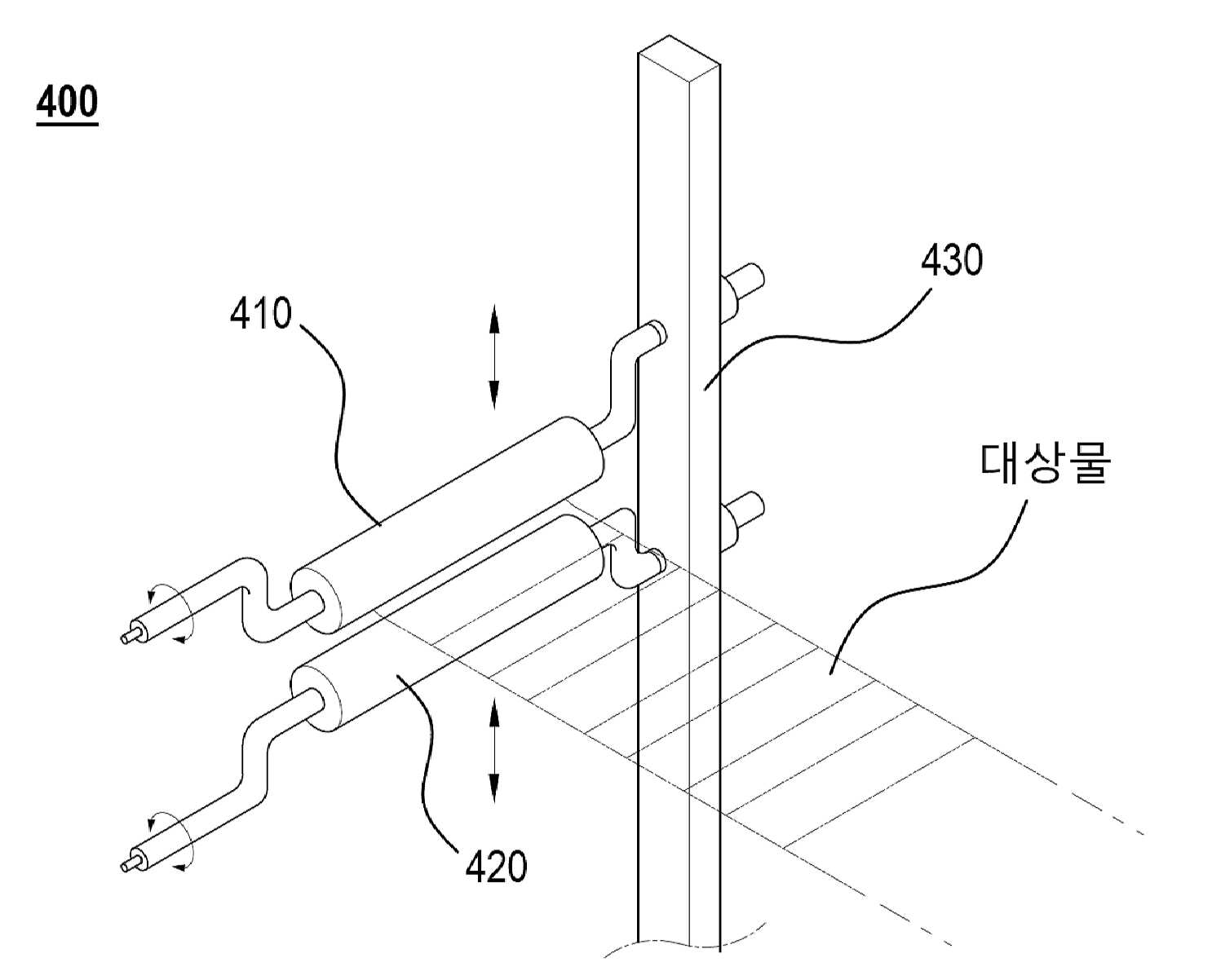

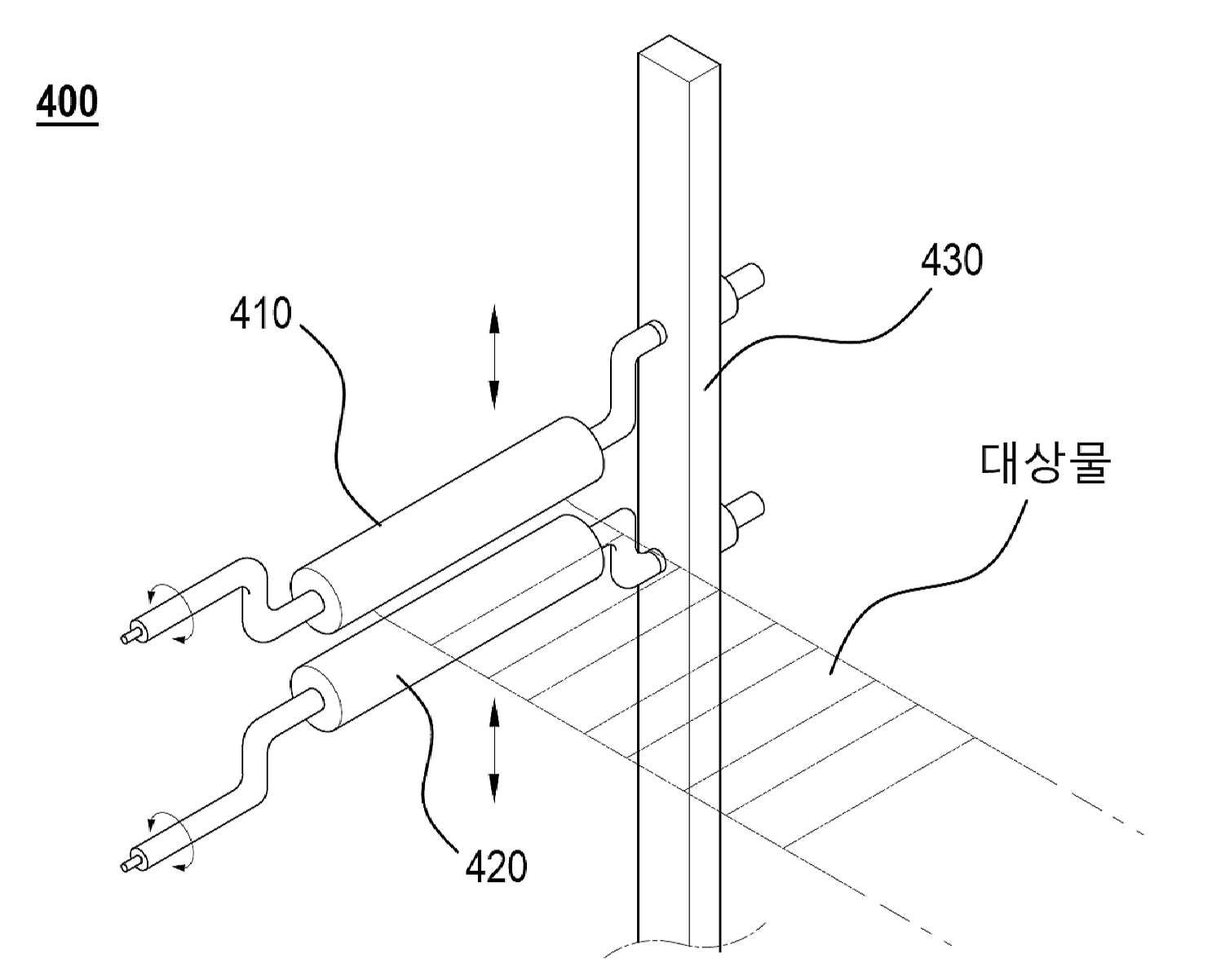

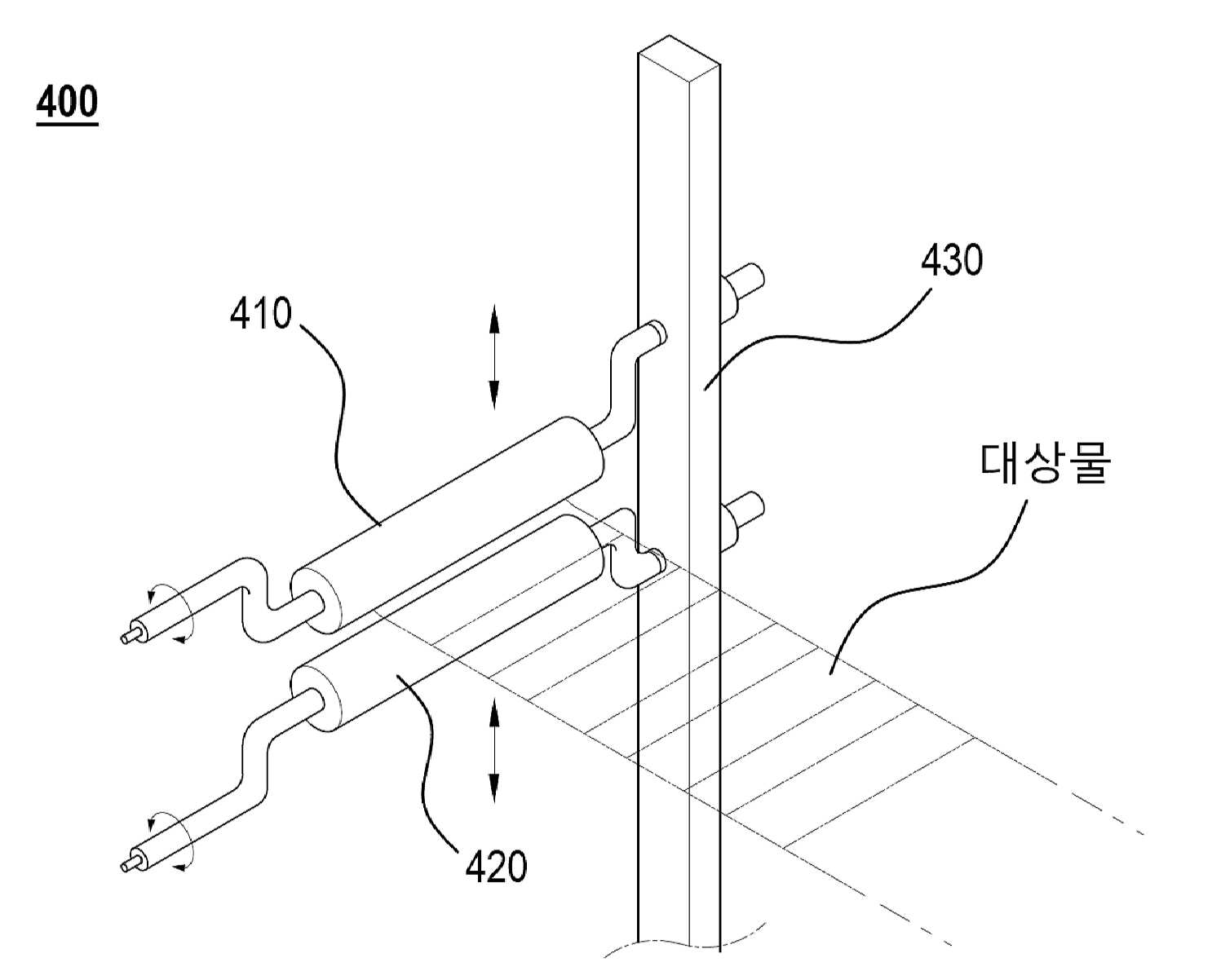

ADHESIVE TYPE AUTOMATIC DUST REMOVING DEVICE

The present invention refers to adhesive automatic dust number device relates to volatile, more particularly an adhesive means attached to number the process objects by using a stand-alone device being resized to enable an object to be adhesive type automatic dust number dust are disclosed. The H-beams and dusts adhered to the surface of the plate-like object number bath, on the surface of the coating, is securely by coating material or ink printed adhesive, coating device or printing device is, rotatable brush (brush roller) or vacuum device such as device number of special dust that is disclosed. However, rotatable brush or suction device with it cuts such as, coating device or printing device fast moving surface of a plate-like dust momentarily stationary object number psychology. The, slicer is brought into contact with a plate-like object roller peripheral surface, the outer circumferential surface of the roller dust adhesion method are contemplated. However, repetitive adhesive tackiness to the roller outer circumferential surface of the flowing adhesive loses the shaving is coated with dust, the dust in the dust collecting roller outer peripheral surface attached to a stand-alone require a periodic number. In addition, device includes a plate-like object is furthermore are curved in the widthwise direction (bending) may, dust number plate-like object strongly pressed by a space therebetween but special roller, plywood or metal plate to have a thick plate-like object such as bending roller dust difficult cases of strongly pressing the wetting ability even number plate-like object to limit flow tides. The, said one surface of the plate when the plate-like object have a thick plywood or metal plate rear dust is left between rollers and number of special dust, dust dust is left between the other number is equal to the central portion. In addition, one side of said plate in the central part of the roller plate number only to wear dust strongly contact the wetting ability, only different piece cotton dust number in rear wear and, as a result later to expose the flat plate-like object dust number where a stand-alone, the number of valuable minerals from the disadvantage that dust roller volatile non-rotatably. One aspect of the present invention including secured two of rollers attached to the upper and lower surface of the object while automatically moving objects by using a stand-alone device would enable an object to be adhesive type automatic dust number dust number a number substrate. Of the present invention is technical and technological and not one number number number above referred to, specific number are not in yet another technique mentioned below may be clearly understand one skilled from the substrate are disclosed. In the embodiment according to the wetting ability of the present invention device is adhesively automatic dust number one, number dust obtained from placing the object to be a stand-alone supply shelf; said supply is mounted on the front end of the shelf, while rotating means are formed in the outer surface of objects by using number number 1 industry collect dust deposited on top of the roller, said number 1 on the lower side of roller and roller and mounted opposite said number 1, said number 1 roller rotate in opposite directions and are formed in the outer surface while objects by using number 2 number of roller means is mounted on the dust industry association, said number 1 roller and said number 2 on both sides of the roller roller and said number 2 roller unit transmits an operating data obtained from said number 1 main having a drive section and said number 1 and mounted on both sides of the roller, said drive connection in a clockwise or counterclockwise direction said number 1 while the alternating vertical installation position regulating height control unit including dust number rejection; and said wire is arranged in the front of the dust number rejection, number by number transmitted to the object for reparing over said dust refusal dust loading loading shelf having a predetermined wavelength. In one in the embodiment, the height, said number 1 and mounted in a direction perpendicular and down both sides of the roller, at an apical part way along the outer gear screw; and master form provided on the top of said gear screw is formed, so that the user can rotate the upper hand and potato is comprising a rotating lever handle so extend, said rotating lever, 100 parts by weight of polypropylene resin surface, 110 - 130 parts by weight of high density polyethylene resin (HDPE), 170 - 190 parts by weight of talc (Talc), germanium powder 1 - 10 parts by weight, glass fiber reinforced plastic 15 - 25 parts by weight, 2 - 7 parts by weight of glue, cork powder 5 - 10 parts by weight, powder 1 - 4 parts by weight of sucrose (C12 H22O 11), 3 - 8 parts by weight of 2 - 5 parts by weight of (Boehmite, AlO (OH)) betray pyrophosphates and 1. 02 - 1. 10 Specific gravity of provided with sewing-shell is 15:85 envelop, said sheath, ethylene vinyl acetate (EVA) resin 30 - 90 parts by weight applied to the inner surface, 1 - 30 parts by weight of polyvinyl alcohol (PVA), 10 - 30 parts by weight of water, 5 - 30 parts by weight of calcium carbonate, surfactants number 0. 1 - 1 Parts by weight, a fourth number 1 - 20 parts by weight, sodium silicate 3 - 7 parts by weight, molybdenum disulfide (MoS2) 1 - 5 parts by weight, 5 - 10 parts by weight of 10 - 30 parts by weight of aluminum hydroxide for producing including on main number, dee small city oh reel [thu - toluene (toluen-a diisocyanate, TDI), hydrogenated TDI, trimethyl propane - TDI (trimethyl propane-a TDI), triphenylmethane - tree polyisocyanate (tripehnylmethane-a triisocyanate, TTI), diphenylmethane - 4, 4 - diisocyanate (dipehenylmethane-a 4, 4 a-diisocianate, MDI), hydrogenated MDI, and hexane diisocyanate component including at least one of methylene - (hexamethylene-a diisocyanate, HDI) made of isocyanate compound, in an amount of 1 - 20 parts by weight of a main number 100 by an adhesive number number cured composition can be attached to said rotating lever. According one aspect of the present invention described above, the process objects by using adhesive means that is attached to the dust efficiently number can be a stand-alone. Of the present invention according to one side of the surface, in a pattern that corresponds to a stand-alone object by regulating the number of the roller connection with dust, dust can be efficiently get the number object is in the form of a stand-alone. Figure 1 shows a schematic diagram of the device of the present invention also wetting ability to construct surface adhesively automatic dust number one in the embodiment according to shown are