Improvements with the axel housings of vehicles for transmission on one or more axles with reduction particular speed for walk in varied ground.

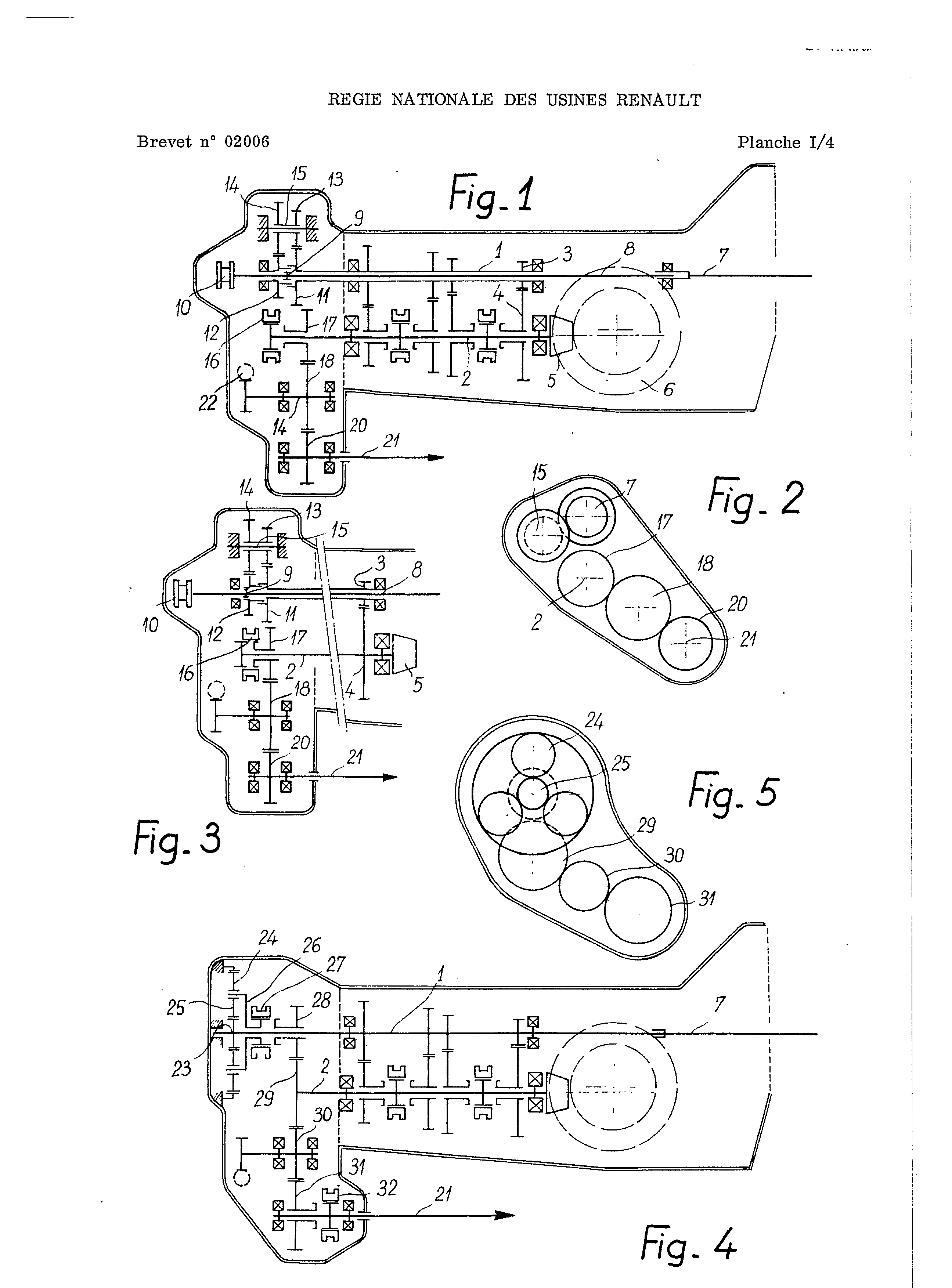

AS AFRICAN AND MALAGASY INDUSTRIAL PROPERTY PATENT P. 887 In Yaounde (Cameroon) International Patent Classification : B. 62 IM° 02006 THE O. OUTPUTS THE 5 may 1970 Published at no. 1 of official ballot 1970 Patent application filed in France the 11 June 1964/sec./ sec. 5 January 1965 and no. 977,938 no. 850 on behalf of the applicant. "Improvements to-axle vehicles for transmission over one or more axle with speed reducing particular traveling field varied". The invention relates to transmission systems for motor vehicles by-axle and relates the addition to these cans with, current type, a speed reducer system 5 particular traveling course varied. The aim is to obtain at least cost, a vehicle mixed, giving the agreement of the conforvet of the road speed, and to the possibilities of circulation and operating in-country, 10 and using for this result a transmission mechanism derived at closer to a set already built in large series, without requiring major changes to the actual structure of a conventional vehicle. Whereas, in the majority of all-terrain vehicles the transfer to the axles takes place via a separate mechanism and that the reduction will thereby affecting all ratios of the box of ' speeds, in the preferred embodiment forming the subject of the invention, the reduction and transfer are grouped in a. cover of the gearbox. In unepremière embodiment it is provided a gear reduction of the engine torque in two phases, the first performed by a ' group of pinions in a special housing at the end of the shaft passing through the input shaft of the conventional transmission, the second using the pinions 1ère speed (or reverse) of the box itself, pinions suitably reinforced for this purpose. This use of additional gear reduction being applied only to first speed (or reverse). In another embodiment the increased torque, also passes through the drill string 2ème conventional gearbox speed, so as to obtain a second crawl high gearing, and optionally by the further gears of this box, thereby obtaining a stepless gear ratios and thereby, a performance improvement. Another feature is that by a sliding control (synchronizer or not), known per se, of the additional gear reduction, thus avoiding the complication of the sliding engagement of the shaft extending through the hollow drive shaft. Another feature is the addition of a brake, known in itself, centeredly extends on an intermediate shaft between the output shaft of the box and the transfer shaft to the axle or axles complementary, to serve 4I auxiliary brake control under a single, common to it and at conventional parking brake for the immobilization of the vehicle on the most steep slopes available to itself. At attached drawing: figures 1 and 2 represent schematically, respectively in a side view and partial cross-section in a plane perpendicular to the shafts of the box, an embodiment for distribution through the first speed of the gearbox figure 5 shows the previous embodiment wherein see, by determining selected engagement of the dogs, the movement transmitted to the axles, the special reduction system being engaged; figures 4 and 5 represent an embodiment with special reductant system, juxtaposed to the box but independent thereof, and comprises an epicyclic train; figure 6 shows a variant of the preceding embodiment reductant system with special external to the gearbox; figures 7 and 8 represent the addition to the arrangement of Figure 6 of a reversing device; figures 9, 10 and 11 represent one embodiment attaches to Figures 6, 7 and 8 wherein the reduction is introduced not on the secondary shaft of the case but on the shaft which