NANO-FIBER SPINNING APPARATUS USING CENTRIFUGAL FORCE AND METHOD OF MANUFACTURING NANO-FIBER USING THE SAME

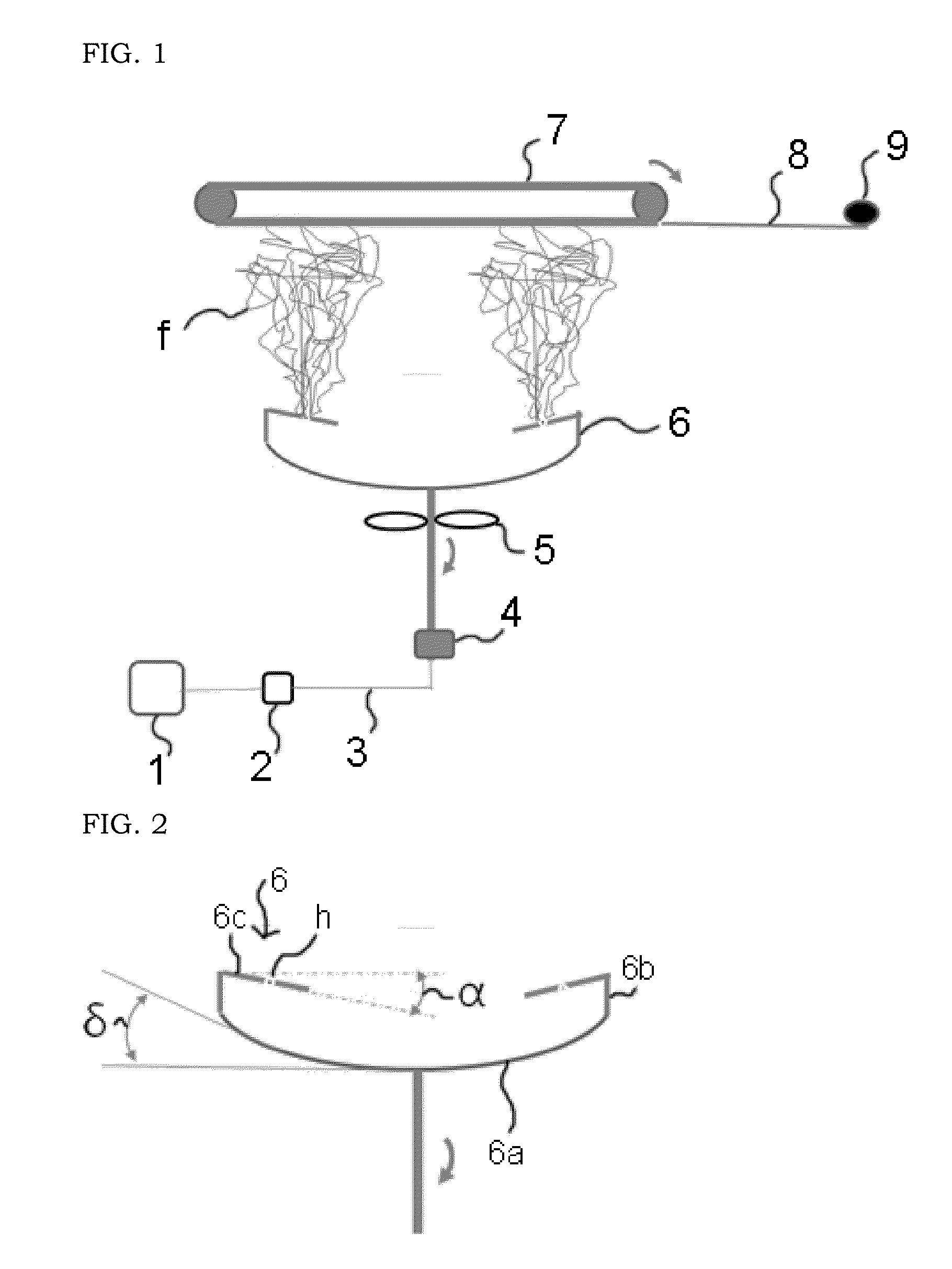

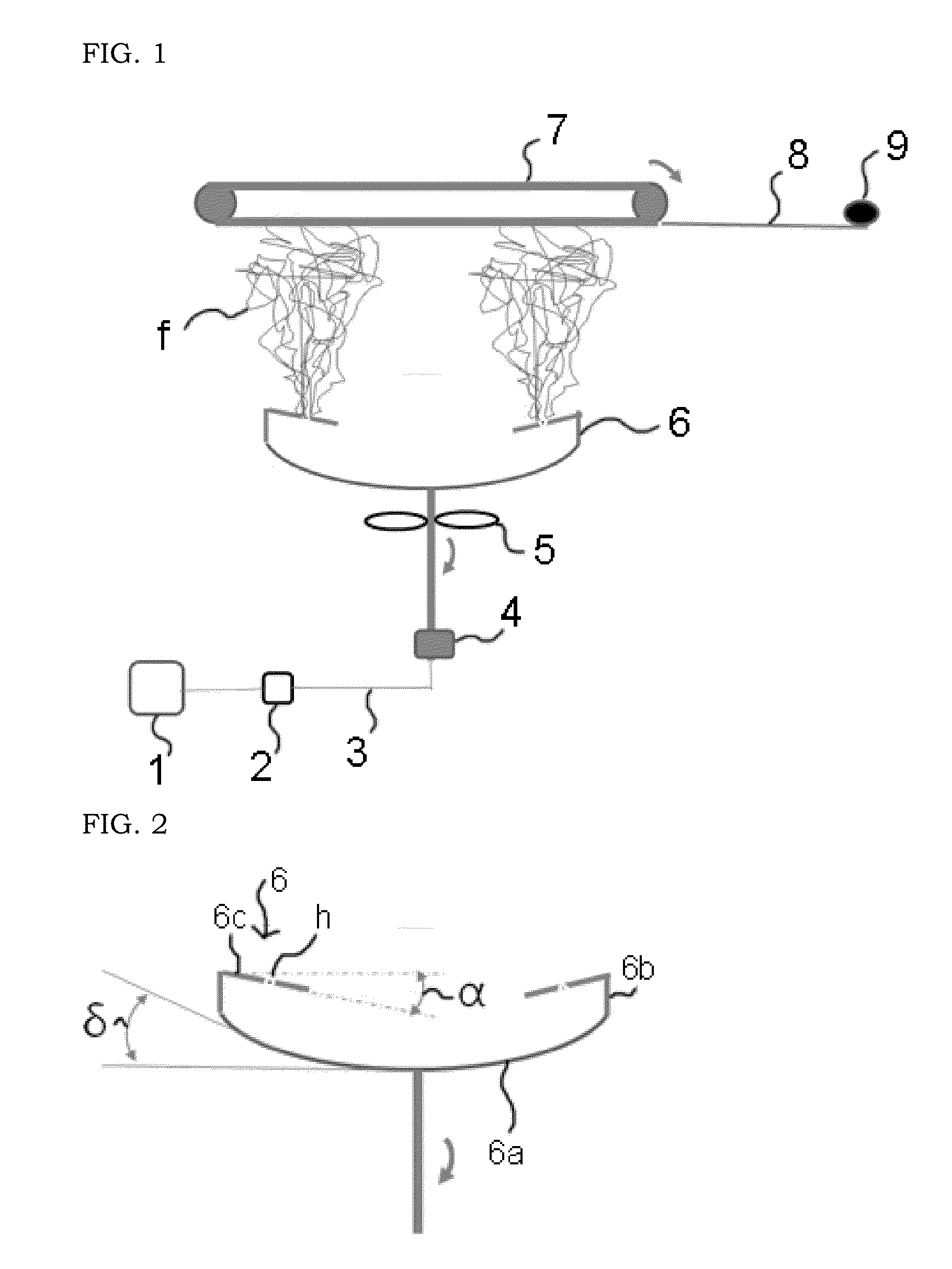

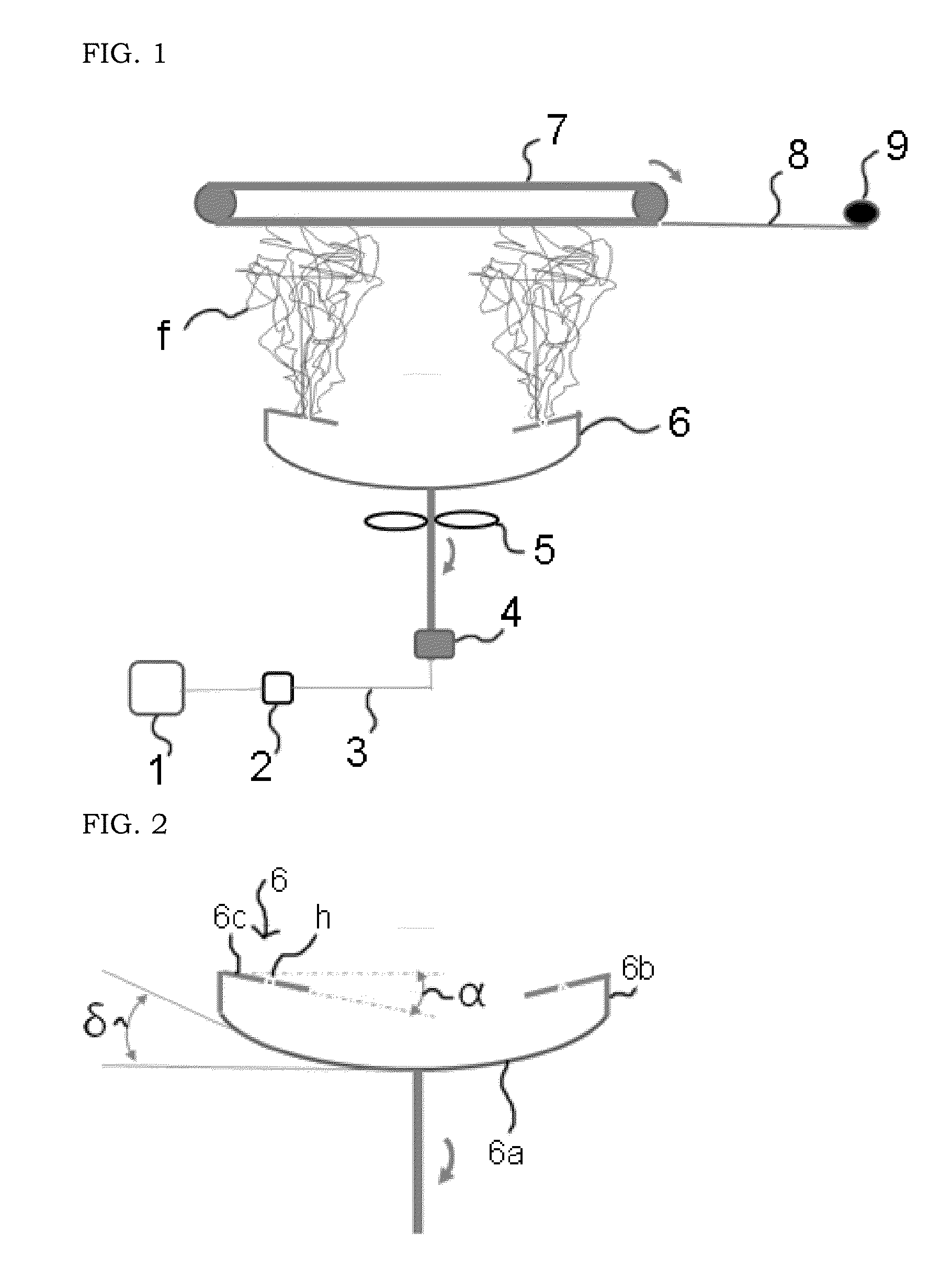

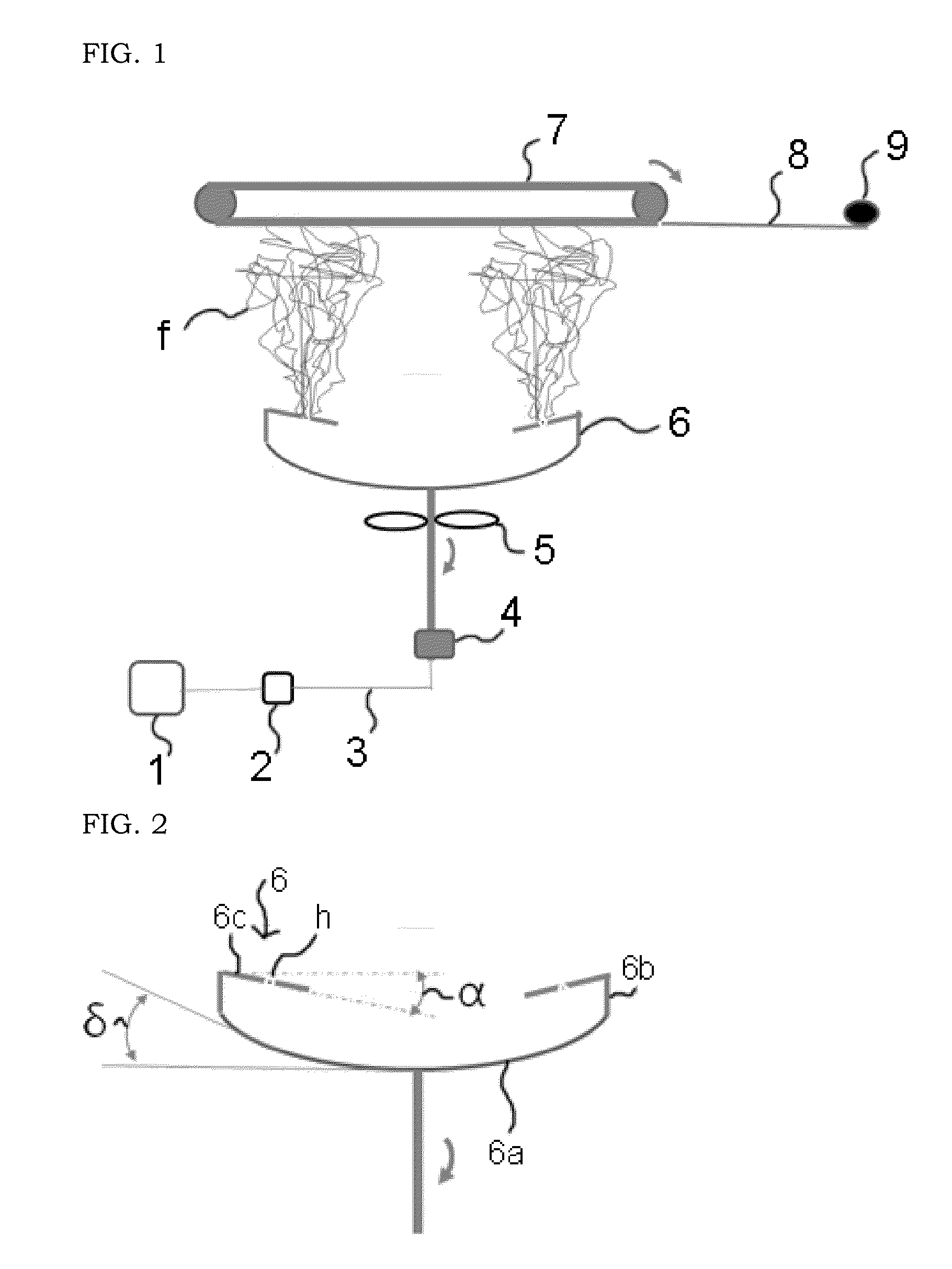

This application claims priority to Korean Patent Application No. 10-2014-0162364, filed on Nov. 20, 2014 in the Korean Intellectual Property Office, the entire disclosure of which is incorporated herein by reference. 1. Field of the Invention The present invention relates to a nano-fiber spinning apparatus using centrifugal force and a method of manufacturing nano-fibers using the same, and more specifically, to a method of manufacturing nano-fibers only using centrifugal force and air flow, which can achieve high production per unit hour without occurrence of a phenomenon that a spinning dope drips in a liquid state (hereinafter referred to as a “drop generation phenomenon”) even though electrostatic power is not applied, as well as a nano-fiber spinning apparatus used for the above method. 2. Description of the Related Art In general, nano-fibers have been prepared by using an electronic spinning (‘electro-spinning’) method. Among conventional electro-spinning apparatuses used for preparing the nano-fibers, a fixed nozzle has mostly been employed as a discharging device of a spinning dope, as disclosed in Korean Patent Registration No. 10-0420460. However, since the conventional electro-spinning apparatuses as described above electrically spin (discharge) the spinning dope through the fixed nozzle, electro-spinning has been executed by electrostatic power alone and thus a discharge rate per unit hole of the nozzle per unit hour was very low in a level of 0.01 g to decrease productivity. Consequently, problems such as difficulties in mass production, highly complex and complicate replacement and cleaning of nozzles, or the like, have been entailed. In general, a production rate of nano-fibers through electro-spinning is in a level of about 0.1 to 1 g per hour, and the solution discharging rate is also very low in a level of about 1.0 to 5.0 mL per