DISC BRAKE

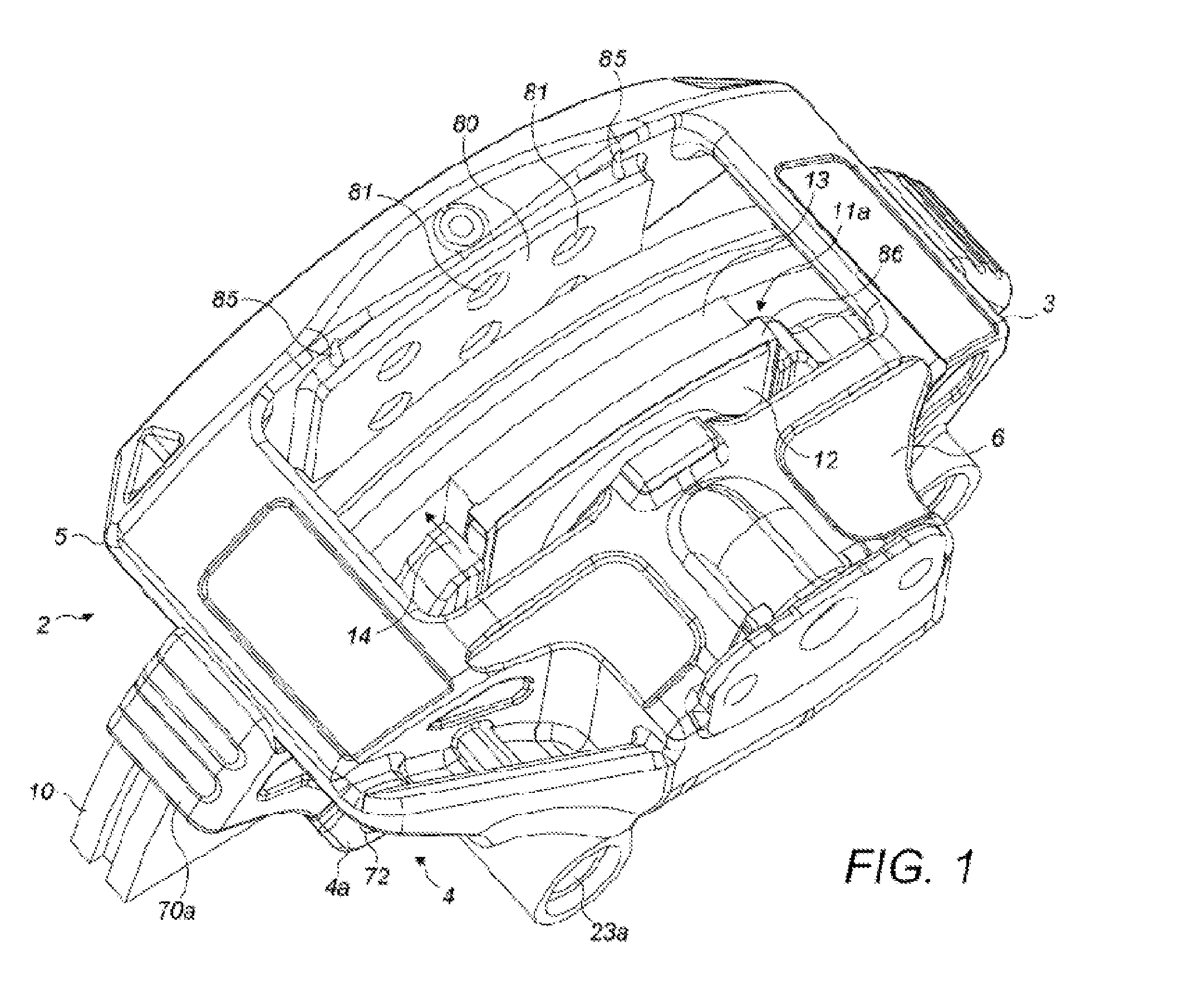

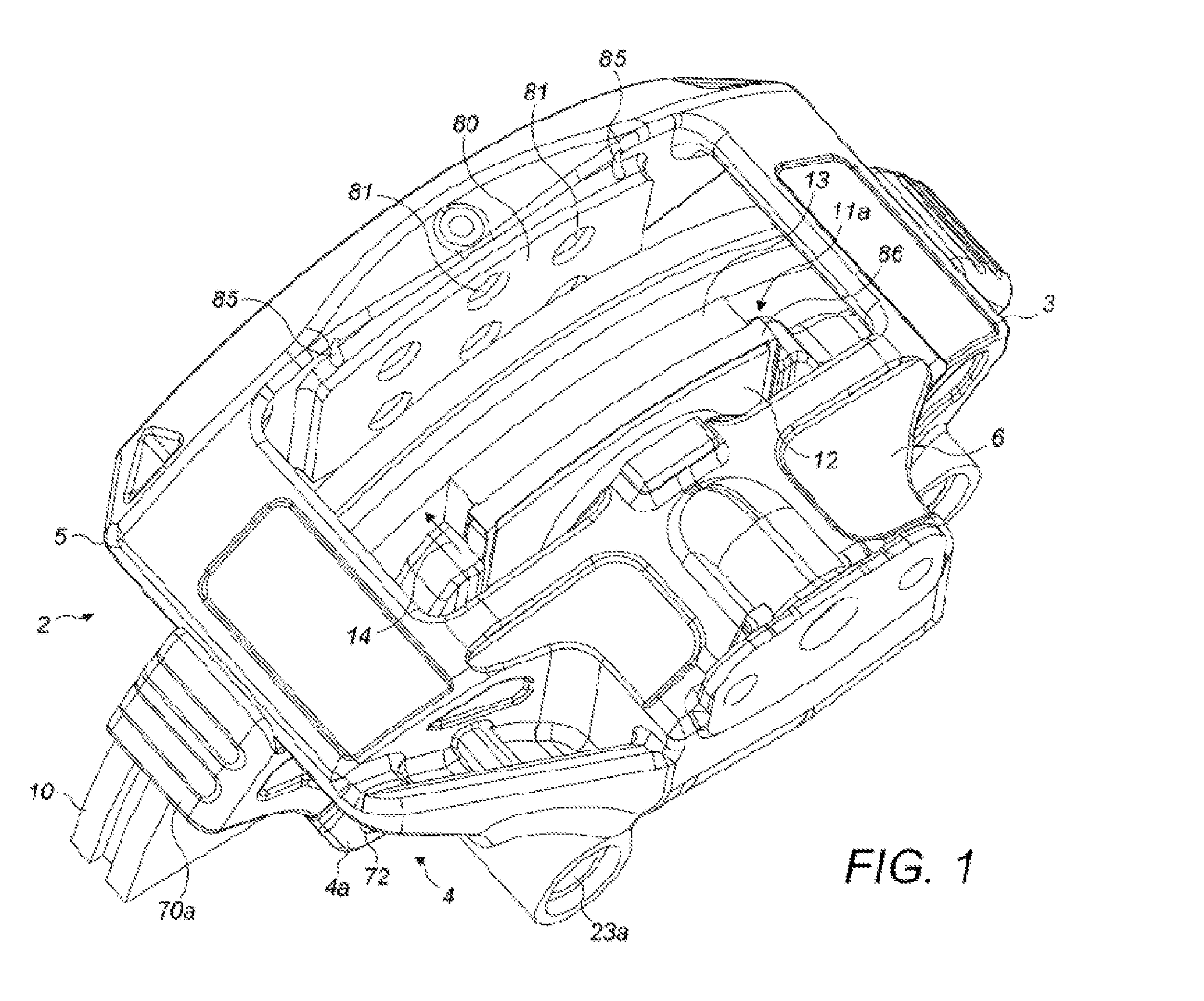

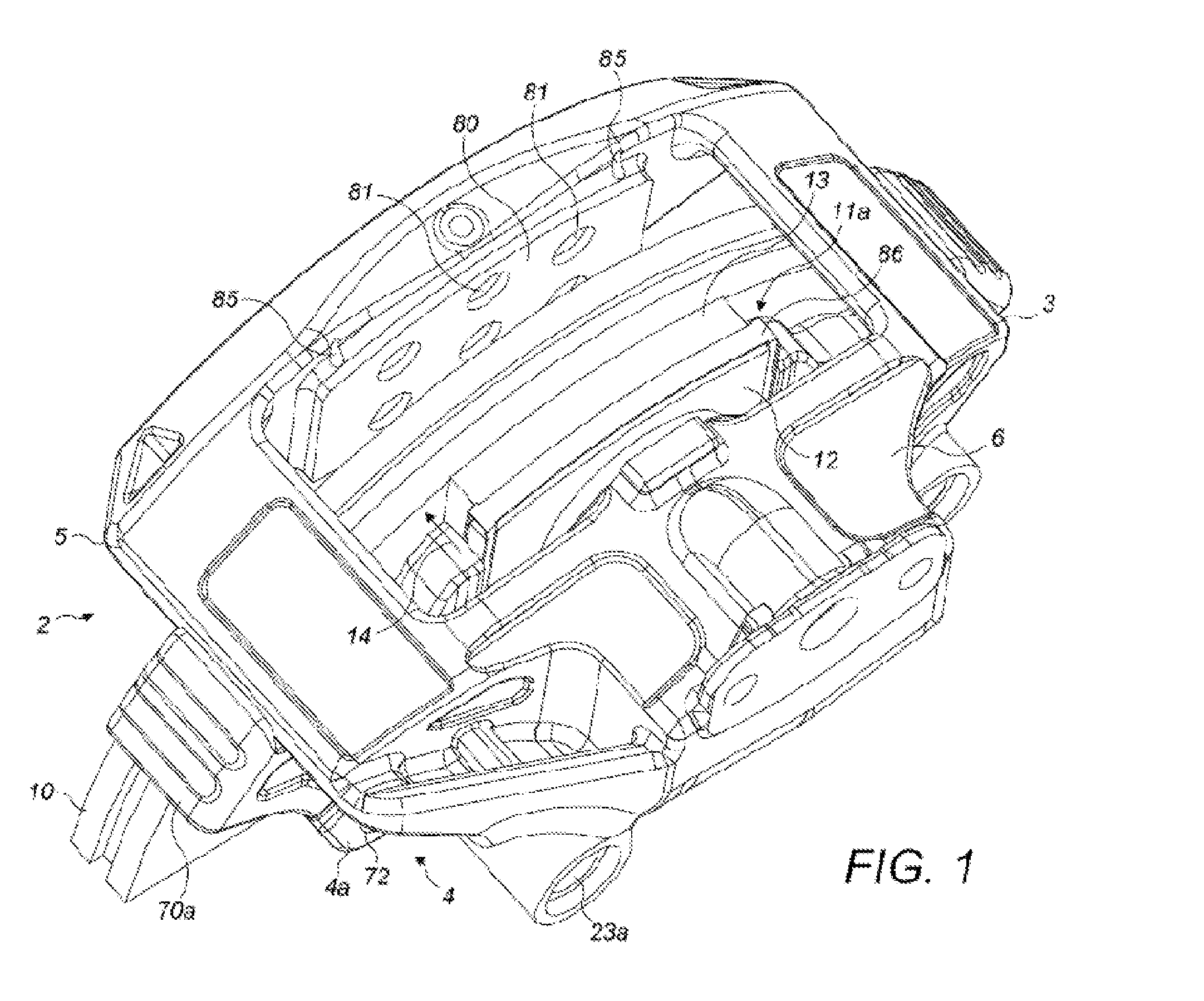

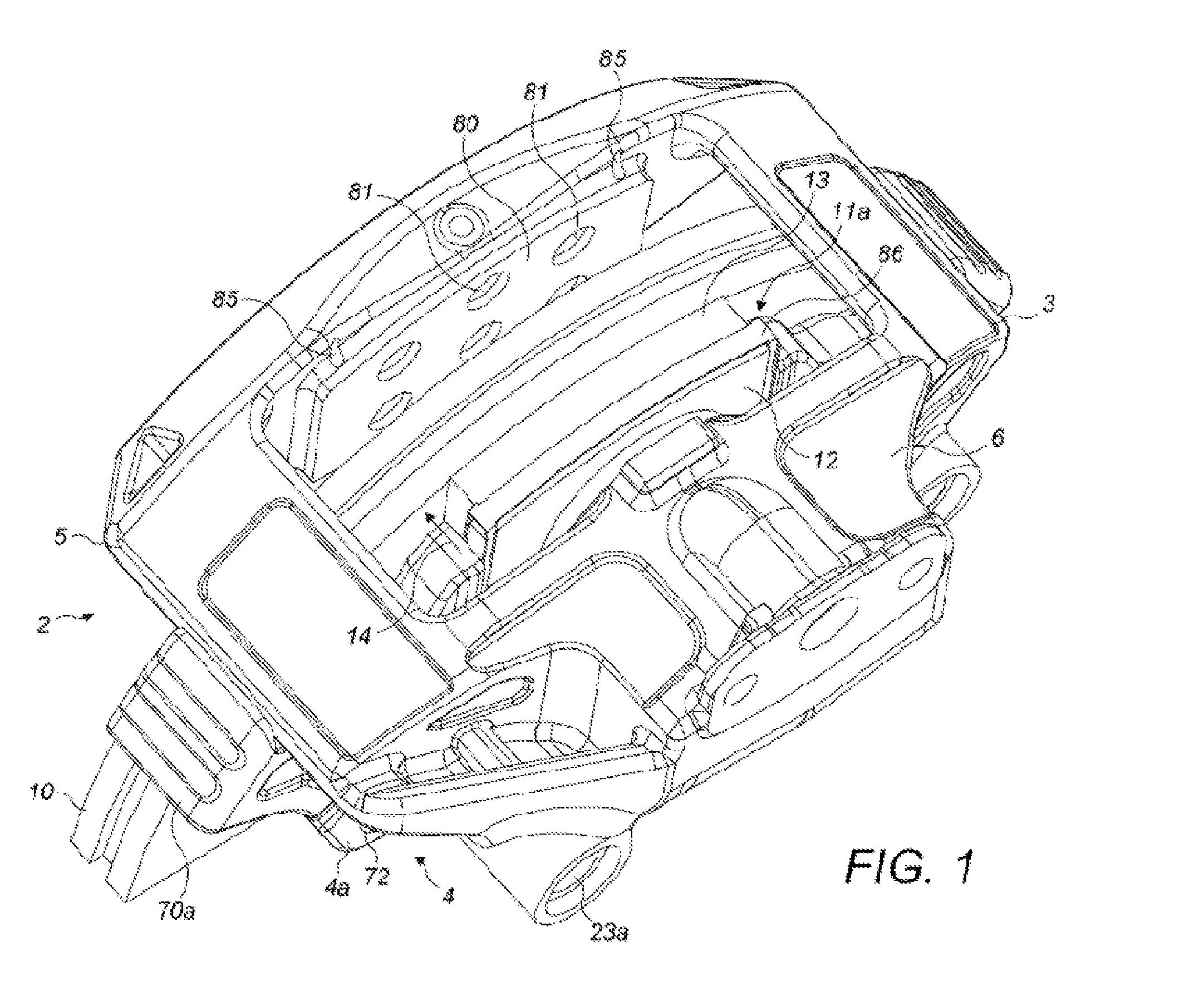

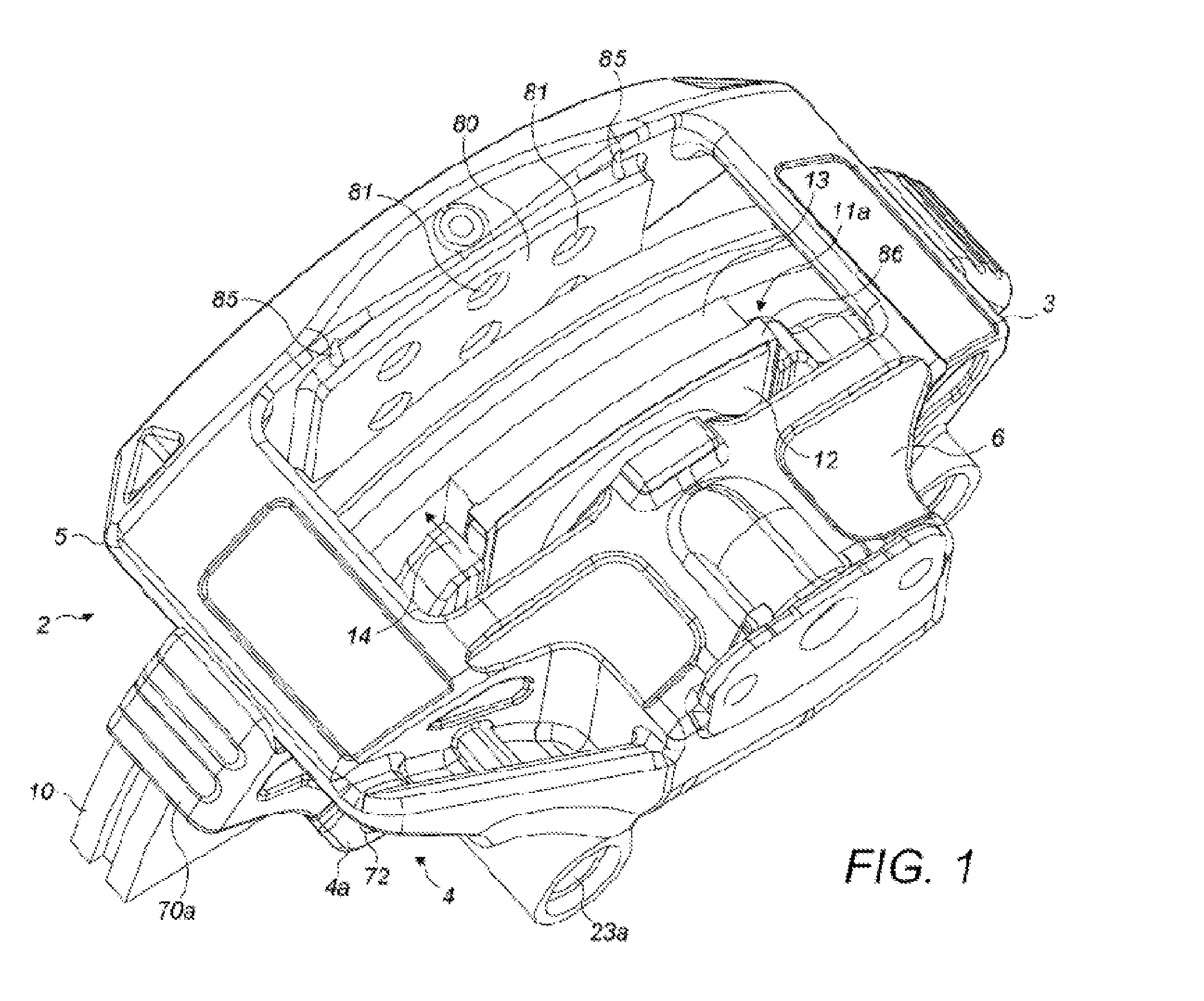

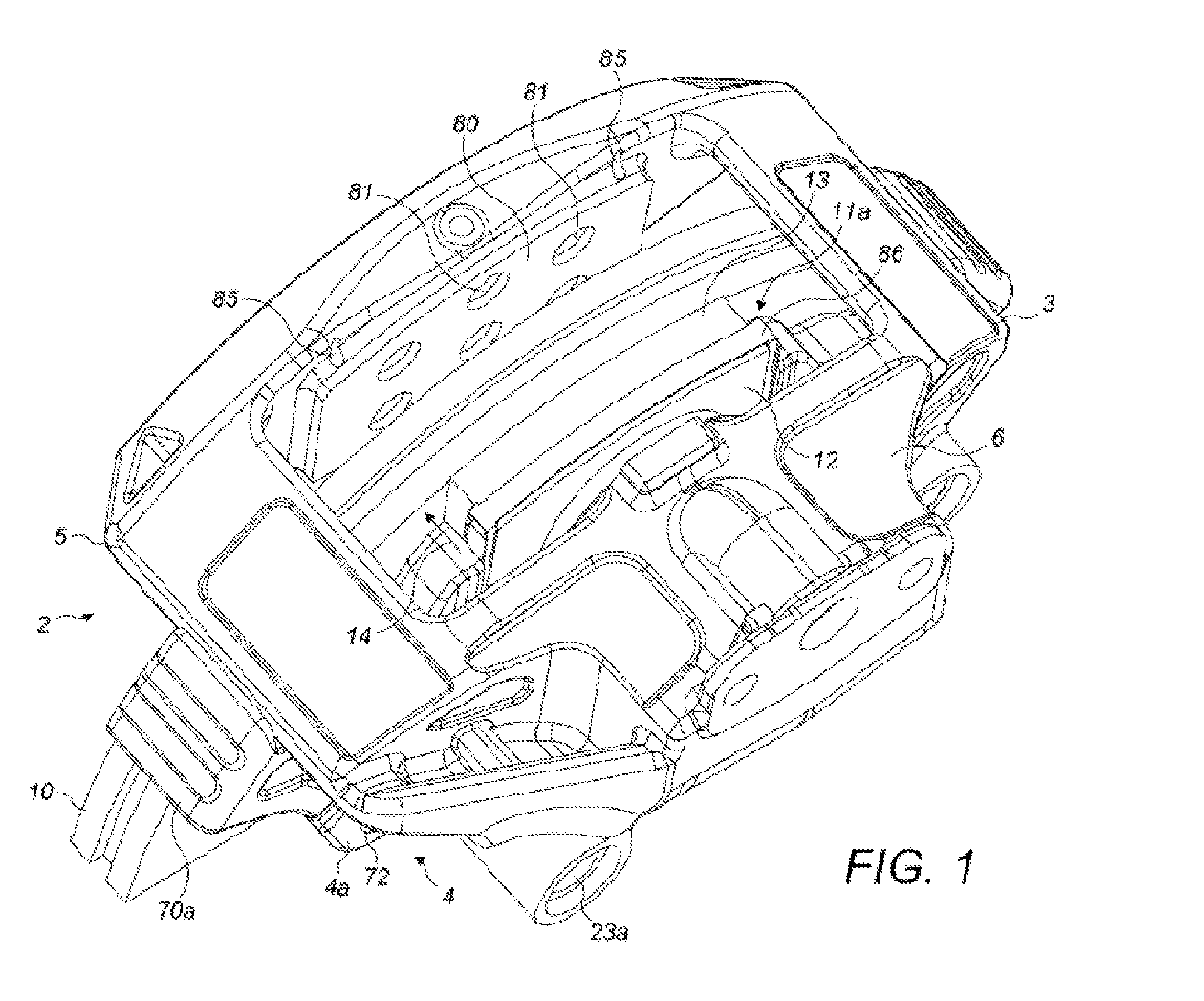

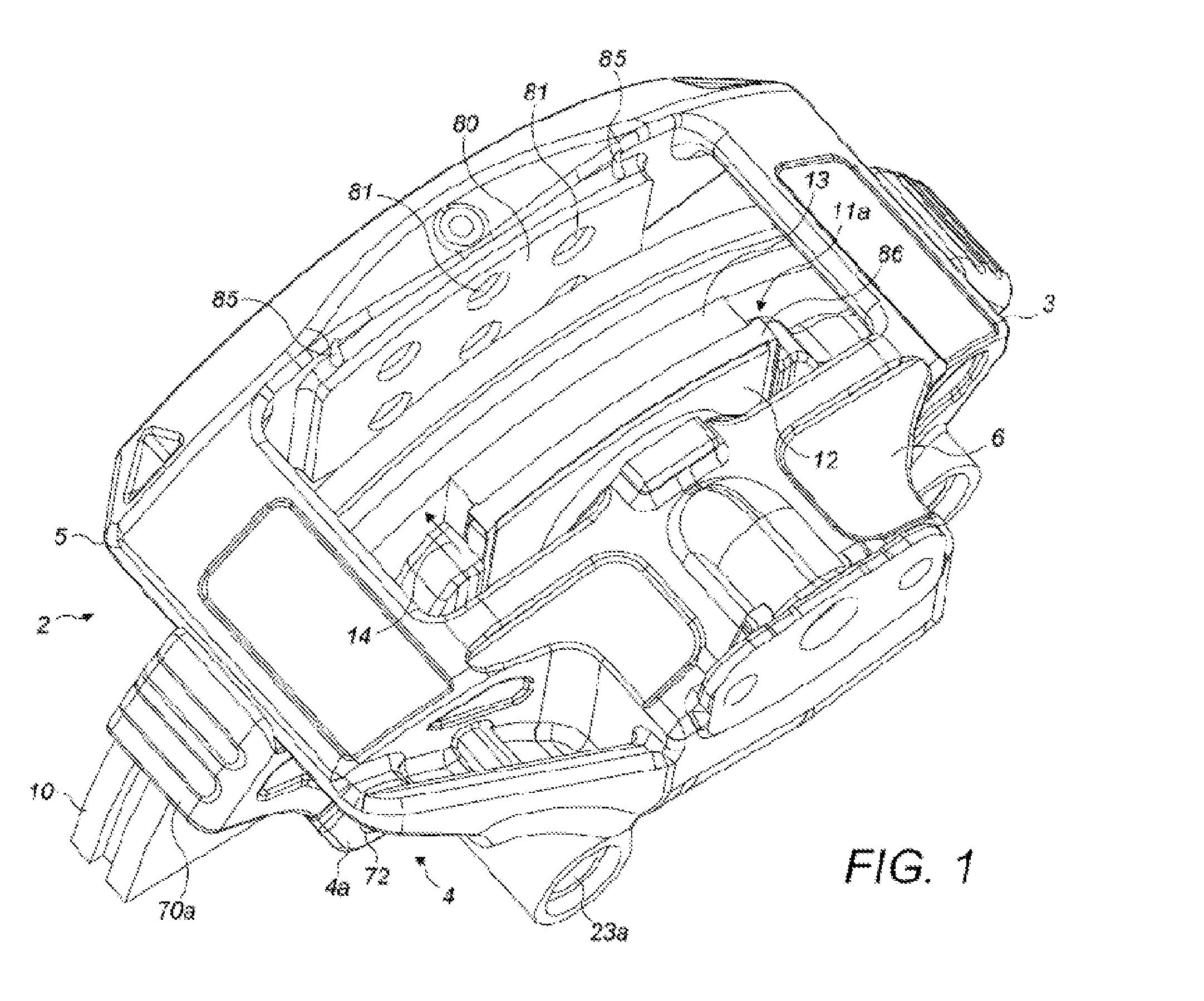

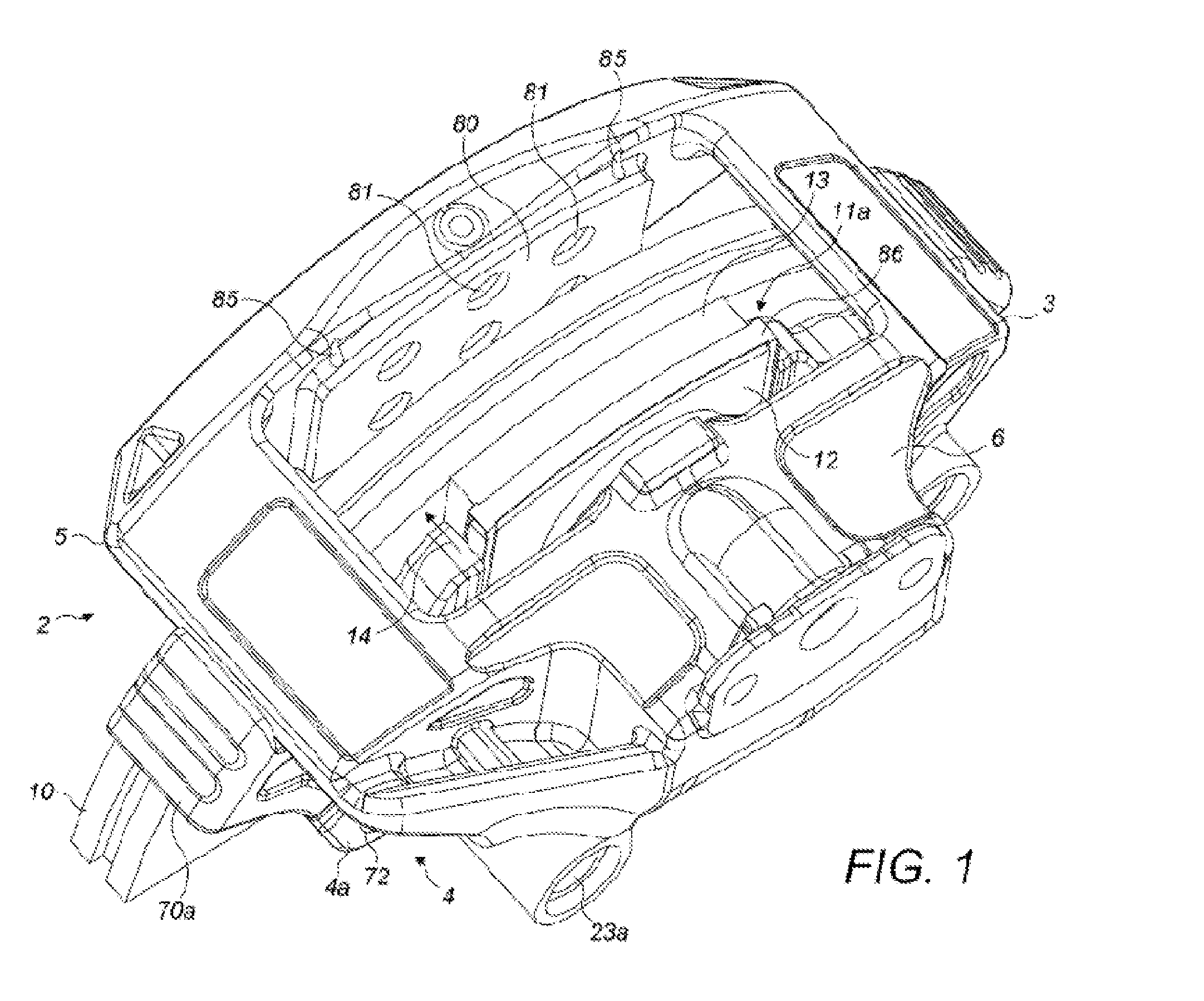

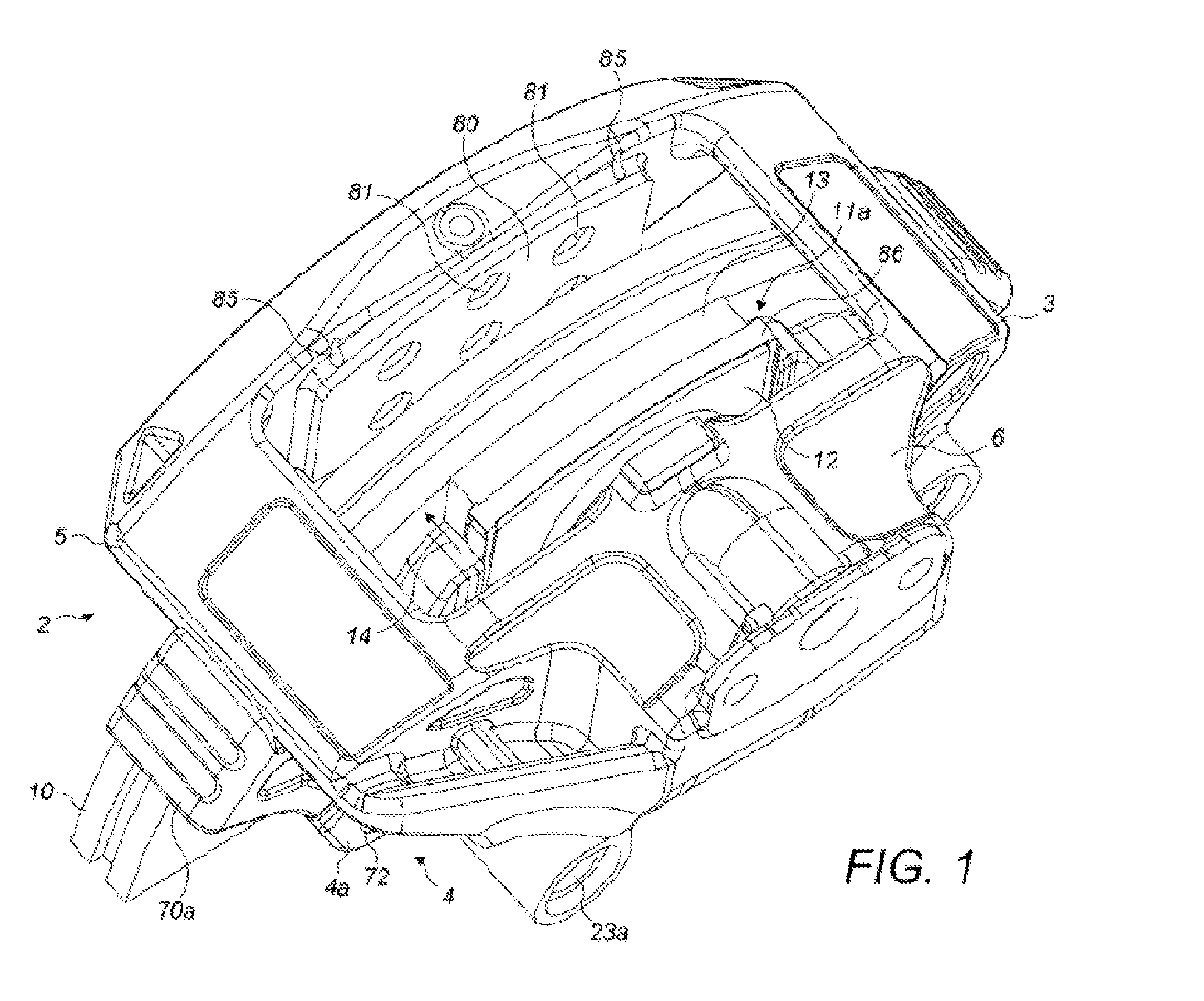

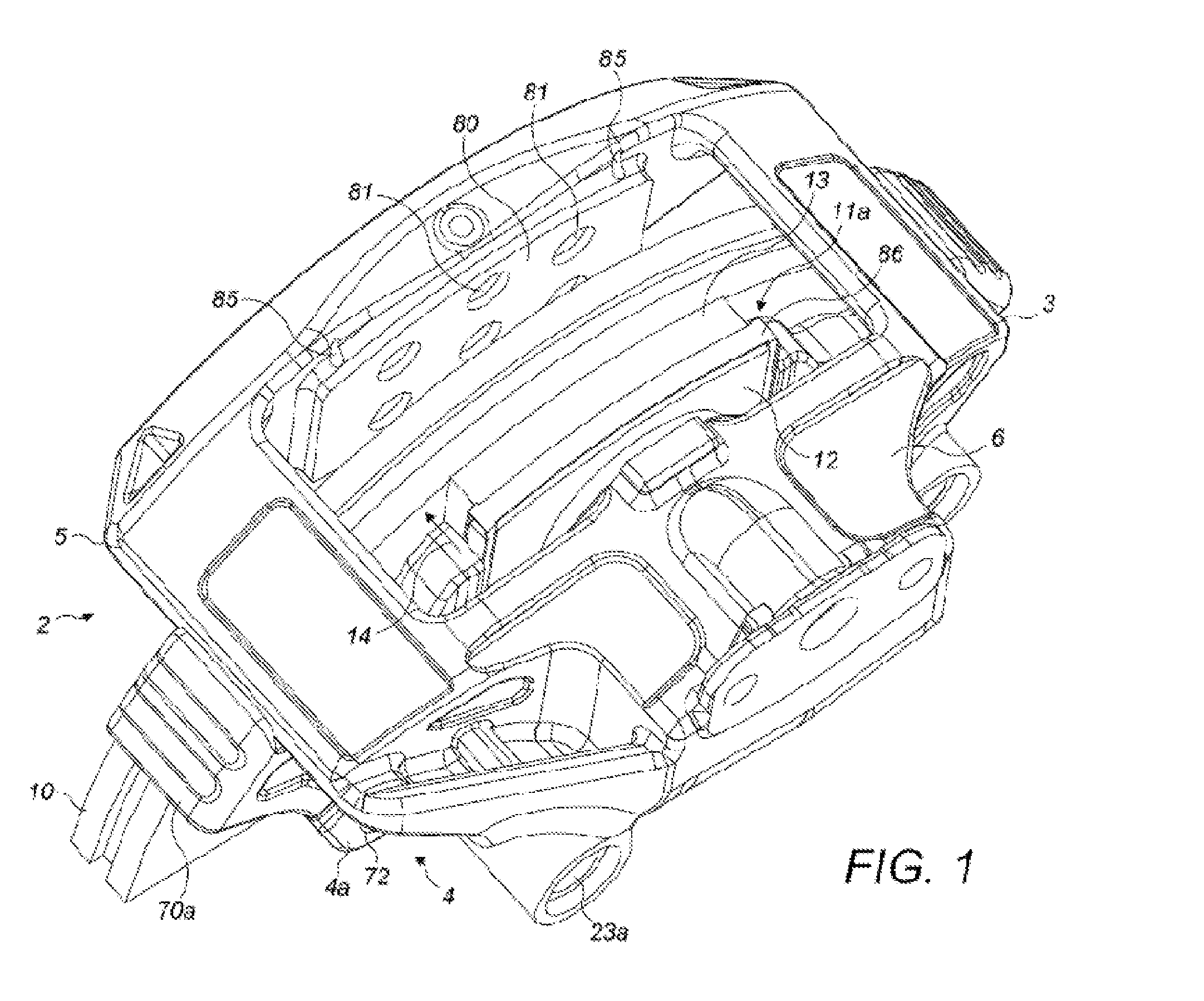

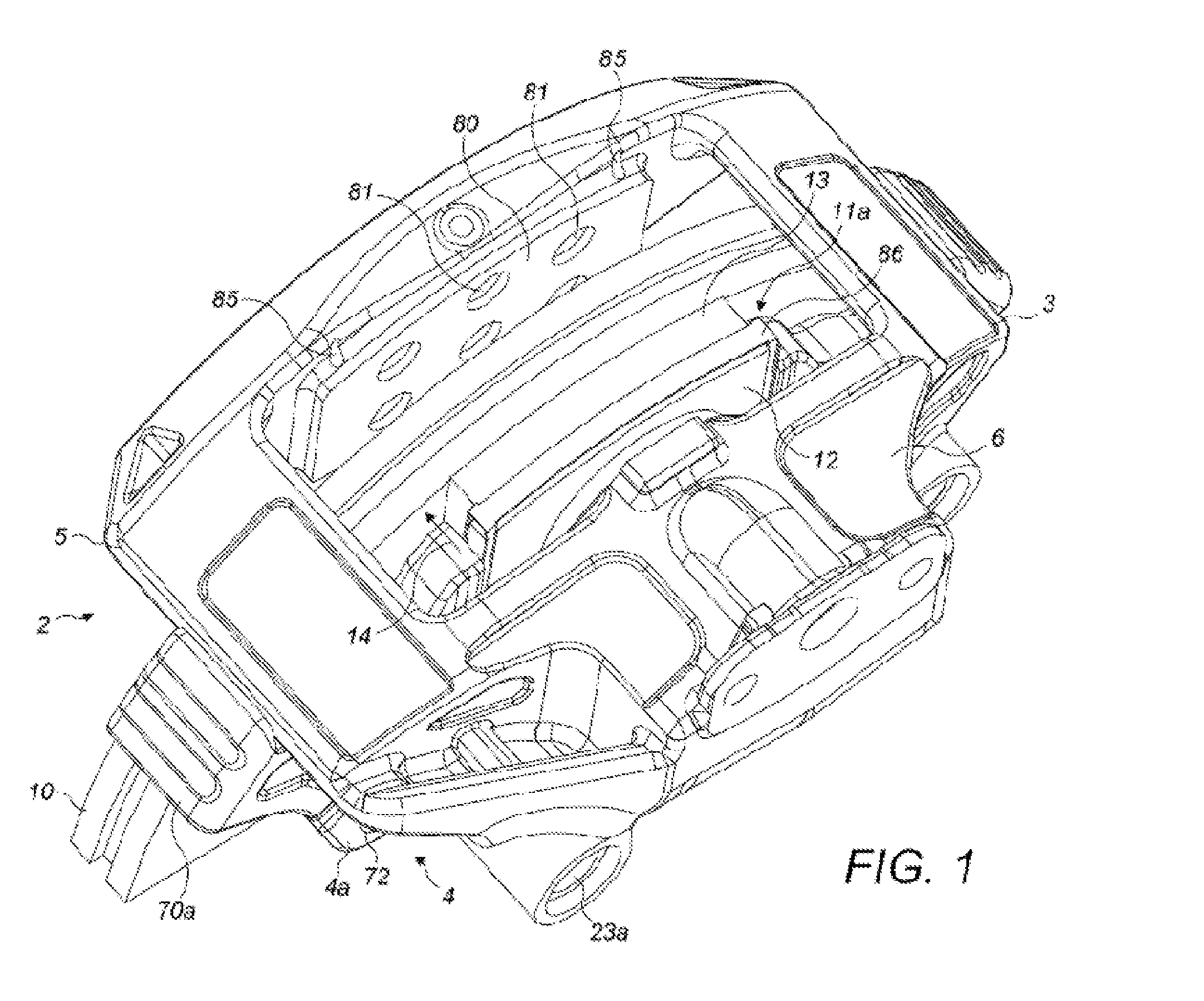

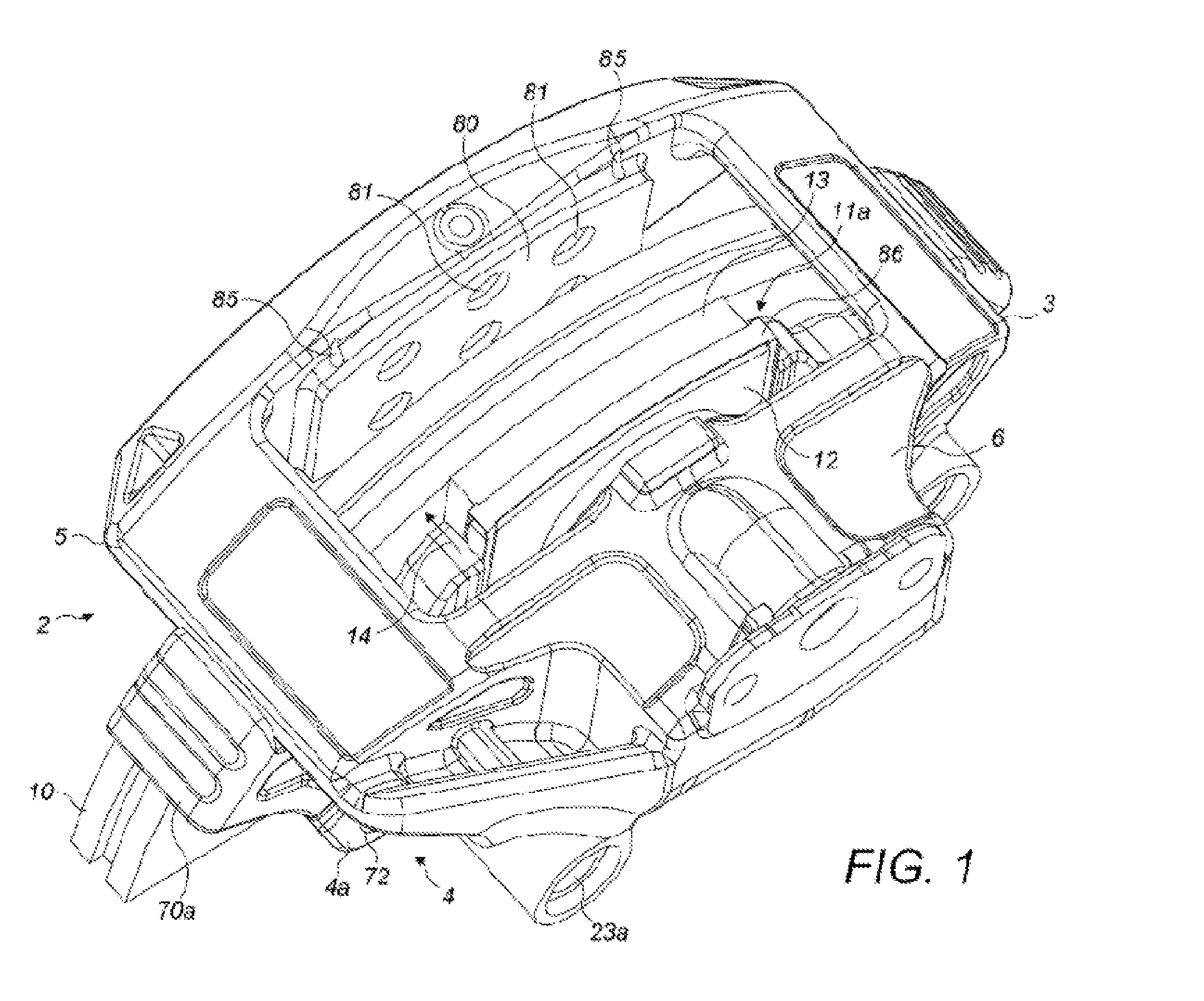

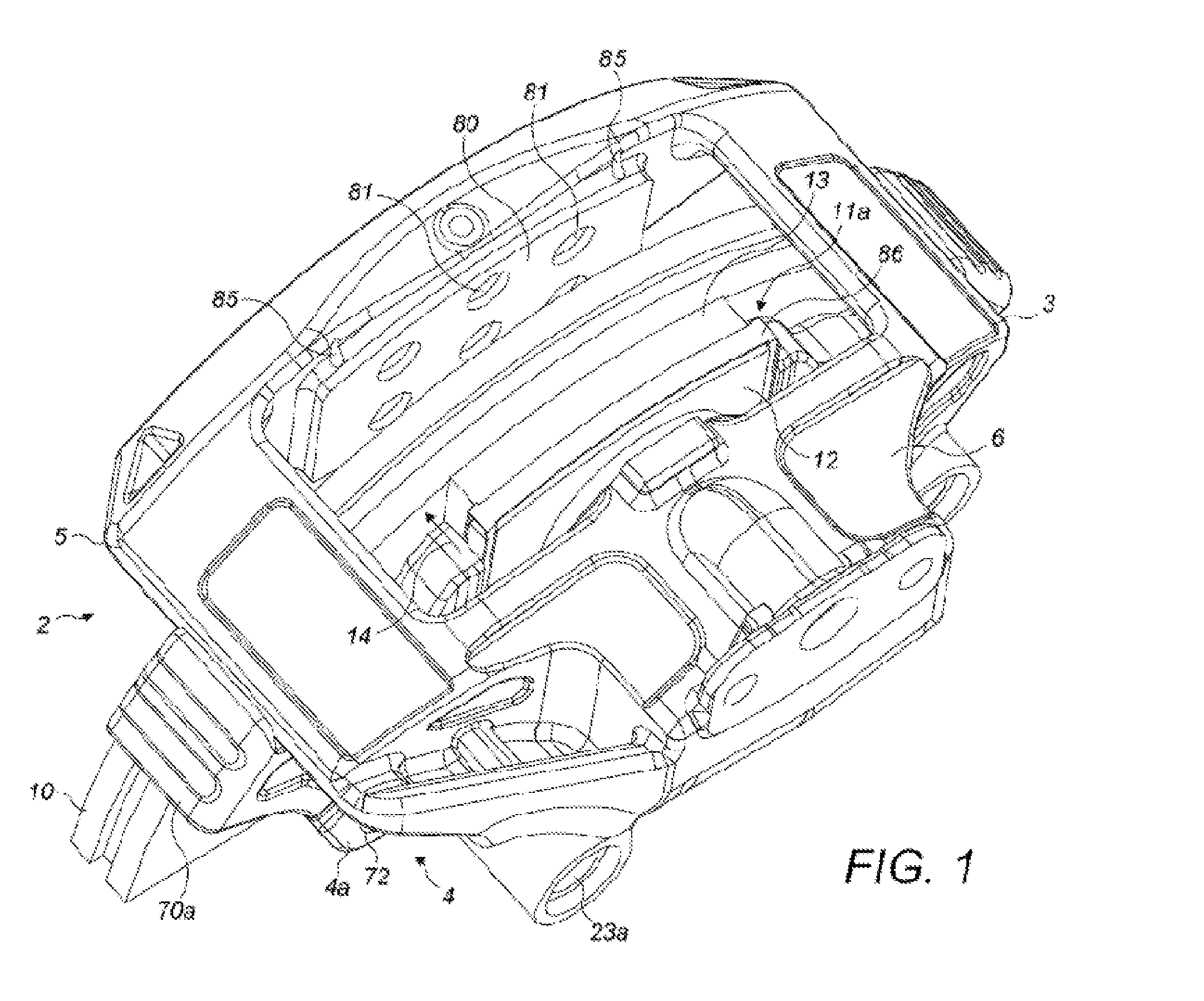

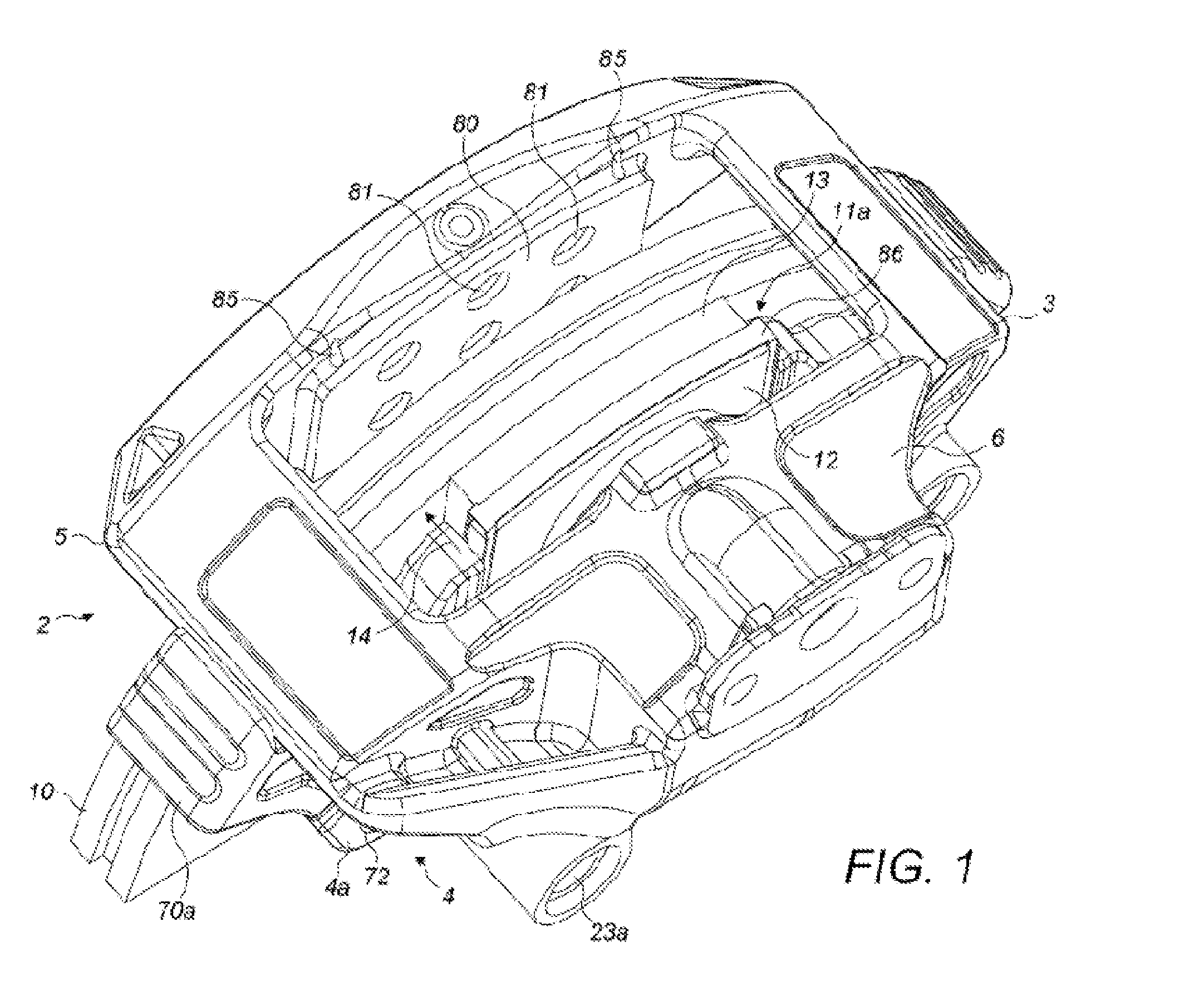

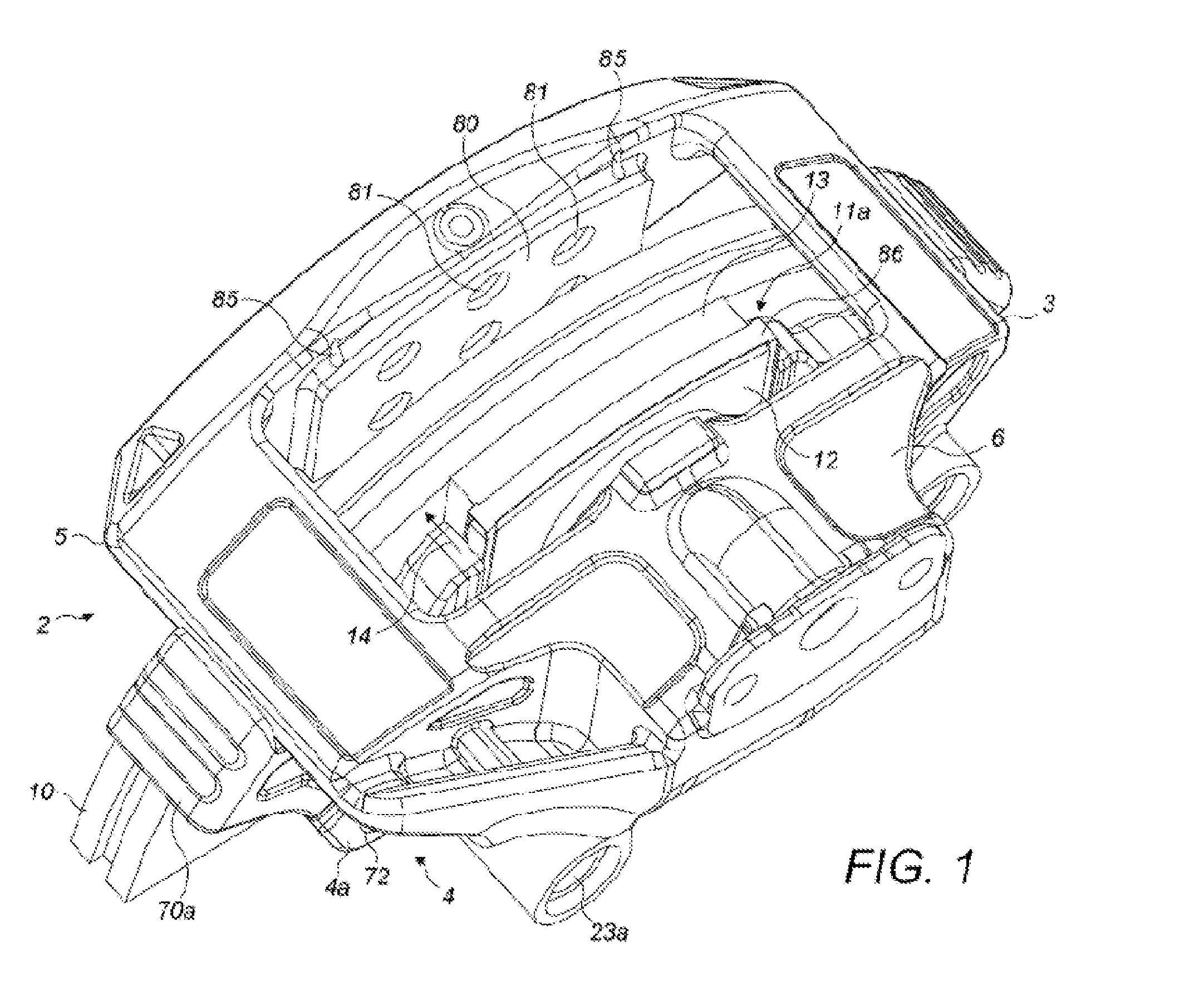

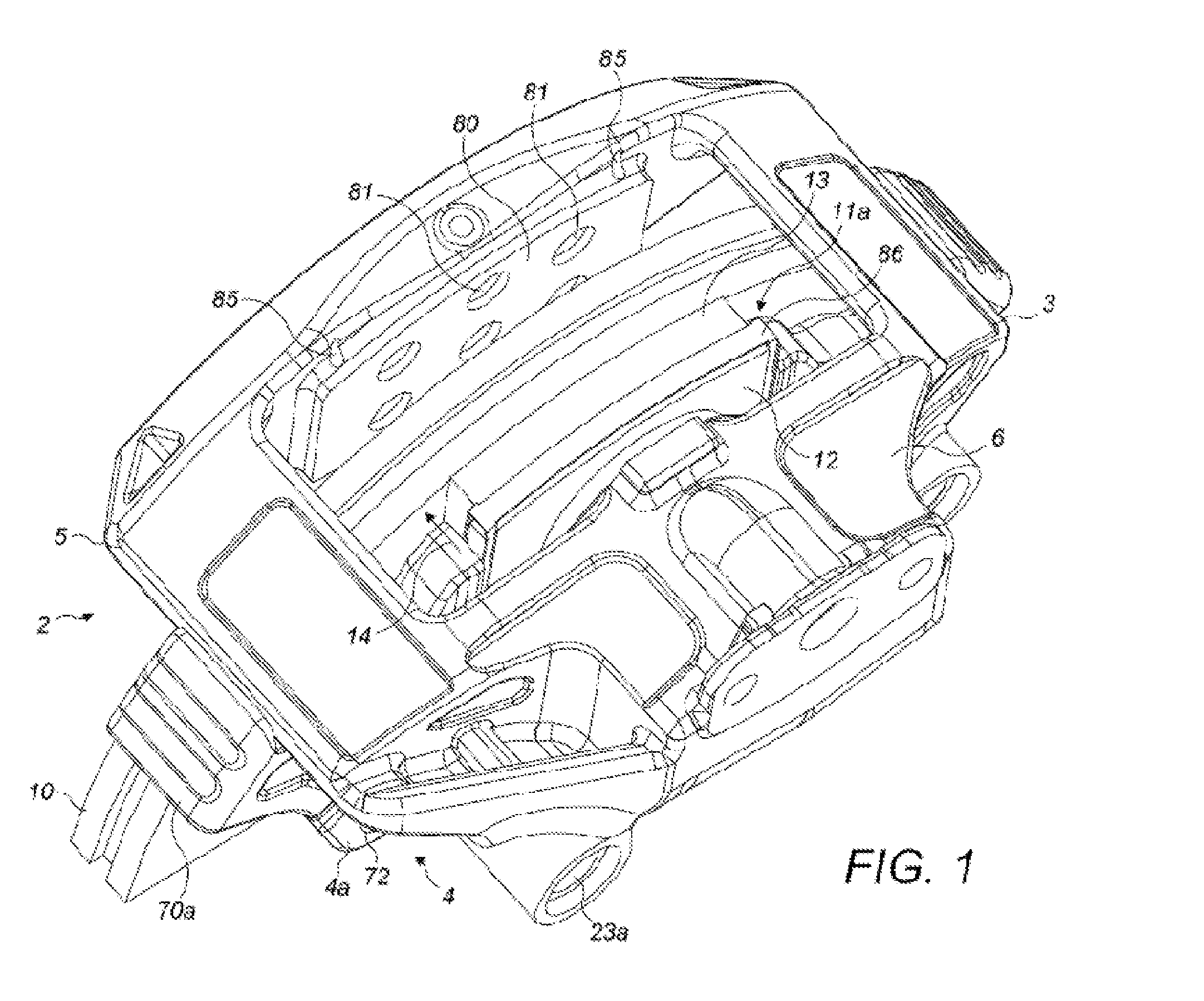

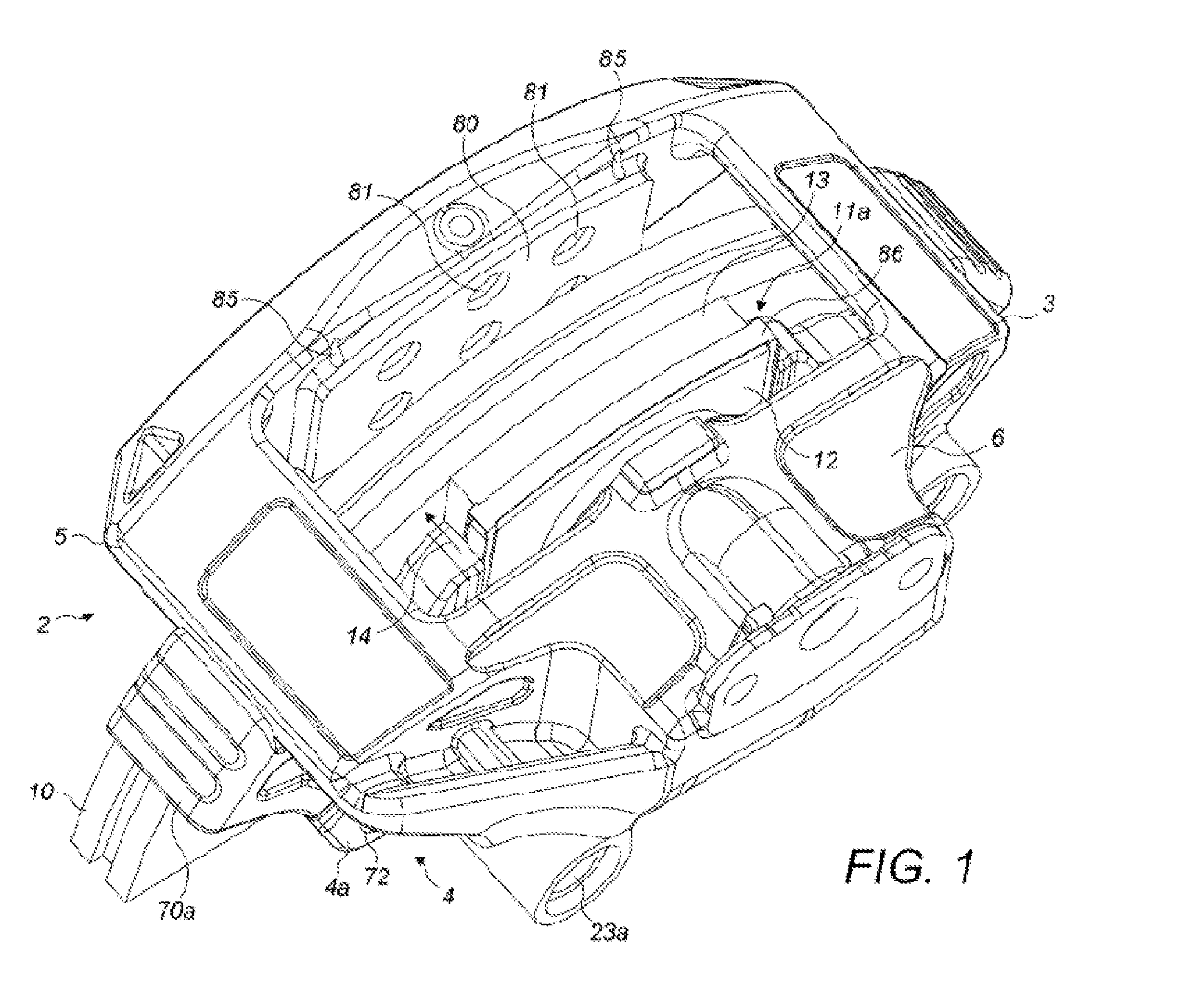

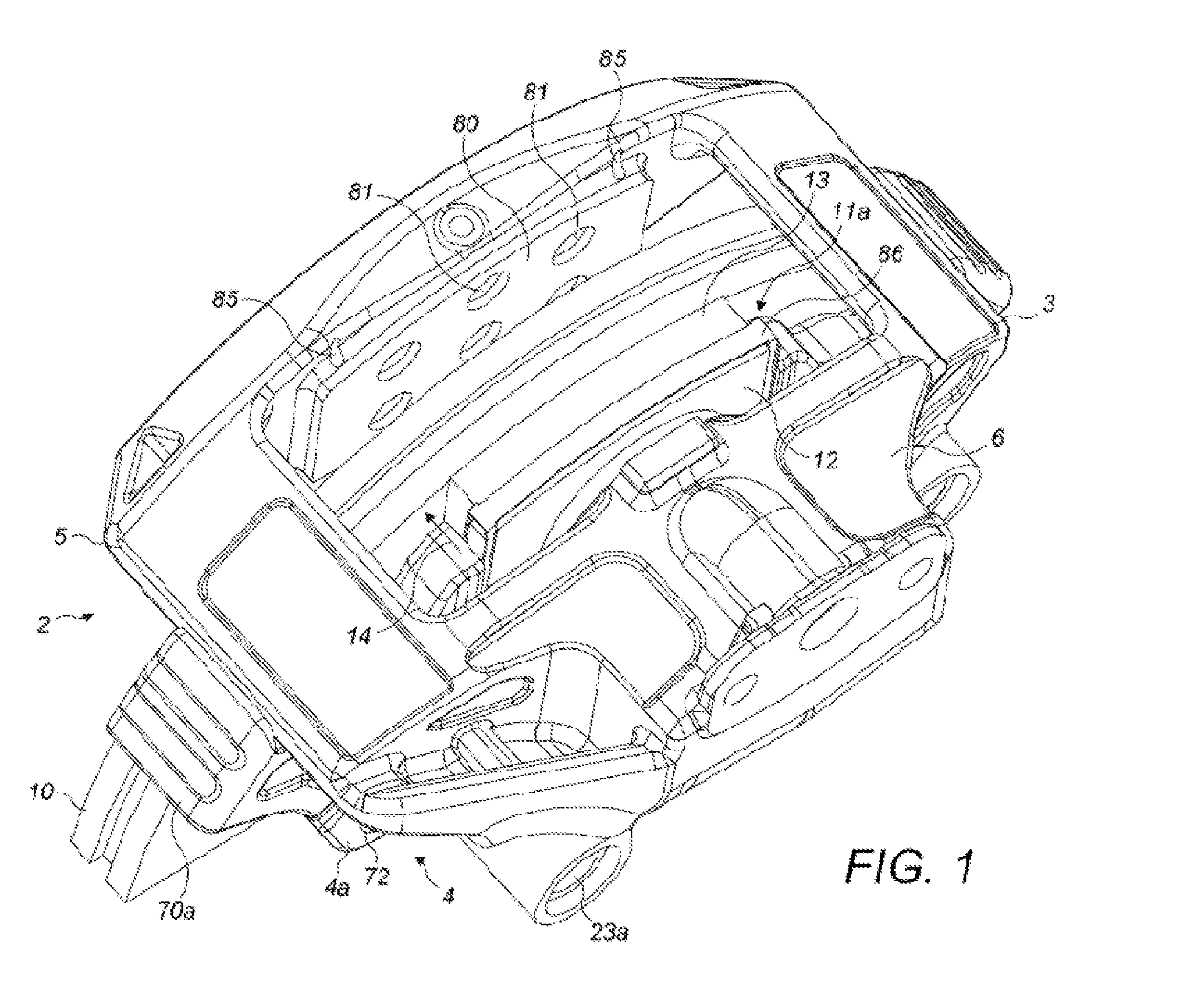

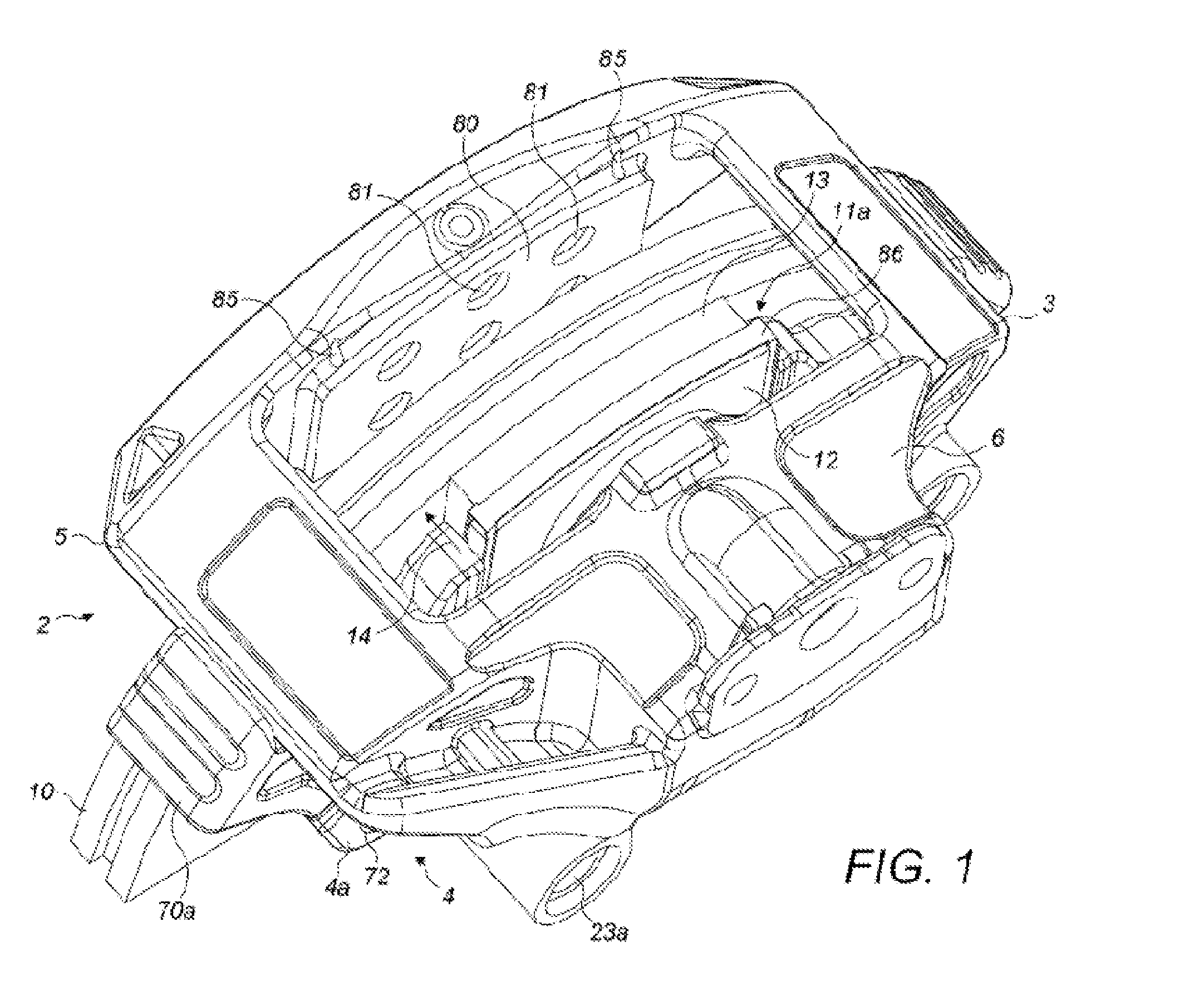

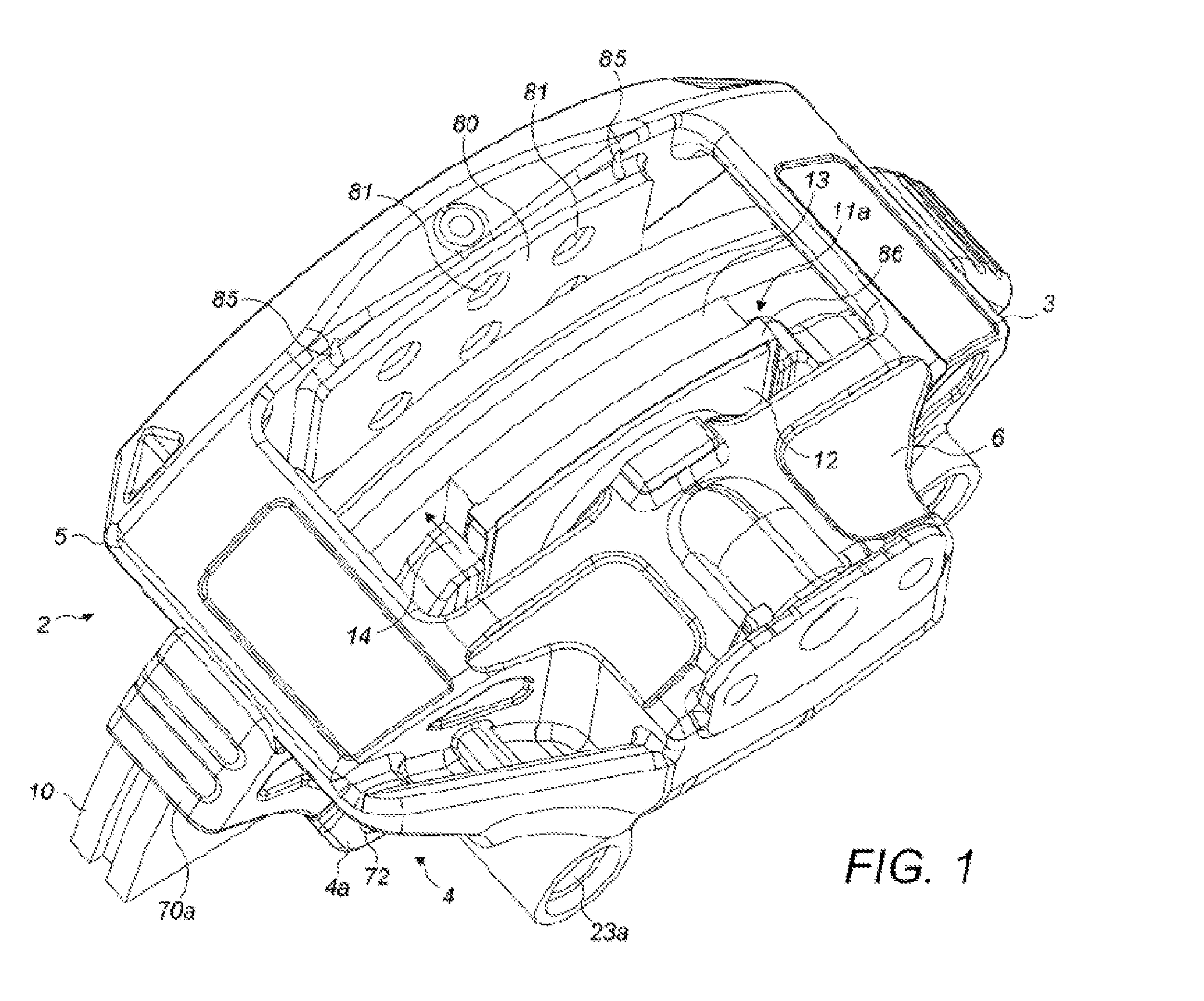

The present invention relates to a disc brake. More particularly, but not exclusively, the present invention relates to an air actuated disc brake including a wear adjustment mechanism. Braking systems of heavy trucks generally use air under pressure as the operating medium. Typically, large air actuators have a mechanical output which applies brake pads to the brake rotor via a lever mechanism. The lever mechanism includes an operating shaft pivotable about two bearing surfaces on a common axis to urge one or more pistons against a brake pad via a cam surface. The shaft has a lever arm acted upon by the air actuator, and may include another generally shorter arm to actuate a wear adjuster mechanism. For larger brake pads, twin pistons are provided to optimize pressure distribution on the brake pad backplate. A known braking mechanism of this type is shown in document W02004/074705 (Knorr-Bremse). For lighter duty applications (e.g., lighter trucks or trailers of tractor-trailer units) with smaller brake pads a single piston is sufficient, but nevertheless two bearings are provided. This arrangement adds to the cost and weight of the brake, complexity of machining the bearing surfaces, and also results in problems in packaging the components within the smaller brake envelope, because space at the inboard (with respect to the vehicle on which the brake is fitted) side of the brake rotor is limited. An example of a brake of this type is EP0730107 (Perrot Bremsen). The present applicant in EP1852627 B1 proposed a solution to this problem. However, the actuation mechanism disclosed therein retains a relatively complex wear adjuster mechanism, cover plate, carrier and pad construction. It is therefore desirable to provide