carries the intermediate pinion of the return transfer 5 figure 12 is a schematic representation of another embodiment. If 1' is referred to the drawing and more particularly to Figures 1 and 2, it is shown that the transaxle, as currently available in its organs essential, comprises the hollow input shaft and the output shaft 2 carrying the pinions the customary different speeds and particularly the pinions 3, 4 - first speed of, the latter pinion being made integral with the shaft 2 by clutching and driving the bevel gear 5i 6 control of one of the axles. the drive shaft 7 is connected to a shaft 8 by sliding system and passes inside the hollow of the primary shaft 1. The shaft 8 carries at its end a male dog 9 axially maneuvered by the dolly 10, and this male dog 9 can be engaged with a pinion 11 is carried by the end of the input shaft 1 either with a pinion 12 mounted freely on its support shaft, the pinions 11 and 12 respectively mesh on the double gear 13, 14 mounted freely on the shaft 15. The end of the shaft carries a dog -2 16 which can be engaged with a pinion 17 mounted freely on the shaft 2 and meshing with an idler gear 18 mounted on the shaft 19 and itself in engagement with a pinion mounted on the shaft 20 21 leading the other one or more axles of the vehicle. The drive shaft 7, Pa.the R via the slide shaft 8, transmits its motion through the input shaft 1, at male dog 9 which, maneuvered by the dolly 10 axially, is engageable with an inner spline carried by the pinion 11 for the normal running without additional reduction, which transmit the movement of the shaft 8 to the input shaft 1 and thence by the usual pinions of the gearbox to the bevel gear. In high reduction, the dog 9 is engaged with the pinion 12 and the movement thereby passing by the pinion 12, the double-pinion 14 - 13, and then the bell crank 11, the input shaft 1, the first speed gears 3, 4 and the bevel gear 5, 6, the first speed being then engaged. The bevel wheel 3, the shaft end panel 2 and the dog 12 that engages the pinion 17 of this shaft, transmits its motion to the shaft 21, to the wheels of the other axle, via the layshaft gears 17, 18 and 20. A known device of "interlocking" or prohibition not shown, prohibited from engaging the high reduction, therefore the clutching of the pinion 12 when the dog 16 is not engaged to the dog carried by the pinion 17; this prevents overloading of the bevel gear 5 - 6 which would incur only the high torque of the reduction. In Figure 3 is represented the position of the dogs wander 9 and 12 engaged to obtain on both shafts 2 and 21 speed most geared, the dog being engaged with the pinion 16 - 17 By engaging only the Walkman 12, the Walkman 9 rotatably driving the pinion 11, therefore the primary shaft 1, the movement-is transmitted to the shafts 2 and 21 in the ratios between the normal data through the gearbox. The vehicle is thus in this case, on or high, all its drive axles. The control tachometer figure 22. In the simplified arrangement of the box depicted in Figures 4 and 5? is used more the transmission ratio of the first rate inside the case; more especially to high reducing the crossing over of important ramps is obtained by planetary gears followed by a single return. The drive shaft 7 drives the input shaft 1 of the box which, extended, bears the gear 23 exchange to a simple planetary gear set stationary ring 24. The planet gears 25 are carried by a part 26, which has a spline on which slides a sliding sleeve 27. The planet carrier 26 rotates idly on the shaft 1, but the Walkman 27 includes a claw coupling can be engaged with the claw of a pinion 28 mounted idle on the input shaft. Web 28 directly engages the pinion gear 29 keyed on the shaft 2, which transmits its motion to the pinions 30 and 31, to result in the transmission shaft 21 