METHOD FOR PRODUCING MATERIAL ALTERNATIVE TO SODIUM USING SEAWATER

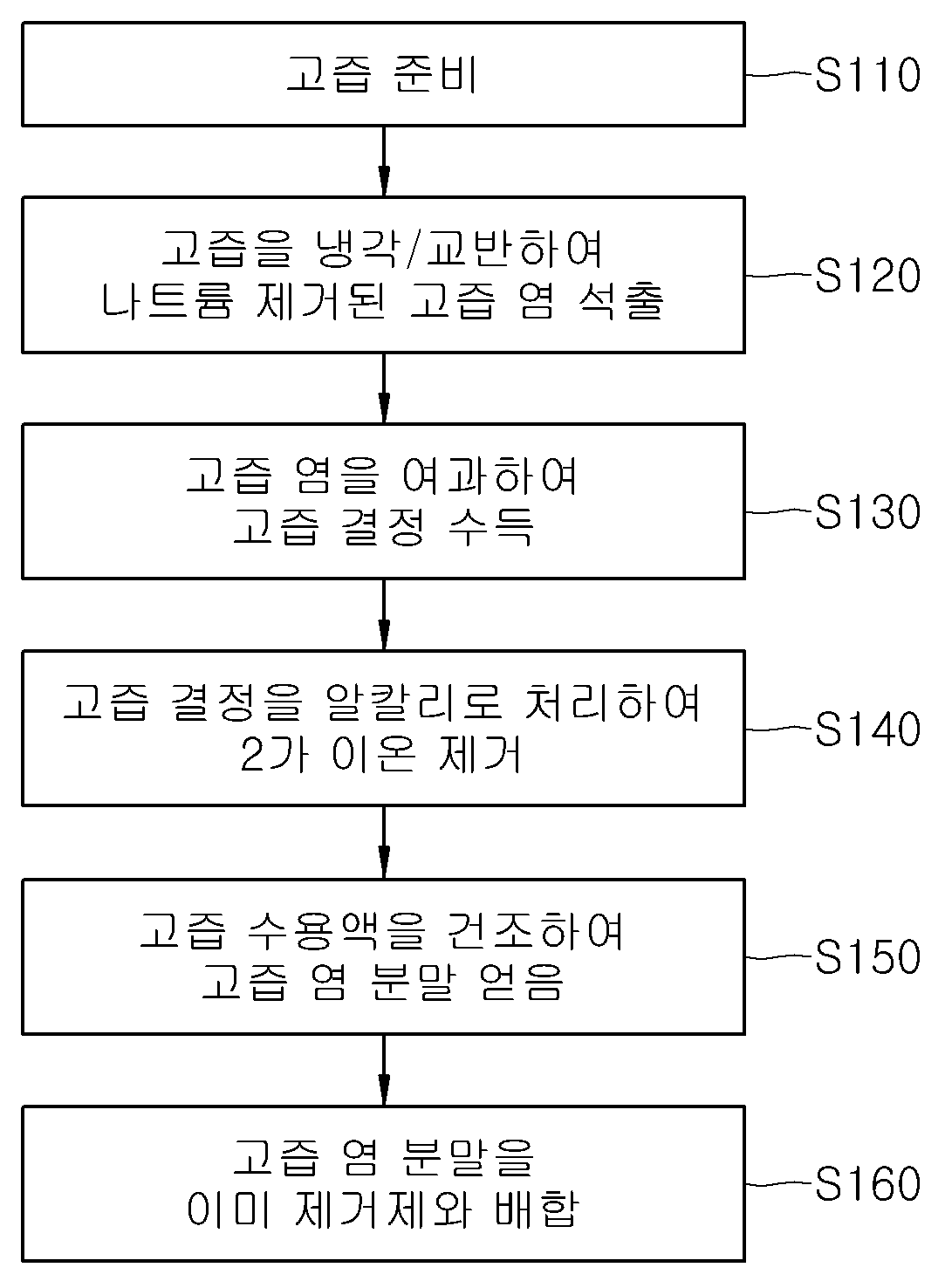

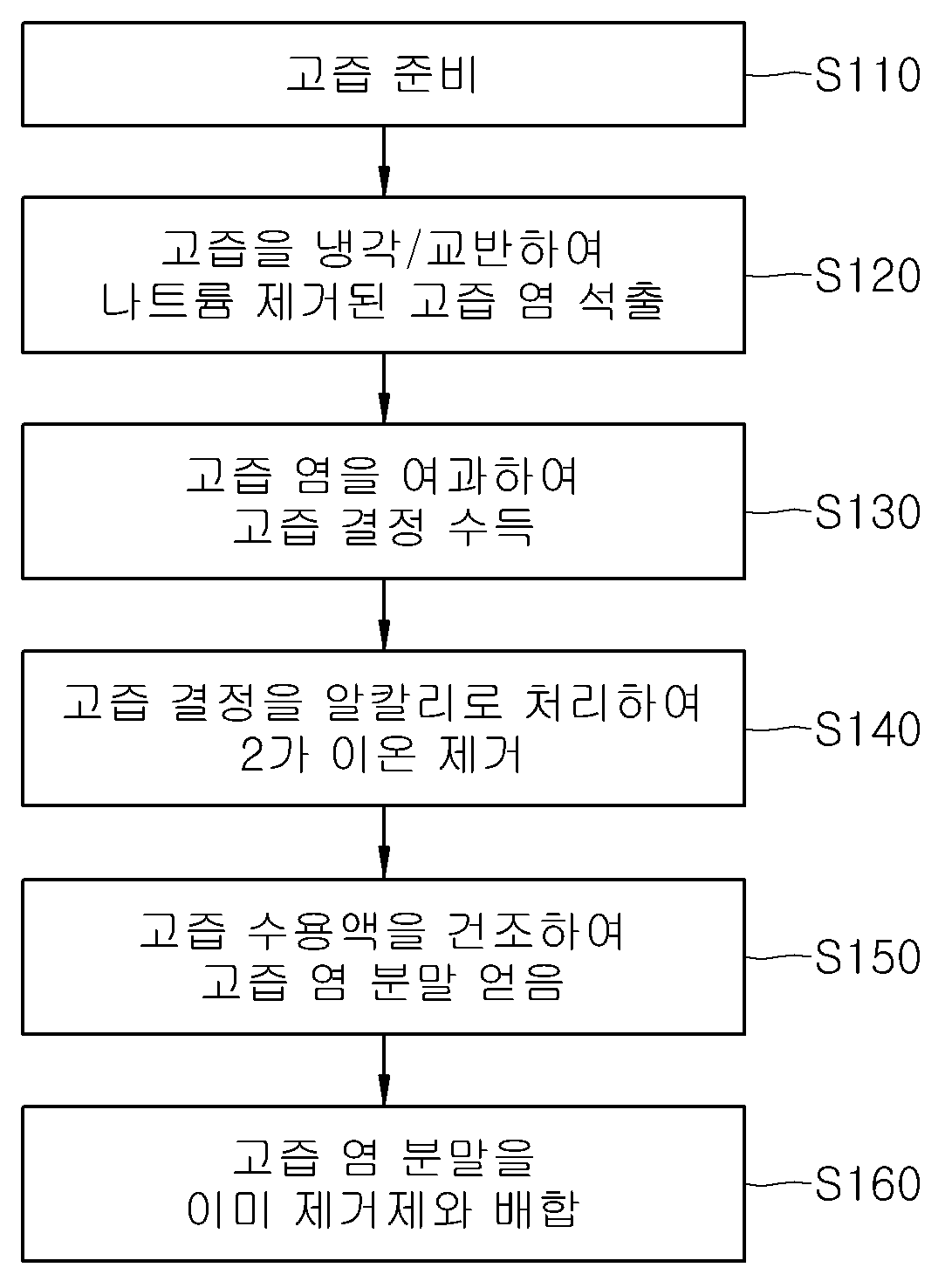

The present invention refers to a method relates to sodium replacement material tank number, positive number number components of the from a by-product salt from seawater salt america sodium replacement material exhibits a number bath to bath method are disclosed. Don't essential element and free to living salt, food does not simply sweet taste even perfume, sweetener, such as Jim left valuable material that influencing the overall taste. In addition salt meat - processing, bread or the like number adjusting properties to serve food flavor and safety even and calculating essentially replacement cannot be disclosed. However salt several serious side effects the excess intake results also other. Hypertension, stroke, cancer, heart disease through various cases since salt like sodium relation megakaryocyte [...] recognized health food etc. can give a low -. According to the world health mechanism (WHO) 2,000 mg sodium daily thereby preparing multimers, about 1 westerner. 5 Times and twice as large as 3,000 mg sodium intake, a 4,800 mg Korean intake can be 2 times are disclosed. The body and lid of-centered cause the largest recrystallized or, if further processed food such as also find out why in 2000. The station including sodium reduced permits etc. to the world. Since not only participates in which salt taste, but according to a different consideration of reducing sodium salt, sodium reduction scheme associated with the studies of expected into at food whose 2000. The majority of current research and developed or sodium salt america umami (umami, taste) on glass ([...]) sodium unique synergy effect mainly utilizes a yeast extract, nucleic acid or peptide current etc.. Recent flavor or amino acid salt america number using the turned on one cost contrast effect satisfactory levels for reinforcing the room was to etc. is not attained. The purpose of the invention can replace the sodium through the mirror number ring and a number that is a number [...] workpiece bath method are disclosed. It is another object of the present invention may have a similar flavor such as sodium sodium replacement material number that is a number [...] bath method are disclosed. The present invention refers to 5 to 30 °C [...] prepared [...] containing sodium component is cooled to precipitate salt and juice for reparing over said number, said juice juice for reparing over sodium salt precipitated salt by filtration determination number separated, said juice obtained by hydrolysis (wednesdays) separated juice determination processing said alkali aqueous solution is an aqueous solution containing aqueous solution to obtain a juice juice for reparing over cation number 2, juice for reparing over said 2 cation is sodium salt aqueous solution and drying the number 2 and number cation is sodium replacement material including a number M. juice for reparing over the salt bath a method number [...] substrate. Said juice for conducting potassium chloride salt powder is characterized. Selectively, M. juice after said salt, said salt powder obtained juice can be first crucible dietary number would already ([...]) number. The, said special number is already number central sodium, potassium central, gamma - polyglutamic acid (γ-a poly glutamic acid; PGA), L - glutamine organo sodium (monosodium glutamate; MSG) can be selected from the group consisting configuration and combination thereof. In an exemplary embodiment form, said alkali sodium carbonate, potassium carbonate, number 3 sodium phosphate, potassium phosphate number 3, sodium acetate, sodium hydroxide, potassium hydroxide and combinations thereof can be selected from