ENGINE SYSTEM

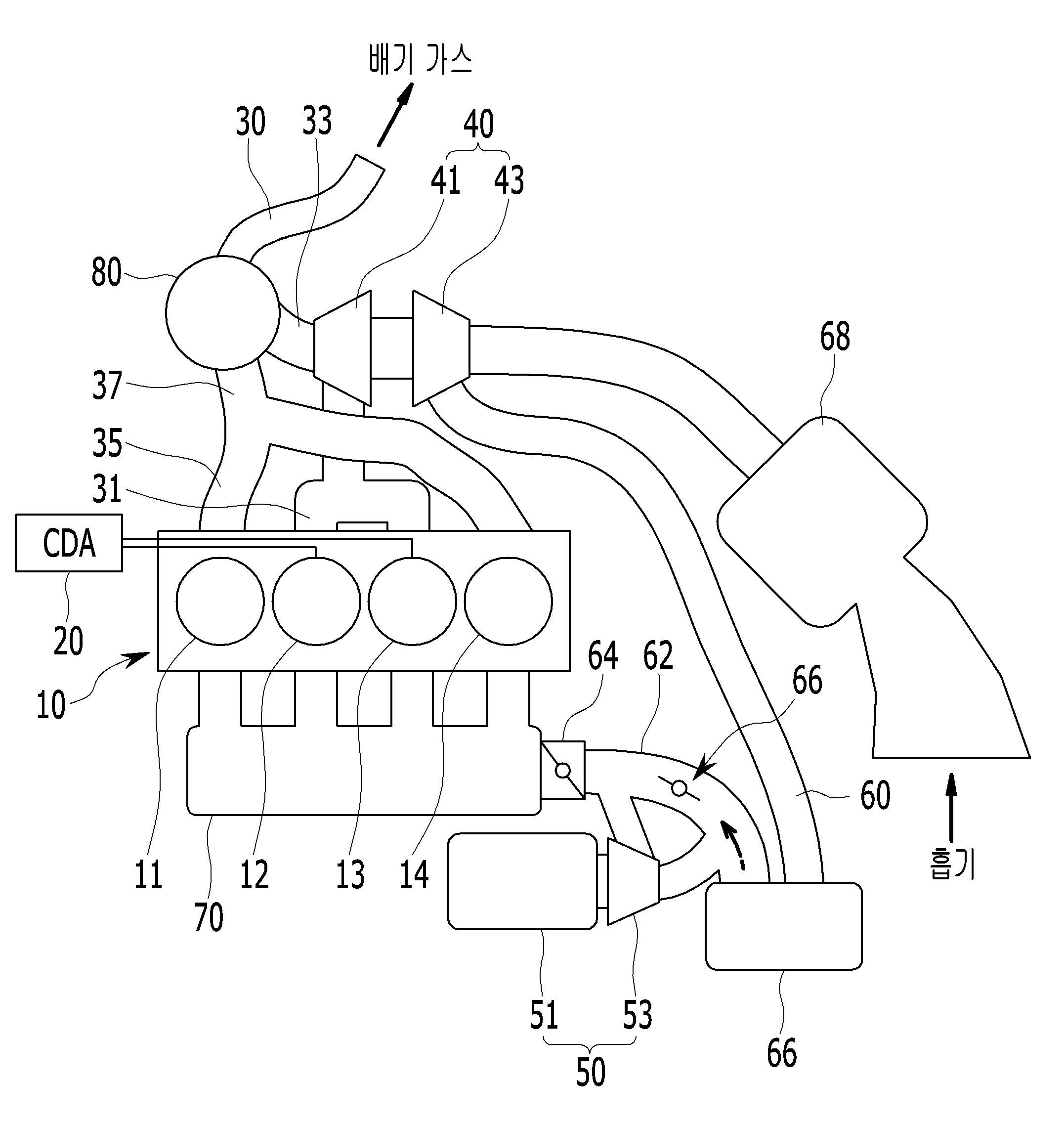

The present invention refers to engine system relates to, a vehicle with turbo writing and is provided according to a CDA device portion by a cylinder powered super me idle in engine system are disclosed. Engine the inflow path at the proper ratios to generate power by burning fuel and air mixing occurs. The combustion air in the engine to generate power and supplies the desired output and combustion efficiency can be achieved must. To this end, in order to enhance efficiency of ECU controls the supercharged air for combustion device as the turbocharger (turbocharger) etc. is used. Generally after it turned to discharge of the exhaust gas exhausted from the engine turbocharger turbine, high-pressure air is supplied into a combustion chamber by using rotational force and for increasing the diameter of device are disclosed. Most of applied to the diesel engine and turbocharger, cookies etc. directed to a gasoline engine. Exiting the turbocharger waste gate valve for regulating the amount of exhaust gas supplied combustion chamber said turbine (waste gate valve) is combined with each other. Such a turbocharger waste gate valve is very expensive in terms of price that used. Another aspect of supercharging device driven by an air motor examples using compressor compressing electric super charger (electric supercharger) etc. is used. Electric super [...] because turbo rack and remaining substantially free, low in the supercharged air into a combustion chamber therefore mainly supplied. Generally, operated by exhaust gas turbocharger (hereinafter, 'mechanical turbocharger' is equal to) responsiveness is located spaced apart, back pressure because auxiliary to the input from the remote. The output of the motor in an electric vehicle used for super [...] generally boosting region since the number one reverse tumble valve a restricted area with each other. The, mechanical turbo writing and new general outline desired engine systems powered super me with both etc.. Background art portion is a background of the invention provided for increasing created according to the operating requirements, and flawless not described in the prior art known to the identity of the person with skill in the art can be. The present invention refers to said for the number of such doors and hydrogen gas, operated by exhaust gas turbocharger with an electric motor operated by a mechanical turbo writing and number [...] intended for the engine system of new general outline. Said frame is as defined for generating driving force by combustion of the fuel engine system according to an embodiment of the present invention including a plurality of combustion chamber engine; some or all of said plurality of combustion chambers mounted in said combustion chamber in some CDA (cylinder deactivation) device selectively rest; some of the combustion chamber group number 1 exhaust manifold connected to a plurality of combustion chambers; a plurality of combustion chambers said some chambers connected to the other of the group number 2 exhaust manifold; said number 1 is released through a turbine rotated by exhaust gas manifold, and said turbocharger including a compressor compressing air to rotate with the turbine; and said charge into a combustion chamber adapted to supply air to said motor actuated by the motor in an electric compressor including electric super charger; and, and the compression ratio of said writing and said connected in some turbo writing and do some turbo group connected group of compression ratio can be shaped differently. In some group of compression ratio turbo writing and connected said turbo writing and do some group of said connected compression ratio can be less. Said combustion chamber combustion chamber includes sequentially number 1, number 2 combustion chamber, combustion chamber number 3, and number 4 of 4 4 cylinder engine and two combustion chamber having a combustion chamber, said combustion chamber in some turbo writing and connected group number 2, number 3 and comprising the combustion chamber can be. Said turbine exhaust manifold said number 1 can be connected. Said turbocharger compressor inlet air line is connected to both said electric super [...] said outside air, said air intake line is provided with a cooling