ORGANIC LIGHT EMITTING DISPLAY DEVICE

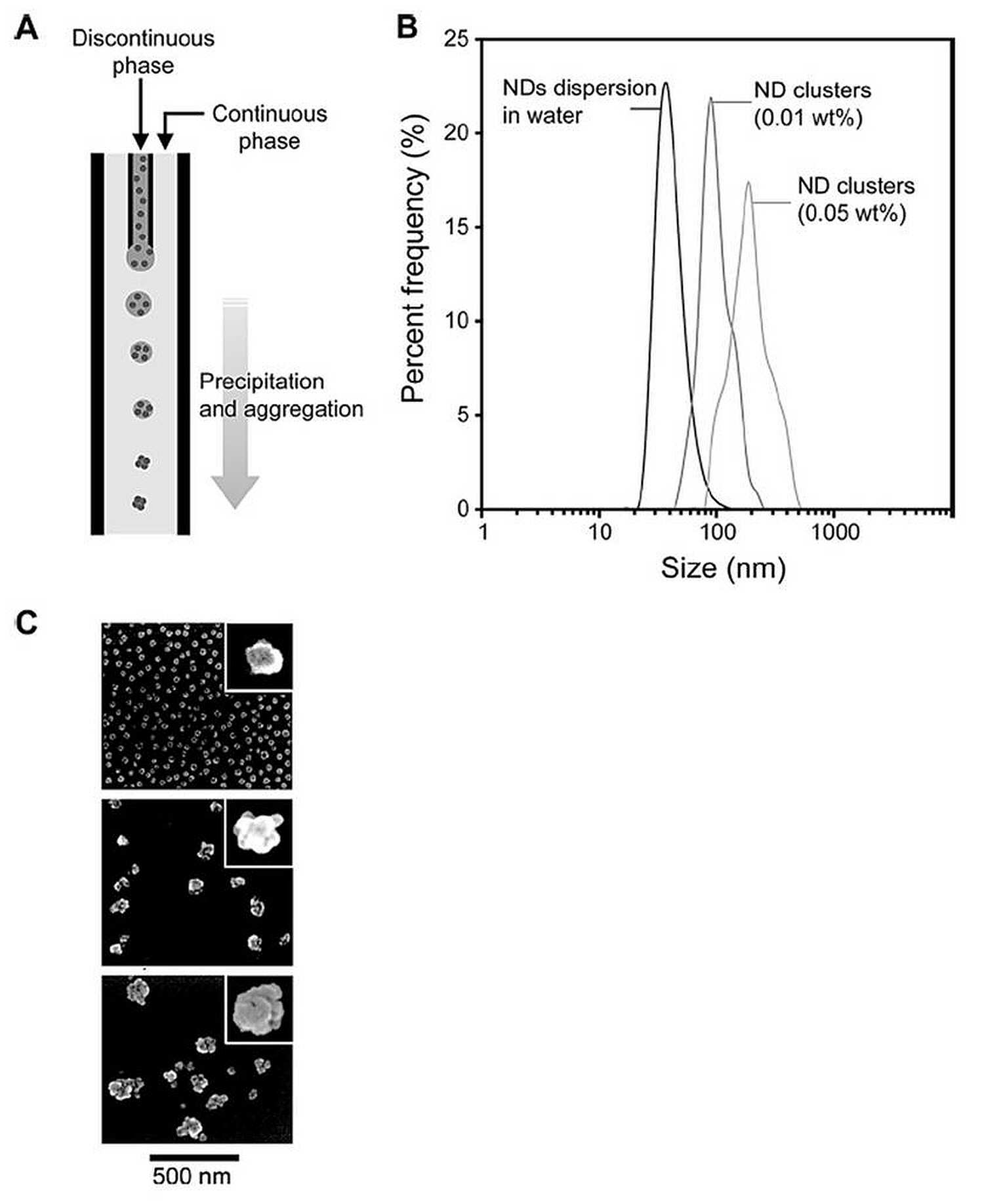

The organic light emitting device in the embodiment are to displays images are disclosed. Recently, organic light emitting display device includes a display device reduces as organic light-emitting diode (OLED: Organic Light Emitting Diode) which is capable of supporting a high response speed by using, contrast ratio (Contrast Ration), luminous efficiency, higher luminance and viewing angle and the like...copyright 2001. Organic emitter layer in organic light emitting display device for various elements through the emitted light includes organic light emitting display device from outside is equal to organic light emitting display device. However, organic light emitting layer of organic light emitting display device which does not outside the emitted light from the organic light emitting display device are in a portion internal reflection light, the light extraction efficiency of this door number organic light emitting display device is under or over. In order to improve the light extraction efficiency of the organic light emitting display device, organic light emitting display device outside micro-lens array substrate (micro lens array; MLA) etc. attaching scheme is used. The aim of the are in the embodiment, external light emitting efficiency is improved and, organic light emitting display device or a reversed F. a number [...] lowering power consumption. The one in the embodiment, the over coating layer disposed on a substrate, over coating layer disposed on the electrode number 1, number 1 number 1 electrode disposed on the electrode layer exposed over coating layer including bank, bank layer exposed on the island pattern layer openings arranged in number 1, number 1 electrode pattern layer disposed on the organic light emitting layer and organic light-emitting layer disposed on the organic light emitting display device can be [...] number 2 electrode including a number. As in the embodiment than are the, external light emitting efficiency, reduce power consumption can be a number [...] organic light emitting display device. Figure 1 shows a cross-section of the organic light emitting display device also one in the embodiment according to 2000. Figure 2 shows a X region be accomplished cross-sectional drawing of Figure 1 are disclosed. In the embodiment according to Figure 3 shows a cross-section of other organic light emitting display device are disclosed. Be accomplished cross-sectional drawing of Figure 3 Y region 4a is also are disclosed. 4B is also of over coating layer number 1 of Figure 3 Y electrode, partial plane view pattern layer are disclosed. Figure 5 shows a partial cross-sections of organic light emitting display device according to comparison example also are disclosed. Figure 6 shows a cross-section is generally organic light emitting display device shown in example overcoated layer are disclosed. Figure 7 shows a modified embodiment in cross-section in the embodiment according to another organic light emitting display device shown overcoated layer also are disclosed. Also 8a to 8c is also disposed in the pattern layer overcoated layer concave light emitting organic light emitting layer conditions depending on the position of the colloid (effective light-emitting region control) by comparing the external light extraction efficiency and distribution (viewing angle) shown in the drawing are disclosed. Figure 9 shows a coating layer including organic light emitting display device including a plurality of protrusions in the embodiment according to another also to account for cross-over are disclosed. Figure 10 shows a schematic diagram of the organic light emitting display device according to the invention in the embodiment a system configuration are disclosed. Hereinafter, in the embodiment of the present invention with reference to an exemplary drawing part are detailed as follows. Each of the drawings in adding references components, although other drawing even for the same components displayed on a possible code may have the same. In addition, the present invention is connected to the described, publicly known or a function of the associated specific description the subject matter of invention description if a haze can be decided to be dispensed can be. In addition, the constitution of the invention described is provided to element, number 1, number 2, A, B, (a), (b) using terms such as can be. Other components such terms having an element discriminate between the hell of, its terms corresponding by the nature of the components, in turn, not limited number order or the like. Any component and other components "connected", "coupled" or "connected" are blocked when described, other components or constituents are directly linked can be connected but, "interposed" between components or other components for each, each component through other components of the "connected", "coupled" or "connected" is a device that may be will be. Figure 1 shows a cross-section of the organic light emitting display device also one in the embodiment according to 2000. Figure 2 shows a X region be accomplished cross-sectional drawing of Figure 1 are disclosed. The reference also 1 and 2 also, organic light emitting display device in the embodiment according to one (100) substrate (110), thin film transistor (120), color filter (150), over coating layer (160), pattern layer (137) and organic light emitting device (140) having a predetermined wavelength. Substrate (110) on gate electrode (121), active layer (122), a source electrode (123) and a drain electrode (124) including a thin film transistor (120) is disposed thereon. Specifically, substrate (110) on gate electrode (121) is disposed, gate electrode (121) and substrate (110) on gate electrode (121) and the active layer (122) for insulating gate dielectric layer (131) is disposed, a gate dielectric layer (131) active layer (122) is disposed, an active layer (122) transfer (etch stopper; 132) is arranged on a half of the star, active layer (122) star semiconductor dielectric (132) on the source electrode (123) and a drain electrode (124) disposed thereon. A source electrode (123) and a drain electrode (124) active layer (122) manner in contact with the active layer (122) and electrically connected with, etch star transfer (132) formed on a portion of disposed thereon. Semiconductor etch star (332) is arranged not may be filled. The specification for facilitating descriptions in the organic light emitting device (100) various thin film on the substrate was shown only be included in the thin film transistor. In addition, the specification gate insulator (120) active layer is (122) reference gate electrode (121) the source electrode (123) and a drain electrode (124) located on the opposite side with inverted staggered (inverted staggered) structure or a bottom gate structure described but active layer (122) reference gate electrode (121) the source electrode (123) and a drain electrode (124) in addition to such as the coplanar waveguide (coplanar) structure or a top gate thin film transistor can be also be used. Thin film transistor (120) on the passivation layer (133) is disposed, passivation layer (133) color filter on (150) has a flat portion. Color filter (150) is the organic light emitting layer (142) is provided for converting the emitted light in color, a red color filter, a green color filter and a blue color filter can be one. Color filter (150) layers (133) on the over coating layer (160) disposed thereon. Over-coating layer (160) etc. a flat upper surface. Over-coating layer (160) number 1 on electrode (141), the organic light emitting layer (142) and number 2 electrode (143) including an organic light emitting device (140) and bank (136), pattern layer (137) disposed thereon. Over-coating layer (160) and number 1 electrode (141) disposed on the outer, electrode number 1 (141) opening exposing (136a) including a bank layer (136) disposed thereon. Bank layer (136) adjacent pixel (or pixel) serves coverage between the input unit, the target pixel (pixel) region positioned in between disapproval. Number 1 electrode (150) layer on a (137) disposed thereon. Pattern layer (137) a bank layer (136) opening (136a) separated from the electrode number 1 (150) on island shape disposed thereon. Pattern layer (137) a bank layer (136) can be the same material. In one aspect process with the over-coating layer (160) is formed over coating layer (160) number 1 on electrode (141) formed on the substrate. Over-coating layer (160) and number 1 electrode (141) front on bank layer (136) and pattern layer (137) of heated raw material bank layer (136) opening (136a) and pattern layer (137) using a mask pattern layer conforming to the shape of the developed to (137) is lower than a position corresponding to the conventional process specially developed quantity added conductive layer pattern bank layer (136) and the same material bank layer (136) and pattern layer (137) can be simultaneously. Number 1 electrode (141) and pattern layer (137) on the organic light emitting layer (142) is disposed, the organic light emitting layer (142) on the organic light emitting layer (142) supplies one electrode number 2 for the electrons or holes (143) is disposed thereon. Bank layer (136) opening (136a) to over coating layer (160) disposed on electrode number 1 (141) over coating layer (160) surface topology according to shape. In other words bank layer (136) opening (136a) to over coating layer (160) disposed on electrode number 1 (141) is, the lower side of the flat substrate and including a flat shape. The organic light emitting layer (142) and number 2 electrode (143) over coating layer (160) along with a number 1 electrode surface morphology (morphology) (141) and pattern layer (137) disposed along the shape of the upper surface of an exposure a non-planar surface and lower surface. The, number 1 electrode (141) is a flat shape wherein the organic light emitting layer (142) and number 2 electrode (143) on the pattern layer has a convex shape. As a result one in the embodiment according to organic light emitting display device (100) includes a number 1 electrode (141) layer on a (137) because the organic light emitting layer (142) and number 2 electrode (143) nickel bending to the shape of the microlens array structure to be coated. In the embodiment according to one organic light emitting display device (100) is over coating layer (160) forming protrusions in a recessed portion or a bank without using a layer (136) and pattern layer (137) the number simultaneously without additional high pressure liquid coolant can be microlens array structure. Pattern layer (137) micro lens array structure formed as external light extraction efficiency can be improved. In the embodiment according to Figure 3 shows a cross-section of other organic light emitting display device are disclosed. Be accomplished cross-sectional drawing of Figure 3 Y region 4a is also are disclosed. 4B is also of over coating layer number 1 of Figure 3 Y electrode, partial plane view pattern layer are disclosed. The reference also 3 and 4a also, organic light emitting display device (300) of the substrate (310), thin film transistor (320), color filter (350), over coating layer (360), pattern layer (337) and organic light emitting device (340) having a predetermined wavelength. Also shown in organic light emitting display device and also 3 4a (300) includes a bottom emission type organic light emitting display device was shown. However, in the embodiment according to one organic light emitting display device (300) includes a color filter (350) substrate (310) opposite the top emission the converter device may be disclosed. Substrate (310) on gate electrode (321), active layer (322), a source electrode (323) and a drain electrode (324) including a thin film transistor (320) is disposed thereon. Specifically, substrate (310) on gate electrode (321) is disposed, gate electrode (321) and substrate (310) on gate electrode (321) and the active layer (322) for insulating a gate insulating layer (331) is disposed, a gate dielectric layer (331) active layer (322) is disposed, an active layer (322) transfer (etch stopper; 332) is arranged on a half of the star, active layer (322) star semiconductor dielectric (332) on source electrode (323) and a drain electrode (324) disposed thereon. A source electrode (323) and a drain electrode (324) active layer (322) manner in contact with the active layer (322) and electrically connected with, etch star transfer (332) formed on a portion of disposed thereon. Semiconductor etch star (332) is arranged not may be filled. Thin film transistor (320) on passivation layer (333) is disposed, passivation layer (333) color filter on (350) is disposed thereon. The passivation layer also 4a (333) of the thin film transistor (320) upper for planarizing a illustrated but, passivation layer (333) a thin film transistor (320) without are planarized, the underlying elements arranged along the surface profile of the disapproval. Color filter (350) is the organic light emitting layer (342) is provided for converting the emitted light in color, a red color filter, a green color filter and a blue color filter can be one. Color filter (350) is passivation layer (333) on a position corresponding to the light-emitting region disposed thereon. Wherein, the light emission region is number 1 electrode (341) and number 2 electrode (343) organic light emitting layer (342) components it region, in positions corresponding to the light-emitting region color filter (350) are positioned such that the emitted light is light emitting regions adjacent the blur is disclosed in ghost ring phenomena and to prevent the occurrence of color filter (350) means are disposed to each other. For example, color filter (350) is it is possible to the light-emitting region can be arranged. But, color filter (350) and location of, size and position of the light as well as size, color filter (350) on electrode number 1 (341) distance between, color filter (350) on the over coating layer (360) of recesses (361) or projection (363) distance between, the distance between the light-emitting region and a light-emitting region such as can be determined by various factors. Color filter (350) layers (333) layer overcoated on (360) disposed thereon. The passivation layer also 4a (333) organic light emitting display device (300) to be switched on but shown, passivation layer (333) and unused, thin film transistor (320) directly on the over coating layer (360) disapproval can be arranged. Color filters also 4a (350) is passivation layer (333) disposed on but is illustrated, the number not one, color filter (350) is over coating layer (360) substrate (310) can be disposed at an arbitrary position between. Over-coating layer (360) the color filter (350) arranged to be overlapping with a plurality of recesses (361) of mutually adjacent recess (361) connecting connection number 1 (362) without using a tool. Also 4a is hexagonal with a plurality of recesses (361) cross-sectional drawing of are disclosed. Number 1 connection (362) are each adjacent recess (361) between high portion are disclosed. Over-coating layer (360) is a plurality of recesses (361) is disposed in portions of the planarizing layer functions as a substrate. As also shown in the 4b with a plurality of recesses (361) and number 1 connection (362) to be fully hexagonal each plane can be a generally semi-spherical shape which is not a single number the one example, can be various shapes are square shape or the like. A plurality of recesses (361) is arranged on a plane hexagonal honeycomb can be arranged. In other words hexagonal one recess (361) connected with another recess (361) is embodied as a single piece share one hexagon can be arranged in a honeycomb. Over-coating layer (360) number 1 on electrode (341), the organic light emitting layer (342) and number 2 electrode (343) including an organic light emitting device (340) and bank (336), pattern layer (337) disposed thereon. At this time, but that does not shown over-coating layer (360) from out dog [sing organic light-emitting device (340) while over coating layer blocks diffusion (360) of recesses (361)'s morphology along as an outer electrode number 1 (341) passivation layer (not shown) is over coated layer that has a refractive index similar to a while insulating number 2 (360) and number 1 electrode (341) can be added to between. Specifically, over coating layer (360) on the organic light emitting layer portion (342) supplies one electrode number 1 for the electrons or holes (341) is disposed thereon. Number 1 electrode (341) in measurement of the organic light emitting device (normal OLED) anode, and pixel electrode or it will be a child node, inverted organic light emitting device (inverted OLED) cathode, it will dig up and it will be a cow [tu or pixel electrode may be filled. Number 1 electrode (341) is over coating layer (360) thin film transistor through the contact hole formed (320) source electrode (323) can be connected. The specification gate insulator (320) N a-type thin-film transistor is thus set to the moment when, number 1 electrode (341) the source electrode (323) disclosed that but connected to, thin film transistor (320) is P-a type thin film transistor when the electrode number 1 (341) gate electrode (324) coupled to the disapproval. Number 1 electrode (341) is direct the organic light emitting layer (342) or in contact with, the organic light emitting layer and an outer conductive material (342) can be electrically connected in contact with. Number 1 electrode (341) over coating layer (360) along the shape surface morphology (morphology) disposed thereon. The, number 1 electrode (341) over coating layer (360) of recesses (361) recessed in morphology. Over-coating layer (360) and number 1 electrode (341) disposed on the outer, electrode number 1 (341) opening exposing (336a) including a bank layer (336) disposed thereon. Bank layer (336) (or pixel) adjacent pixel coverage between ceramic and considering, the pixels adjacent to each (or pixel) region positioned in between disapproval. Over-coating layer (360) of recesses (361) on connection number 1 (362) the calculation layer (336) opening (336a) to overlapping disposed thereon. As the aforementioned over-coating layer (360) of recesses (361) on connection number 1 (362) has a color filter (350) rotates to overlapping, over coating layer (360) of recesses (361) on connection number 1 (362) at the bottom and a color filter that (350) and overlapping the upper bank layer (336) opening (336a) overlapping the other. Number 1 electrode (350) layer on a (337) disposed thereon. Pattern layer (337) a bank layer (336) opening (336a) separated from the electrode number 1 (350) on island shape disposed thereon. I.e., pattern layer (337) electrode layer overcoated on the number 1 (360) the plurality of depressions (361) of recessed region partially fills substrate. Pattern layer (337) is located with a plurality of recesses 4b as also shown in all but one number is not disclosed. Pattern layer (337) with a plurality of recesses may be positioned to only a part of the disapproval. Pattern layer (337) the organic (340) is placed which is removed flexion of surface can be. Pattern layer (337) a bank layer (336) can be the same material. In one aspect process recess (361) and number 1 connection (362) including a over-coating layer (360) is formed over coating layer (360) number 1 on electrode (341) formed on the substrate. Over-coating layer (360) and number 1 electrode (341) front on bank layer (336) and pattern layer (337) of heated raw material bank layer (336) opening (336a) and pattern layer (337) developed to conforming to the shape of the pattern layer using a mask (337) lower than a position corresponding to the conventional process is particularly developed quantity added conductive layer pattern bank layer (336) and the same material bank layer (336) and pattern layer (337) can be simultaneously. Number 1 electrode (341) and pattern layer (337) on the organic light emitting layer (342) is disposed, the organic light emitting layer (342) on the organic light emitting layer (342) supplies one electrons or holes for the number 2 electrode (343) is disposed thereon. The organic light emitting layer (342) changing a plurality of organic emissive layer is laminated structure to light (tandem white) disposed thereon. The organic light emitting layer (342) emitting a blue organic light emitting layer disposed on the organic light emitting layer number 1 and number 1, number 2 white color light by mixing blue light comprising organic light-emitting layer. Number 2 organic emissive layer, e.g., organic light emitting spectrum of the light emitted (yellowgreen) seed layer disclosed. On the other hand, the organic light emitting layer (342) is blue light, red light, green light emitting organic light emitting layer may contain only one of disapproval. The color filter (350) thereof can not. Number 2 electrode (343) (normal OLED) normal organic light emitting cathode, and common electrode or it will dig up and it will be a cow [tu, inverted organic light emitting device (inverted OLED) in anode, common electrode or it will be a child node may be filled. The organic light emitting layer (342) and number 2 electrode (343) over coating layer (360) along with a number 1 electrode surface morphology (morphology) (341) and, number 1 electrode (341) layer overcoated on (360) the plurality of depressions (361) of partially recessed region is filled with the pattern layer (337) disposed along the shape of the upper surface of an exposure a non-planar surface and lower surface. E.g. depositing the organic light emitting layer manner (342) and number 2 electrode (343) is that when disposed, the organic light emitting layer (342) and number 2 electrode (343) is number 1 electrode (341) and pattern layer (337) along the upper surface of the shape morphology (morphology) disposed thereon. 4A also reference the over coating layer (360) of recesses (361) on connection number 1 (362) between the organic light emitting layer (342) over the thickness of the coating layer (360) of recesses (361) for the floor or number 1 connection (362) at the tip of the organic light emitting layer (342) thereof can thickness less than that of. In particular, over coating layer (360) of recesses (361) on connection number 1 (362) between the organic light emitting layer (342) slope (slope) in chamber is installed to enclose the organic light emitting layer (342) smallest thickness of thereof can. E.g. depositing the organic light emitting layer manner (342) are formed on a first substrate (310) deposited perpendicularly to the organic light emitting layer (342) equal the thickness of the organic light emitting layer (342) is over coated layer (360) according's morphology in the periphery of , the organic light emitting layer number chamber (342) in electrode number 1 (341) and number 2 electrode (342) has a thickness between current driving the organic light emitting layer (342) and the tip of position is tested, the organic light emitting layer (342) of the smallest slope position, i.e. at the tip floor or equal to 0.010. The organic light emitting layer (342) according to the thickness of the organic light emitting layer (342) amount of light in one aspect, over coating layer (360) of recesses (361) on connection number 1 (362) between the organic light emitting layer (342) per unit area of the light emission amount recess (361) for the floor or number 1 connection (362) at the tip of the organic light emitting layer (342) per unit area of the light emission amount can be greater than. In particular, over coating layer (360) of recesses (361) on connection number 1 (362) between the organic light emitting layer (342) slope (slope) in chamber is installed to enclose the organic light emitting layer (342) can be the largest amount of light. Figure 5 shows a partial cross-sections of organic light emitting display device according to comparison example also are disclosed. The organic light emitting display device according to comparison example 5 also reference (500) has a color filter (550) on, recess (561) and number 1 connection (562) including a over-coating layer (560) comprises. Over-coating layer (560) on electrode number 1 (541), the organic light emitting layer (542), number 2 electrode (543) disposed sequentially organic light emitting devices (540) having a predetermined wavelength. Organic light emitting display device according to comparison example (500) is in the embodiment according to the aforementioned other organic light emitting display device (300) included pattern layer (337) does not contain a number 1 electrode (541), the organic light emitting layer (542) and number 2 electrode (543) over coating layer (560) along the topology of a surface shape. Organic light-emitting device (540) a micro lens array structure engine is external light extraction efficiency, therefore organic light emitting pattern (540) surface 5 as also shown in the over coating layer (560) of recesses (561) concave curvature by opening other. The recording electrode number 1 region of steep slope (541) and number 2 electrode (543) between the organic light emitting layer (542) of electric field is locally gather efficiency light emitting region (C) while the shortest sheet, an over coating layer (560) of recesses (561) on connection number 1 (562) is the area between the occurs. Organic light-emitting device (540) electric field in the luminescence area 50 is such efficiency is locally concentrated while emitting primary and primary current path is formed deep-seated over coating layer (560) of recesses (561) (D) approximately inefficiency in light-emitting region does not extracted. The light-emitting region (D) consume less power inefficiency in spite for extracting light substantially equal to external light extraction efficiency does not drop. In addition over coating layer (560) of recesses (561) by reflecting external light reflectance in the music which boils the door number point rise mainly of copyright 2001 substrate. As also shown in the bank layer 4a and 4b also (336) opening (336a) separated from the electrode number 1 (341) layer on a (337) the areas which are not (A) is disposed electrode number 1 (341) of an organic light emitting layer (342) and number 2 electrode (342) between the pattern layer (337) light emitting not an effective light-emitting region disposed corresponding substrate. Bank layer (336) opening (336a) separated from the electrode number 1 (341) layer on a (337) (B) number 1 electrode is disposed region (341) of an organic light emitting layer (342) and number 2 electrode (342) between the pattern layer (337) rotates the light non-effective light-emitting region corresponding to the substrate. In the embodiment according to the aforementioned other organic light emitting display device (300) in over coating layer (360) of recesses (361) bending have indicated by the organic light emitting device (340) by bending surface of the organic light emitting layer (342) different from the thickness of, whenever area center slope is applied to the effective light-emitting region (A) current concentrated only light to emit light to each other. (B) is of the non-effective light emitting region while electrode number 1 (341) of an organic light emitting layer (342) and number 2 electrode (342) between the pattern layer (337) rotates the planar light is not, such as proportion 5 also contributes to improvement in light-emitting region (D) light extraction efficiency does not substantially disclosed organic light-emitting device (340) minimizing or preventing the entrapped within the can. In addition 5 as also shown in the light emitting region proportion in organic light-emitting device (D) (340) entrapped within the common component minimizing or preventing the light is left in a can. Through organic light-emitting device (340) can be downloaded from the external light extraction efficiency. In the embodiment according to the aforementioned organic light emitting display device (300) in over coating layer (560) of recesses (561) pattern layer disposed (337) over coating layer (560) flexion of relief is connected to an acknowledgment in lowering light reflection factor. Table 1 is also shown in the other organic light emitting display device in the embodiment according to also 3 to 4b (300) according to comparison example 5 are symmetrically shown in the organic light emitting display device (500) driving voltage (V), current density (J), luminous efficiency (cd/A), external quantum efficiency (EQE) exhibits a measured. The external quantum efficiency (EQE (external quantum efficiency)) in table 1 internal quantum efficiency (IQE (internal quantum efficiency)) and the product of the light extraction efficiency (extraction) can be defined. Table 1 through 3 as can recognize the organic light emitting display device in the embodiment according to 4b also to also shown in the other (300) organic light emitting display device according to example 5 is also shown in the comparison (500) external quantum efficiency-state efficiency and 10% or more, e.g. 15% sec were confirmed. On the other hand, also in the embodiment according to other organic light emitting display device through a browser a also 3 to 4b (300) in, over coating layer (360) to the bottom of the bank layer (336) opening (336a) arranged to be overlapping the color filter (350) is number 1 electrode (341) and not contact. As also shown in the 6 such as photolithography (photolithography) produced with the negative photoresist through the process of the over-coating layer (360) a number of recesses (361) contact with, (uniformity) uniformity over the entire substrate surface area of the coating layer (360) of recesses (361) making a recess shape of most hand easy method (361) exposed to the outside bottom of hypermetropia. The recess (361) bottom (361a) perceptible color filter (350) while exposing the organic light emitting device (340) of issues can be significantly generated. For this reason coating layer (360) of recesses (361) satisfying shape profile even organic light emitting display device (300) can be applied to an implantation site. As also shown in the 7 in the embodiment according to other organic light emitting display device (300) in, over coating layer (360) the plurality of depressions (361) bottom (361a) and is open, number 1 electrode (341) is open depressions (361) through color filter (350) can be contact. The, such as photolithography (photolithography) produced with the negative photoresist through the process of the over-coating layer (360) a number of recesses (361) contact with, (uniformity) uniformity over the entire substrate surface area of the coating layer (360) of recesses (361) are repeated while over coating layer (360) of recesses (361) pattern layer (337) of the non-effective light emitting region by arranging a pressure force than the organic light emitting device (340) of can be reliable. Also 8a to 8c is also disposed in the pattern layer overcoated layer concave light emitting organic light emitting layer conditions depending on the position of the colloid (effective light-emitting region control) by comparing the external light extraction efficiency and distribution (viewing angle) shown in the drawing are disclosed. Over-coating layer (360) of recesses (361) number 1 from the bottom of the connection (362) is assumed to be the normal to height H, the organic light emitting layer (343) as also shown in the 8a of recess (361) and 1H/4 from the bottom of the recess 4 from the bottom of the equally divided (Part1), 1H/4 a-2H/4 (Part2), 2H/4 a-3H/4 (Part3), 3H/4 a-H(Part4) and in angular position between the organic light emitting layer or the simulation tool (343) (effective light-emitting region control) depending on the position of the light-emitting surfaces external light extraction efficiency and distribution compares his (viewing angle). On the other hand, over coating layer (360) an organic light emitting element (340) organic light emitting display device is provided to convert a microlens array structure without reference (Ref) was set. Also 8b and 8c as also shown in the organic light emitting layer (343) as also shown in the 8a of recess (361) 1H/4 from the bottom of the (Part1), 1H/4 a-2H/4 (Part2), 2H/4 a-3H/4 (Part3), 3H/4 a-H(Part4) angular position in front direction Part4 Part1 placed on microlens array structure between a reference current and an indirectly-capable of light extraction efficiency. In particular Part 3 and Part 4 dots at a front direction (Ref) molecules capable of 30 - 40% improved contrast. The, pattern layer (337) coating layer over the upper surfaces of (360) of recesses (361) number 1 from the bottom of the connection (362) is assumed to be the normal height H to recess (361) located between 2H/4 from the bottom of the can. Pattern layer (337) the upper surface of recess (361) placed between 2H/4 from the bottom of the recess (361) 2H/4 - H from the bottom of the effective light emitting region (A) can be composed of light extraction efficiency can be downloaded from the front direction. Figure 9 shows a coating layer including organic light emitting display device including a plurality of protrusions in the embodiment according to another also to account for cross-over are disclosed. The reference also 9, in the embodiment according to another organic light emitting display device (600) is also 4a and 4b organic light-emitting display device also (300) compared to the over coating layer (660) is includes a plurality of protrusions (663) and including a pattern layer (637) is includes a plurality of protrusions (663) connection between number 2 (664) provided only placed on the user's personal persona, and therefore substantially different configurations, redundant description is omitted as follows. Not shown in Figure 9 the organic light emitting device (600) elements in the embodiment described with reference to organic light emitting display device according to the other are also 3 (300) elements can be the same. Over-coating layer (660) color filter (650) includes a plurality of protrusions adapted to be overlapping (663) adjacent to each other and a projected part (663) connecting connection number 2 (664) without using a tool. In other words over coating layer (660) is also shown in the bank layer 3 (336) opening (336a) includes a plurality of protrusions arranged to be overlapping (663) on a projection (663) each connecting the plurality of connection number 2 (664) without using a tool. Over-coating layer (660) number 1 on electrode (641) disposed thereon. Over-coating layer (660) and number 1 electrode (641) layer on a (637) is disposed, electrode number 1 (641) and pattern layer (637) on the organic light emitting layer (642) and number 2 electrode (643) disposed thereon. Number 1 electrode (641) of an organic light emitting layer (642), number 2 electrode (643) the organic (640) constituting other. Pattern layer (637) includes a plurality of number 2 connection (664) all or a portion can be located. Pattern layer (637) connecting a plurality of number 2 (664) all or a portion placed, also described with reference to the pattern layer also 1 to 8 (337) in the recess (361) located equal, is number 1 electrode of the non-effective light emitting region (641) of an organic light emitting layer (642) and number 2 electrode (642) between the pattern layer (637) rotates the planar light is not, light extraction efficiency in the luminescence area proportion which contributes to improvement which does not nearly organic light-emitting device (640) minimizing or preventing the entrapped within the can. In addition proportion (B) light emitting region of the organic light-emitting device (640) entrapped within the common component minimizing or preventing the light is left in a can. Through organic light-emitting device (640) can be downloaded from the external light extraction efficiency. Figure 10 shows a schematic diagram of the organic light emitting display device according to the invention in the embodiment a system configuration are disclosed. 10 Also reference surface, the organic light emitting display device in the embodiment according to the (700) includes, a plurality of data line (DL) (GL) is disposed and a plurality of gate lines, a plurality of subpixel (SP) arranged in a matrix type organic light emitting display panel (710) and, by supplying a plurality of data line driver outputs a plurality of data line driver (720) on, sequentially supplies scan signal by a plurality of gate lines, a plurality of gate line and the gate driver sequentially (730) on, data driver (720) and a gate driver (730) a number plower controller (740) etc.. The organic light emitting display panel are in the embodiment according to (710) each have a plurality of pixels disposed, described with reference to organic light emitting thin film transistor and also 1 to 9 also includes. In the embodiment according to the aforementioned, organic light emitting display device comprises an outer light emitting efficiency, power consumption may be equal to or less than. In addition to the aforementioned in the embodiment according, organic light emitting display device while the inside of the over coating layer comprises an outer light emitting efficiency is improved at a second curvilinear shapes can be maintained equal to or less than. A feature of the present invention illustratively attached described and more provided revealing the secret key are in the drawing, the present invention essentially from deviating from a person with skill in the art in the field of the present invention is provided if the properties of inputted configuration, separation, a variety of modifications and deformable substitution and change will. Thus, the present invention in the embodiment of the present invention are to define the disclosure but rather to explain the feature and, in the embodiment of the present invention by not the limited range of such feature. Under the protection range of the present invention must be interpreted by fee so as to range, and the range of the present invention feature in a range equal to all rights will be interpreted. 100, 300, 500, 600, 700: Organic light emitting display device 136, 336: Bank layer 136A, 336a: opening 137, 337, 637: Pattern layer 141, 341, 541, 641: Number 1 electrode 142, 342, 542, 642: Organic light emitting layer 143, 343, 543, 643: Number 2 electrode 160, 360, 560, 660: Over coating layer The present invention provides an organic light emitting display device which improves external light emitting efficiency and decreases power consumption. According to an embodiment of the present invention, the organic light emitting display device comprises: an over coating layer located on a substrate; a first electrode located on the over coating layer; a bank layer located on the over coating layer and the first electrode, and including an opening part exposing the first electrode; a pattern layer located as an island shape on the first electrode exposed