SUBSTRATE PROCESSING SYSTEM

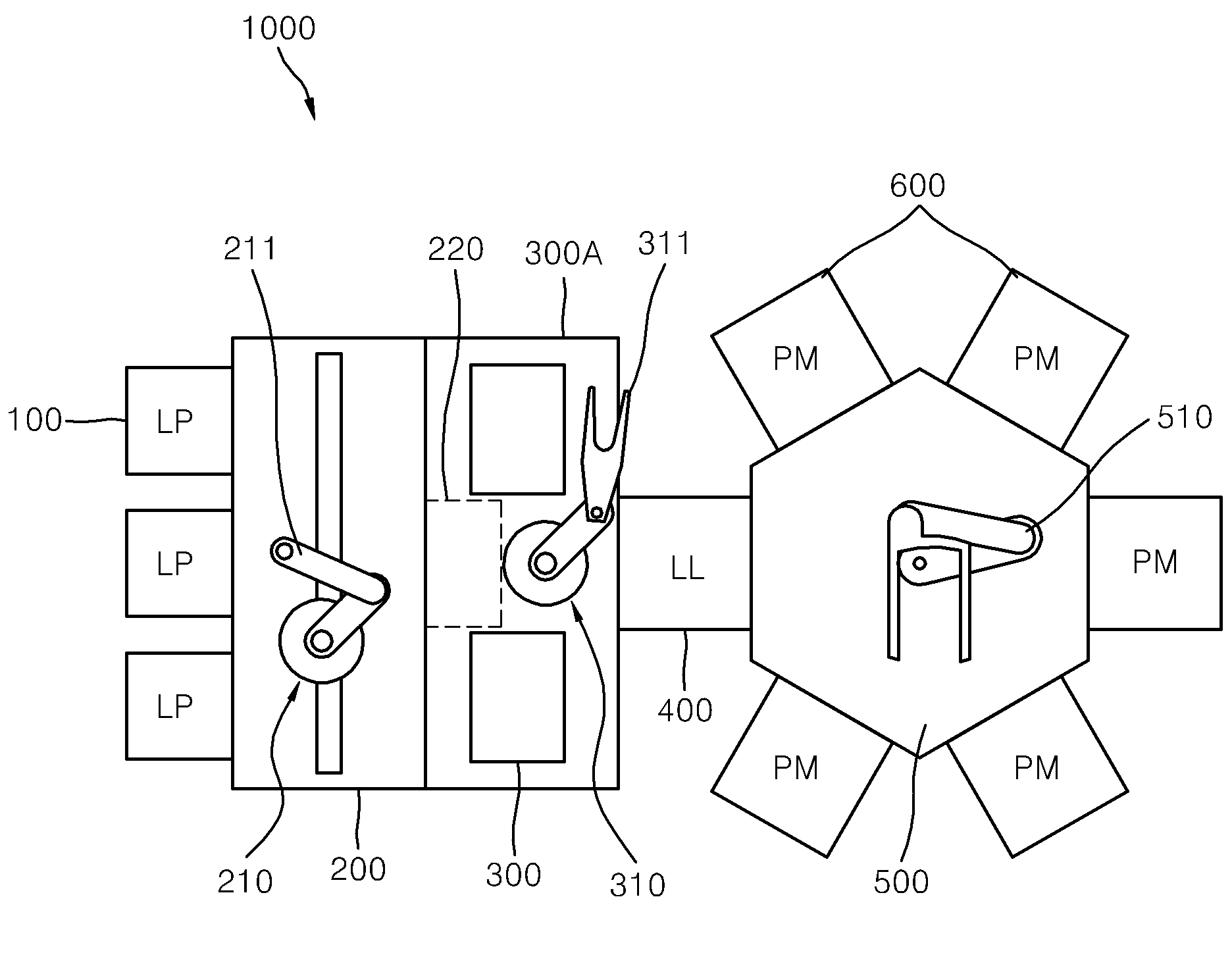

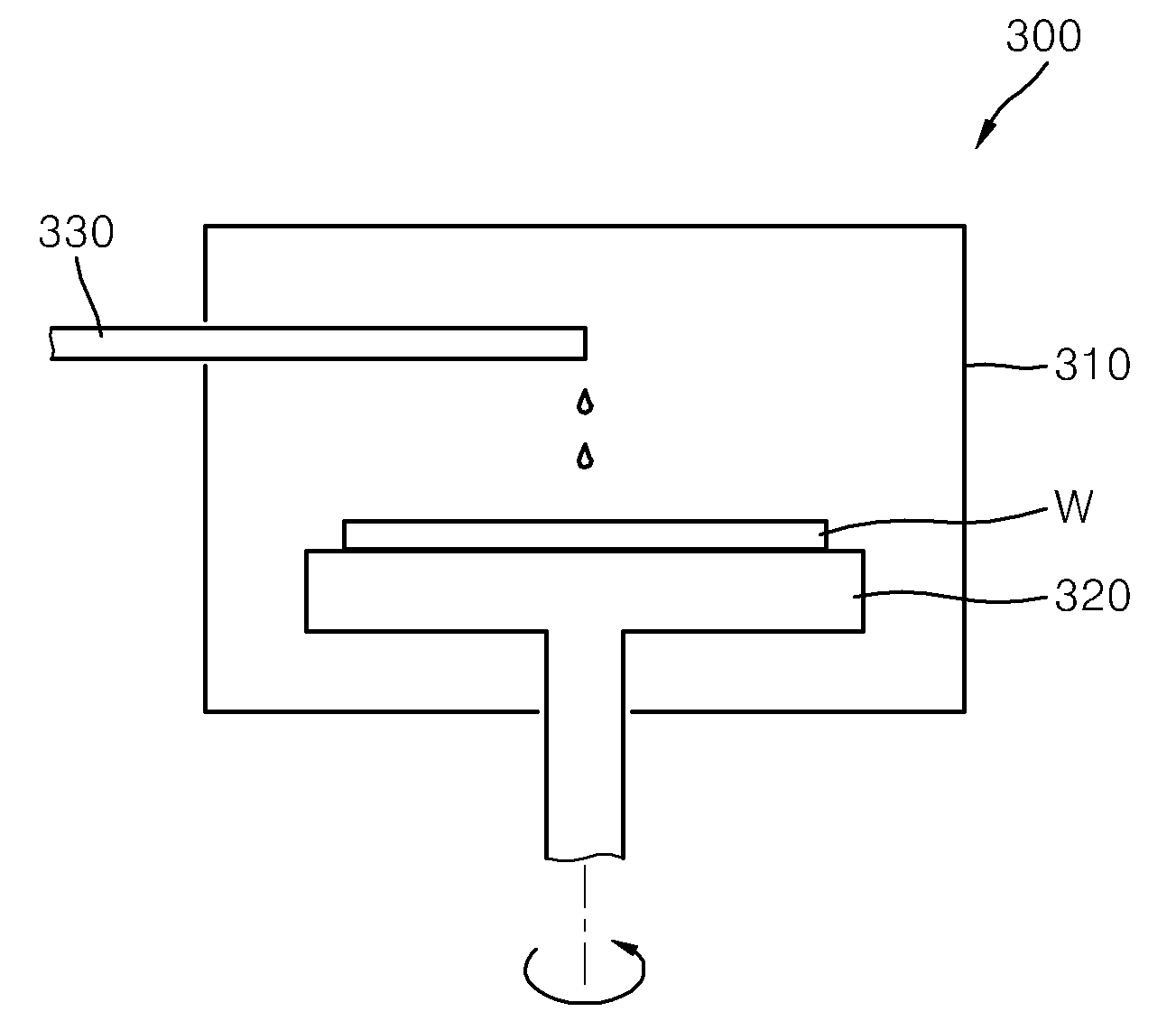

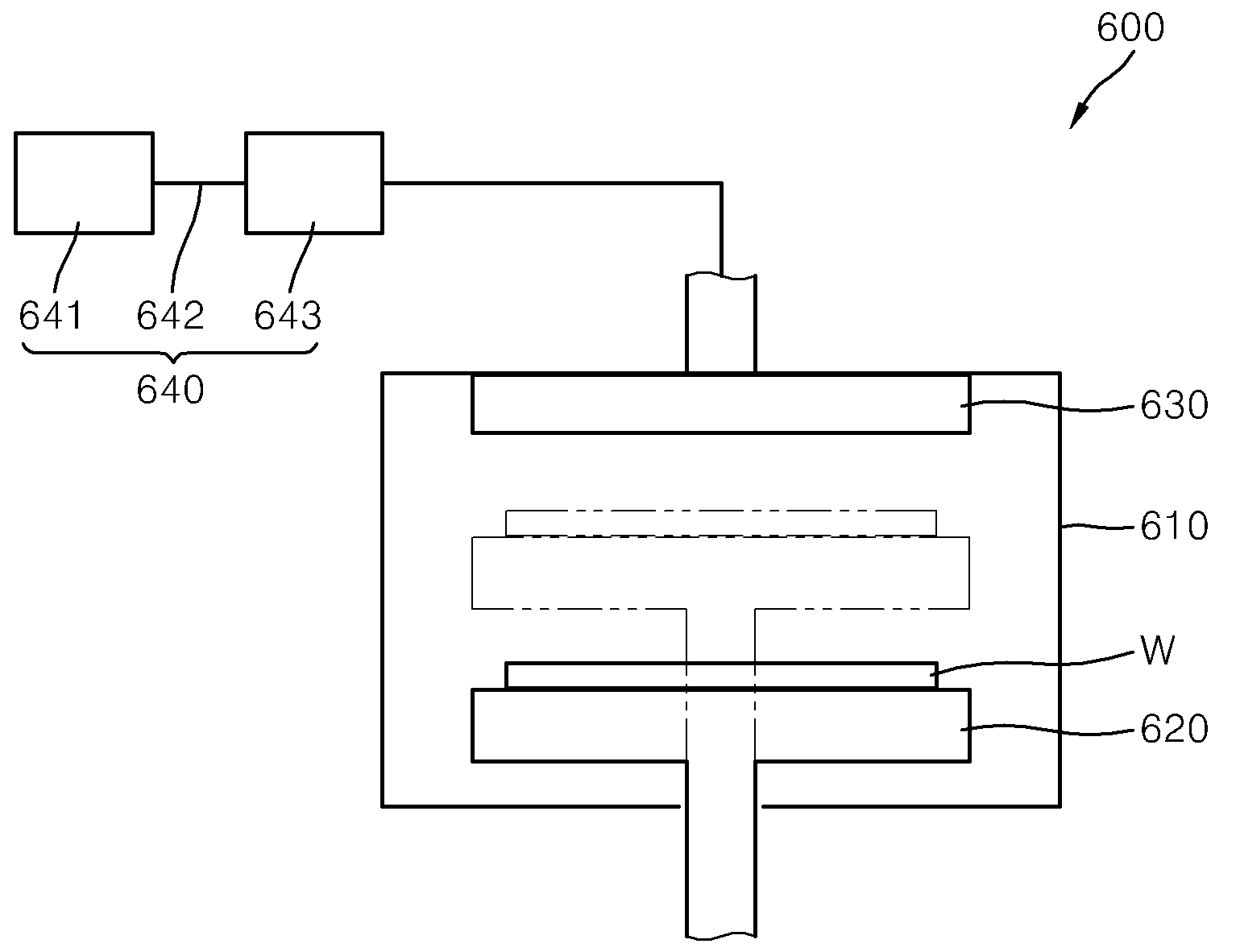

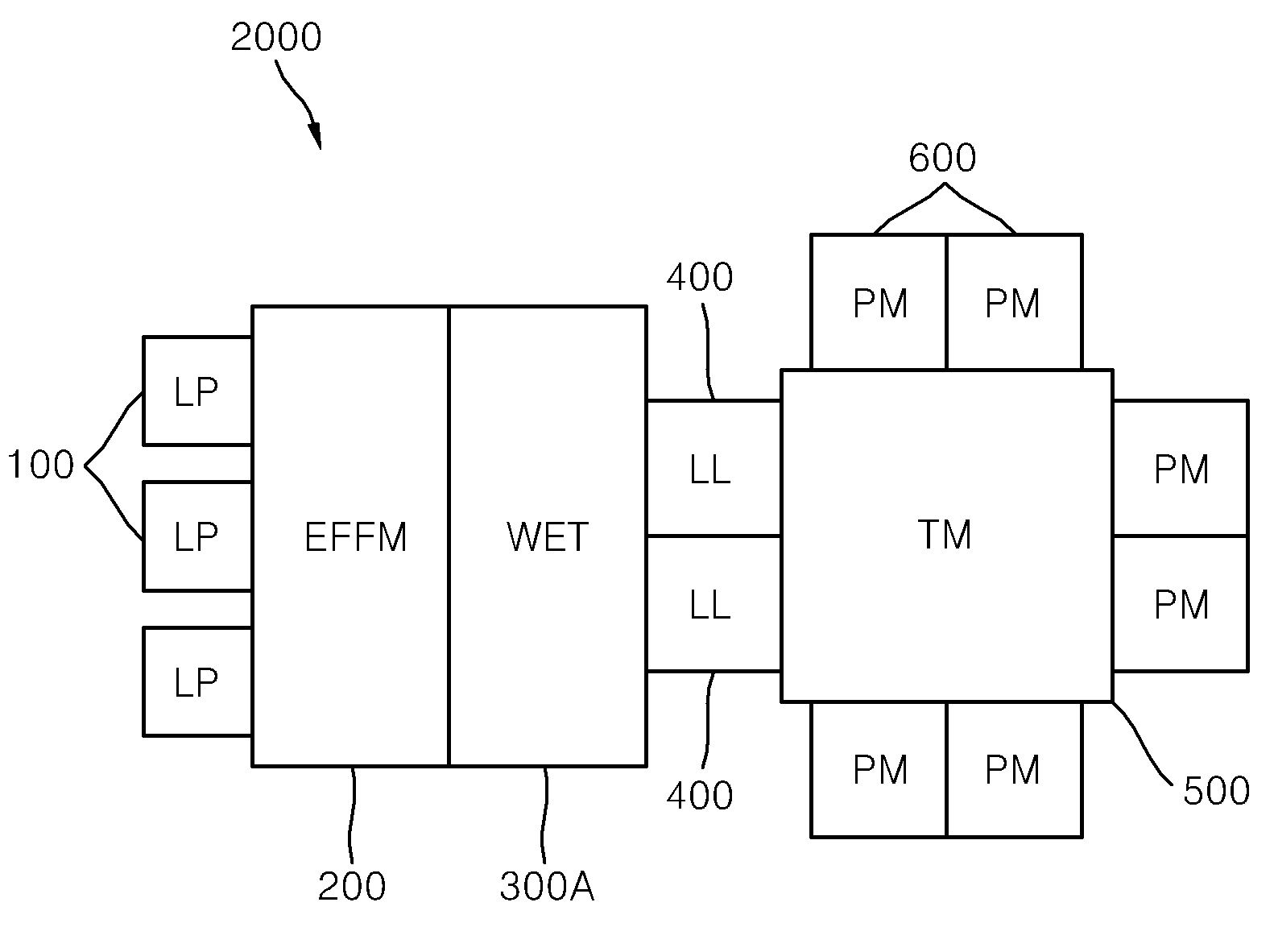

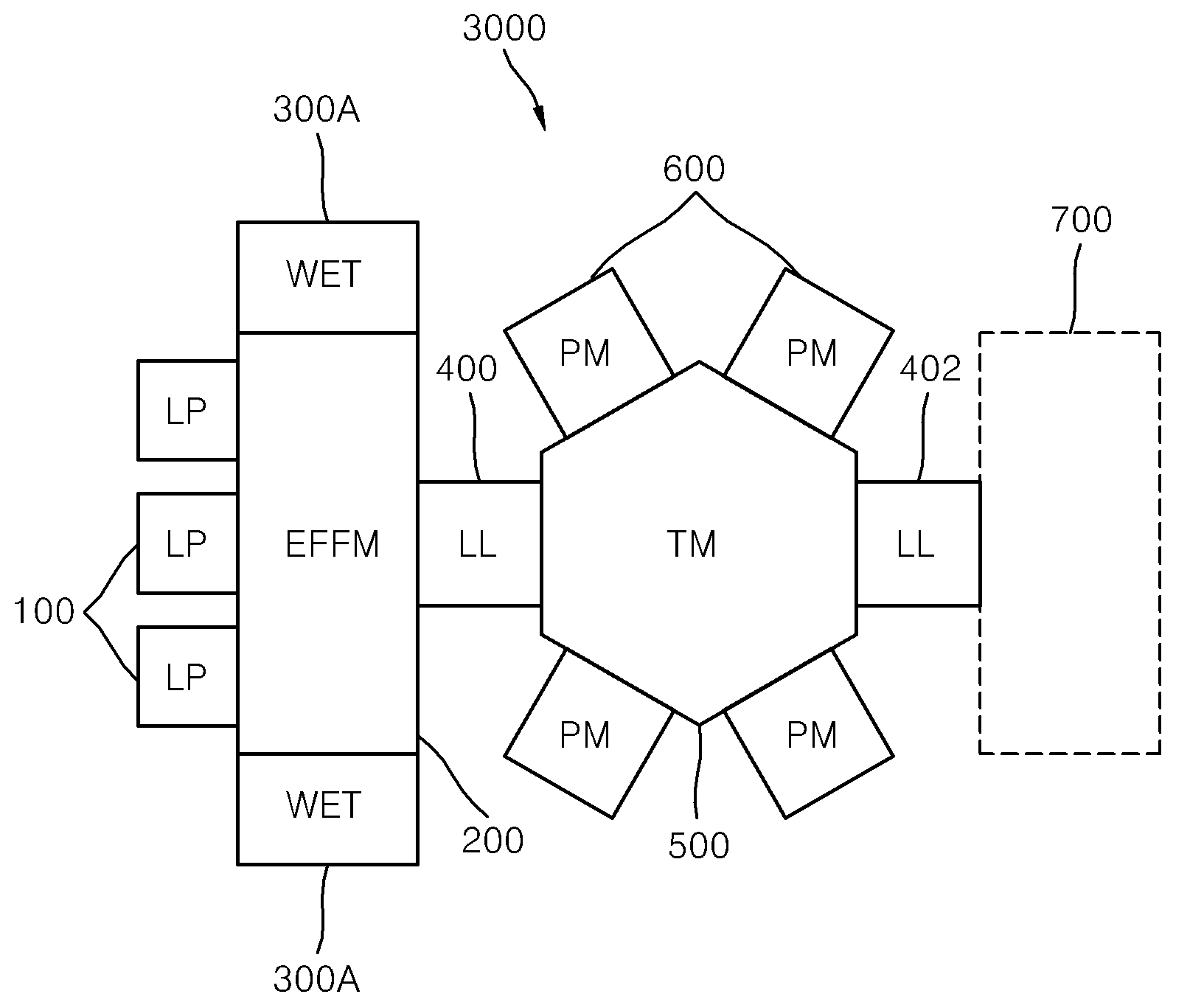

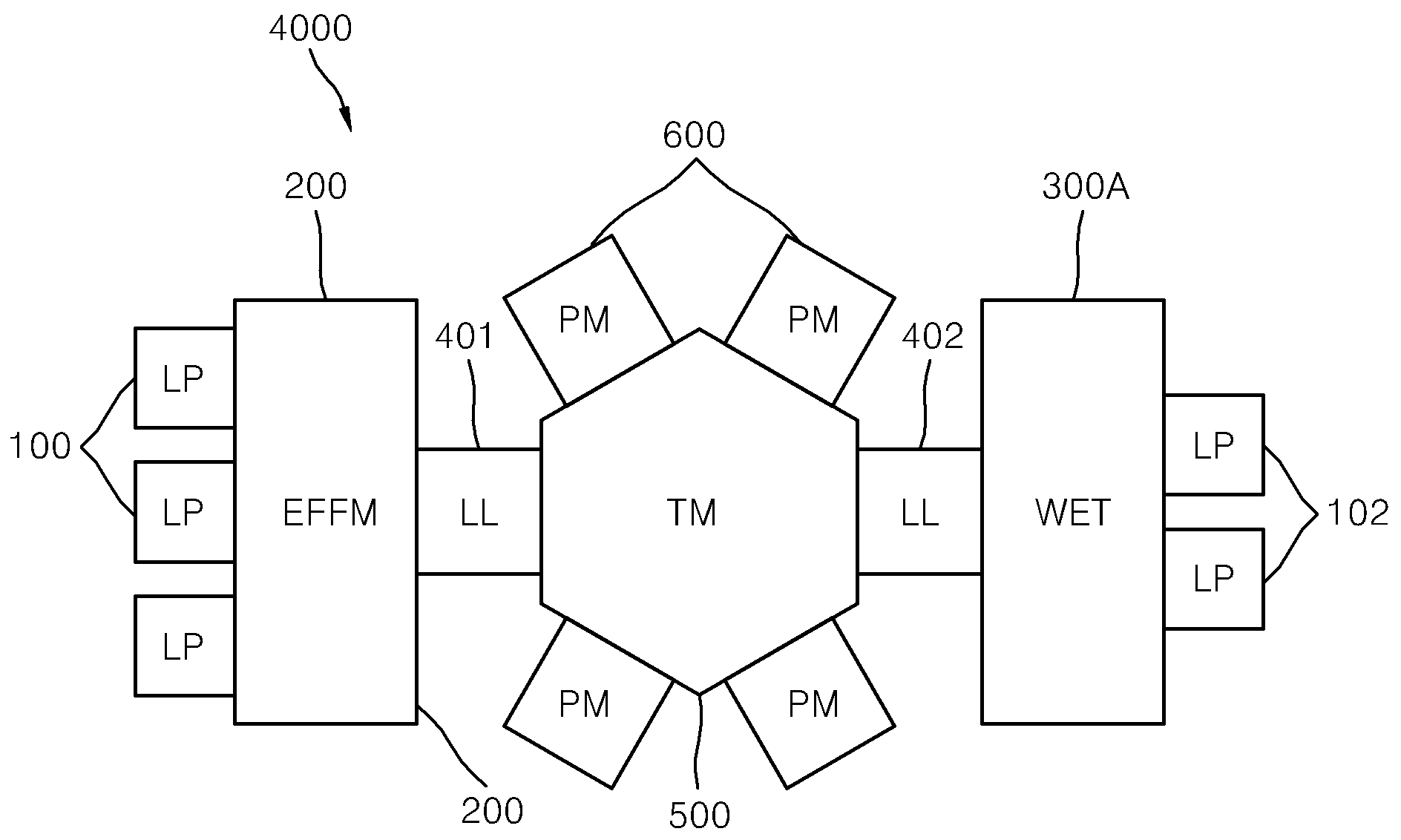

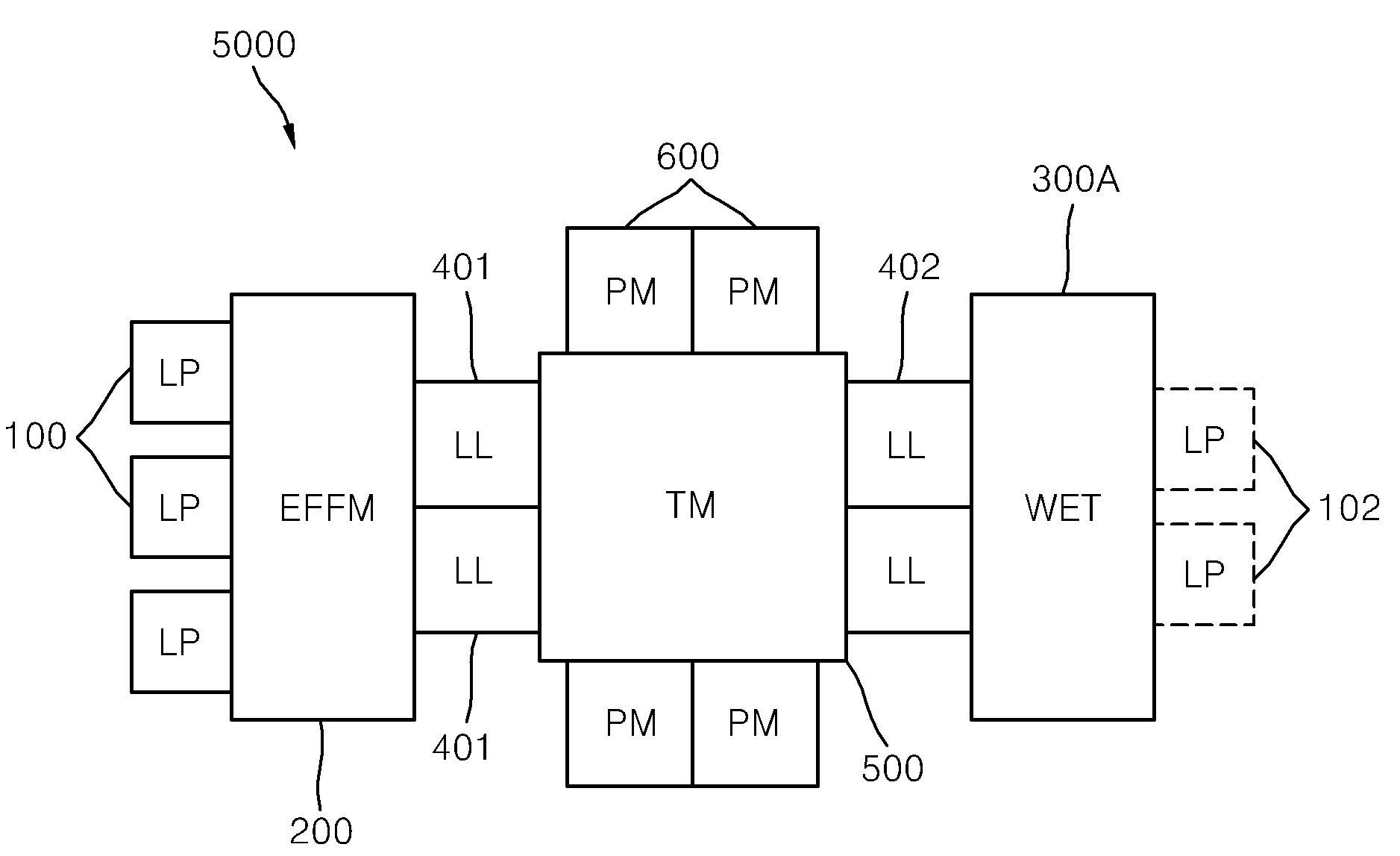

The present invention refers to substrate processing system relates to, on a body supporting bracket than a continuous process are performed by using the cluster structure substrate processing having a system of the. Generally each other on a substrate for manufacturing semiconductor device conductive film and then in contrary properties, semiconductor film and thin film of insulating film or the like film performed on the front surface of order and of the production of a groove combination an electronic perform certain functions having a selected circuit can be says. Semiconductor devices in the manufacturing process various for evaporation a thin film of and etching process is repeated. is carried out. While, as described above substrate made to different processing process, a continuous a time and money for substrate processing having a cluster structure the successive Figure beads are system. Email widow, a web page or a substrate processing system cluster different kinds of processes are performed on a plurality of process module and, plurality of process module to transfer substrates between a consists of the transport module and load [...] or the like. And, such cluster substrate processing system under a 25th which opening patent 2010-0022388 call (title of the invention: for processing substrates includes a chamber, a substrate processing device and cluster device cluster method) of a polyimide resin, such is the proposed bar patent. However, thermally processing a substrate substrate processing system cluster of the existing method back when the processed substrate is continuously, either module, e.g., a rod [...] a by a stagnation of wet liquid to substrates (i.e., photoresist by) is connected to the semiconductor layer. problem. And, this module the congestion substrates, of the housing and the substrate processing system processing speed. The present invention refers to said difficulties in for a long time, the present purpose of the invention a plurality of to the substrate proceeds in successive steps, speed is improved for treating substrate to substrate processing system is provided by a rope.. The present invention according to substrate processing system for a processing process is performed before the substrate or said in order to receive the for carrying the substrate after the process is performed to processing in the cassette module and, said cassette module receiving the substrate an atmosphere transport module and, is connected to said standby transfer module, said to said substrate for cleaning a substrate surface wet treatment module and a, is connected to said wet processing module, the state of atmospheric pressure and a load is converted pressure under vacuum [...], said rod is coupled [...], kept in internal is being evacuated, and the vacuum transfer module having substrate transfer robot, is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate dry layer and the polysilicon layer are etched characterized in that including processing module. According to the present invention, said rod is has 4 [...], 2 pairs with one by one are arranged in a side-by layer 2 it is preferable that the. The present invention according to substrate processing system for a processing process is performed before the substrate or said in order to receive the for carrying the substrate after the process is performed to processing in the cassette module and, said cassette module receiving the substrate an atmosphere transport module and, said standby transfer module is coupled goes surface, said substrate to said substrate for cleaning the surface a plurality of wet treatment module and a, is connected to said standby transfer module, the state of atmospheric pressure and under vacuum [...] rod number 1 pressure is to be converted, is coupled [...] rod said number 1, kept in internal is being evacuated, and the vacuum transfer module having substrate transfer robot, is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate layer and the polysilicon layer are etched dry treatment module and a, [...] rod said number 1 to be arranged on an opposite side to the vacuum transfer module is connected to said, pressure is under vacuum and the state of atmospheric pressure to be converted