hour [D. H. H. Renecker et al., Nanptechnology 2006, Vol. 17, 1123]. Another conventional electro-spinning apparatus is an electro-spinning apparatus that executes electro-spinning using electrostatic power and centrifugal force, simultaneously, and by supplying a polyvinyl pyrrolidone solution to a conical vessel rotating at 50 rpm while applying high voltages thereto, without any nozzle, which has been described in an article disclosed in the bulletin, Small 2010, by Jinyuan Zhou et al. of Nanzhou University (Small, 2010 Vol. 6, 1612-1616). However, although the above electro-spinning apparatus may utilize centrifugal force and electrostatic power to improve the production rate per unit hour even without any nozzle, it entailed such problems that the spinning dope is continuously fed into a conical vessel to cause a difficulty in continuous production, a collector is located below the conical vessel to occur a phenomenon of dripping the spinning dope in a liquid state (‘drop generation phenomenon’) other than a fiber form, and the like. Further, an alternative electro-spinning system mode provided with a plurality of nozzles arranged on a nozzle panel has also been well known [H. Y. Kim, WO 2005 073441, WO 2007 035011]. The above-described electro-spinning system mode embraces very low production rate of nano-fibers per unit hole and using nozzles to cause a problem of troublesome cleaning. A mechanism for formation of nano-fibers through holes of a rotating cylindrical vessel is generally similar to a mechanism for formation of threads by a rotor in open-end method in a cotton spun process, and Parker et al. of Harvard University discloses a method of manufacturing nano-fibers which includes collection of nano-fibers formed through holes of a rotating cylindrical vessel in a cylindrical collector mounted on an outer periphery thereof, through an article published in 2010 [Nanoletters, 10, 2257-2261, 2010]. Further, U.S. Pat. No. 8,231,378 B2 discloses a superfine fiber creating spinneret in which centrifugal force acts in a circumferential direction by arranging holes around the circumference of a cylindrical vessel to