the group consisting of. Other exemplary embodiment form, juice drying said aqueous solution includes vacuum drying, and hot air-dried, spray drying, freeze-drying and in either process can be performed by a combination of these. In another exemplary embodiment form, said aqueous solution can be used in drying excipient juice number. For example, number said excipient is starch, dextrin, gum (gum tragacanth) space [thu coating, hydrocolloids must gum (gum Karaya), hydration gum, gum arabic (gum Arabic), xanthan gum, gellan gum (gum gellan), process for photogrammetric gum (gum tamarind), southbound gum (gum tara), the nose it sells gum (gum copal) and combinations thereof can be selected from the group consisting of. In another exemplary embodiment form, said juice salt precipitation step, comprising 20 to 100 rpm stirring speed in performing time agitation can be 1 hr to 96. On the other hand, said alkali treatment by, said aqueous solution containing magnesium ion and calcium ion aqueous solution 1% hereinafter said juice juice remaining content can be adjusted contrast, 40 to 80% positive number salt bath sodium replacement material [...] finally number be a contrast level. In the present invention when positive number number of sodium component and utilizing high pressure liquid coolant remaining [...] salt, potassium salt as a material number 2 is a stand-alone number ions sodium guardrail replacement salt america number was a high pressure liquid coolant. Sodium by potassium chloride for reparing over already gone from sea water for reparing over of the present invention method number number number formed on the equal to or higher than the high pressure liquid coolant. High pressure liquid coolant recycling [...] occurs when the positive number number salt can be, incorporated into the etching processes is relatively mirror number [...] dry unit number and the durability, can be similar to sodium salt america and exert umami or the like. I.e., according to the present invention obtained by the number of 40 to 80% of the potassium chloride salt contrast level [...] sealer is coated powder valuable minerals. The present invention according to sodium replacement material utilized to foods, such as chlorinated sodium salt such as sodium chloride can be replaced be the potassium salt of potassium. The increased intake of potassium sodium intake during the outputs, according to health risk can be preventing excessive sodium intake on. In addition, sodium potassium intake balance is determined by the balanced mineral intake can be reduced. Figure 1 shows a number of the present invention exemplary embodiment also according to sea the sodium salt america [...] deformation created when a decoded signal determine the timing flow chart using a number tank replacement number are disclosed. In the embodiment according to Figure 2 of the present invention time precipitation of a crystal state when juice [...] according an exemplary photograph indicative of the state of precipitation are disclosed. Conventional, as a synergistic effect such that the exposure of cattle and horse using yeast extract sodium salt america and glass, nucleic acid, peptide has been used for increasing, it became to flavor or amino acid salt america using reinforcing the room number, cost and satisfactory contrast level me. The present invention high pressure liquid coolant occurs when the sealer is coated in the victims of the number number number 2 is a stand-alone such as sodium salt of potassium ions from juice officinalis salt by means of the present invention to the arrears of work. According to the present invention obtained by potassium chloride salt such as sodium chloride can be the major component of most similar taste, 70 to 80% of sodium chloride salt america generally potassium chloride as a complete replacement of a known sodium salt america cannot be stably transfers the case after reaction can be reinforcing. The product may maintain the nutritional intracellular osmotic equilibrium and moisture such as sodium antagonism is subjected to sodium and the resultant signal is alleviating diseases could be bonded each other. According to the result of dRis [potassium of metabolic and nutritional] study is designed in such a potassium intake, stroke, tubular alginate, osteoporosis, and diabetes improving, etc. is applied to 3,500 mg/day young people until the intake recommendation. This recommended intake that cooperates with numerical as sodium, sodium potassium equal molar ratio from 1:4 which consists in taking the most ideal because disclosed. Country sodium, potassium intake recommended amount even if heat but some difference, such as sodium of potassium intake extent at the same pitch is about 1:1. However, nutritive daily sodium intake level compared which average 4,800 mg, 3,445 mg daily potassium intake can be male, female 2,687 mg level recommended intake similar but, compared to sodium intake is relatively larger low levels are disclosed. Table 1 study for domestic ([...], 2007 - 2010 years National health nutrition irradiation columns of an adult Korean potassium intake status, 2014) reporting in a age, sex, revealing the average intake (mg/day) by seniority order potassium 1 are disclosed. The same terms as much as 3 times the steam taken in the event that the ratio of sodium potassium than has been reported. I.e., sodium nutritive too high levels and absolute intake, an unbalanced state of fundamental potassium intake can be serious with it. The optimal adjustment to eat such as sodium potassium balance needs, the present invention refers to a method number bath to potassium chloride sodium chloride [...] thing are disclosed. Hereinafter, the present invention added if necessary with reference to the detailed drawing of the SFC substrate. Figure 1 shows a method of the present invention exemplary embodiment also form a flow chart according to determine the timing number bath sodium replacement material are disclosed. As also shown in the 1, a method of the present invention is sodium replacement material number bath, sodium chloride (brine) (step S110) number for reparing over the steps of juice, juice prepared [...] sodium salt precipitation step (step S120) number for reparing over cooling and agitating component, determining (step S130) includes the step of separating juice filtration of the precipitated salt juice, separated juice (or juice determination processing with an aqueous alkaline solution) alkali treatment after hydrolysis (wednesdays) determination to step number (step S140) ions in an aqueous solution 2 is juice industry, juice (step S150) drying the aqueous solution to obtain a juice salt powder, and optionally on the number (step S160) blended juice salt powder already number comprise wetting ability. The steps of providing a positive number (step S110) [...][...] e.g. salt prepared in number for sea water evaporation and precipitation by high pressure liquid coolant can be employed for reparing over sodium chloride component number, [...] prepared and stored in a container or the like. Then, cooling and agitating prepared juice (step S120) decodes [...] sodium component number for reparing over salt precipitation. Sea salt or ion such as content is included in a constant ratio, evaporation and precipitation discharged [...] ion content and volatile sodium chloride through a number constant disclosed. In addition, solubility of the solubility temperature crystallization each ion compounds have associated [...] θ1. I.e., constant temperature and time conditions are the same juice when precipitation [...] precipitated crystal ion of fundamental. In particular, the temperature of the sodium chloride and potassium chloride containing salt components from among [...] s402. solubility (reference to table 2). The [...] shark's number for sodium chloride contained in a stand-alone, 5 to 30 °C [...], preferably 5 to 20 °C juice for reparing over sodium salt precipitation is cooled to a number can be disclosed. 