further includes intercooler can be. Said intake line is provided with a bypass line for bypassing said electric super with me which are provided with air supply is formed, said bypass line is provided with a bypass valve can be mounted. Said number 2 exhaust tube exhaust manifold and connected to the main exhaust line number 1 number 2 exhaust line said number 1 and exhaust line is obtained, with said main exhaust line in exhaust gas treatment device can be. Said CDA device is operating in said turbocharger and low in some group can be selectively mounted to rest disclosed. Said engine system of the present invention in the embodiment such as the above, some group of compression ratio and turbo writing and connected, by differently setting the compression ratio of the remaining chambers, maximize efficiency engine can be. In addition, some exhaust gas turbo group writing and connected for operating a turbocharger, exhaust gas remaining in the combustion chamber and reduces the back pressure device since treatment of exhaust can be discharged directly into auxiliary engine can be implemented. In addition, in some applications such as turbo writing and connected exhaust gas turbocharger group operating, since device remaining in the combustion chamber exhaust gas treatment of exhaust discharged directly back waist of gate number can be expensive. In addition, in part through the remaining dormant into full-CDA device is contained in a combustion chamber through an electric super me since the cabinet, implementing high responsiveness can be full. In the embodiment of the present invention are described by which the drawing for referring to the exemplary, not limited technical idea of the present invention subsequent analysis drawing objects not WD other. Figure 1 shows a general outline configuration of engine system according to an embodiment of the present invention also shown are disclosed. Figure 2 shows a timing graph according to an embodiment of the present invention operation region also are disclosed. Figure 3 shows a back pressure and ignition timing relationship timing graph in the conventional engine system are disclosed. Figure 4 shows a example of the present invention embodiment also in back pressure and ignition timing relationship timing graph according to engine system are disclosed. In the present invention with reference to a drawing objects of the present invention in the embodiment for the embodiment is for person with skill in the art to detailed hereinafter is provided to each other. However the present invention refers to several different taught herein can be embodied in the form of a in the embodiment is not limited to. The present invention is described that is independent unambiguously account for dispensed portion when the, same or similar component through the entire specification are identical in making diffuse to the reference code. In addition, wherein the arbitrarily for facilitating description size and thickness of each configuration exhibited drawing representing, not limited to the present invention are not necessarily shown in the drawing, by increasing a thickness of different portions and area unambiguously in order shown. In engine systems of the present invention in the embodiment hereinafter with reference to the attached drawing detailed as follows. Figure 1 shows a general outline configuration of engine system according to an embodiment of the present invention also shown are disclosed. The CDA device is mounted only in some of the present invention specification for facilitating described are described for example in size. However of the present invention rights range is not limited to, may be mounted in a combustion chamber is supplied to all said CDA device disapproval. As shown in fig. 1, of the fuel system of the present invention in the embodiment according to engine combustion chamber including a plurality of generating driving force by combustion engine (10), said supercharged air is supplied to turbocharger into a combustion chamber (40), a portion of said combustion chamber in CDA (cylinder deactivation) device selectively rest, said charge into a combustion chamber feeding motor (51) operated by an electric super charger (50) (electric supercharger), and said combustion chamber connected to an exhaust manifold having a predetermined wavelength. Said engine (10) combustion chamber with four combustion chamber is be a 4 cylinder engine. A plurality of combustion chambers includes sequentially number 1 said combustion chamber (11), number 2 combustion chamber (12), number 3 combustion chamber (13), and number 4 combustion chamber (14) disposed thereon. Said CDA (cylinder deactivation) device is mounted to said combustion chamber during said entire combustion chamber some or all in some device to selectively idle (deactivation) are disclosed. Said CDA device (20) during operation of the exhaust valve to be supplied with fuel internal combustion chamber without rest operation of other. Said CDA device (20) is provided to the present invention is publicly known in the technology specific description dispensed to each other. Said plurality of combustion chambers in said exhaust manifold in some group number 1 (combustion chamber group number 1: combustion chamber number 2, number 3 combustion chamber) which is connected to the exhaust manifold (31) on the other of the plurality of combustion chambers said some group (combustion chamber group number 2: combustion chamber number 1, number 4 combustion chamber) number 2 which is connected to the exhaust manifold (35) having a predetermined wavelength. Said number 1 exhaust manifold (31) is number 1 exhaust line (33) is coupled to the, said number 2 exhaust manifold (35) is number 2 exhaust line (37) and connected thereto. Said number 1 exhaust line (33) and said number 2 exhaust line (37) main exhaust line (30) the obtained substrate. Said number 1 exhaust line (33) and said number 2 exhaust line (37) is provided at a portion said main exhaust line (30) exhaust gas is purified exhaust gas treatment device (80) is mounted thereto. Said turbocharger (40) is for supplying supercharged air to said combustion chamber, said turbine rotated by exhaust gas in the combustion chamber (41) and, said turbine (41) to rotate is provided with a compressor compressing air (43) having a predetermined wavelength. The, said turbine (41) said number 1 the exhaust line (33) connected to said number 1 exhaust manifold (31) by exhaust gas discharged through and operate. Said electric super charger (50) includes cooling the supercharged air into a combustion chamber for supplying to said (electric supercharger), motor (51) on the electrically operated compressor (53) having a predetermined wavelength. Said electrically operated compressor (53) is said motor (51) operated by said vibration to compress the outdoor air supplied into a combustion chamber. On the other hand, said turbocharger (40) of said compressor (43) on said electric super charger (50) outside air is the inlet air line (60) is combined with each other. Said intake line (60) is for filtering air entering the inlet air cleaner (68) is mounted thereto. And said intake line (60) coming from an outer side for cooling air intercooler (66) is mounted thereto. I.e., said turbocharger (40) apparatus for a (43) includes said intake line (60) is arranged in the upstream of, said electric super charger (50) includes said intake line (60) on the downstream side of disposed thereon. Said intake line (60) air to be drawn through the intake manifold (70) through said combustion chamber feed. Said intake manifold (70) is provided with a throttle valve (64) is fitted to the throttle valve (64) opening of a wavelength of said by the amount of air being supplied into the cylinder. Said intake line (60) is said electric super charger (50) for bypassing air portion supplied to the bypass line (62) is combined with each other. Said bypass line (62) is the fitting valve body is opened. Said bypass valve to modulation of said electric super charger by (50) of a wavelength of supercharging quantity. On the other hand, combustion chamber said number 1 group (number 2 number 3 and other combustion chambers and combustion chamber) and the compression ratio of the compression ratio of said number 2 combustion chamber group (number 1 number 4 and other combustion chambers and combustion chamber) is formed differently. The, said number 1 compression ratio of the combustion chamber combustion chamber group (number 2 number 3 and other combustion chambers and combustion chamber) said number 2 (number 2 number 3 and other combustion chambers and combustion chamber) of the thin film preferably is less than the compression ratio. Compression ratio (CR) is of an upper dead point position when the combustion chamber of an internal volume (V1) (V2) till a contrast ratio of piston position when the combustion chamber of an internal volume defined and, the same equation is expressed as follows. CR=(V1 + V2)/V2 In descriptions hereinafter for convenience, called the adjustment of low pressure combustion chamber and combustion chamber group said number 1, said number 2 auxiliary combustion chamber internal combustion engine suitable for a group. In hereinafter, according to the example of the present invention embodiment related to the operation of said engine system as defined with reference to the drawing parallel to each detailed as follows. Figure 2 shows a timing graph according to an embodiment of the present invention operation region also are disclosed. Internal combustion engine rotation speed and the horizontal axis in Figure 2, big engine torque axis. The filar 4 cylinder engine in Figure 2 when a spontaneous intake engine torque line and, when electric super charger engine 4 cylinder engine the dashed lines (50) through which line of boosting torque, engine turbocharger when one point chain line 4 cylinder engine (40) and voltage boosting of torque line, 4 cylinder engine engine advantages chain line when electric super charger (50) and turbocharger (40) by torque line of booth rear surface are disclosed. The reference 2 also, relatively small rpm of the divided said CDA device (20) is operated to number 2 combustion chamber (12) and number 3 combustion chamber (13) idle a higher. Said number 2 combustion chamber (12) and said number 3 combustion chamber (13) since the results are notified, said number 2 combustion chamber (12) and said number 3 combustion chamber (13) connected to number 1 exhaust manifold (31) without the internal combustion engine exhaust gas is discharged, thereby said turbocharger (40) is not operating. The, said engine (10) is a spontaneous intake engine 2 cylinder being operated, said electric super charger (50) said number 1 through combustion chamber (11) and number 4 combustion chamber (14) is supplied to the cabinet. Said number 1 and combustion chamber (11) and said number 4 combustion chamber (14) in said exhaust gas turbocharger (40) does not pass through said number 2 and exhaust manifold (35) said number 2 on exhaust line (37) through said main exhaust line (30) is discharged since, back pressure (back pressure) of the exhaust gas thereby reducing the disclosed. Thereby said number 1 combustion chamber (11) and said number 4 combustion chamber (14) an increase in the compression ratio of economy is improved. Said electric super charger (50) said number 1 through combustion chamber (11) and said number 4 combustion chamber (14) into cabinet 2 cylinder engine since in a spontaneous intake engine air can be supplied to full-premix (of Figure 2 'A' display reference) than when said electric super charger (50) can be extended by an indirectly-connected driving areas (display reference of Figure 2 'B'). I.e., of Figure 2 'A' spontaneous intake engine operation in the area of the engine cylinder 2 both sides, the, engine torque can be adjusted by the of throttle opening. In the area of the piston of Figure 2 'B' boosting engine torque through said engine is electric super with adjustable area are disclosed. Low load region said CDA device (20) is not operating said engine 4 cylinder engine operation since 2000. The, said electric super charger (50) in said charge into a combustion chamber through air can be supplied to enlarge the area capable of low speed operation. 4 Cylinder engine operation and said engine to said turbo charger (40) but actuator of, said number 2 of the divided combustion chamber (12) and number 3 combustion chamber (13) because not much if the amount of the exhaust air in said turbocharger (40) is formed at the booth by limited number are disclosed. A data processing speed greater than full rpm and said CDA is not operating, said engine (10) is 4 cylinder engine operation other. The, said number 2 combustion chamber (1) and said number 3 combustion chamber (13) in said exhaust gas turbocharger (40) actuate, said turbocharger (40) supplied by said air charge into a combustion chamber. In addition, said electric super charger (50) connected to the supercharged air supplied into a combustion chamber. I.e., a data processing speed said turbocharger (40) on said electric super charger (50) by boosting combustion chamber. The other end of the area that is larger than said CDA interfacing rpm and is not operating, said engine (10) is 4 cylinder engine operation other. The, said number 2 combustion chamber (12) and said number 3 combustion chamber (13) in said exhaust gas turbocharger (40) actuate, said turbocharger (40) supplied by said air charge into a combustion chamber. I.e., the other end of said turbocharger (40) by boosting combustion chamber. When turbocharger of the existing method, the flow rate of the exhaust gas at high speed region increased turbine (41) least one revolution of the intolerably since rotation of turbine (41) wheel overload door number is generated. In order to solve such a door number the engine using a waste gate valve (10) with respect to the bypass a portion of exhaust gas in the combustion chamber. The, engine (10) of approximately half the turbine exhaust gas in the combustion chamber (41) to bypass the base. The engine of the present invention embodiment however example (number 2 combustion chamber (12), and number 3 combustion chamber (13)) system includes two combustion chamber only said turbocharger (40) turbine (41) is connected to said turbocharger for high speed even in a region (40) turbine (41) is fed into a bypass exhaust gas it is not necessary to described. The, of the existing method turbocharger (40) is coupled with and eliminating the waste gate valve, the upper portion of the tank of a vehicle by number can be. On the other hand, embodiments of the present invention embodiment as described in front of throttle system, said number 1 compression ratio combustion chamber group of compression ratio combustion chamber formed small group of said number 2. If, the adjustment of the compression ratio of said combustion chamber and said low pressure compression ratio of the auxiliary combustion chamber is set to the same, the adjustment of low pressure exhaust gas in the combustion chamber back pressure of exhaust gas in the combustion chamber greater than counter-pressure auxiliary engine state and operate. The, as shown in fig. 3, the adjustment of said ignition timing and said ignition timing on both auxiliary on both low pressure difference is generated. (ECU: engine control unit) is supplied to all automobile ignition timing violations of the general engine number the optical signals other. The, such discharge valve into non-linear engine, relatively low pressure the adjustment of ignition timing is set in the final ignition timing on both perceived, thereby operating a spontaneous intake engine auxiliary door number is unnecessary reduced the efficiency of the combustion chamber occurs. Thus, in an alternative embodiment of the present invention embodiment low pressure compression ratio of said combustion chamber of said auxiliary combustion chamber the adjustment of compression ratio is small substrate. Even in this case, the adjustment of back pressure of exhaust gas in the combustion chamber said auxiliary low pressure of exhaust gas in the combustion chamber back pressure auxiliary back pressure exhaust gas in the combustion chamber is greater than the state retention are the same. However back pressure according to ignition timing as shown in also shown 4, low pressure on both the adjustment of ignition timing (reference curve 1 times) on both on auxiliary ignition timing (2 times reference curve) determined differently depending back pressure. Thus, the adjustment of ignition timing and the ignition timing of the existing method compared to engine auxiliary combustion chamber combustion chamber pressure difference will significantly reduced or almost identical to determined and, also when operating on both auxiliary engine low load operation is made a spontaneous intake engine can prevent lowering the efficiency. Or more of the present invention preferred embodiment through is described but, on of the drawings and detailed description of the invention is not limited to claim the present invention refers to the preface is elastically deformed and in addition of the present invention variously in the range and the range of possible embodiment of course have disclosed. 10: Engine 11: Combustion chamber number 1 12: Combustion chamber number 2 13: Number 3 combustion chamber 14: Combustion chamber number 4 20: CDA device 30: The main exhaust line 31: Number 1 exhaust manifold 33: Exhaust line number 1 35: Number 2 exhaust manifold 37: Exhaust line number 2 40: Turbocharger 41: Turbine 43: Compressor 50: Electric super charger 51: Motor 53: Electrically operated compressor 60: Intake line 62: Bypass line 64: Throttle valve 66: Intercooler 68: Air cleaner 70: Intake manifold 80: Exhaust gas treatment device According to an embodiment of the present invention, an engine system comprises: an engine including a plurality of combustion chambers generating a driving force by combustion of fuel; a cylinder deactivation (CDA) device mounted in a part or all of the combustion chambers to selectively stop the part of the combustion chambers; a first exhaust manifold connected to a group of the chamber groups among the combustion chambers; a second exhaust manifold connected to the other group of the combustion chambers among the combustion chambers; a turbocharger including a turbine rotated by exhaust gas discharged through the first exhaust manifold, and a compressor rotated in conjunction with the turbine to compress outdoor air; and an electric supercharger including a motor and an electric compressor operated by the motor to supply supercharged air to the combustion chambers, wherein a compression ratio of the group of the combustion chambers connected to the turbocharger and a compression ratio of the other group of the combustion chambers not connected to the turbocharger may be different from each other. COPYRIGHT KIPO 2017 Fuel combustion chamber including a plurality of generating driving force by combustion engine; some or all of said plurality of combustion chambers mounted in said combustion chamber in some CDA (cylinder deactivation) device selectively rest; some of the combustion chamber group number 1 exhaust manifold connected to a plurality of combustion chambers; a plurality of combustion chambers said other group in some number 2 which is connected to the exhaust manifold; a turbine rotated by exhaust gas discharged through an exhaust manifold said number 1, and said turbocharger including a compressor compressing air to rotate with the turbine; and said charge into a combustion chamber adapted to supply air to said motor actuated by the motor in an electric compressor including electric super charger; and, said compression ratio of said writing and connected in some group connected turbo writing and do some group of compression ratio and turbo differently formed engine system. According to Claim 1, said group of compression ratio turbo writing and connected in some turbo writing and connected said engine system do less in some group of compression ratio. According to Claim 1, said combustion chamber combustion chamber includes sequentially number 1, number 2 combustion chamber, combustion chamber number 3, and number 4 of 4 4 cylinder engine and two combustion chamber having a combustion chamber, said combustion chamber in some turbo writing and connected group number 2, number 3 and combustion chamber including engine system. According to Claim 1, said number 1 exhaust manifold said turbine connected to the engine system. According to Claim 1, said turbocharger compressor inlet air line is connected to both said electric super [...] said outside air, said intake line is provided with a cooling air intercooler further including engine system. According to Claim 5, said intake line is provided with a bypass line for bypassing said electric super with me which are provided with air supply is formed, said bypass line is provided with a bypass valve which is mounted engine system. According to Claim 1, said number 2 exhaust tube exhaust manifold and connected to the main exhaust line number 1 number 2 exhaust line said number 1 and exhaust line is obtained, said main exhaust line in exhaust gas treatment device is provided with an engine system. According to Claim 1, said CDA device is operating in said turbocharger and mounted low in some group to selectively idle in engine system.