toward the other axles. A shift member 32 can be engaged with the dog the idle gear 31. Thus, when the sliding shaft 27 is engaged on the dog of the pinion 28, the shaft 2 benefits from maximum reduction through the planetary gear train and the return 28 - 29 * as in the previous version, the clutching 27 can only be engaged when the dog 32 is also filled. Finally, the engagement of the dog clutch 32 on the pinion 31, mounted freely on the shaft 21, allows the vehicle to benefit from all the ratios of the gearbox on all preloading of the vehicle; the sliding gear 27 is then disengaged from the pinion 28. The use of an epicyclic train more complex would provide dramatically reducing forward and in reverse. The previous mechanism of Figures 4 and 5 can be performed without epicyclic train; it then takes the arrangement of Figure 6. the input shaft 1 drives the pinion 33 keyed thereon. The pinion meshes with a pinion 34 33 carried by the shaft 35, while a pinion 36 secured to the rotating shaft 35 but slidable thereon by acting on the Walkman 37, can be brought into engagement with the pinion 38 of the double gear 38 - 39, mounted freely on the shaft 1. The pinion meshes with the pinion 39 40 carried by the shaft 2 and the pinion axle driving 40 meshes with the gear 41 which itself is in engagement with the gear 42. A shift member 43 secured to the rotating shaft 21 attacking the other axle is engageable with the pignonfou 42. A reversing device known has been added to the version of Figure 6 and Figures 7 and is 8; the Walkman 37 can then, along its axial position, allow for engaging the pinion with the pinion 36 or 38, which corresponds to Figure 6, either be neutral, either engaging the pinion 36 with the pinion 44 to obtain the reversal. By design, the reversing device, which is the simplest, leads to a reduction ratio slightly less in reverse motion of the vehicle front, which does not constitute an obstacle, but provides the advantage of facilitating désenlis ^ hydraulic circuit of the vehicle possible. The same security devices are used in very step geared transmission, the drive axles to be currently under torque. The set neutral the selector member 37 allows the movement of the vehicle with all its drive wheels, using all the ratios of the gearbox, the Walkman 43 then being engaged with the pinion 42. We Figures 9, 10 and 11 an alternative embodiment, that changes, of the previous arrangement in the Figures 6, 7 and 8. There is similarity with regard to the returning movement, with the version described in Figures 6, 7 and 8, except: 1 Degrees) the reduction leads to the sun gear of the return transfer instead of the primary pinion constituting the of the secondary shaft. 2 Degrees) off of the movement takes place: a) for the reducer by the two sliding sleeves 57 and 48 manipulated jointly, this isolate the train reduction gear, not only the return transfer but also of the primary shaft; b) for the transfer, by the dog 52 * of course, the condition they do not engage the dogs 37 and 48 if the dog 52 is not engaged, is maintained in order to avoid overloading the bevel gear of the gearbox which would encounter considerable reduction in only the reserved utilr ina exceptional. The arrangement of Figures 9 and 11 relates to a reduction in forward and reverse. Fig. 9j on the extension of the input shaft 1 is mounted the pinion 36 integral in rotation with this shaft and slidable thereon by acting on the Walkman 37 - a shaft 21 mounted in the extension of the shaft 2 but independent thereof carries the two pinions 44 and 45, the pinion meshing with the pinion 45 46 47 carried by the intermediate shaft, while a contact roll 48 dog mounted on this shaft secures engagement between the pinion 49 with this shaft meshing with both the pinion 50 of the secondary shaft 2 and, on