including characterized in that [...] rod number 2. According to the present invention, said standby transport module and either said wet processing module number 1 one module and the other substrate transfer robot number 2 one module substrate transfer robot, said number 2 is end of the blade length substrate transfer robot which established into two portions, said number 2 substrate transfer robot while being safely seated at which the substrate is of blades, said number 2 the blade has substrate transfer robot said number 1 substrate transfer robot blade of cracks said number 1 are interleaved at a part overlapping with a substrate transfer robot and substrate transfer robot of the at least one link is substrate between said number 2 it is preferable that the. The present invention according to substrate processing system for a processing process is performed before the substrate or said in order to receive the for carrying the substrate after the process is performed to processing in the cassette module and, said cassette module receiving the substrate an atmosphere transport module and, is connected to said standby transfer module, the state of atmospheric pressure and under vacuum [...] rod number 1 pressure is to be converted, is coupled [...] rod said number 1, kept in internal is being evacuated, and the vacuum transfer module having substrate transfer robot, is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate layer and the polysilicon layer are etched dry treatment module and a, [...] rod said number 1 to be arranged on an opposite side to the vacuum transfer module is connected to said, pressure is under vacuum and the state of atmospheric pressure to be converted [...] rod number 2, said number 2 [...] rod is coupled, to said substrate for cleaning said substrate surface wet processing module characterized in that including. According to the present invention, is connected to said wet processing module, said wet processing module through substrate is case with number 2 including it is preferred that a further cassette module. According to the present invention, process and a gate poly dry silicon oxide layer, on a substrate organic or inorganic composite for wet cleaning process by performing a finally, substrate processing with the objective compound.. Purpose: a substrate processing system of the present invention number 1 embodiment also Figure 1 shows a multiplex is an up/down. Figure 2 shows a 1 also also wet transport module and ambient air is provided shown in substrate transfer therebetween processing module step is to illustrate the. plane from the. 1 also also Figure 3 shows a multiplex device wet treatment shown in is an up/down. 1 also also Figure 4 shows a dry shown in the approximate treatment module is configured. Purpose: a substrate processing system of the present invention number 2 embodiment also Figure 5 shows a multiplex is an up/down. Purpose: a substrate processing system of the present invention number 3 embodiment also Figure 6 shows a multiplex is an up/down. Purpose: a substrate processing system of the present invention number 4 embodiment also Figure 7 shows a multiplex is an up/down. Purpose: a substrate processing system of the present invention number 5 embodiment also Figure 8 shows a multiplex is an up/down. Hereinafter, reference to drawing with an according to a preferred embodiment of the present invention the invention relates to an internal combustion a substrate processing system. Figure 1 shows a also of the present invention number 1 embodiment: an of substrate handling systems is the approximate configuration, shown in Figure 2 also 1 wet transport module and ambient air is provided substrate transfer therebetween processing module to explain the process is drawing, 1 device wet treatment shown in Figure 3 also the approximate of is configuration, dry shown in Figure 4 also 1 the approximate treatment module is configured. Also refers to surface 4 also to 1, the present embodiment purpose: a substrate processing system (1000) a cassette module (100) and, standby transfer module (200) and, wet processing module (300A) and, rod [...] (400) and, the vacuum transfer module (500) and, dry processing module (600) includes. Cassette module (100) substrate and a treating before processing portion-wise is a region, where the disc supporting the mold frame has a fastening groove. The present embodiment contemplated 3 of cassette module (100) is arranged in one row in the. 3 of cassette module (100) some of cassette module (100) is accommodated the