30 °C [...] cooling temperature is exceeded, solubility in potassium chloride salt precipitation cannot be increased too much because of the potassium chloride, [...] is preferably carried out in the aforementioned cooling temperature range. In addition, determining number 20 to 100 rpm for separating juice juice for reparing over sodium salt component, preferably 40 to 60 rpm stirring rate 1 hr to 96 in time, preferably 24 hr to 72 and its use as agitating time juice can be disclosed. In the embodiment according to an exemplary of the present invention determining juice cation exchanger membrane associated with the stirring conditions, stirring time 1 time, preferably less than 24 it makes do, the [nu if a time in determining potassium chloride ion content of 2 precipitated juice content of low ratio of potassium chloride as a material increased too much sodium replacement ratio in output from other. Stirring time time 96, preferably 72 time is exceeded, the RF too long the potassium chloride precipitation amount comparing step data to an other (also reference 2). In addition, stirring speed is less than 20 rpm is constant uniform distribution of internal temperature juice in ion ratio there can be not precipitate, stirring speed is 100 rmp exceeds deposit crystals, even if the pin is re-dissolving [...] door number point can be separated. Subsequently, precipitated sodium salt by filtration (step S130) number for reparing over juice juice are isolated each other determination. Sodium number juice for reparing over crystal, one behind precipitation, filtration of the precipitated crystals can be separated. The filtration can be filtration equipment generally, concentrated juice supernatant and potassium chloride crystals are isolated each other. Then, separated juice 2 is a stand-alone number determination processing (step S140) S. juice crystals alkali ions. One exemplary embodiment form, juice can be hydrolysis (wednesdays) determination after alkali treatment, optionally treated juice determination may be filled with an aqueous alkaline solution. The metal ion salt precipitation reaction step which can be used, such as a compound, such as calcium or magnesium 2 monovalent cation is an alkali, for example sodium carbonate or magnesium carbonate have low solubility through the reaction between the calcium carbonate formed on the substrate. The sodium carbonate alkali treatment and filter such as the magnesium or calcium component 2 cation is selectively number can be a stand-alone. [Compound] As above an alkali processing method for separating a juice instead of 10 to 40% (w/v) aqueous solution and results in a precipitation determination by hydrolysis, preferably 20 to 30% (w/v) to an aqueous solution obtained by hydrolysis and 923 disclosed. Determining the concentration of the aqueous solutions of the potassium chloride content is below 10% (w/v) aqueous solution precipitation would deteriorate, alkali treatment is in an even number is 2 cation is that it becomes, volatile, door number number tank efficiency is lowered flow tides. While, determining the concentration of the aqueous solution precipitation (w/v) 40% is exceeded, positive number determination do not dissolve well in water and precipitation such as the number is equal to a upper surface of the base presence to alkali treatment. Alkali treatment used does not specifically defined alkali, e.g., sodium carbonate, potassium carbonate, number 3 sodium phosphate, potassium phosphate number 3, sodium acetate, sodium hydroxide, potassium hydroxide and combinations thereof can be selected from the group consisting of. The at least one 1 can be adjusted with an alkali, preferably sodium carbonate, sodium hydroxide and/or potassium hydroxide ions using a stand-alone number 2 is the now. A predetermined alkali aqueous solution used per 1 kg juice solids 0. 