 n second elements at one end in the longitudinal direction into the central position of the second point between the point of second elements n the central position of the other end in the longitudinal direction between the point of location and n + 1 elements into the second elements, the set region number 1 number 2 to the area beneath the end of said number 2 lens longitudinal end; sequentially number m set region incident angle of incident light (-5) obtain a dispersed in dispersion value settings; (-6) said setting a peak average dispersion value to said reference, said dispersion value setting said reference average dispersion value is summed with the summed iteratively summed background set region sequentially if it is less than the entire set region obtain incident angle of incident light dispersion value sum dispersion; (-7) said dispersion value derived from the average dispersion value (-6) said sum to said summing section greater than said reference priority set region width of the upper surface of a right-angled prism steps; wherein, said step of determining each of a right-angled prism angle of angles, each upper surface of a right-angled prism (c 1) to obtain the average incident angle of beam emitted a predetermined first incidence 9990 001809999 (c 2) selecting each right-angled prism is incident reference, said each said reference incident light is (c 1) average derived from incident light incident angle closest chamber number step; (c 3) at a front side of a right-angled prism incident said number 2 in the incident reference said total reflection at the descending operation of determining whether or not said reference; and (c 4) said total reflection at the incident of a right-angled prism said reference angle of said beveled of determining whether or not the descending operation of the right-angled prism; wherein, said step (c 4), right-angled prism of descending operation of the formula 1 does not totally incident in said reference by said angle of angles of a right-angled prism determines, if said total reflection at the incident of descending operation of said right-angled prism reference formula 2 of a right-angled prism number method for determining the angle of angles by said solar cell module. (Type 1) (Type 2) (H: number 2 lens refractive light solar vertical distance between points L: the horizontal distance between the center of θ at the number 2 lens refractive light solarp : Θ angles of a right-angled prismIn : N incident angle of incident light incident on the upper surface of a right-angled prism reference0 : Refractive index n exterior environmentp : Refractive index of lens number 2) Back number Back number According to Claim 1, said step (c 3), θ determined by formula 3Pc On θ derived by said type 1p By comparing, in descending operation of the judges whether or not the incident of a right-angled prism is totally said reference, θPc Θ >p When no inspection light is placed, θPc Θ <p When the number of passes is decides which inspection light, said step (c 4), θPc Θ >p Using said angle of angles of a right-angled prism is filled in said type 1 determines, θPc Θ <p Said type 2 is for determining the angle of said beveled of a right-angled prism when using number solar cell modules which bath method. (Type 3)