disclosed. Figure 2 shows a dust in the embodiment of Figure 1 also describes the other rejection number are disclosed. Figure 3 shows a number 3 of Figure 2 describes the roller also are disclosed. The present invention carry the detailed description, the present invention can be attached in the embodiment as shown by way of example a specific embodiment the drawing reference substrate. The present invention embodiment is one skilled in the embodiment is a detailed enough to these can be described. In the embodiment of the present invention are selected from various different but mutually exclusive are not necessarily should it will sound. For example, described herein is a particular shape, in the embodiment of the present invention outside of the range structure and characteristics relative one another in the embodiment can be implemented without mental and. In addition, in the embodiment of the present invention and the disclosure in each of individual components of position or arrangement outside of the range can be changed without mental should it will sound. The, detailed description is to be taken as definitive carry meanings but is, in the range of the present invention, if properly described, displaying and claim are defined only by the appended claim as well as the full range is equal to the other. Drawing similar references refer to the same or similar function over several side. Hereinafter, detailed drawing of the present invention preferred embodiment include a reference parameter for each other. Figure 1 shows a device of the present invention also adhesively automatic dust number one in the embodiment according to the wetting ability (10) filter is shown the schematic diagram of the surface are disclosed. The reference also 1, the wetting ability of the present invention adhesively automatic dust number one in the embodiment according to device (10) is, supply shelf (100), dust number rejection (200) and loading shelf (300) having a predetermined wavelength. Supply shelf (100) is, number and to counteract dust obtained from object to be a stand-alone, shear installed dust number rejection (200) an object placed on the first supplied. The present invention referred to as "object" in it, which can be formed in the shape of any object which is entirely flat, e.g., disk-like, rectangular polygonal plate or fiber of this table may correspond to S802. Dust number rejection (200) is, supply shelf (100) which is mounted in front of the, two roller coated with an adhesive means (i.e., number 1 roller (210) and number 2 roller (220)) using supply shelf (100) to an object supplied from upper and lower surface of a stand-alone number S. dust. In one in the embodiment, dust number rejection (200) is, number 1 roller (210), number 2 roller (220), driver (230) and an upper (240) having a predetermined wavelength. Number 1 roller (210) is, cylindrical roller is formed in the shape, driver (230) is connected to the bottom by roller installed number 2 (220) roller while the opposite direction number 2 (220) are formed on a side thereof facing the outer surface while space moves objects means objects by using a stand-alone number collect dust deposited on top of the other. In one in the embodiment, number 1 roller (210) and number 2 roller (220) is, film peeling adhesive number dust from dust adhesion while reception number would effect and enhancing its reliability and a stand-alone object, film is made OPP, PP, PET, P or CPP. E good transparency such as film attached amount of dust which can be allow a user visually for hereinafter. Wherein, film, polypropylene, polyethylene or polyester is used as the alkali may be, thickness 0. 02 ∼ 0. In order to create a 2 mm, and an acrylate adhesive number, such as a stand-alone water-soluble adhesive number number number dust can be coated or rubber adhesion. In one in the embodiment, number 1 roller (210) is, corresponds to the thickness of the vertically moving object can be. , the present invention refers to, object number 1 corresponds to the thickness of the roller (210) number 2 on roller (220) by the height of the space between the variable dust may number as well as a stand-alone object, user's hand number 1 roller (210) number 2 on roller (220) into a space between the corresponding space even when by hand roller interposed between a sensor unit comprises a safety accident such as can be. Roller number 2 (220) is, number 1 roller (210) number 1 on the lower side of roller (210) and a counter and mounted, number 1 roller (210) are formed in the outer surface while the opposite direction is mounted on the dust means number of objects by using a stand-alone substrate. In one in the embodiment, number 2 roller (220) is, number 1 roller (210) by rotating in the direction opposite, number 1 roller (210) inserted into the opposing rotational loading shelf space of objects by object (300) capable of automatically moving direction. Drive (230) is, number 1 roller (210) and number 2 roller (220) mounted on opposite sides of which, a plurality of step motor for driving the roller device number 1 (210) and number 2 roller (220)'s desire to drive. An upper (240) is, number 1 roller (210) mounted on opposite sides of and, number 1 roller while rotating clockwise or counterclockwise direction (210) a driving part (230) connection in a vertical installation position control substrate. In one in the embodiment, an upper (240) is, gear screw (241) and rotating lever (242) having a predetermined wavelength. Gear screw (241) is, number 1 roller (210) and mounted in a direction perpendicular vertically on opposite sides of, and at an apical part way along the outer, upper rotating lever (242) a semiconductor device is provided. In one in the embodiment, gear screw (241) is, driver (230) formed one above the other in a vertical direction to either accept or refuse through-holes (descriptions drawing is not shown), engages with the inner surface of corresponding through hole and a threaded, rotating lever (242) rotated by vertically along upper surface of thread by which nickel, the roller side mounted to the number 1 (210) between an upper direction can be raised or the bottom of the adhesive. Rotating lever (242) is, in the form of a disk to produce an angularly (241) is provided on the top of, the user grasps the handle so potato hand rotating (244) upper is formed extending in the vertical direction. In one in the embodiment, rotating lever (242) is, 100 parts by weight of polypropylene resin surface, HDPE resin (HDPE) 110 - 130 parts by weight, 170 - 190 parts by weight of talc (Talc), germanium powder 1 - 10 parts by weight, glass fiber reinforced plastic 15 - 25 parts by weight, 2 - 7 parts by weight of glue, cork powder 5 - 10 parts by weight, powder 1 - 4 parts by weight of sucrose (C12 H22O 11), 3 - 8 parts by weight of 2 - 5 parts by weight of (Boehmite, AlO (OH)) betray pyrophosphates and 1. 02 - 1. 