an air actuated disc brake having a wear adjuster that is simpler, requires fewer parts and is more compact. The present invention seeks to overcome or at least mitigate the problems associated with the prior art. A first aspect of the present invention provides a disc brake. The disc brake may have a caliper configured to straddle a rotor and retain first and second brake pads in at least an inboard-outboard direction; a piston slidable within the caliper, for applying a force to the first brake pad to move it towards the rotor during a brake operation, the piston comprising an inner portion restrained from rotating and a rotatable outer portion, the inner and outer portions being in threaded engagement, such that rotation of the outer portion of the piston causes the inner portion of the piston to move axially relative to the outer portion of the piston; an operating shaft for applying an actuating force to advance the piston when the operating shaft is actuated; a wear adjustment mechanism for adjusting the clearance between the inboard brake pad and the rotor, to account for wear of the brake pads and rotor; and a transmission path of the wear adjustment mechanism, from the operating shaft to the outer piston, wherein the transmission path comprises a one-way clutch that directly engages the outer portion of the piston, such that when adjustment of the clearance is required, applying the operating shaft causes the one-way clutch to engage the outer portion of the piston and cause the outer portion of the piston to rotate, and the inner portion to advance in the direction of the rotor. As the one-way clutch directly engages the outer portion of the piston, the number of components required is