7 To 1. 4 Mole can be using. 0 Alkali solution. 7 Mole aqueous solutions after the end of the precipitation reaction is below 1% to greater than about 2 ion content of juice may be remaining ([...]) namely, 1. 4 Mole if it exceeds a, with theoretically all ions remaining number 2 is a stand-alone because positive amount of highly need free. Then, number 2 is ion salt powder (step S150) obtain juice juice for reparing over drying the aqueous solution. An aqueous solution for drying method are specially number not one juice, juice by reaction and drying the aqueous solution can be any method of employing powder. For example, an aqueous solution juice to dry vacuum drying, and hot air-dried, spray drying, freeze-drying and drying is either process by a combination of these can be. One exemplary embodiment form, juice alone when drying an aqueous solution, drying groups can be poor. Drying by finally wishes to obtain acrylic resin increases yield of potassium component such as potassium chloride, can be used for number excipient powder building improved physical properties. Excipients do not specifically defined number is, for example starch, dextrin, gum (gum tragacanth) space [thu coating, hydrocolloids must gum (gum Karaya), hydration gum, gum arabic (gum Arabic), xanthan gum, gellan gum (gum gellan), process for photogrammetric gum (gum tamarind), southbound gum (gum tara), the nose it sells gum (gum copal) and combinations thereof can be selected from the group consisting of. Preferably excipient number is dextrin, hydration gum, gum arabic and combinations thereof can be selected from the group consisting of. The amount of excipient number specifically but not limited, e.g. a predetermined 0 juice solids in the filtrate. 1 To 3. 5 Times can be added in an amount of preferably. Excipients filtrate amount of juice solids in the contrast number 0. 1 To less than when added, can be drying yield is lowered, the amount of filtrate juice solids in contrast excipient number 3. 5 Times greater than when added to, in too low content of potassium chloride, sodium inch utilizing a door number is allocated too much amount thereof can is to be used. In a drying step (step S160) through, but can be obtained powder sodium inch as potassium chloride, sodium component and an ionic component selectively the aforementioned process number 2 number number number previously mixing juice for reparing over salt powder can be a stand-alone would already ([...]) (step S160). Special number is already number specifically but not limited, a central sodium, potassium central, gamma - polyglutamic acid (γ-a poly glutamic acid; PGA), L - glutamine organo sodium (monosodium glutamate; MSG) can be selected from the group consisting configuration and combination thereof. One exemplary embodiment form, the wetting ability of the potassium chloride salt powder in weight of juice is already number number 0. 5 Amount to 2 times can be combined disclosed. The hypoglycemic agent blended amount of juice in a predetermined number of the potassium chloride salt powder already number 0. 