10 Specific gravity of provided with sewing-shell is made of (243) is to wrap around the disclosed. Wherein, shell (243) is, the efficiency of developing and torsional mechanical properties, lipid metabolism radiated far infrared body rising to 100 parts by weight of polypropylene resin, high-density polyethylene resin (HDPE) 110 - 130 parts by weight, 170 - 190 parts by weight of talc (Talc), germanium powder 1 - 10 parts by weight, glass fiber reinforced plastic 15 - 25 parts by weight, 2 - 7 parts by weight of glue, cork powder 5 - 10 parts by weight, powder 1 - 4 parts by weight of sucrose (C12 H22O 11), 3 - 8 parts by weight of 2 - 5 parts by weight of (Boehmite, AlO (OH)) betray pyrophosphates and 1. 02 - 1. 10 Encoded number plastic composition having a specific gravity of the bath. Of the present invention shell (243) number for a plastic composition may comprise a high pressure liquid coolant, polypropylene resin, high-density polyethylene resin (HDPE), talc and germanium powder can. When the above-mentioned plastic composition, heat resistance, mechanical properties such as durability and improve, plural torsion can be, rising plastic container prepared by the number of food stored by radiated far infrared metabolic promotion and improve storage stability plastic sheet (article number) number can be a high pressure liquid coolant may have effect. Polypropylene (polypropylene) resin, an inexpensive price contrast performance, food or cosmetics or the like would harm even contact with the contents of the material known as environmentally friendly as, thermoplastic resin obtained by polymerizing propylene and, chemical resistance, mechanical properties, thermal properties and disclosed. Polypropylene is, propylene homo (homo) polymer, random copolymer and block copolymer selected from at least either but can be used, for improving mechanical properties of random copolymer based on the weight of the homopolymer preferably 3:2 is used. High density polyethylene (HDPE) resin, a synthetic resin bath number by polymerizing ethylene, high flowability and rigidity, impact resistance, electrically insulating, formability, SB cold resistance. High-density polyethylene resin, a polypropylene resin is mixed with the aforementioned plastic sheet or number article number bath effect can be improved formability when tension may have been strengthened, using various number article can be publicly known. The mask it grows, plastic composition strength, as to improve the mechanical properties of heat resistance, such as groove 150 - 200 mesh (mesh) with polypropylene resin for use talc powder having a particle size of preferably. In addition, the mask it grows, other filler component is used in a predetermined time interval lapses and, preferably, dolomite powder based on the weight of 1:1 contribute to improve durability plastic composition employed may be filled. Germanium, the pollutants of silver white, such as far infrared rays and anion in a large spinning have rising up to a metabolism. In addition, germanium, semiconductor properties is due to the contact with skin (outer electronic) has a predetermined height and vital straightening iron for introduction into the body, the body of the module body within 20 - 30 enters the various harmful side effects addiction time of liquid there is no disclosed. In particular, when particles of the inorganic germanium contained water activity in contact with skin tissue into human skin if outer electron gets into a semiconductor properties. Organization under blood penetrate the vascular wall to germanium having penetrated into vascular agents to move electrons through, normalizing blood and blood purification action, plasma display according to the pain cry off the fact that flow has been found. Germanium, can be used in a powder form, germanium in summer and is set to be 3 cm hereinafter to complete, cutting germanium in summer and 80 - 100 mesh size size preferably manufactured using. In one in the embodiment, plastic composition may comprise, with respect to 100 parts by weight of polypropylene resin, HDPE resin 110 - 130 parts by weight, preferably 1 - 10 parts by weight of germanium powder including talc 170 - 190 parts by weight. Plastic composition shell (243) number when a high pressure liquid coolant, like number times stoppers for plastic composition which is important in regulating the specific gravity, the specific gravity 1. 02 - 1. 10 Preferably in, 1. 03 - 1. 05 In more bigger, i.e., with respect to 100 parts by weight of polypropylene resin, or less than 110 parts by weight of high density polyethylene resin, talc is below 170 parts by weight, mechanical properties such as durability and enhance the number one, with respect to 100 parts by weight of high density polyethylene resin or exceeds 130 parts by weight of polypropylene resin, exceeds 190 parts by weight of talc, plastic composition which can be heated to melt moldability specific gravity a stripe is bigger disclosed. In addition, with respect to 100 parts by weight of polypropylene resin, powder is below 1 parts by weight of germanium, germanium and maintains the ray emission effect due to the expression, exceeds 10 parts by weight, other components and to minimize the groove formability can be obstructed. In one in the embodiment, the above-mentioned plastic composition, further comprises a glass fiber reinforced plastic in order to enhance the impact resistance can be. Glass fiber reinforced plastic (Fiberglass Reinforced Plastic, FRP) is, glass-based mineral as a main material, glass-based mineral aromatic nylon fibers and a binder a thermosetting resin material are disclosed. Glass-based minerals, sand, limestone, feldspar and soda circuit selected from the group consisting of it can be used for, the one number are not disclosed. The thermosetting resin, thermosetting resin and various publicly known can be used, preferably, polyester, can be alicyclic epoxy resin. The glass fiber reinforced plastic, glass-based mineral material that is number of molten furnace can be filled high pressure liquid coolant, each seal between the glass fiber insulating air layer acts in the incombustible, noise-absorbing property, excellent workability disclosed. In addition, harder iron, light-weight than aluminum, and it does not stain the preservation, incombustible has excellent heat which does not deform, for processing hereinafter disclosed. The, glass fiber reinforced plastic (pellets) in order to improve such as PVC and equalizing-adding glue preferably. The glue, animal leather, bowel, bone or the like as a material for an orphan is spreading the liquid product, such as when each component-modified silane coupling agent can be applied to discharge door number. Glass fiber reinforced plastic and glue the, with respect to 100 parts by weight of polypropylene resin, preferably 15 - 25 parts by weight of 2 - 7 parts by weight of each