thus scatter micro- or nano-fibers in the circumferential direction and collect the same in a collector mounted in the circumferential direction. Further, heat may be applied thereto. However, the above-described conventional methods cannot collect nano-fibers upwardly to hence have a difficulty in production of a nano-fiber web, and encounter a problem of deteriorated solvent volatility. In consideration of the above-described circumstances, it is an object of the present invention to provide a method of manufacturing nano-fibers with desired efficiency, only using centrifugal force and air flow even without application of electrostatic power, which exhibits high production rate per unit hour but does not occur a phenomenon of dripping a spinning dope in a liquid state (hereinafter, referred to as ‘drop generation phenomenon’). Another object of the present invention is to provide a nano-fiber spinning apparatus using centrifugal force, which is used in the above method. In order to accomplish the above objects, there is provided a nano-fiber spinning apparatus, including: (i) a top plate which has nano-fiber spinning holes, and is slantly formed at an inclination angle decreasing from outer peripheral edges to a center with respect to a virtual horizontal line connecting the outer peripheral edges of a cylindrical side wall so as to have a disk shape; (ii) a bottom plate having a curved surface which is concaved and inclined upwardly so as to have a dish shape; and (iii) the cylindrical side wall which connects the top plate and the bottom plate, so as to be wholly formed in a spin-top shape. After supplying a spinning dope to the nano-fiber spinning apparatus, the nano-fibers are spun toward a collector placed on a top site using centrifugal force while generating an air flow toward the collector from an air generator located below the nano-fiber spinning apparatus. The present invention may only use centrifugal force and air flow without application of electrostatic power, and spin nano-fibers without using conventional spinning nozzle, therefore, can attain some advantages of, in particular: avoiding danger in working