5 When less than a stand-alone number which does not efficiently for removing bitter taste of potassium chloride, potassium chloride salt powder is blended amount of juice in 2 times a predetermined number would already number is exceeded, namely already in another can be generated. According to the process of the present invention finally obtained positive number 40 to 80% of potassium chloride salt contrast level final [...] sodium replacement material are disclosed. The sodium prepared by the number according to the present invention alternative material may be used alone, if necessary positive number can be created by mixing a salt utilized in that salt as sodium replacement material. Hereinafter, the present invention through an exemplary in the embodiment more detailed as follows. In the embodiment of the present invention is to for example only, and not the limited to a portion in which the present invention feature in the embodiment. [In the embodiment] In the embodiment 1: Sodium inch chloride potassium powder number bath Salt bath [...] for reparing over positive number number 1. Which can be 5 kg, 50 rpm while stirring and cooling the sodium component number 10 °C [...] stopped by precipitation time was 48 from a stand-alone. Found (filter paper) separating a low-temperature and precipitation supernatant mixture was determined. Separated aqueous solution heat treatment is performed after the high pressure liquid coolant 25% juice applied number number number determining 50g precipitation, sodium carbonate 0. 98 Mole theoretical residual ratio is so followed by ion 2 was 30%. Sodium carbonate precipitate was created that is 30 minutes after charging sufficiently agitating after filtering. Filtrate 1 times a predetermined solids filtrate dextrin, hydration gum 0. 1 Times, gum arabic 0. 1 Times the weight ratio which can, spray dryer using the fan 170 °C (Spray Dryer), stored in the [...] 110 °C to dry powder. The enhanced content of about 40% of the potassium chloride ratio since a building, building a central 40% by weight of sodium salt powder put in the juice sum never stood the arrears of work. In the embodiment 2 To 5: precipitation temperature and time according to potassium chloride powder number bath Table 3 to a precipitation temperature, time and stirring speed and least one number [...] juice salt precipitation, the same method as in the embodiment 1 inch of sodium potassium chloride powder was number procedures performed high pressure liquid coolant. In the embodiment 7 To 9: alkali treatment amount according to potassium chloride powder number bath 25% Aqueous solution by hydrolysis and precipitation [...] number high pressure liquid coolant, shown in table 4 that a dose of sodium carbonate using the procedures performed in the embodiment 1 and the same number [...] alkali treatment method of sodium potassium chloride powder was number inch as high pressure liquid coolant. Comparison example 1: On sale sodium inch Sodium inch as, a cooling fan and a validator in server participant (number per one number is (main) c number) was prepared. Comparison example 2: Potassium chloride powder number bath not alkali treatment 25% Aqueous solution by hydrolysis and precipitation determination number high pressure liquid coolant, sodium carbonate is not alkali treatment using a number [...] said in the embodiment 1 and the same procedures as potassium chloride powder was performed method number sodium inch high pressure liquid coolant. 