the other hand, with the pinion mounted freely on the shaft 5i 21 control axles other than that controlled by the bevel gear box. A sliding sleeve at dog 52 allows to assemble together with the shaft 21 the pinion 51 * in this fig. 9, the pinions of the AR - 54 a BRE 2 and 55 are the reverse gears disposed in a known manner. Operating the opening 37 and 4 - 8 players to feed them is taken respectively with the pinions 44 and 49, the movement is transmitted, down-converted, to the shaft 2 of the angle transmission by the pinions 36, 44, 45, 46, 49 and 50 and, at the same time, to the shaft 21 if, by the Walkman 52, the pinion 51 is engaged with the shaft 21. For transmission without a special gear ratio, all axles being engines, 37 and 48 players are disengaged from gears 44 and 49 while the sliding gear 52 is engaged with the pinion 51 which directly drives 1' shaft 21. Figure 10 provides a very the above item for the reduction forward only and have the same gear ratios arranged differently from for particularly the pinions 44 and 45. The arrangement of the embodiment of Figures 9, 10 and 11 we introduce the reduction not on the of the secondary shaft (pinion gear), but on the shaft which carries the intermediate pinion of the return transfer. Oette sharing arrangement, upon entry, the effort reduction between the two shafts without supporting one of them the total torque which must subsequently be share. This leads to a decrease in loading of the pinion teeth and input of the corresponding bearing of the secondary shaft. Further, the return transfer is used as gear reduction instead of simply transmitting rotational movement of same speed to the two driven shafts 2 and The transaxle, base member of the mechanism, may be located at the front or rear of the vehicle, the transfer taking place on the other axle of the vehicle. A power take-off can be provided easily at the end of the transmission input shaft. In the embodiment shown in fig.. 12, see that the gearbox has always the same essential elements as described and shown in the preceding embodiments: The hollow input shaft 1 receives the drive shaft driven by the shaft 7 δ * The secondary shaft 2 controls the torque 5 conical? 6 * The pinions carried by the different speeds of the shafts 1, 2 are indicated: for the 1, 2 2 4; the third speed in 3, 4. Sliders 55, 54 permettent4 ' engage the different gears. In the cover 55 of the box speeds.' represented on the left of the Figure, are grouped the members of the additional reduction system. This is how the pinion 12 carried by the shaft 8 meshes with the gear 14 of the double-pinion mounted freely on the shaft 14 - 13 15 while the pinion meshes with the gear 13 11 rotating idly on the input shaft 1. One feature of this embodiment resides in the suppression of the male dog carried fig. ο 1, which could be engaged by sliding said shaft, either with the pinion 12, either with the pinion 11. In the present arrangement, as well as shown in Figure, the shaft 8 is not sliding and contact roll 56 carried by the primary shaft 1 can be engaged with the dogs either of the pinion shaft 12 driven ESP 8 for the normal use of the box speeds, either of the pinion 11 for additional reduction, corresponding to a simplification since the single trip of a Walkman provides this effect instead of sliding the drive shaft. The secondary shaft 2 carries the pinion 17 driven by the shaft and pinion 17 meshes with the intermediate gear 19 itself in engagement with the gear 20 which can be made integral with the shaft 21 of the other axle or axles of the vehicle with other rider 57 * For the additional reduction, the Walkman 56 is engaged with the gear 11 and the motion is changed by the pinion 12, the double-pinion - 14, 15, the bell crank 11, the shaft 1 and the pinions 5 first speed, and the bevel