due to application of high voltages; preparing nano-fibers with high productivity (discharge rate); overcoming troubles in nozzle replacement and cleaning thereof; easily volatilizing and recovering a solvent; and efficiently preventing a phenomenon of dripping a spinning dope in a liquid state (‘drop generation phenomenon’) on the collector other than a fiber form, thereby improving quality of nano-fiber webs. The above and other objects, features and other advantages of the present invention will be more clearly understood from the following detailed description taken in conjunction with the accompanying drawings, in which: Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. As illustrated in The bottom plate 6 The inclination angle α between the top plate 6 An inclination angle δ between the curved surface forming the bottom plate 6 According to the present invention, since the top plate 6 The number of the nano-fiber spinning holes h formed in the top plate 5 The nano-fiber holes h formed in the top plate 6 Meanwhile, as illustrated in Specifically, as illustrated in Next, rotating the nano-fiber spinning apparatus 6 using the motor 4 connected to a lower end thereof generates centrifugal force, which may be used to spin the spinning dope fed into the nano-fiber spinning apparatus 6 through the nano-fiber spinning holes h toward the collector 7 provided above the nano-fiber spinning apparatus 6 in a nano-fiber form f. At the same time, an air flow is generated in a direction of the collector 7 by the air generator provided below the nano-fiber spinning apparatus 6 to collect spun nano-fibers f in the collector 7. Thereafter, the collected nano-fibers f may be separated and formed into a nano-fiber web 8, followed by winding the web. An example of the air generator may be a rotating fan 5 fixed to the connection bar for connecting the motor 4 and the nano-fiber spinning apparatus 6. The present invention only uses the centrifugal force and air flow without application of electrostatic power and spins nano-fibers without using conventional spinning nozzles, therefore, may attain beneficial features, including: avoiding