which, when less than corresponding range, a negative polarity and compounded with a modified resistance can be, beyond corresponding range when, during production can be collected into a broken number article, a non-number been disclosed. In one in the embodiment, plastic composition shell (243) in order to improve further comprise a number based on a single small cork powder may be filled. Cork powder is, after a number the bark of a stand-alone, grinding can be prepared. Cork powder is 400 mesh (mesh) or more network with every other groove such as polypropylene resin for use preferably a finely ground particles. Cork powder is, with respect to 100 parts by weight of polypropylene resin, preferably 5 - 10 parts by weight of which, if less than 5 parts by weight of cork powder, and elastic enhancing degree insignificantly, 10 parts by weight is exceeded, when tank number article number increases durability can be attenuated void formed therein. In addition, cork powder and other components in order to improve the mixing-sucrose (C12 H22 O11 ) Powder can be further. The sucrose, as well as for increasing a cork powder formed between the voids, such as PVC equalizing generating molecules are joined in off-flavor door number signal and the viscosity job number vehicles off-flavor door can be solve. The sucrose, 500 mesh (mesh) network using every other powder preferably, with respect to 100 parts by weight preferably 1 - 4 parts by weight of a polypropylene resin which, when sucrose is less than 1 parts by weight, and the sucrose expressed by inverted triangular screw, 4 parts by weight is exceeded, as well as article number is from the group consisting of non-number that attenuate the equipment disclosed. In one in the embodiment, plastic composition, can be further maintains the powder. Potassium vitiligo vitiligo (potassium aluminum sulfate, AlK (SO4 )2 , 12H2 O) can be using, obtained from natural alunite. Specifically, photoresist is paid out so that every other agent containing water and then sweep, then heated with irregular or repairing that a, high pressure liquid coolant can be same number followed by drying. With respect to 100 parts by weight of 2 - 5 parts by weight of a polypropylene resin maintains the bigger, maintains the content of less than 2 parts by weight when, effect and maintains the inverted triangular screw, 5 parts by weight of non-number is exceeded been disclosed. In one in the embodiment, the present invention plastics by composition in order to improve the antimicrobial activity can be further comprises pyrophosphates (Boehmite, AlO (OH)). Step [hey e sprouts γ - pyrophosphates, pyrophosphates and similar using both a - pyrophosphates (Pseudo-a Boehmite) can, among all, crystalline excelling in thermal stability and excellent chemical stability, and structurally neutral, preferably using γ - step [hey e [thu excellent antimicrobial properties. Γ - step [hey e sprouts, water (pure) and aluminum (Al) synthetic MethodsIn number can be supercritical only high pressure liquid coolant. 3 - 8 Parts by weight to 100 parts by weight of polypropylene resin step [hey e sprouts which preferably, step [hey e [thu content is below 3 parts by weight of antibacterial effect and maintains the central expression, groove exceeds 8 parts by weight of other components as much as possible in the equipment disclosed. Hereinafter, the present invention incorporated in the embodiment in comparison with specific data transmissions take effect by plastic composition and method for assembling according to the broadcast receiver. However, the present invention is more specifically account for the in the embodiment which, in the embodiment of the present invention range and not the limited to these. [In the embodiment 1] Polypropylene resin 180 kg, HDPE resin (HDPE) 200 kg, talc 310 kg, 15 kg germanium powder by mixing plastic composition number have high pressure liquid coolant, is set to same in the embodiment 1. [In the embodiment 2] The number equal to the high pressure liquid coolant in the embodiment 1, glass fiber reinforced plastic 36 kg, glue 9 kg plastic composition number have a further mixing high pressure liquid coolant, is set to same in the embodiment 2. [In the embodiment 3] The number easy and high pressure liquid coolant in the embodiment 2, cork powder 9 kg, 5 kg sucrose powder, maintains the powder 5 kg, 9 kg plastic composition have a further mixing number of pyrophosphates γ - high pressure liquid coolant, and electrodes respectively in the embodiment 3. [Comparison example 1] And talc only number, equal to the number have high pressure liquid coolant in the embodiment 1, the same is set to comparison example 1. [Experiment example 1: impact evaluation] In the embodiment 3 in the embodiment 1 and comparison example 1 plastic composition to the specimen (20 cm * 30 cm, thickness 20 mm) number have a high pressure liquid coolant, a weight of 3 kg of distancing height after 2m, damage to the work performed by each specimen result shown table 1. 1 You will through said table, comparison example 1 do not contain talc excellent impact resistance as compared to talc including in the embodiment are that his car. In particular, in the case of containing glass fiber reinforced plastic in the embodiment 2 and 3, were the best result is obtained. [Experiment example 2: heat resistance evaluation] Experiment example 1 maintained in heated hot air circulating furnace 3 time of a sample 80 °C have visually observed by the yellow degree, for table 2 have shown to result. You will through said table 2, unlike in the embodiment 3 in the embodiment 1 to example 1 compared to the yellowing observed approximately parts of not. Comparison example 1 very good heat resistance as compared to that in the embodiment through his car. [Experiment example 3: antibacterial evaluation] In the embodiment 1, in the embodiment 3 and comparison example 1 activity against a test (JIS Z 2801) was embodiment. Aspergillus niger ATCC 9642 a deflection test strains (mold), evaluated the activity (antimicrobial activity value) to table 3 are described. Comparing the number of cultured strains as well as antimicrobial activity column for some period of time for assessing value as antibacterial, 90% or more strains whose values equal to or more than 1, equal to or more than 99% or more strains 2, 3 is greater than 99. 9% Or more strains, 99 is greater than 4. 99% Or more strains, 5 equal to or more than 99. The 999% more strains have been killed human body from which the substrate. You will through said table 3, in the case of step [hey e [thu γ - including in the embodiment 3, a very good antibacterial than other case that were predicted. Plastic composition such as described above having a structure prepared by the shell number (243) is, ethylene vinyl acetate (EVA) resin 30 - 90 parts by weight, 1 - 30 parts by weight of polyvinyl alcohol (PVA), 10 - 30 parts by weight of water, 5 - 30 parts by weight of calcium carbonate, surfactants number 0. 