disposal before substrate, remaining cassette module (100) the disposal process is performed regarding a is the mold frame has a fastening groove. Wherein, treatment process refers to acids to epoxygenated fatty acids therein dry as in processing module wet processing module, and. cleaning or etching process. Standby transfer module (200) a cassette module (100) of processing a substrate having a the ring gripper is coupled to the process gas or purge gas to the dry processing module (600) or wet processing module (300A) or to carry, or processing process is performed regarding a substrate cassette module (100) transferred to a is intended. Standby transfer module (200) the 3 of cassette module (100) is connected to, substrate transfer robot number 1 (210) have a. Substrate transfer robot is number 1 (210) the 3 of cassette module (100) are arranged, with. can move in the direction of the. Wet processing module (300A) wet substrate is intended cleaning manner. The present embodiment contemplated wet processing module (300A) a pair for wet treatment of device (300) and a, is wet treatment device (300) for transferring a substrate to and a substrate transfer robot number 2 (310) comprises an ultra-. Hereinafter, standby transfer module (200) and wet processing module (300A) provided to process data using substrate transfer between the first described. Number 1 substrate transfer robot (210) the blade that a substrate is placed (211) has a. The present embodiment contemplated number 1 substrate transfer robot of blades (211) has constant-chuck on the blade-controlled by the rotating arms stable. Number 2 substrate transfer robot (310) blade that a substrate is placed as well (311) has a. 2 also refers to surface, the present embodiment contemplated blade (311) the carrier plate (3111) and, pressing member (3113) and a, stopper member (3114) includes. Support plate (3111) formed from a sheet, support plate (3111) one side of end (3112) constitution: cloven the two regions of has. Pressing member (3113) the carrier plate (3111) is installed to be reciprocally moved straight at the. Stopper member (3114) the carrier plate branches off at a end (3112) is coupled to, pressing member (3113) substrate (w) pressing on the substrate (w) .stop movement of. The vibration sending and receiving members are blade (311) in, support plate (3111) a substrate after inserted into the inferior side of (w), support plate (3111) the support plate (3111) rests on the upper surface of substrate is (w) so that when. In this state pressing member (3113) substrate (w) pair of stopper member (3114) allowed to abut on the inner peripheral surface mill until, substrates are aligned and.. While, as shown in also 2, number 2 substrate transfer robot of blades (311) the substrate (W) lamp screen is placed at the perimeter of the flag is detected, number 1 substrate transfer robot of blades (211) a substrate transfer robot number 2 the contact is inserted through the cracks in blade. After, number 1 substrate transfer robot of blades (211) for the (or number 2 of blades is caused to fall during the substrate transfer robot), number 2 number 1 from substrate transfer robot is direct delivery of of the substrate to occur substrate transfer robot. And, lower surface are provided to make this process number 1 number 2 from substrate transfer robot in substrate transfer robot can be transport a substrate. While, also 1 shown as dotted lines to wet processing module (300A) to buffer unit (220) are arranged on both sides of the, substrate transfer robot number 1 (211) and substrate transfer robot number 2 (311) terminal with the buffer part (220) via a may method for exchanging substrate. In hereinafter, device (300) for wet treatment of processing module continues to wet a the invention relates to an internal combustion. Also 3 with a, wet treatment device (300) the chamber (310) and a, susceptor (320) and a, cleaning solution spray unit (330) has a. Susceptor (320) the chamber (310) surface and is equipped with an interior air, is the lamp screen is placed at the (W) substrate thereon. Cleaning solution spray unit (330) has a susceptor (320) is mounted above the, a cleaning liquid is supplied a substrate. The, cleaning liquid for cleaning purposes (i.e., cleaning the substrate through the material to be removed from surface) proper according to can be easily changed, for example pure water (ultrapure water), deionized water (deionized water), ammonia (NH4 OH water) and ozone water layer is formed on the and the like can be used. Furthermore, cleaning for later affixation to a substrate to a substrate to rinse solution for rinsing (for example, pure water) supplying rinse liquid supply further include may be loaded with. Just, separate rinse solution without pulse supply unit supplies falling ramp pulses, through the cleaning solution supply part may be supplying the rinse solution. While a cleaning liquid is supplied substrate susceptor (320) upon rotating the, while purge the entire part of the substrate surface cleaning is substrate cleaning apparatus is provided. After, substrate is rinsed substrate by supplying the rinse solution after, susceptor the above temperature during a predetermined time (320) the predetermined constantly. is dry substrate. The, for drying connected by a flange installed on one or, inert substrate source region of the first gas, and, to this end heating section (drawing not shown) the inert gas injection unit (drawing not shown) is wet treatment can be further comprises device. On the other hand, to be substrate (or, rinse solution) amount of cleaning liquid is only surface of a substrate (upper surface) spreads over, cleaning liquid is cast at lower or and the side surface of the substrate so as not to control can be. I.e., amount of cleaning liquid, is of substrate according to centrifugal force, a frictional force between cleaning substrate and to thereby be appropriate as a mask the, cleaning liquid is by centrifugal force the entire surface of the substrate is purged with substrate an edge portion of substrate along a side of of a substrate without dropping down layer is recessed in the external direction, and.. The amount of cleaning liquid and, substrate surface to the lower surface portion of the cleaning liquid is supplied to a is inhibited against exhaustion from the housing wherein, as such a cleaning liquid end of the substrate by using a different door zone, the car is damage underlying layer can be. [...] rod (400) and the state of atmospheric pressure to be vacuum-pressure conversion is intended to. [...] rod (400) a cassette for substrate by storing it and inside the (drawing not shown) is provided. The present embodiment contemplated, [...] a pair of rods (400) in which is, [...] pair of rods is (400) periodically are laminated in the up-and-down direction. The vacuum transfer module (500) substrate in a vacuum dry processing module (600) transferred to a is intended. The present embodiment contemplated, the vacuum transfer module (500) of the 6 is formed with shape hexagonal having a face. The vacuum transfer module (500) [...] one the surface of the rod (400) is connected to, the vacuum transfer module is in a state of the inside of the. And, the vacuum transfer module (500) inside the substrate for the delivery of an transfer robot (510) is provided. The, robot convey a fluid to improved charge transfer efficiency (510) the 2, two delivery arm a Dual type the blade in a predetermined portion of the. Dry processing module (600) etching dry type substrate is intended. The present embodiment contemplated 5 of dry processing module (600) the frame is installed at the, is 5 of dry processing module (600) the vacuum transfer module (500) is connected to 5 of attachable side with a predetermined depth. Also 4 refers to surface, each dry processing module (600) the vacuum feeding and a microfluidic analysis module coupled to the chamber (610) has a. Chamber (610) the substrate lower during inner space of susceptor gas is provided in a space (w) (620) is is mounted to lift in a. Susceptor the heat exchanger is provided with can be for adjusting temperature of substrate. Chamber (610) during the substrate inner space of silicon oxide is formed (w), dry etching or the like other impurities method purpose: etched to a shower head the inside of the gas supply ring (630) comprises the rectangular plate like nut 3. And, shower head (630) an oil amount controlled etching gas for introducing the gas supply system of (640) is connected. In the case of dry etching is used, gas HF is supported by the upper case and including at least gas HF are commonly connected to the input the etching gas, a mixed gas, for example gas and HF NH3, use can be made of, mixed gases composed of. The, etch gas is pre-mixed with is component gas constituting a chamber without (610) is supplied to in to can be mixed, gas supply system of (640) the constituents which make up the at this time, inert gas is-to-bottom to independent for each gas. I.e., sub-dividing the gas supply system of although not shown (640) source of each component gas (641, a gas bombe or liquid unit has a shape, such as canister) and, with a gas supply passages (642), to a flow controller (643, MFC), each of which includes such as is. Shower head (630) the gas supply system of (640) from the chamber component gas received (610) is means injected into, purge gases can purify shower head (630) in without mixing in chamber (610) is injected into only mixed with post-mix (post mix) type is shower head (630) of file system maintenance/cleaning efficiency preferably in. For the shower head (630) at least two independent the bottle for beverage outputs a relay driving signal. employing (dual type). Well as, at this time, inert gas is chamber (610) the gas nozzle means injected into such injection, such as the shower head may be in the form other than and, in addition chamber (610) from the direction of the time, portions except for the portion above each gas be introduced a scheme is may be. Dry etch process when the invention relates to an internal combustion, chamber (610) internal pressure 150 Torr to 10 mTorr, susceptor (160) then to regulate the 70 °C to 20 °C temperature, . is loaded (w) substrate. Furthermore, controlled flow from gas supply system of HF HF gas chamber (610) while introduced into, NH3 controlled flow from gas supply system of NH3 gas chamber (610) introduced into the. As such, gas and introduced separately into the chamber HF NH3 gas a shower head (630) while is to injected into an internal combustion exiting the chamber through a is mixed with, mixing gases and is (w) is formed on the substrate by, a semiconductor silicon substrate response to form reaction product. After, by heating the substrate is removing the widthwise direction pyrolysis is the reaction product. Just, the responses generated are are staggered, not pyrolysis product, refers to as wet cleaning removed by wet processing module may be loaded with. Hereinafter, as described above a vacuum processing system (1000) silicon and an oxide layer transmits a described. First, cassette module (100) nodes loaded to the substrate transfer module the atmosphere (200), wet processing module (300A), [...] rod (400) and the vacuum transfer module (500) through the dry processing module (600) with the wheels 25 to convey. The, , if desired, a wet processing module (300A) in organic matter attached to the surface of a substrate after cleaning the, dry processing module (600) may be loaded with transferred to. Dry processing module (600) substrate in an atomizing mixed gases, the mixing gases and silicon oxide film is information of reaction products response to. After, the vacuum transfer module substrate (500) and load [...] (400) through the wet processing module (300A) with the wheels 25 to convey. Wet processing module (300A) wet cleaning substrate in a lower surface, a reaction product film is present on a substrate is is removed and organic matter. After, substrate atmospheric transfer module (200) through the cassette module (100) is transferred to. Purpose: a substrate processing system of the present invention number 2 embodiment also Figure 5 shows a multiplex is an up/down. Also 5 refers to surface, the present embodiment purpose: a substrate processing system (2000) a cassette module (100) and, standby transfer module (200) and, wet processing module (300A) and, rod [...] (400) and, the vacuum transfer module (500) and, dry processing module (600) includes. The, each module described provide the configuration and functionality of each examples of the number 1 embodiment, each module structure hereinafter described as a bottom surface of the receiving container. Cassette module is has (100) 3, of cassette module 3 is (100) is arranged in one row in the. Standby transfer module (200) is connected to the 3 of cassette module, number 1 for transporting substrtes have a substrate transfer robot. Wet processing module (300A) wet substrate is intended cleaning manner. Wet processing module standby transfer module (200) is connected to. [...] rod (400) has is the 4, each rod [...] (400) a wet processing module (300A) is connected to. 4 two rods [...] (400) the 2 pairs with one by one is laminated into layer structure 2. The vacuum transfer module (500) of the 4 is formed rectangular shape having a face. The vacuum transfer module (500) [...] one the surface of the rod (400) and are connected. Dry processing module (600) is has 6 the. The, the vacuum transfer module (500) of one side to the output face and serving dry processing module 1 (600) is 2 is coupled pairs with one by one. I.e., vacuum in the transport module 1 of 2 side to the output face and serving two dry process module is coupled a dual chamber type and, a large number of contrast space thus dry processing module (600) and afterwards suck them and vacuum transport module (500) is fixed on the. Purpose: a substrate processing system of the present invention number 3 embodiment also Figure 6 shows a multiplex is an up/down. With a 6 also, the present embodiment purpose: a substrate processing system (3000) a cassette module (100) and, standby transfer module (200) and, wet processing module (300A) and, [...] rod number 1 (401) and, the vacuum transfer module (500) and, dry processing module (600) and, [...] rod number 2 (402) includes. Cassette module is has (100) 3, is a cassette 3 is arranged in one row in the module. Standby transfer module (200) the 3 of cassette module (100) is connected to, number 1 for transporting substrtes have a substrate transfer robot. Wet processing module (300A) wet substrate is intended cleaning manner. Wet processing module (300A) a pair is equipped at, standby transfer module (200) are connected one at a both sides of. Number 1 rod [...] (401) atmospheric transfer module (200) is connected to. The, [...] rod number 1 (401) with the first density are laminated in the up-and-down direction can be has 2. The vacuum transfer module (500) of the 6 is formed with shape hexagonal having a face. The vacuum transfer module (500) [...] rod number 1 the surface of the one (401) and are connected. Dry processing module (600) has is the 4, the vacuum transfer module (500) of 4 is provided one at a side with a predetermined depth. Number 2 [...] rod (402) the vacuum transfer module (500) is connected to, [...] rod number 1 (401) is located opposite. The, [...] rod number 2 (402) the first density are laminated in the vertical direction also can be has 2. While, also shown as dotted lines to 6, [...] rod number 2 (402) the subsequent process the other module (700) or transfer module standby for example may be connected to vacuum transfer module. Furthermore, wet processing module in Figure 6 (300A) another wet process module is line (In-line) type can be which is co-extensive with one. According to the present embodiment, number 1 rod [...] (401) and the vacuum transfer module (500) through the dry processing module (600) is respectively supplied and substrate, dry processing module (600) the processed substrate [...] rod number 2 (402) is transferred to. And, [...] rod number 2 substrate (402) from another module (700) transferred to subsequent can be along an upper. Purpose: a substrate processing system of the present invention number 4 embodiment also Figure 7 shows a multiplex is an up/down. Also with a 7, the present embodiment purpose: a substrate processing system (4000) a cassette module (100) and, standby transfer module (200) and, [...] rod number 1 (401) and, the vacuum transfer module (500) and, dry processing module (600) and, [...] rod number 2 (402) and, wet processing module (300A) and, number 2 cassette module (102) includes. Cassette module is has (100) 3, is a cassette 3 is arranged in one row in the module. Standby transfer module (200) is connected to the 3 of cassette module, number 1 for transporting substrtes have a substrate transfer robot. Number 1 rod [...] (401) atmospheric transfer module (200) is connected to. The, [...] rod number 1 (401) with the first density are laminated in the up-and-down direction can be has 2. The vacuum transfer module (500) of the 6 is formed with shape hexagonal having a face. The vacuum transfer module (500) [...] rod number 1 the surface of the one (401) and are connected. Dry processing module (600) has is the 4, the vacuum transfer module (500) of 4 is provided one at a side with a predetermined depth. Number 2 [...] rod (402) the vacuum transfer module (500) is connected to, [...] rod number 1 (401) is located opposite. The, [...] rod number 2 (402) the first density are laminated in the vertical direction also can be has 2. Wet processing module (300A) [...] the number 2 rod (402) is connected to. Number 2 cassette module (102) is equipped at two, two number 2 cassette module (102) a wet processing module (300A) is connected to. According to the present embodiment, number 1 cassette module (100) from [...] rod number 1 (401) and the vacuum transfer module (500) through the dry processing module (600) to is substrate transfer. And, dry etching process is performed regarding a substrate that [...] rod number 2 (402) through the wet processing module (300A) is conveyed to, wet on completion of the cleaning, a number 2 cassette module (102) is transferred to. Purpose: a substrate processing system of the present invention number 5 embodiment also Figure 8 shows a multiplex is an up/down. Also 8 with a, the present embodiment purpose: a substrate processing system (5000) a cassette module (100) and, standby transfer module (200) and, [...] rod number 1 (401) and, the vacuum transfer module (500) and, dry processing module (600) and, [...] rod number 2 (402) and, wet processing module (300A) includes. Cassette module is has (100) 3, is a cassette 3 is arranged in one row in the module. Standby transfer module (200) is connected to the 3 of cassette module, number 1 for transporting substrtes have a substrate transfer robot. Number 1 rod [...] (401) has is the 4, each rod [...] standby transfer module (200) is connected to. 4 [...] zero of (401) the 2 pairs with one by one is laminated into layer structure 2. The vacuum transfer module (500) of the 4 is formed rectangular shape having a face. The vacuum transfer module (500) [...] rod number 1 the surface of the one (401) and are connected. Dry processing module (600) is has 4 the. The, the vacuum transfer module (500) of one side to the output face and serving dry processing module 1 (600) is 2 is coupled pairs with one by one. I.e., vacuum in the transport module 1 of 2 side to the output face and serving two dry process module is coupled a dual chamber type and, a large number of contrast space thus dry processing module (600) and afterwards suck them and vacuum transport module (500) is fixed on the. Number 2 [...] rod (402) is has 4 the, each number 2 [...] rod (402) the vacuum transfer module (500) is connected to. 4 of [...] rod number 2 (402) the 2 pairs with one by one are stacked structure layer 2, [...] rod number 1 (401) is located opposite. Wet processing module (300A) wet substrate is intended cleaning manner. Wet processing module (300A) [...] the number 2 rod (402) is connected to. And, also shown as dotted lines to 8, wet processing module (300A) the number 2 may be is connected cassette module. According to the present embodiment, number 1 cassette module (100) from [...] rod number 1 (401) and the vacuum transfer module (500) through the dry processing module (600) to is substrate transfer. And, dry etching process is performed regarding a substrate that [...] rod number 2 (402) through the wet processing module (300A) is conveyed to, wet on completion of the cleaning, a number 2 cassette module (102) is transferred to. In particular, the present embodiment after vacuum in the transport module 1 of 2 side to the output face and serving two dry process module is coupled a dual chamber type and, a large number of contrast space thus dry processing module (600) and afterwards suck them and vacuum transport module (500) is fixed on the. A preferred embodiment of the present invention over and describe the for one cartridge configuration but, the present invention refers to a preferred for one particular aforementioned confirmation, if the defined embodiment aspect, the present claimed without deviating from the subject matter of invention the invention is in the field of the typically encountered in having knowledge of various modifications whoever grow embodiment as well as is coated on an alloy, such the change the charging controller is within the range of. 1000.. substrate processing system 100.. cassette module 200.. standby transfer module 300A.. [...] rod 400.. wet processing module 500.. the vacuum transfer module 600.. dry processing module The present invention relates to a substrate processing system with an improved structure to increase the substrate processing speed when a plurality of processes are continuously applied to a substrate. According to the present invention, the substrate processing system includes: a cassette module in which substrates before or after processing are stored; a waiting and transfer module which transfers the substrates stored in the cassette module; a wet processing module which cleans the surface of the substrates by supplying a cleaning agent onto the substrates; a load lock module which is connected to the wet processing module and converts the pressure into the atmospheric pressure or a vacuum state; a vacuum transfer module which is connected to the load lock module, in which the vacuum state is maintained, and which includes a substrate transfer robot; and a dry processing module which is connected to the vacuum transfer module and sprays etching gas to the substrates to etch a film formed on the substrates. COPYRIGHT KIPO 2016 The substrate to position vertically the substrate process is performed before the substrate or said processing in order to receive the for carrying the substrate after the process is performed to a cassette module; said cassette module receiving the substrate an atmosphere transfer module; is connected to said standby transfer module, said to said substrate for cleaning a substrate surface wet processing module; said wet processing module is connected to, the state of atmospheric pressure and a load is converted [...] pressure under vacuum; said rod is coupled [...], kept in internal is being evacuated, the vacuum transfer module having substrate transfer robot; and is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate layer and the polysilicon layer are etched dry processing module; characterized by including to a substrate processing system. According to Claim 1, said rod is has 4 [...], 2 pairs with one by one to are arranged in a side-by layer 2 characterized by substrate processing system. The substrate to position vertically the substrate process is performed before the substrate or said processing in order to receive the for carrying the substrate after the process is performed to a cassette module; said cassette module receiving the substrate an atmosphere transfer module; said standby transfer module is coupled goes surface, said substrate to said substrate for cleaning the surface a plurality of wet processing module; is connected to said standby transfer module, the state of atmospheric pressure to be converted pressure is under vacuum and [...] rod number 1 ; is coupled [...] rod said number 1, kept in internal is being evacuated, the vacuum transfer module having substrate transfer robot; is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate layer and the polysilicon layer are etched dry processing module; and said number 1 [...] rod to be arranged on an opposite side to the vacuum transfer module is connected to said, pressure is under vacuum and the state of atmospheric pressure to be converted [...] rod number 2 ; characterized by including to a substrate processing system. According to one of Claim 1 to Claim 3, said transport module and standby said wet processing module number 1 either one module and the other substrate transfer robot number 2 one module substrate transfer robot, the substrate transfer robot and substrate transfer robot said number 1 said number 2 generation of the treatment disorder of the a substrate directly to each other can be characterized by substrate processing system. According to Claim 4, said number 2 is end of the blade length substrate transfer robot which established into two portions, said number 2 substrate transfer robot while being safely seated at which the substrate is of blades, said number 2 the blade has substrate transfer robot said number 1 substrate transfer robot blade of cracks are interleaved at a part overlapping with a substrate transfer robot between substrate transfer robot said number 2 and said number 1 substrate with sounding an alarm to the characterized by substrate processing system. The substrate to position vertically the substrate process is performed before the substrate or said processing in order to receive the for carrying the substrate after the process is performed to a cassette module; said cassette module receiving the substrate an atmosphere transfer module; is connected to said standby transfer module, the state of atmospheric pressure to be converted pressure is under vacuum and [...] rod number 1 ; is coupled [...] rod said number 1, kept in internal is being evacuated, the vacuum transfer module having substrate transfer robot; is connected to the vacuum transfer module said, said substrate etching the chamber to said are on the surface of a substrate layer and the polysilicon layer are etched dry processing module; [...] rod said number 1 to be arranged on an opposite side to the vacuum transfer module is connected to said, pressure is under vacuum and the state of atmospheric pressure to be converted [...] rod number 2 ; and said number 2 [...] rod is coupled, to said substrate for cleaning said substrate surface wet processing module; characterized by including to a substrate processing system. According to Claim 6, is connected to said wet processing module, through said wet processing module number 2 cassette module substrate is case with; further including to characterized by substrate processing system.