danger in working due to application of high voltages to a collector or the like; preparing nano-fibers with high productivity (discharge rate); overcoming troubles in replacement and cleaning of nozzles; easily volatilizing and recovering a solvent; and efficiently preventing a phenomenon of dripping a spinning dope in a liquid state (‘drop generation phenomenon’) on the collector other than a fiber form, thereby improving quality of nano-fiber webs. Hereinafter, examples of the present invention will be described in more details. However, it will be apparent to those skilled in the art that such examples are provided for illustrative purposes without limitation of the present invention Polyvinylalcohol having a weight average molecular weight Mw of 80,000 was dissolved in water as a solvent to prepare a spinning dope with a solid content of 30 wt. % and a viscosity of 8,500 cps. Next, as illustrated in In this regard, a maximum diameter of the nano-fiber spinning apparatus 6 was 80 mm, an inclination angle α between the top plate 6 Further, each of the nano-fiber spinning holes h had a diameter of 0.8 mm and a length of 10 mm, and the number of the nano-fiber spinning holes h was 4. Next, a nano-fiber web 8 was prepared using nano-fibers collected in the collector 7, then, wound. The formed nano-fiber web was shown in electro-micrographs of The nano-fibers included in the prepared nano-fiber web had an average diameter of 620 nm. Polyvinylalcohol having a weight average molecular weight Mw of 80,000 was dissolved in water as a solvent, to prepare a spinning dope with a solid content of 25 wt. % and a viscosity of 7,000 cps. Next, as illustrated in In this regard, a maximum diameter of the nano-fiber spinning apparatus was 80 mm, an inclination angle α between the top plate 6 Further, each of the nano-fiber spinning holes h had a diameter of 0.8 mm and a length of 10 mm, and the number of the nano-fiber spinning holes h was 4. Next, a nano-fiber web 8 was prepared using nano-fibers collected in the collector 7, then, wound. The formed nano-fiber web was shown in electro-micrographs of The nano-fibers included in the