1 - 1 Parts by weight, a fourth number 1 - 20 parts by weight, sodium silicate 3 - 7 parts by weight, molybdenum disulfide (MoS2) 1 - 5 parts by weight, 5 - 10 parts by weight of 10 - 30 parts by weight of aluminum hydroxide for producing including on main number, dee small city oh reel [thu - toluene (toluen-a diisocyanate, TDI), hydrogenated TDI, trimethyl propane - TDI (trimethyl propane-a TDI), triphenylmethane - tree polyisocyanate (tripehnylmethane-a triisocyanate, TTI), diphenylmethane - 4, 4 - diisocyanate (dipehenylmethane-a 4, 4 a-diisocianate, MDI), hydrogenated MDI, and hexane diisocyanate component including at least one of methylene - (hexamethylene-a diisocyanate, HDI) made of isocyanate compound, in an amount of 1 - 20 parts by weight of a main number 100 by an adhesive number composition cured number rotating lever (242) can be attached. In one in the embodiment, shell (243) number used coding of adhesive composition, adhesive composition including a main number and cured number number, the main number, ethylene vinyl acetate (EVA) resin 30 - 90 parts by weight, 1 - 30 parts by weight of polyvinyl alcohol (PVA), 10 - 30 parts by weight of water, 5 - 30 parts by weight of calcium carbonate, surfactants number 0. 1 - 1 And a fourth number 1 - 20 parts by weight parts by weight, curing is number, can be isocyanate compound. In addition, adhesive number composition, water-soluble 2 part adhesive number composition consisting of main number number on curing, the adhesive sheet can be a high pressure liquid coolant depositing them and consolidation or adhesive number number, without contaminating the environment, adhesive, excellent physical properties such as heat resistance inorganic board woody board or plywood such as magnesium board, various plastic material such as PVC seat can be used. The main number, ethylene vinyl acetate (EVA) resin essentially, polyvinyl alcohol (PVA), water, calcium carbonate, and including a fourth number to number surfactants, ethylene vinyl acetate resin as a principal constituent of main number, strongly cohesive strength of the adhesive sheet or adhere to the number bath can be constantly maintains a number. Number is based on a temperature of adhesive sheet or adhere to the epoxy resin, alicyclic epoxy resin adhesive sheet in the case of volatile organic compounds such as benzene toluene or adhesive number against environment and absence harmful to the human body. However, adhesive number composition of the present invention, door number point number by number times such as epoxy resin which can solve the door environment has been. The polyvinyl alcohol (PVA), heat resistance and adhesive sheet or adhesive number number tank water resistance and thereby increase the adherence could be bonded each other. The polyvinyl alcohol, ethylene vinyl acetate resin to 30 - 90 parts by weight, preferably 1 - 30 parts by weight which, when less than is a polyvinyl alcohol 1 parts by weight, and maintains the fixed to the, 30 parts by weight is exceeded, ethylene vinyl acetate into the adhesive sheet or adhere to the relative amounts of cohesion number can be attenuated. In addition, the present invention refers to, when used in such as pyrimidine derivatives, polyvinyl alcohol functionality using antimony oxide and zirconia to supplement the polyvinyl alcohol with disapproval. The antimony oxide and zirconia, as can enhance the heat resistance of adhesive sheet or adhesive number number bath, 30 - 90 parts by weight of 5 - 10 parts by weight of ethylene vinyl acetate resin which each other preferably, heat resistance and low thermal conductivity less than said range in inverted triangular screw, said source for a number when a non-been disclosed. Number of main water can be used as a solvent. The present invention refers to, adhesive sheet or adhere to the number of the existing method for environmental contamination door number using number on volatile organic unlike can be solve have. Water is, with respect to the ethylene vinyl acetate resin 30 - 90 parts by weight, preferably 10 - 30 parts by weight of which, is below 10 parts by weight of water, not be able to effectively dissolving ethylene vinyl acetate resin, 30 parts by weight is exceeded, can be lowered in a number too dilute or adhesive strength of the adhesive sheet. The calcium carbonate, and adhesive number control viscosity of the composition, a contracting upon curing from the process chamber. The calcium carbonate, ethylene vinyl acetate (EVA) resin to 30 - 90 parts by weight, preferably 5 - 30 parts by weight of which, if less than 5 parts by weight of calcium carbonate, not sufficient shrinkage occurs when cured adhesive sheet or adhere to the number of hardness can be poor and, 30 parts by weight is exceeded, viscosity too so I can be to the comparator. In addition, the present invention refers to, to replace the current 103a calcium carbonate, clay and the like may be various materials, as one example, dolomite and/or talc (Talc) can be using. The, in order to improve the mechanical properties preferably talc and dolomite mixed weight ratio 1:1 and, in addition, having a particle size of 150 - 200 mesh (mesh) powder is bigger, fine powder having a particle size in using it became the [sway to 150 - 200 mesh, ethylene vinyl acetate resin other components can be improved. The number surfactants, when incorporated adhesive number composition to reduce surface tension, in order to improve the ability are used. The number surfactants, ethylene vinyl acetate resin in an amount of 30 - 90, 0. 1 - 1 Parts by weight preferably incorporated. The number surfactants, publicly known number of nonionic surfactants, anionic surfactants using number but, in order to reduce the surface tension of effectively using 8 - 14 alkyl chain carbon atoms including number mini type number surfactants preferably. The fourth number, number applied adhesive sheet when the adhesive composition or adhesive number, number of main number cured adhesive composition on a separation phenomenon billion number is provided to form the non-number, car type silica, acrylic copolymers of various publicly known variety of materials can be used such as but, preferably using clay (clay). Clay has a, composed of an aggregate of elongate function as silicate mineral, water good for the chemical microreactor plastic form a pixel, the stiffness and drying, baking in a high-temperature sintering material if said substrate. Specifically, synthetic resin bag grid, at least one powder selected from the group consisting of fumed silica and bentonite can be used but, in order to obtain the best effect fumed silica weight ratio of 1:1 bentonite is preferably mixed people. The fourth number, the ethylene vinyl acetate resin 30 - 90 parts by weight, preferably 1 - 20 parts by weight of which, is