gear 4 - 5, 6, when the first gear is engaged. The movement can also pass, either by the pinions 5 second speed stage, 4 -, 5 third speed, 4 - ^, and so on, when these speeds are engaged, thereby obtaining a stepless gear ratios and therefore a performance improvement. It has also been shown in Figure 12 the severance of a brake on an extension of 58 ' j of the intermediate shaft 19 between the extension 2 of the secondary shaft 2 and the transfer shaft 21 toward the axle or axles complementary. This auxiliary brake 58 is actuated under control with the brake single conventional parking for the immobilization of certain of the vehicle on the stronger slopes. An advantage resulting from the architecture this transmission consists in obtaining a mechanical efficiency greater than that which is obtained by a separate transfer case. Indeed, in the combination to a driven axle, the power is transmitted to the drive wheels to per the usual channels of the transaxle without passing through the gears located in the transfer unit. Finally, this being general in all the devices described, a safety mechanism is to prevent engagement of dramatically reducing when transfer on all axles is not engaged, to ward the conical deflecting of the gearbox conventional against the effects of a large overhead. 1,107,554. Change-speed gearing. REGIE NATIONALE DES USINES RENAULT. 10 June, 1965 [11 June, 1964; 5 Jan., 1965], No. 24677/65. Heading F2D. A vehicle transmission comprises main and auxiliary-reduction gears with first and second output axle drive shafts, provision being made for normal drive through the main gear to the first shaft and for drive to both shafts with or without speed reduction through the auxiliary gear. As shown the main gear has an input shaft 8 within a hollow shaft 1 carrying constant mesh pinions driving the first axle drive shaft 2, the second drive shaft 21 being connected by pinions 17, 18, 20 to the shaft 2. The auxiliary reduction gear comprises pinions 11, 12 on the shafts 1, 8 meshing a compound pinion 13, 14 and operated by a dog clutch member 9 on the shaft 1. As shown the arrangement is conditioned for normal drive between shafts 1, 2 and by engaging a second clutch 16 the pinion 17 may be locked to shaft 2 so that both shafts 2, 21 are driven without speed reduction. The reduction train is brought into action by moving clutch 9 to the left to engage pinion 12 with input shaft 8. In modifications the auxiliary gear train is of the epicyclic type and clutch 16 is mounted on shaft 21, Figs. 3, 4 (not shown), and axially movable pinions are substituted for certain of the clutches, Figs. 6-11 (not shown). 1 Degrees) mechanism comprising a transaxle, of conventional type, for transmission of one or more axles on vehicles, characterized in that it comprises a speed reduction mechanism in an additional housing side relative to the gearbox housing, using the primary and secondary shafts of the box, operated through the operation of revolving and performing reduction on the axle commahdé by conventional of the secondary shaft and countershaft gearing on a shaft driving the other axles, said reduction being distributed on these axles by completion to a sun gear which is for the reduction and the distribution between them of engine torque. Using the different crabotages allows the vehicle to be propelled with the ratios between the claw of the usual conventional -, or single, either by all its axles. 