prepared nano-fiber web had an average diameter of 580 nm. As described above, since nano-fiber spinning apparatus according to the present invention only uses the centrifugal force and air flow without application of electrostatic power and spins nano-fibers without using conventional spinning nozzles, it may accomplish some advantages, including: avoiding danger in working due to application of high voltages to a collector or the like; preparing nano-fibers with high productivity (discharge rate); overcoming troubles in replacement and cleaning of nozzles; easily volatilizing and recovering a solvent; and efficiently preventing a phenomenon of dripping a spinning dope in a liquid state (‘drop generation phenomenon’) on the collector other than a fiber form, thereby improving quality of nano-fiber webs. While the present invention has been described with reference to the preferred embodiments, it will be understood by those skilled in the related art that various modifications and variations may be made therein without departing from the scope of the present invention as defined by the appended claims. Disclosed is a nano-fiber spinning apparatus using centrifugal force which includes: (i) a top plate 6c which has nano-fiber spinning holes h, and is slantly formed at an inclination angle with a virtual horizontal line connecting top of a side wall 6b in a disk shape; (ii) a bottom plate 6a having a curved surface which is concaved and inclined upwardly in a dish shape; and (iii) the cylindrical side wall 6b connecting the top plate 6c and the bottom plate 6a, so as to be wholly formed in a spin-top shape. Also, disclosed is a method of manufacturing nano-fibers which includes, after supplying a spinning dope to the above nano-fiber spinning apparatus 6, spinning nano-fibers with centrifugal force toward a collector 7 provided above the apparatus while generating an air flow toward the collector by an air generator provided below the nano-fiber spinning apparatus 6. 1. A nano-fiber spinning apparatus using centrifugal force, comprising:

(i) a top plate which has nano-fiber spinning holes, and is slantly formed at an inclination angle decreasing from outer peripheral edges to a center with respect to a virtual horizontal line connecting the outer peripheral edges of a cylindrical side wall so as to have a disk shape; (ii) a bottom plate having a curved surface which is concaved and inclined upwardly so as to have a dish shape; and (iii) the cylindrical side wall which connects the top plate and the bottom plate, so as to be wholly formed in a spin-top shape. 2. The apparatus according to 3. The apparatus according to 4. The apparatus according to 5. The apparatus according to 6. The apparatus according to 7. A method of manufacturing nano-fibers using centrifugal force and an air flow, comprising:

supplying a spinning dope formed of at least one selected from a polymer solution and a polymer molten material to a nano-fiber spinning apparatus, including: (i) a top plate which has nano-fiber spinning holes, and is slantly formed at an inclination angle decreasing from outer peripheral edges to a center with respect to a virtual horizontal line connecting the outer peripheral edges of a cylindrical side wall so as to have a disk shape; (ii) a bottom plate having a curved surface which is concaved and inclined upwardly so as to have a dish shape; and (iii) the cylindrical side wall which connects the top plate and the bottom plate, so as to be wholly formed in a spin-top shape, and the bottom plate is connected to a motor by a connection bar; rotating the nano-fiber spinning apparatus by driving the motor to generate centrifugal force, which in turn, spins the spinning dope fed into the nano-fiber spinning apparatus through the nano-fiber spinning holes toward a collector provided above the nano-fiber spinning apparatus, in a form of nano-fiber; and generating an air flow upwardly of the nano-fiber spinning apparatus by an air generator provided below the nano-fiber spinning apparatus, so as to collect the nano-fibers spun through the nano-fiber spinning holes into the collector. 8. The method according to RELATED APPLICATIONS

BACKGROUND OF THE INVENTION

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF THE INVENTION

Example 1

Example 2