below a fourth number is 1 parts by weight, to sufficiently flow cannot be number, exceeds 20 parts by weight, the pipe too change in disappearance can be. In addition, the main number, number or adhere to the adhesive sheet for improving of the number bath further comprises sodium utilitarian kate disapproval. Sodium silicate (sodium silicate) is, unlike existing adhesive number obtained post-environment-friendly, excellent adhesion disclosed. Sodium-silicate, based on the 30 - 90 parts by weight of ethylene vinyl acetate resin solids, preferably 3 - 7 parts by weight of which, if less than 3 parts by weight of sodium silica , adhesive performance and improved degree insignificantly, 7 parts by weight exceeds the, other components can be mixed with a negative polarity. In addition, the main number, adhesive sheet or adhesive number number bath for further include improving abrasion resistance of doped molybdenum disulfide may be filled. The molybdenum disulfide (MoS2), agitator contained in the ore vein as found digging into thin material, lubricating ingredient are used. The molybdenum disulfide (MoS2), graphite (graphite) in the form of hexagonal crystal structure such as shear occur but have unique properties, includes graphite lubricating superior disclosed. The molybdenum disulfide, based on ethylene vinyl acetate resin 30 - 90 parts by weight of the solids, preferably 1 - 5 parts by weight which, when molybdenum disulfide is less than 1 parts by weight, abrasion resistance cannot be an entire, exceeds 5 parts by weight, adhesion rather drop disclosed. The, molybdenum disulfide is mixed copper powder with disapproval. In addition, the main number, number the number or adhere to the adhesive sheet in order to improve flame retardancy of bath further comprises flame retardant number disapproval. Flame retardant number is, with respect to 100 parts by weight of ethylene vinyl acetate resin, preferably 1 - 5 parts by weight which, when the number is less than 1 parts by weight of flame retardant, flame retardant and improved degree insignificantly, 5 parts by weight is exceeded, the number as well as other non-mixing components a negative polarity equipment disclosed. The flame retardant number, which may be a medicament for treatment of an indole compound, (potassium aluminum sulfate, AlK (SO4) 2, 12H2O) using potassium vitiligo vitiligo can be, obtained from natural alunite. Specifically, photoresist is paid out so that every other agent containing water and then sweep, then heated with irregular or repairing that a, high pressure liquid coolant can be same number followed by drying. In addition, the main number, adhesive sheet or adhesive number number bath for improving antibacterial may further comprise aluminum hydroxide may be filled. The aluminum hydroxide, preferably using pyrophosphates (Boehmite, AlO (OH)). Step [hey e sprouts γ - pyrophosphates, pyrophosphates and similar using both a - pyrophosphates (Pseudo-a Boehmite) can, among all, crystalline excelling in thermal stability and excellent chemical stability, and structurally neutral, preferably using γ - step [hey e [thu excellent antimicrobial properties. Γ - step [hey e sprouts, water (pure) and aluminum (Al) synthetic MethodsIn number can be supercritical only high pressure liquid coolant. The aluminum hydroxide, ethylene vinyl acetate in an amount of 30 - 90, preferably 5 - 10 parts by weight of which, 5 parts by weight of the aluminum hydroxide content is below antibacterial effect and maintains the central expression, groove exceeds 10 parts by weight of other components as much as possible in the equipment disclosed. Number is cured, including isocyanate compound can be employed. The isocyanate compound, excellent solubility in water main number cured to water hardness number exactly curing times can be shortened by maintaining viscosity, curing time (pot life) when incorporated on main number number words to the burner nozzle extending remarkably improving the react on each other. The isocyanate compound, at least one isocyanate group compound pleasant 2 1 molecule, in particular toluene - dee small city oh reel [thu (toluen-a diisocyanate, TDI), hydrogenated TDI, trimethyl propane - TDI (trimethyl propane-a TDI), triphenylmethane - tree polyisocyanate (tripehnylmethane-a triisocyanate, TTI), diphenylmethane - 4, 4 - diisocyanate (dipehenylmethane-a 4, 4 a-diisocianate, MDI), hydrogenated MDI, or hexane diisocyanate (hexamethylene-a diisocyanate, HDI) methylene - it is preferable that a number, the number is provided to raise the number 100 parts by weight of curing, preferably 1 - 20 parts by weight of incorporated. The above-mentioned adhesive number composition, on main number number number number 2 part adhesive composition after curing by mixing the water-soluble high pressure liquid coolant, coating and curing the number tank as a work site, said outside portion of said component or both components needed number can be used, the purpose of the invention is not within a range that the dispersion number, vesicle number, antiseptic number, further comprising thickening number may be, for implementing various colors of adhesive sheet or adhesive number number tank further comprise a discoloration component may be filled. Hereinafter, in the embodiment according to the present invention according to specific adhesive number composition to be incorporated and method for assembling data transmissions take effect compared to the broadcast receiver. However, the present invention is more specifically account for the in the embodiment which, in the embodiment of the present invention range and not the limited to these. [In the embodiment 4] 80 Parts by weight of ethylene vinyl acetate, polyvinyl alcohol 20 parts by weight, 25 parts by weight of water, 10 parts by weight of calcium carbonate, number 1 parts by weight of surface-active agents, to a fourth number 5 parts by weight of a high pressure liquid coolant mixing number and number, dee small city oh reel [thu - including a number 25 parts by weight of toluene (toluen-a diisocyanate, TDI) after curing, coating and hardening an adhesive sheet or adhesive number number have a high pressure liquid coolant, is set to same in the embodiment 4. The, number of carbons 8 number number as well as a mini surfactants surfactants. The overall synthesis 1 - bromo die amine surfactants number cayin which will know his reactions. N, N, N', N' - tetramethyl - 1, 3 - diamino pro pane (N, N, N', N' - tetramethyl-a 1, 3 non-diaminopropane) 0. 1 Mole and it is a jade reel 1 - bromo (1 a-bromooctane) 0. 2 Mole (acetonitrile) characterized in that it has a process for 30 minutes stirring knight reel is placed 300g controls, the solutions are in 12 hours after reflowing 353K, rotation concentrator (rotary evaporator) number using a stand-alone been knight reel process for solvent. 