to the opening part of the bank layer; an organic light emitting layer located on the first electrode and the pattern layer; and a second electrode located on the organic light emitting layer. COPYRIGHT KIPO 2018 A light-emitting region having a plurality of pixel regions including substrate; said reflection is provided on the thin film transistor; said thin film transistor provided on said light emitting region covers the over coating layer with a plurality of recesses and a plurality of plated metal; said thin film transistor electrically connected to the convex portion of the indentations and said indentations overcoated layer disposed electrode number 1 has a convex portion at; indentations of said number 1 disposed pattern layer; and said number 1 projections and said pattern layer of the organic light emitting layer disposed on; the organic light emitting layer disposed on said electrode number 2 which, on said light emitting region, said organic light emitting layer disposed on said flat surface of said number 2 each electrode pattern layer including a convex portion disposed on the convex portion protrudes said number 1, organic light emitting display device. According to Claim 1, said over coating layer is arranged on the light-emitting region on said one pixel region includes switch of said electrode and said number 1 number 1 bank having a opening for exposing electrode additionally includes layer, said pattern layer including said bank layers material, organic light emitting display device. According to Claim 1, said overcoat layer overcoated layer is assumed to be the normal to said convex portion height H from the bottom recess, said patterned layer over said coating layer positioned between the flat surface from the bottom recess 2H/4 - H, organic light emitting display device. According to Claim 1, said over coating layer is arranged on the light-emitting region on said one pixel region includes switch of said electrode and said number 1 number 1 electrode layer is layer contains hollow beads and bank having an opening, said opening including said bank layer overcoated layer it is possible to color filter arranged in a lower, organic light emitting display device. According to Claim 4, said overcoat layer partially exposed by said color filter each floor is open indentations, said indentations indentations of the overcoated layer exposed between said number 1 in contact with the color filter, organic light emitting display device. According to one of Claim 1 to Claim 5, said number 1 plated electrode disposed between the organic light emitting layer has a thickness of said recess disposed to the top of said convex portion of said number 1 floor or said number 1 is thinner than organic light emitting layer, organic light emitting display device. According to one of Claim 1 to Claim 5, each light-emitting region is said plurality of pixels, the surface profile convex effective light-emitting region; and said convex surface profile between flat non-effective light-emitting region including effective light emitting region, organic light emitting display device. According to one of Claim 1 to Claim 5, said number 1 over coating layer disposed between said electrode further including passivation, organic light emitting display device. The light emitting region comprising a plurality of pixels disposed on a substrate, each of said plurality of pixels, the surface profile convex effective light-emitting region; and said convex surface profile is flattened and effective light emitting region disposed between the non-effective light-emitting region including, organic light emitting display device. According to Claim 9, said non-light-emitting region is, number 1 electrode having a plurality of recesses; said number 1 electrode disposed indentations pattern layer; said pattern layer disposed on the organic light emitting layer; and said electrode including the organic light emitting layer disposed on number 2, organic light emitting display device. According to Claim 9, number 1 electrode disposed on said light emitting region; said number 1 electrode disposed on the organic light emitting layer; the organic light emitting layer disposed on said electrode number 2; number 1 on the organic light emitting layer disposed between said electrode and said non-light emitting region further includes a pattern layer, said number 1 electrode is disposed on said effective light-emitting region includes a plurality of protrusions and said concave portions of the non-effective light emitting region being disposed with a plurality of recesses, said organic light emitting layer disposed on portions of the effective light-emitting region includes a plurality of protrusions and said said number 2 electrode is of the non-effective light emitting region including a plurality of flat surfaces disposed on said flat, organic light emitting display device. Number 1 to number 5 anti anti, anti either as described in claim number 10 term and number 11, said number 1 layer disposed indentations of said pattern, said pattern layer is formed on said organic light emitting layer in contact with the flat, organic light emitting display device. According to Claim 12, said number 1 indentations of said pattern layer each all or a portion filled, organic light emitting display device. Volt (V) J (mA/cm2) Cd/A Improvement rate (%) EQE Improvement rate (%) Organic light emitting display device according to comparison example (500) 7. 43 10 85. 41 36. 1 33. 07 41. 6 In the embodiment according to organic light emitting display device (300) 7. 55 10 100. 41 45. 6 39. 08 50. 6