2 Theoretical residual ratio is 100% ion are disclosed. Experiment example 1:Precipitation temperature and time according to ion content comparison Said in the embodiment 1 in the embodiment 2 to 5 in number prepared by the precipitation in determination ion content in determining and precipitation prepared by the number to screen, shown in table 5 for the result. In the embodiment 1 to 5 in order to compare a alkali treatment process according to ion content of temperature and time is before ion analyzing his products. Said as shown in table 5, in the embodiment 1 of potassium (K) and chlorine (Cl) high ratio of ionic content, low ion content of 2 ratio showing a lack crucial critically tune, the great difference in the embodiment 2 to 6 in the embodiment 1 of box may range can be molecules because they are not desired. But, in the embodiment 2 of potassium (K) and chlorine (Cl) and to show differences in the ion content in the embodiment 1, aggregates are expected precipitation in a short time. Experiment example 2:Alkali The amount processing The 2 Number of special ion Each number in the embodiment 6 to 8 said in the embodiment 1 and 25% hydrolyzed polyvinyl alcohols and aqueous solution an aqueous solution prepared by the precipitation determination when the ion content of the alkali treatment, the result shown to table 6. Said as shown in table 6, the results of potassium (K) in the embodiment 1, 7, 8, 9 have no components but large difference ratio of ionic content, namely in particular in the embodiment 1 and 2 in the embodiment 9 already contained in ion content of 1% in a preferable result has been reduced due the ratio within range. However 2 ion content of nearly 1% ratio meets the user feels the alkali processing except the embodiment namely because it does not need not necessarily be occur no matter what can be. Experiment example 3. Juice Number of base salts salt powder [...] Functional evaluation comparison In juice prepared by the number said in the embodiment 1 positive number salt and salt powder, juice prepared by the number in comparison example 2 salt powder, a validator of salt america and removing bitter taste functional evaluation value of the fan have, for table 7 shown to result. 50% Sodium chloride in addition to constituting the number article number article includes a validator fan since potassium chloride, sodium chloride 50% juice salt powder of the present invention was assessed by mixing together. Said as shown in table 7, in the embodiment 1 inch has a positive number obtained sodium salt salt america compared to same or transmission option. In the embodiment 1 has a positive number for removing bitter taste of slightly increased but inch sodium salts, namely sodium inch as compared to embodiments of comparison has been confirmed that the state has been deteriorated. In the embodiment of the present invention in an exemplary embodiment the present invention based on said type and are described but, the present invention is not limited to said embodiment forms and in the embodiment has a feature. Rather the present invention if the aforementioned embodiment forms and in the embodiment is provided to various deformation in person with skill in the art based on weight change and hereinafter for the can. However, the range of the present invention such distortion and change is the fact that both rights through portals claim special disclosed. The present invention relates to a method for producing a material as an alternative to sodium from which divalent salt is removed through alkali treatment onto crystals from which sodium is removed from extract (bittern). According to the present invention, it is possible to apply the extract which is by-product produced during production of refined salt, and also to produce the alternate material having similar taste as sodium in a cost-effective way. In addition, various diseases caused by intake of excessive amount of sodium can be prevented as well. COPYRIGHT KIPO 2017 5 To 30 °C [...] prepared [...] containing sodium component is cooled to said juice for reparing over salt precipitation step number; filtering said juice salt precipitated sodium salt number determining step of separating juice for reparing over; said juice obtained by hydrolysis (wednesdays) separated juice determination processing said alkali aqueous solution is an aqueous solution containing juice 2 cation number obtaining juice for reparing over aqueous solution; and said 2 cation is sodium salt aqueous solution and drying the number 2 and number juice for reparing over cation is sodium replacement material including a number M. juice for reparing over the salt bath method. According to Claim 1, characterized in that said potassium chloride salt powder is juice powder sodium replacement material a number bath method. According to Claim 1, M. juice after said salt, said salt powder obtained juice already number dietary first crucible including a sodium replacement material number bath method number being resized. According to Claim 3, said special number is already number central sodium, potassium central, gamma - polyglutamic acid (γ-a poly glutamic acid; PGA), L - glutamine organo sodium (monosodium glutamate; MSG) and combination of a number bath method selected from the group consisting sodium replacement material. According to one of Claim 1 to Claim 3, said alkali sodium carbonate, potassium carbonate, number 3 sodium phosphate, potassium phosphate number 3, sodium acetate, sodium hydroxide, potassium hydroxide and combinations thereof selected from the group consisting sodium replacement material number consisting of a bath method. According to one of Claim 1 to Claim 3, juice drying said aqueous solution includes vacuum drying, and hot air-dried, spray drying, freeze-drying and these combination of a method performed by the process of either sodium replacement material number tank. According to one of Claim 1 to Claim 3, an aqueous solution of sodium replacement material in said juice drying excipient number is a number bath method. According to Claim 7, number said excipient is starch, dextrin, gum (gum tragacanth) space [thu coating, hydrocolloids must gum (gum Karaya), hydration gum, gum arabic (gum Arabic), xanthan gum, gellan gum (gum gellan), process for photogrammetric gum (gum tamarind), southbound gum (gum tara), the nose it sells gum (gum copal) and combination of a number bath method selected from the group consisting sodium replacement material. According to one of Claim 1 to Claim 3, said juice salt precipitation step, stirring speed 20 to 100 rpm agitation time 1 hr to 96 in performing a method number bath including sodium replacement material. According to one of Claim 1 to Claim 3, by alkali treatment move, said aqueous solution containing magnesium ion and calcium ion juice remaining content adjusted aqueous solution sodium replacement material in said juice 1% hereinafter contrast number bath method. In the embodiment Temperature (°C) Time (h) [...] (rpm) In the embodiment 2 5 1 50 In the embodiment 3 20 48 50 In the embodiment 4 22. 5 48 50 In the embodiment 5 25 48 50 In the embodiment 6 30 72 50 Determining dose (g) juice Sodium carbonate dose (mol) 2 Ion theory residual ratio In the embodiment 7 50 0. 42 70. 00% In the embodiment 8 50 0. 7 50. 00% In the embodiment 9 50 1. 4 0. 00% Na (%) K (%) Cl (%) Mg (%) Ca (%) In the embodiment 1 0. 67 47. 77 49. 20 1. 22 1. 59 In the embodiment 2 0. 64 36. 19 37. 15 1. 22 1. 60 In the embodiment 3 0. 58 46. 68 46. 10 1. 36 1. 64 In the embodiment 4 0. 55 47. 23 45. 40 1. 50 1. 68 In the embodiment 5 0. 46 45. 29 45. 60 1. 73 1. 61 In the embodiment 6 0. 37 46. 94 45. 80 1. 91 1. 70 K (%) Mg (%) Ca (%) In the embodiment 1 46. 32% 0. 65% 0. 04% Comparison example 2 45. 20% 1. 89% 1. 11% In the embodiment 7 44. 21% 1. 50% 0. 29% In the embodiment 8 44. 48% 1. 07% 0. 10% In the embodiment 9 42. 64% 0. 17% 0. 01% Salt america A bittering Positive number salt ●● - Comparison example 1 ●●● ●◐ Comparison example 2 ●●● ●●● In the embodiment 1 ●●● ●