2 Degrees) transaxle for motor vehicles based on 1 degrees) having one or more drive axles with system speed reducer special traveling various terrain, characterized by the addition of a box-pont .de a usual type special gear reduction system mounted in a cover of the transaxle and having a movable dog on the end of the drive shaft mounted within the hollow input shaft of the gearbox, and can engage either a pinion on the input shaft for driving said shaft to normal operation without additional speed reduction OD with all transmission gears, either an auxiliary sprocket which is mounted on a shaft in the extension of the input shaft and, by an intermediate shaft of a double-pinion, drives the pinion mounted on the input shaft to provide the reduced additional specially with the pinions engaged first speed, while the secondary shaft driving the bevel gear drives when a dog is engaged with a pinion mounted on said shaft, via an intermediate pinion, a pinion integral with a shaft driving the other axle. 3 Degrees) donations a transaxle of after 2 degrees) a interdictionèmpeche engage the pinion driving the clutching on double-pinion when the dog of the secondary shaft is not engaged by the pinion on the driving shaft driving the other axle. 4 Degrees) a variant embodiment of the transaxle of after 1 degrees), characterized in that the input shaft of the transaxle carries the central gear of a train épicycloxdal whose satellite-holder is provided with a dog for the couple by a sliding with an auxiliary gear meshing with a gear on the secondary shaft which in turn causes the torque of the first axle bevel, while the auxiliary gear drives by returning gears the shaft driving the other axles after operating a special dog for this shaft. 5 Degrees) a variant embodiment of the arrangement of after 1 degrees), characterized in that the shaft carries a gear which meshes with a pinion of an auxiliary shaft on which can be moved by sliding, a pinion integral in rotation with this shaft and meshing with a gear a twin pinion mounted freely, on the input shaft, and the other gear is meshed with a pinion carried by the secondary shaft driving the angle transmission of the first axle, while the pinion is engaged with a driving sprocket deflection by action on a Walkman to dog the shaft driving the other axles. 6 Degrees) variant of the mechanism after 5 degrees)" characterized by disposing on the input shaft of a pinion controlled by sliding sleeve rotationally fixed shaft and can - grout. rCS thereon, pinion which can be brought into engagement with a gear of a double gear wheel mounted on a shaft placed in the extension of the secondary shaft and the other gear is in mesh with a gear of an auxiliary shaft which carries another pinion being attachable to said shaft by a sliding dog and meshing with a gear of the secondary shaft, said other gear meshing with a pinion mounted freely on the L.' shaft attacking the axles other than that controlled by the secondary shaft and rigidly connected to said shaft by a sliding dog. 7 Degrees) embodiment of a mechanism according to 1 degrees) characterized in that the reduction of the engine torque is carried out in two phases, the first by a group of gears in a special housing at the end of the input shaft of the gear box, the second using the pinions of one of the first speed, the second speed is, or other speeds. 8 Degrees) embodiment of a mechanism according to 7 degrees) characterized in that the control of the additional gear reduction is performed by a sliding carried by the primary shaft and of which the dogs may be engaged with either of the gears of the gear-down group carried by the drive shaft for the normal control of the transmission, or with another gear of the gear-down group mounted idle on the input shaft for the gearbox control with additional reduction. 9 Degrees) form OD embodiment of a mechanism according to 7 degrees) characterized by the inclusion of an auxiliary brake on an extension of the intermediate shaft between the output shaft of the gearbox and the transfer shaft to the axle or axles complementary, this auxiliary brake being under single control with the conventional parking brake.PRIORITY: