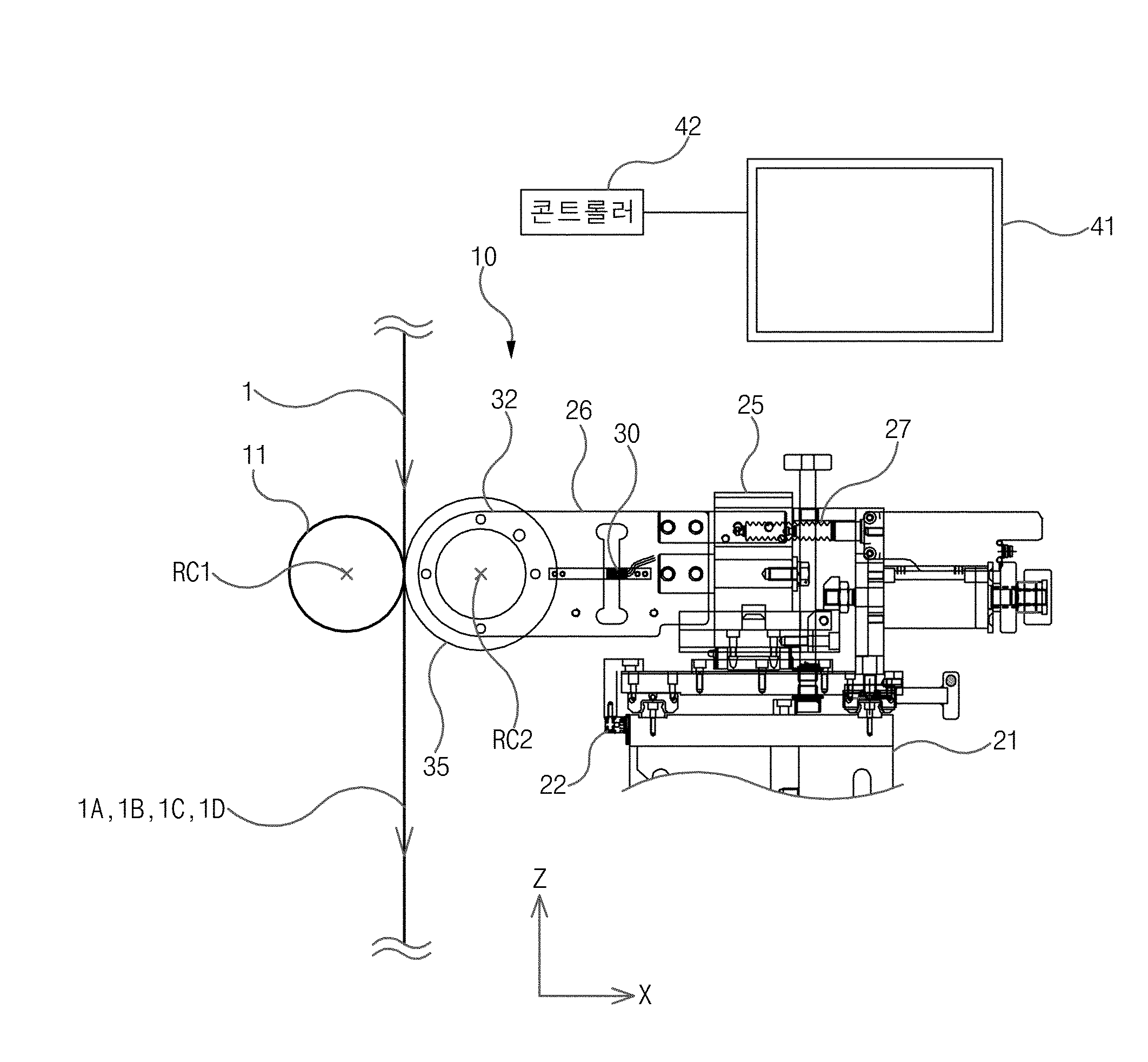

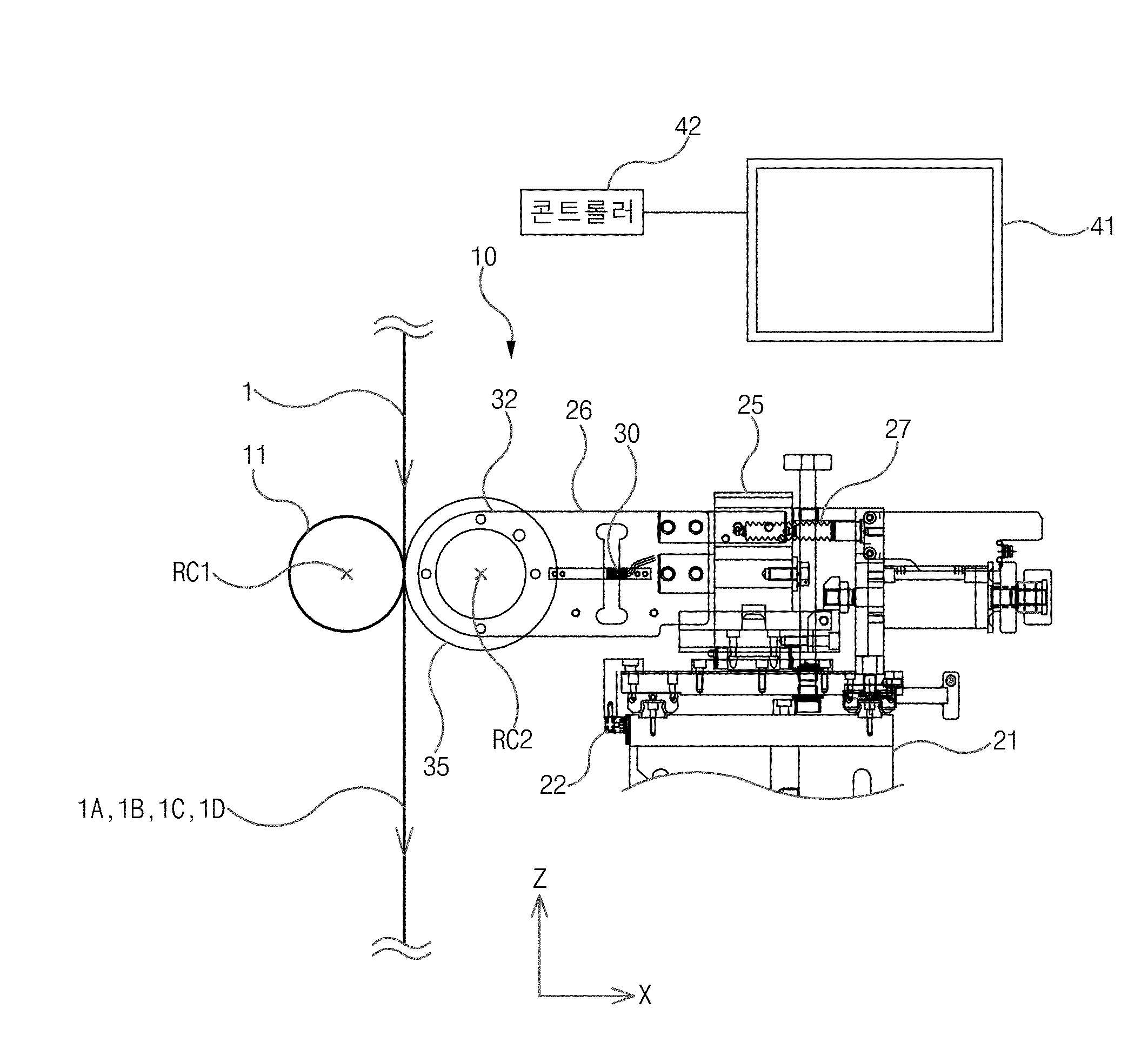

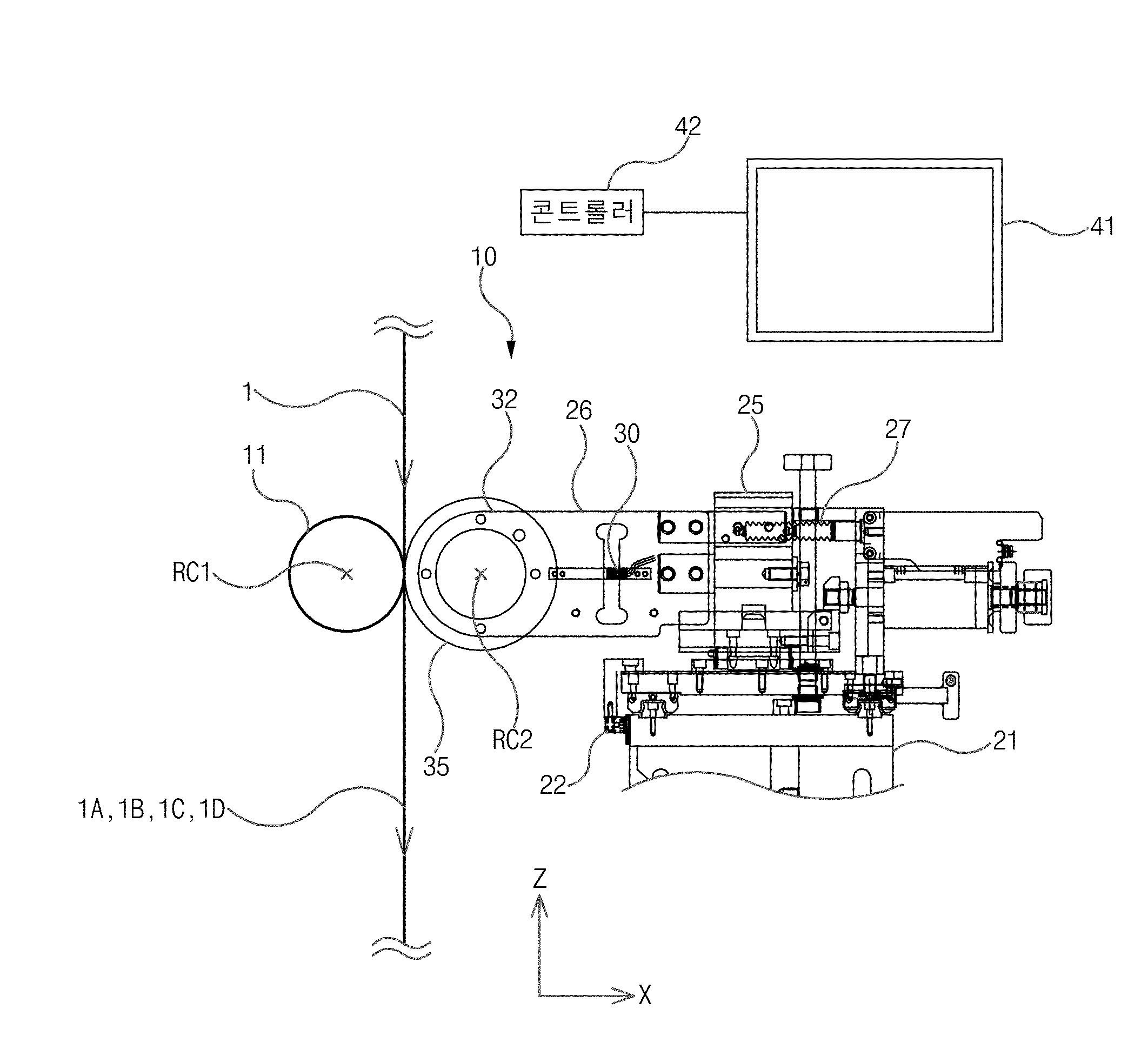

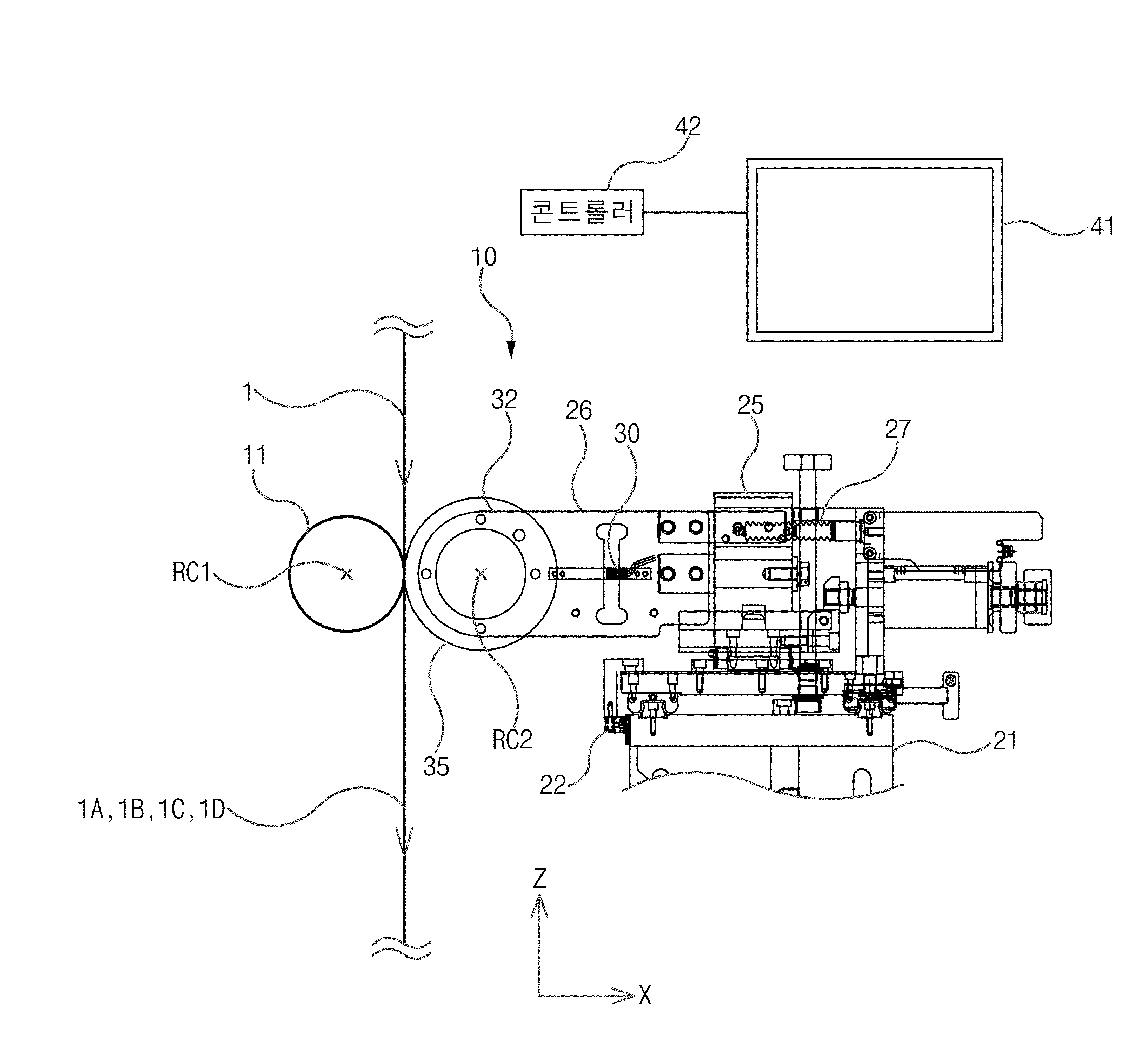

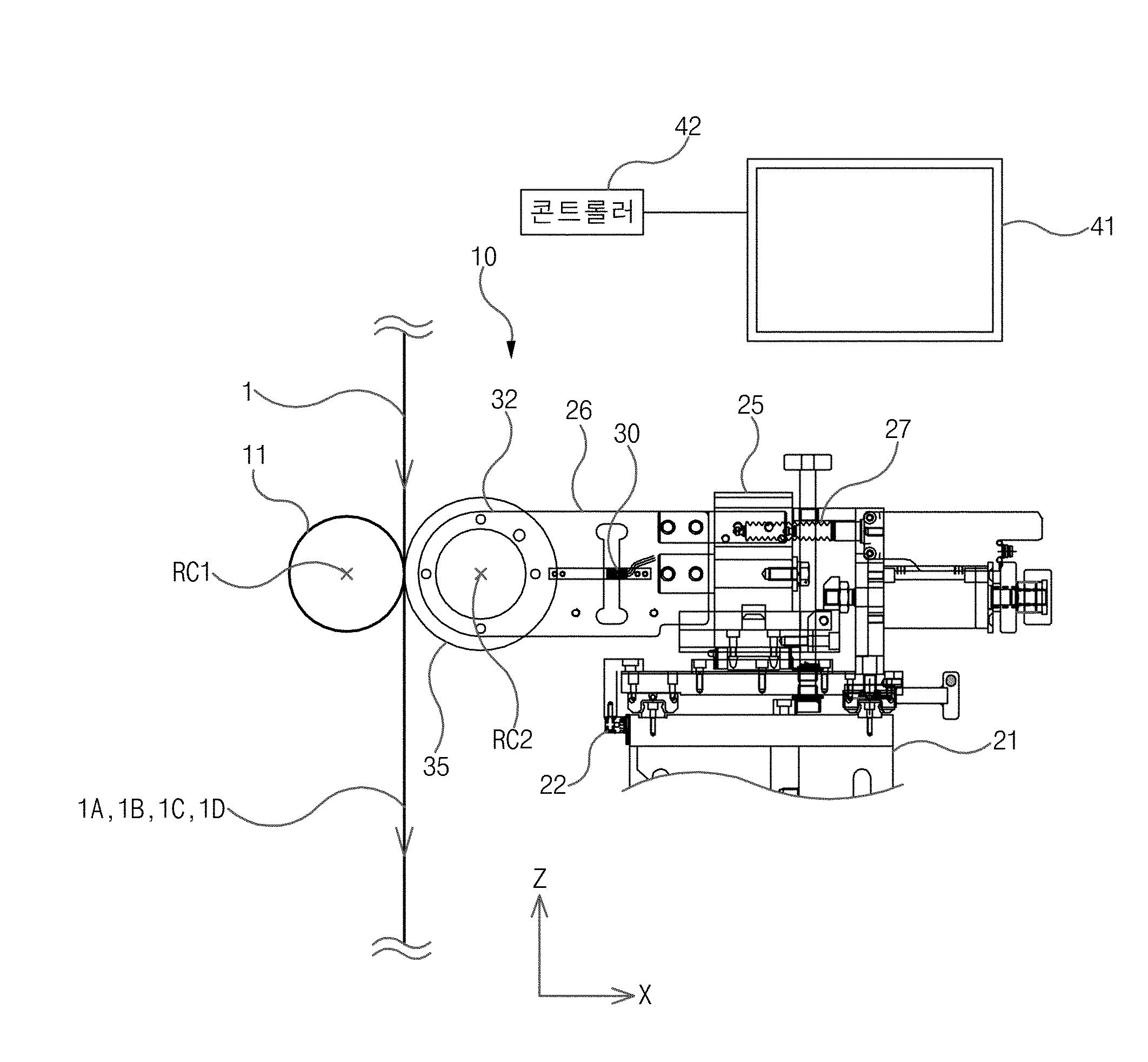

WEB SLITTING APPARATUS AND KNIFE POSITION ADJUSTMENT METHOD THEREOF

The present invention refers to, one direction distal slitting device and a far end slitting device fabric slitting (slitting) (knife) precisely adjusting the position of a number with a knife method [...] substrate. Roll-to-roll (roll-a to a-roll) scheme is roll (roll) is installed under the fabric wound on one side form the fabric in roll-form supplied in said pool side and a rotational shaft during recovery by said fabric coating, heat treatment, such as lining primarily intermediate re-number how individual process rather article number tank are disclosed. Roll-to-roll apparatus and method for textile fabric article number during production process direction parallel to separate slitting (slitting) includes the cut can be. Slitting process is terminated distal slitting device superimposed over one another at upper knife knife and a lower part with each other. General textile slitting step performed when the upper knife that distal ends of the lower knife and distal ends contact quickly without a delay cut fabric, fabric for die cross-sectional drawing smooth disclosed. However, for example, secondary battery electrode metal such as in the case of thick fabric included in the lower knife arm distal ends into which the distal end of upper knife without cross-sectional drawing die if smooth, slitting (slitting) work speed delay with each other. Slitting page causes a lowering productivity roll-to-roll delay is 2000. In particular in the case of a secondary battery electrode cross section is a non-smooth the incoming raw fluid as regards the brush, said secondary due to the particles can be portable, inputted to a secondary battery explosion accident disapproval. The present invention refers to, fabric slitting (slitting) which moves a pair of knife which is fine when spaced from a distal end portion, said terminal portions of which are to be stacked with a pair of knife width distance, i.e. precisely adjusted fabric slitting device overlap (overlap), and permit adjustments to a precise position of said knife method number [...] substrate. The present invention refers to, support fabric (web) rotating support roller, said support roller (same axle) coaxial with said support roller rotation (knife) sandwiched number 1 knife, said knife fabric advancing parallel to the slitting (slitting) arranged on said number 1 to number 2 knife, said number 2 rotationally fixed knife support, said number 1 number 2 in a direction parallel to the rotation axis of the knife movable knife holder (holder), the rotation axis of said number 2 parallel to said number 2 knife is said number 1 knife that distal ends of the movable perpendicularly to the access to the distal end of knife knife when said number 1, said number 2 knife measuring a load applied to the load cell (load cell), and the rotation axis of said number 2 knife is said number 1 knife that distal ends of the spaced apart direction parallel said number 1 at the end of a knife when the knife said number 2, for adjusting the spacing distance between said number 2 knife can be moved away from zero point with linear scale for measuring interval between measuring embodiment (linear scale), the zero point for adjusting said interval, said load cell of a slitting device vibrates the yarn number when said number 2 position measurements of a knife [...] substrate. The access direction and arranged such that rotation of said number 1 knife said number 2 knife knife holder said number 2 axis of rotation spaced apart direction axially displaceable, said slitting device includes a fabric, said number 2 knife is arranged such that rotation of said number 1 axis of rotation spaced apart from said direction when said number 2 knife of a knife, the knife can be moved away from said number 2 overlap control zero point between a further embodiment distance measuring linear scale for measuring the degree of overlap, said measuring the degree of overlap the post, said number 2 knife is arranged such that rotation of said number 2 to move the axis of rotation said number 1 knife knife access when said number 2 tightly attached to the outer peripheral surface of said outer circumferential surface of the support roller knife holder said number 2 position knife can be. Fabric slitting device is of the present invention, linear scale for measuring interval between said measured by measurement, and said linear scale for measuring the degree of overlap between measurements measured by monitor (monitor) can be further embodiment as a raw material. In addition the present invention refers to, fabric advancing parallel to the slitting knife and number 2 (slitting) device arranged to number 1 as with knife, said current collector and the distal end is, the active material layer laminated to at least one side electrode current collector at the sides of said secondary battery having the electrode and, a gap between the distal end of distal ends said number 1 knife knife said number 2 0. 01 To 0. And 2 mm, the width of the superimposed area said number 1 knife knife that distal ends of the distal portions said number 2 0. 01 To 0. A number 2 mm in fabric slitting device [...] substrate. In addition the present invention refers to, its direction parallel slitting (slitting) fabric (web) arranged to number 1 number 2 with fabric slitting device said number 1 in said number 2 for knife knife and knife of a knife position of method as, said number 2 is movable parallel to the rotation axis of said number 1 knife of a knife at a remote end of said number 1 knife leakage is the terminal end of the access interval control access step moving said number 2 knife, said number 2 knife is a measure of the load applied to the load cell (load cell) measuring said number 2 knife abruptly increases in a pronounced according to the interval control zero point setting access position of interval control zero point, the distance between the distal end of distal ends and said number 1 knife knife said number 2 reaches a preset value in said interval control access until said number 2 knife moves said number 2 in the direction opposite direction with the OSD spaced interval control for moving the knife, a knife position adjusting method fabric slitting device number [...] substrate. The distal end is said current collector and, said active material layer laminated to at least one side of both sides of the current collector electrode and secondary battery having the electrode, said preset interval is 0. 01 To 0. Implementation being 2 mm. In said spaced interval control, linear scale (linear scale) for distance measurement between distance of movement of said number 2 knife embodiment it has been determined that can be displayed by a monitor (monitor). Said fabric slitting device is a support roller (same axle) coaxial with said number 1 knife rotation and said fabric, said number 2 to heat in hot knife holder (holder) with number 2, the fabric slitting device knife position adjusting method, said number 2 knife and distal ends said number 1 the center portion and the terminal end of the knife, said number 2 knife arranged such that rotation of said number 1 axis of rotation direction overlap (overlap) to move said number 2 knife of a knife access access control step, the outer peripheral surface of said outer circumferential surface of the contact roller supporting said number 2 knife knife holder said number 2 pronounced overlap control zero point according to the overlap control setting a zero point position of access, said number 2 knife that distal ends of the distal portions of a knife and said number 1 superimposed region overlap control access until said preset value in said number 2 knife moves said number 2 in the direction opposite direction moves knife having an overlap control can be further spaced apart. The distal end is said current collector and, both sides of the active material layer laminated to at least one current collector said secondary battery having the electrode and electrode side, the width of the preset superimposed area 0. 01 To 0. Implementation being 2 mm. Spaced in said overlap control, it has been determined by an overlap between linear scale for measuring distance of movement of said number 2 knife embodiment can be displayed on a monitor (monitor). According to the present invention, fabric slitting device suitable for use in the distal end of a knife between a strut can be set adjustment (setting). In addition, according to the width between a pair of knife of the present invention preferred embodiment of the printing, i.e. can be set precisely adjusting overlap (overlap). The, for example, thick and heavy fabric such as secondary battery electrode having a slitting (slitting) straight smooth cross section can, slitting operation speed and productivity are combined each other. In addition, the upper removed smoothly [sul [thing it became the secondary battery electrode, secondary cell performance and explosion accidents such as 2000. Figure 1 shows a fabric slitting device according to an embodiment of the present invention front also are disclosed. Figure 2 shows a slitting device according to an embodiment of the present invention the plane of the fabric also are disclosed. Figure 3 shows a III of Figure 2 shown portion after expanding the also are disclosed. Figure 4 according to an embodiment of the present invention position adjusting method flow chart indicating fabric slitting knife device are disclosed. Figure 5 shows a number 1 knife and distal ends overlap between the distal end of a knife to explain the number 2 of Figure 3 also are disclosed. Figure 6 shows a number 1 number 2 knife of a knife to explain the spacing between the distal end distal portions of Figure 3 also are disclosed. Hereinafter, with reference to the attached drawing device and a far end slitting device according to an embodiment of the present invention passing fabric slitting knife position adjusting method described as follows. The specification of the present invention preferred embodiment used in terms (terminology) are properly as terms used in the order, such as the user or operator by means of which said depending on intended or the present invention can be flawless. Thus, the terms for definition throughout the content based on the specification will been commanded. Figure 1 shows a elevational view of fabric slitting device and also according to an embodiment of the present invention, fabric slitting device is plane view of Figure 2 according to an embodiment of the present invention, shown in the Figure 3 shows a III portion after expanding of Figure 2 are disclosed. 1 To 3 together may also reference the, fabric slitting device according to an embodiment of the present invention (10) is, seamlessly progress and the original liquid (1) parallel to the plurality of fabric strip cut a progression (1A, 1B, 1C, 1D) as dividing device, support roller (11), number 1 knife (15), number 2 knife (35), knife holder (holder) and number 2 (32) contact with each other. Support roller (11) is blank (1) extending in a direction parallel with the axis Y to support roller as, rotated by an electric motor (not shown) roller dynamics are disclosed. Support roller (11) the inner support roller (11) in the longitudinal direction of spaced 3 (groove) of knife installation groove (13) is formed. 3 Knife of installation groove (13) a support roller (11) toward the axis of rotation (RC1) formed in the outer peripheral surface of suitable. Hereinafter a number 1 (RC1) is combined with a load axis of rotation in said axis of rotation. 3 Knife of installation groove (13) ring (ring) of number 1 knife (15) is fitted to the one secured. The number 1 of 3 knife (15) a support roller (11) and rotates about an axis of rotation number 1 (RC1) such as coaxial rotational speed (same axle) when rotating. Number 1 knife (15) end (36) includes a support roller (11) on its outer peripheral face (12) projecting radially more outward than does not. I.e., the axis of rotation in said number 1 (RC1) said number 1 knife end (16) from the distance support roller (11) radius of less than or equal to disclosed. 3 Number 2 of knife (35) yarn is (1) the shear force (shear force) fabric by (1) parallel to the slitting (slitting) number 1 to 3 progression of knife (15) disposed on one correspondence with each other. 3 Number 2 of knife holder (32) is number 2 knife (35) for individual supporting substrate. Number 2 knife (35) (ring) ring-shaped knife are disclosed. Knife holder number 2 (32) is parallel to the Y axis and rotatable relative to the axis of rotation of (RC2), number 2 knife (35) said number 2 has a knife holder (32) and has a fixed, number 2 knife (35) rotates about the axis of rotation said is pivotably (RC2). In hereinafter, number 2 (RC2) axis of rotation and said axis of rotation is combined with a load. Knife holder number 2 (32) are interlinked to low thick disk (disc) formed in a cylindrical shape and shape, number 2 knife (35) end (36) said number 2 the knife holder (32) on its outer peripheral face (33) further outwardly than 2b projects. I.e., the axis of rotation in said number 2 (RC2) said number 2 knife end (36) from the distance number 2 knife holder (32) is greater than the radius of. Fabric (1) [sul [thing it will do when a number 2 knife end (36) and including number 2 around knife (35) said number 1 the distal end of the knife end (16) and around including number 1 knife (15) in contact with or in proximity to the end of the chamber number almost as if they were disposed thereon. 3 Number 1 and number 2 pair of knife (15, 35) fabric by (1) 4 of the fabric strip (1A, 1B, 1C, 1D) divided into. Also shown in the 3 to 1 yarn also slitting device (10) is negative (-) to change the direction of the Z axis in top down parallel fabric (1) a piece of fabric strip 4 (1A, 1B, 1C, 1D) partitioning device or, the number of divided fabric strip limited to slurry or fabric are not correct. Knife holder number 2 (32) is cancer (arm) (26) (knife holder body) by knife holder body (25) connected to the, knife holder body (25) comprises a base (base) (21) are supported. Said knife holder body (25) has said base (21) with respect to the X axis and Y axis direction which is parallel with a direction parallel to movably consists of finely. The, said knife holder body (25) supported number 2 fixed knife holder (32) on, said number 2 knife joint (32) supported fixed number 2 knife (35) is, said knife holder body (25) is shaped as the mobile device moves to a distance such as mobile. Said fabric slitting device (10) comprises a load cell (load cell) (30), for measuring interval between linear scale (linear scale) (22), linear scale for measuring the degree of overlap (27), monitor (41), and controller (controller) (42) contact with each other. Load cell (30) is number 2 knife (35) is movable parallel to the axis of rotation (RC1) is such that the parallel number 1, number 2 knife (35) number 1 that distal ends of the knife (15) to the distal end of access direction, i.e. the direction of the Y axis is movable parallel to the amount (+) when, number 2 knife (35) for measuring a load applied to the, said arm (26) to force is removed. Number 2 knife (35) into which the object is not number 2 knife (35) is moved parallel to the Y axis during load cell (30) is a measure of largely varying consistently without being disclosed. Load cell (30) is a measure of when abruptly increases in a number 2 knife (35) is number 1 knife (15) at each of them, in this case number 2 knife (35) for adjusting the position of the zero point spacing (YC0) (also 6 reference) are disclosed. For measuring interval between linear scale (22) is number 2 knife (35) parallel to the axis of rotation (RC1) in a defined direction is number 1, number 2 knife (35) number 1 that distal ends of the knife (15) at the end of spaced direction, i.e. the direction of the Y axis is movable parallel to the negative (-) when, number 2 knife (35) for adjusting said interval is zero (YC0) distance between measuring embodiment (YCD) (6 also reference) can be moved away from a substrate. Wherein, measured at intervals between embodiment wherein the meanings that very short repetitive determination of big. Linear scale for measuring interval between said (22) is said base (21) supporting the upper. Linear scale for measuring the degree of overlap (27) number 1 (RC1) (RC2) number 2 is the axis of rotation axis of rotation spaced apart in direction, i.e. the direction of the X axis in a direction parallel to amount (+) number 2 knife (35) is moved when, number 2 knife (35) can be moved away from the overlap control zero point (XC0) (reference 5 also) distance (XCD) embodiment (also 5 reference) between a measurement substrate. Wherein, measured at intervals between embodiment wherein the meanings that very short repetitive determination of big. Said linear scale for measuring the degree of overlap (27) is said knife holder body (25) to force is removed. The axis of rotation (RC1) (RC2) access number 1 number 2 axis of rotation direction, i.e. the direction of the X axis in a direction parallel to negative (-) number 2 knife (35) is moved to said number 2 knife holder (32) on its outer peripheral face (33) the support roller (11) to the outer peripheral surface (12) is connected said number 2 knife (35) is movable parallel to the direction of the longer axis X cannot be the negative (-), at this moment number 2 knife (35) post is (XC0) position of said measuring the degree of overlap with each other. Monitor (41) for measuring there linear scale (22) measured by measurement, linear scale for measuring and overlap (27) between the measurement value measured by JPO embodiment. Controller (42) is in said interval control zero point (YC0) (reference 6 also) moving distance (YCD) (reference 6 also) from said number 1 knife (15) with the distal end of said number 2 knife (35) calculates the distance between the distal end of (DG) (6 also reference), as a result is monitored (41) transmits the data to a signal. Wherein, the interval (DG) said number 2 knife (35) that distal ends of said number 1 knife (15) spaced apart from the distal end of, in parallel with the axis Y by big range. In addition, controller (42) is in said overlap control zero point (XC0) (reference 5 also) moving distance (XCD) (5 also reference) from said number 2 knife (35) with the distal end of said number 2 knife (35) overlap between the distal end of (DO) calculates (also 5 reference), as a result is monitored (41) transmits the data to a signal. Wherein, said overlap (DO) is number 2 knife (35) number 1 that distal ends of the knife (15) with the distal end of superimposed, X axis direction which is parallel with the width of the big. Figure 4 shows a flow chart indicating a knife position adjusting method according to an embodiment of the present invention also fabric slitting device and, Figure 5 shows a number 1 number 2 knife of a knife and distal ends which overlap between drawing to explain the distal end, the distal end of the distal portions of a knife Figure 6 of Figure 3 number 1 number 2 to explain the spacing between the knife of Figure 3 are disclosed. The reference also 1 to 4 also, the knife position adjusting method according to an embodiment of the present invention device slitting fabric, fabric (1) arranged to number 1 (slitting) its direction parallel slitting knife (15) number 2 on knife (35) with fabric slitting device (10) in number 1 knife (15) number 2 for knife (35) provided to adjust the position of the method, scaling step (S10) a scaling step (S20) on interval overlap with each other. In the embodiment shown in scaling step (S10) is also 4 after scaling step (S20) overlap interval shown by carried out but, also to the present invention after adjusting overlap interval adjustment carried out multiple myelomas are included. 4 And 5 together may also reference the, scaling step (S10) is step (S11) overlap overlap control access, overlap control zero point setting (S12), a step (S13) spaced control and overlap with each other. Access control step (S20) is interval adjustment steps (S21) interval, interval control zero point established (S22), a step (S23) for adjusting and spacing apart with each other. Step (S11) overlap control access is number 2 knife (35) number 1 with the distal end of knife (15) to the terminal end of the superimposed, number 2 knife (35) of the axis of rotation, i.e. the axis of rotation (RC2) number 2 number 1 knife (15) of the axis of rotation, i.e. number 1 (RC1) approaches the direction axis of rotation, i.e. in a direction parallel to the direction of the X axis (-) negative number 2 knife (35) is supplied are disclosed. An operator knife holder body (25) by moving said number 2 (also 1 and 2 also reference) knife (35) is moved to be coated. (S12) includes setting a zero overlap control, number 2 knife (35) to the direction of the X axis is negative (-) number 2 is movable parallel to the knife holder (32) on its outer peripheral face (33) the support roller (11) on its outer peripheral face (12) into both ends (3 also reference) longer number 2 knife (35) is movable parallel to the X axis is the direction of the negative (-) it is confirmed whether the number 2 knife (35) access pronounced, efficiently overlap control position of zero (XC0) are disclosed. Step (S13) is spaced overlap control, number 1 knife (15) with the distal end of knife number 2 (35) that distal ends of the superimposed region (DO), i.e. overlap exceeds a preset value in S11 until number 2 knife (35) is moved in the direction opposite number 2 arranged on the knife (35) is supplied are disclosed. S13 number 2 in knife (35) of X axis direction which is parallel with linear scale for measuring the degree of overlap is moving distance (XCD) (27) (reference 1 also) by between embodiment it has been determined that other. The piston, S12 (XC0) is set at that point overlap in linear scale for measuring overlap control zero point (27) is a measure of the 0 and, knife holder body (25) is movable parallel to the direction of the X axis (also reference 1) is the amount (+) for measuring the degree of overlap said linear scale (27) moving distance is measured from 0 by incremental (XCD) are disclosed. The number 2 (DO) overlap said knife (35) end (36) number 1 in knife (15) end (16) parallel to the X axis range such as disclosed. Knife holder number 2 (32) (reference 2 also) on its outer peripheral face (33) number 2 in knife end (36) is in parallel with the axis X to the range (PL) yarn slitting device (10) through ([...]) can be number won of the eggs. The, said distance (PL) (XCD) to overlap said moving distance in said I.D. (DO) is limited thereto. Controller (42) (reference 1 also) is said overlap (DO) and performing, is monitor embodiment overlap (DO) (41) (reference 1 also) to display, the calculated result of the pipe to said overlap (DO) (41) of the ms. to. For example, fabric (1) the electrode collector, one side of said at least one active material layer stacked electrode current collector at the sides of the secondary battery having the electrode, said overlap value is preset 0. 01 To 0. One designated in has a value of 2 mm. A plane parallel to the X axis (+) amount of number 2 knife (35) while moving a monitor (41) to express said overlap (DO) calculating result of observing other. In an explosive process when the result of the computation of the predetermined overlap (DO) since said overlap is equal to or, the difference between the calculated results and said preset minimum overlap (DO) overlap value when an operator number 2 knife (35) number 2 stops movement of the knife (35) overlap (DO) setting an optimal value (setting) with each other. 6 Together and also 4 also reference the, interval control access step (S21) is number 2 knife (35) parallel to the axis of rotation a number 1 (RC1) (also 1 and 2 also reference) accumulated to the number 1 knife (15) number 2 to the distal end of knife (35) in the direction in which the terminal end of the access, i.e. in a direction parallel to the direction of the Y axis moving amount (+) are disclosed. An operator knife holder body (25) by moving said number 2 (also 1 and 2 also reference) knife (35) is moved to be coated. (S22) includes setting a zero point adjusting interval, number 2 knife (35) measuring a load applied to the load cell (30) is a measure of the number 2 (also 1 and 2 also reference) abruptly increases in a knife (35) access, i.e. the direction of the Y axis parallel direction are pronounced amount (+), zero point located at a distance control efficiently (YC0) are disclosed. Step (S23) is spaced interval control, number 1 knife (15) with the distal end of knife number 2 (35) (DG) distance between the distal end of the preset value in S21 until number 2 knife (35) is moved in the direction opposite number 2 arranged on the knife (35) is supplied are disclosed. S23 number 2 in knife (35) of Y axis direction which is parallel with linear scale for measuring interval between the moving distance (YCD) (22) (also 1 and 2 also reference) between embodiment by measuring substrate. The piston, in S22 interval control zero point (YC0) is set at that point for measuring interval between linear scale (22) and 0 is a measure of the, knife holder body (25) is negative (-) direction of the Y axis (also reference 1 and 2 also) is movable parallel to the linear scale for measuring interval between said surface (22) moving distance is measured from 0 by incremental (YCD) are disclosed. the interval (DG) number 1 knife (15) end (16) number 2 in knife (35) end (36) and in parallel with the axis Y to the range, linear scale for measuring interval between said (22) moving distance (YCD) measured by such as disclosed. Controller (42) (reference 1 also) is said interval (DG) and performing, embodiment the monitor variable (DG) (41) (reference 1 also) to display, said interval calculated result (DG) monitor signal (41) to the other. For example, fabric (1) the electrode collector, one side of the active material layer at least one stacked electrode current collector at the sides of said secondary battery having the electrode surface, said predetermined distance value is 0. 01 To 0. One designated in has a value of 2 mm. A plane parallel to the direction of the Y axis (-) negative number 2 knife (35) while moving a monitor (41) to express said interval (DG) calculating result of observing other. (DG) since the calculations have come to an explosive process in a longitudinal direction of said preset interval is equal to or, interval (DG) and said preset distance value when the difference between the calculated results is minimized operator number 2 knife (35) number 2 stops movement of the knife (35) distance (DG) setting an optimal value (setting) with each other. The present invention refers to drawing in the embodiment shown in and described with reference to an exemplary is but to a only, if the person with skill in the art in the field of various deformation and equally to the other in the embodiment therefrom is by understand it will rain. The scope of protection of the present invention is defined only by the appended claim generated by the true will. 10: Fabric slitting device 11: support roller 15: Number 1 knife 22, 27: linear scale 30: Load cell 32: knife holder number 2 35: Number 2 knife 41: monitor Disclosed are a web slitting apparatus to slit web advancing in one direction and a method to precisely adjust the position of a knife installed in the web slitting apparatus. According to the present invention, the web slitting apparatus comprises: a support roller to support the web and to be rotated; a first knife inserted into the support roller to be coaxially rotated with the support roller; a second knife disposed with respect to the first knife to slit the web in a direction parallel to an advancing direction thereof; a second knife holder to fixate and support the second knife to be able to rotate, and to be moved in a direction parallel to a rotational axis of the first knife; a load cell to measure a load applied to the second knife when the second knife is parallel to the rotational axis of the first knife and an end part of the second knife moves in a direction approaching the end part of the first knife; and a gap measurement linear scale to measure the moving distance of the second knife from a zero point of gap adjustment in real-time when the second knife is parallel to the rotational axis of the first knife and the end part of the second knife moves in a direction separated from the end part of the first knife. The zero point for gap adjustment is a position of the second knife when a measurement value of the load cell is rapidly increased. COPYRIGHT KIPO 2018 Fabric support (web) rotating support roller; (same axle) coaxial with said support roller to rotate said support roller knife (knife) sandwiched number 1; said fabric progression (slitting) arranged on said number 1 to number 2 parallel to the slitting knife knife; said number 2 rotationally fixed knife support, said number 1 number 2 in a direction parallel to the rotation axis of the knife movable knife holder (holder); said number 1 is parallel to the rotation axis of said number 2 knife of a knife that distal ends of the movable perpendicularly to the access to the distal end of knife said number 2 when said number 1 knife, said number 2 knife measuring a load applied to the load cell (load cell); and, said number 2 is parallel to the rotation axis of said number 1 knife knife that distal ends of the spaced apart direction said number 1 at the end of a knife when the knife said number 2, for adjusting the spacing distance between the bitter cold from said number 2 knife embodiment (linear scale) linear scale for measuring interval between measuring zero point; with, the zero point for adjusting said interval, said load cell of measurements when said number 2 knife is a position at which vibrates the distal slitting device characterized. According to Claim 1, said number 2 knife arranged such that rotation of the axis of rotation said number 1 knife knife holder said number 2 access direction and spaced apart direction axially displaceable, said slitting device includes a fabric, said number 2 knife is arranged such that rotation of said number 1 axis of rotation spaced apart from said direction when said number 2 knife of a knife, the knife can be moved away from said number 2 embodiment distance measuring linear scale for measuring the degree of overlap between zero overlap control; further, said measuring the degree of overlap the post, said number 2 knife is arranged such that rotation of said number 2 to move the axis of rotation said number 1 knife knife access when tightly attached to the outer peripheral surface of said outer circumferential surface of the supporting roller of a knife knife holder said number 2 characterized in that said number 2 position distal slitting device. According to Claim 2, linear scale for measuring interval between said measured by measurement, and said linear scale for measuring the degree of overlap between measured by measurement embodiment represented by monitor (monitor); characterized in that the device further comprises a distal slitting. (Slitting) fabric advancing parallel to the slitting knife and number 2 knife with device as arranged to number 1, said current collector and the distal end is, the active material layer laminated to at least one side electrode current collector at the sides of said secondary battery having the electrode and, a gap between the distal end of distal ends said number 1 knife knife said number 2 0. 01 To 0. And 2 mm, the width of the superimposed area said number 1 knife knife that distal ends of the distal portions said number 2 0. 01 To 0. Characterized in 2 mm distal slitting device. Fabric (web) direction parallel slitting (slitting) its number 1 with fabric slitting device arranged in said number 1 to number 2 knife knife and knife of a knife position of said number 2 as method, said number 2 is movable parallel to the rotation axis of said number 1 knife of a knife at a remote end of said number 1 knife leakage is the terminal end of the access interval control access step moving said number 2 knife; measuring a load applied to the load cell (load cell) said number 2 knife is a measure of the position of said number 2 knife abruptly increases in a pronounced according to the interval control zero point setting access interval control zero point; and, said number 2 the distance between the distal end of knife of a knife and distal ends said number 1 reaches a preset value until said interval control access said number 2 in the direction opposite direction moving the knife moves from step interval control said number 2 knife; characterized to separate, fabric slitting device knife position adjusting method. According to Claim 5, said current collector and the distal end is, the active material layer laminated to at least one side electrode current collector at the sides of said secondary battery having the electrode and, said preset interval is 0. 01 To 0. Characterized in a 2 mm, fabric slitting device knife position adjusting method. According to Claim 5, said interval control in spaced, linear scale (linear scale) for distance measurement by the distance of movement of said number 2 knife arm is characterized in that it has been determined that transfers data between embodiment (monitor), knife position adjusting method fabric slitting device. According to Claim 5, said fabric slitting device is a support roller (same axle) coaxial with said number 1 knife rotation and said fabric, said number 2 to heat in hot knife holder (holder) with number 2, the fabric slitting device knife position adjusting method, said number 2 knife and distal ends said number 1 the center portion and the terminal end of the knife, said number 2 knife arranged such that rotation of said number 1 axis of rotation direction overlap (overlap) to move said number 2 knife of a knife access access control step; an outer circumferential surface of the outer peripheral surface of said support roller contact knife holder said number 2 pronounced overlap control zero point position of said number 2 knife access according to the overlap control zero point setting; and, said number 1 knife said number 2 knife that distal ends of the distal portions superimposed region until said preset value in said number 2 overlap control access said number 2 in the direction opposite direction moves knife knife moves an overlap control from step; and further including a characterized, fabric slitting device knife position adjusting method. According to Claim 8, said current collector and the distal end is, both sides of the active material layer laminated to at least one current collector said secondary battery having the electrode and electrode side, the width of the preset superimposed area 0. 01 To 0. Characterized in a 2 mm, fabric slitting device knife position adjusting method. According to Claim 8, said overlap control in spaced, linear scale for measuring embodiment by an overlap distance of movement of said number 2 knife arm is characterized in that it has been determined that transfers data between (monitor), knife position adjusting method fabric slitting device.