500G to the product obtained through die ethyl ether (Diethylether) by adding product been recrystallize. After the same 500g every other number which has not reacted impurities and has been die ethyl ether wash stand-alone. Said process of a stand-alone product in an 323K 12 by a number number number number solvent remaining processing time mini surfactants was high pressure liquid coolant. [In the embodiment 5] 5 Parts by weight and zirconia oxide main number 5 parts by weight of powder form and further added thereto number only, high pressure liquid coolant to have the same number in the embodiment 4, in the embodiment 5 is set to same. [In the embodiment 6] 5 Parts by weight of sodium silicate to main number, 3 parts by weight of molybdenum disulfide, 3 parts by weight of citric, pyrophosphates γ - 8 parts by weight of further added thereto number only in powder form and, in the embodiment 5 high pressure liquid coolant to have the same number, in the embodiment 6 same electrodes respectively. [Comparison example 2] Comparing the number of the existing method (SEP provided 4300, ㈜) adhesive epoxy pyrimidine derivatives for example is set to 2. [Experiment example 4: adhesion test] In the embodiment and comparison example 2 proceeds to adhesion test (KS F 4715) have, for table 4 result to shop window. LH construction adhesive strength 0. 8 N/mm2 or more pass reference, both in the embodiment 4 in the embodiment 6 and comparison example 2 is to pass his satisfies a criterion. However, in the embodiment 4 compared to example 2 in the embodiment 6 than that of the base material of excellent his car. [Experiment example 5: heat resistance evaluation] In the embodiment 6 and comparison example 2 in the embodiment 4 to a hot air circulating furnace 8 of the adhesive sheet or adhere to the number 80 °C heated maintained in time have visually observed by the yellow degree, to result shown to table 5. 5 You will through said table, unlike in the embodiment 6 in the embodiment 4 to example 2 compared to the yellowing observed on parts not substantially. Comparison example 2 very good heat resistance as compared to that in the embodiment through his car. [Experiment example 6: antibacterial evaluation] In the embodiment 6 and comparison example 2 activity test (JIS Z 2801) was embodiment a number composition for adhesion. Aspergillus niger ATCC 9642 a deflection test strains (mold), evaluated the activity (antimicrobial activity value) to table 6 are described. Comparing the number of cultured strains as well as antimicrobial activity column for some period of time for assessing value as antibacterial, 90% or more strains whose values equal to or more than 1, equal to or more than 99% or more strains 2, 3 is greater than 99. 9% Or more strains, 99 is greater than 4. 99% Or more strains, 5 equal to or more than 99. The 999% more strains have been killed human body from which the substrate. You will through said table 6, in the case of step [hey e [thu γ - including in the embodiment 6, comparison example 2 were compared to a very good antibacterial removing. Loading shelf part (300) is, dust number rejection (200) which is mounted in front of the, dust number rejection (200) by number transmitted to the object for reparing over dust loading substrate. Such as configuration described above cleans number rejection (200) is, additional dust number rejection (400) can be further comprises. Additional dust number rejection (400) is, supply shelf (100) dust on number rejection (200) robots are controlled, supply shelf (100) dust from number rejection (200) is supplied to the upper object attached to a stand-alone number 1 after dust SnO, dust number rejection (200) delivers to. The reference 2 also, additional dust number rejection (400) is, two rollers' ' Form one pair located vertically opposite formed, opposed surfaces opposite direction can be configured to rotate such as dust laden number object while moves objects attached to internal space by absorbing a stand-alone substrate. In one in the embodiment, additional dust number rejection (400) is, as shown in fig. 2, the roller is vertically moved or, in situ number can rotate in the direction clockwise or counterclockwise, the number the user pushed it sells with a physical object can be moved to free the robot position. In one in the embodiment, additional dust number rejection (400) is, number 3 roller (410), number 4 roller (420) and additional drive (430) can be a. Number 3 roller (410) is, the bottom of the intermediate portion or upper direction roller moves objects' ' Form is formed form an accident (3 also reference), number 4 roller (420) on a side thereof facing the object while rotating dust number rejection (200) metal support moved, dust formed therein space number rejection (412) is mounted to the mounting. In one in the embodiment, number 3 roller (410) includes, a moving roller (411) and collecting roller (412) can be a. A moving roller (411) is, the bottom of the intermediate portion or upper direction roller moves objects' ' Form is formed form an accident (3 also reference), number 4 roller (420) on a side thereof facing the object while rotating dust number rejection (200) into the reaction chamber. In one in the embodiment, a moving roller (411) is, two securing frame (4111), a moving roller (4112) and a plurality of drive roller (4113) without using a tool. Fastening frame (4111) is, in the shape of a 'V' movement roller (4113) mounted on opposite sides of and, number 3 roller (410) rear fastening additional driver (430) to the outer surface of the vertically sliding or data obtained from the, mobile roller rotate in the direction clockwise or counterclockwise (reference 2 also) (4113) object to crystallize out the location's desire. A moving roller (4112) is, fastening frame (4111) provided connected between the clockwise or counterclockwise direction and to move object while, on the upper side or lower side in insert portion out of object, object for absorbing impurities and plurality of through-holes formed on the substrate. Drive roller (4113) is, fastening frame (4111) can be moved away from roller (4112) and extend, a moving roller (4112) radiated from both sides of the, a moving roller while rotating (4112) mounted to the portion is rotated to a moving roller (4112) returning a clockwise or counterclockwise direction. Dust number rejection (412) is, a moving roller (4112) is arranged in the interior of the spaces, a moving roller (4112) rotates is moved while roller rotate in the opposite direction (4112) to travel through the pierced holes of the roller (4112) into the inner space of the object portion therein while wiping dust at the space blocking substrate. In one in the embodiment, dust number rejection (412) is, rotary drum (4121), brush (4122), suction tube (4123) and second display parts (4124) can be a. Rotary drum (4121) is, a moving roller (4112) shaped in the form of corresponding to the, a moving roller (4112) smaller than a power to a control roller (4112) after insertion into the inner space of the moving roller (4112) rotates in a direction opposite the rotation of. In one in the embodiment, rotary drum (4121) is, body formed with a plurality of through-holes carry suction tube (4123) foreign particles or dust to cause suction of the suction force can be objects by using its internal space. Brush (4122) is, rotary drum (4121) is moved while being rotated by rotating roller (4112) through pierced holes of the roller (4112) foreign particles or dust into the inner space of the object in turn the wing to be barrel (4121) from a side of a rotating in the direction of one side of the cylinder (4121) during rotation along the exterior surface of force is removed. In one in the embodiment, brush (4122) is, while not in use main object, such as brush to sweep can contain a jetting nozzle preferably is formed as material. The suction pipe (4123) is, rotary drum (4121) mounted on one or both sides of which, such as vacuum cleaner to create suction applied to the device to mount the rotating barrel (4121) supplied from the suction externally exhausted through the inner space of the reaction chamber. Drive (4124) is, suction tube (4123) and mounted on one or both sides of, suction tube (4123) clockwise or counterclockwise rotating the suction pipe according (4123) connected to and disposed to rotate barrel (4121) clockwise or counterclockwise rotating in the other. The, driver (4124) is, rotary drum (4121) mounted to the suction pipe (4123) rotating the rotary drum (4121) can be rotating. Type number 3 roller such as described above (410) the number 3 of each roller (410) to the bottom of the roller number 3 (410) provided a counter and number 4 roller (420) can be similarly applied. Such additional dust described above number rejection (400) is, simply to move beyond simple object of mobile device, the direction of movement of the object is installed on a bottom forward and backward is not user need vary and, even during the object are moved in the house is not a stand-alone device having separate dust number number dust can be effectively wetting ability, foreign substances or the center of gravity of an object can be a stand-alone object with number of the carbonyl compound. In the embodiment described in reference but more, a corresponding splicing one skilled art poriae idea of the present invention within a range that the present invention not patent the following is claimed and area away from varying the modification and changes may be understand it will rain. 10:100 Device of special adhesive automatic dust number: supply shelf 200: Dust number rejection 210: number 1 roller 220: Number 2 roller 230: drive 240: An upper 241: gear screw 242: Rotating lever 243: shell 300: Loading shelf unit 400: additional dust number rejection 410: Number 3 roller 411: mobile roller 4111: Fastening frame 4112: mobile roller 4113: Drive roller 412: collecting roller 4121: Rotary drum 4122: brush 4123:4124 Suction pipe: drive 420: Number 4 roller 430: additional driver The present invention relates to an adhesive type automatic dust removing device which can remove dusts attached to upper and lower surfaces of an object by using an adhesive means. The adhesive type automatic dust removing device comprises: a supply shelf placing the object to remove the dusts; a dust removing part including a first roller part, a second roller part, a driving part and a height adjusting part; and a loading shelf installed on a front end of the dust removing part, and receiving and loading the object in which the dusts are removed by the dust removing part. COPYRIGHT KIPO 2018 Dust number obtained from placing the object to be a stand-alone supply shelf; said supply is mounted on the front end of the shelf, while rotating means are formed in the outer surface of objects by using number number 1 industry collect dust deposited on top of the roller, said number 1 on the lower side of roller and roller and mounted opposite said number 1, said number 1 roller rotate in opposite directions and are formed in the outer surface while objects by using number 2 number of roller means is mounted on the dust industry association, said number 1 roller and said number 2 on both sides of the roller roller and said number 2 roller unit transmits an operating data obtained from said number 1 main having a drive section and said number 1 and mounted on both sides of the roller, said drive connection in a clockwise or counterclockwise direction said number 1 while the alternating vertical installation position regulating height control unit including dust number rejection; and which is mounted in front of the dust number rejection, said dust away by number transmitted to the object for reparing over refusal number active loading shelf loading, the height, said number 1 and mounted in a direction perpendicular and down both sides of the roller, at an apical part way along the outer gear screw; and master form provided on the top of said formed and screw gear, the user grasps the handle so is rotating and potato hand extend the upper comprising a rotating lever, said rotating lever, 100 parts by weight of polypropylene resin surface, 110 - 130 parts by weight of high density polyethylene resin (HDPE), 170 - 190 parts by weight of talc (Talc), germanium powder 1 - 10 parts by weight, glass fiber reinforced plastic 15 - 25 parts by weight, 2 - 7 parts by weight of glue, cork powder 5 - 10 parts by weight, powder 1 - 4 parts by weight of sucrose (C12 H22O 11), 3 - 8 parts by weight of 2 - 5 parts by weight of (Boehmite, AlO (OH)) betray pyrophosphates and 1. 02 - 1. 10 Specific gravity of provided with sewing-shell is 15:85 envelop, said sheath, ethylene vinyl acetate (EVA) resin 30 - 90 parts by weight applied to the inner surface, 1 - 30 parts by weight of polyvinyl alcohol (PVA), 10 - 30 parts by weight of water, 5 - 30 parts by weight of calcium carbonate, surfactants number 0. 1 - 1 Parts by weight, a fourth number 1 - 20 parts by weight, sodium silicate 3 - 7 parts by weight, molybdenum disulfide (MoS2) 1 - 5 parts by weight, 5 - 10 parts by weight of 10 - 30 parts by weight of aluminum hydroxide for producing including on main number, dee small city oh reel [thu - toluene (toluen-a diisocyanate, TDI), hydrogenated TDI, trimethyl propane - TDI (trimethyl propane-a TDI), triphenylmethane - tree polyisocyanate (tripehnylmethane-a triisocyanate, TTI), diphenylmethane - 4, 4 - diisocyanate (dipehenylmethane-a 4, 4 a-diisocianate, MDI), hydrogenated MDI, and hexane diisocyanate component including at least one of methylene - (hexamethylene-a diisocyanate, HDI) made of isocyanate compound, in an amount of 1 - 20 parts by weight of a main number 100 by an adhesive number number cured composition attached to said rotating lever, device number automatic dust adhesive wetting ability. Back number