minimized, as there is no need for separate barrels and gears etc., as required by the prior art. The one-way clutch may be a wrap spring that encircles the outer portion of the piston. In other embodiments the one way clutch may be of a suitable alternative type, such as ball and ramp/roller clutch/sprag clutch arrangements. Encircling the piston with a wrap spring helps to ensure that the surface area for frictional engagement is relatively large. This can assist in minimizing wear between the components, increasing the life of the brake. The operating shaft may be supported on a bearing surface of the caliper arranged in line with the piston, such that the actuating force is transmitted in line from the operating shaft to the piston. This may minimize the machining operations that are needed, and reduce the size of the operating shaft. The disc brake may further comprise a cylindrical roller to transmit the actuating force from the operating shaft to the piston. The disc brake may further comprise a follower to receive the roller, wherein the follower and the piston comprise opposing faces, the faces arranged to be in slidable contact. This means that no transverse motion of the piston is needed in addition to the axial motion. The transmission path may comprise a predetermined amount of backlash between the operating shaft and the one-way clutch, such that the one-way clutch is not driven until a predetermined running clearance is exceeded. The transmission path may comprise a friction clutch located between the drive ring and the one-way clutch, wherein the friction clutch is configured to slip if a more than a predetermined force transmitted therethrough. The friction clutch may comprise one or more input plates and one or more output plates arranged in a face-contacting relationship. The transmission path may comprise a drive ring located between the operating shaft and the friction clutch, the drive ring may be arranged to be rotationally driven by the operating shaft about a common axis with the piston. At least a proportion of the backlash may be located between the drive ring and the friction clutch. Alternatively or in addition, at least a proportion of the backlash may be located between the operating shaft and the drive ring. The operating shaft may comprise one or more projecting operating arms, and the drive ring may have a forked portion projecting inboard, to be engaged by the one or more operating arms, wherein at least a proportion of the backlash is between the operating arm of the operating shaft and the forked portion of the drive ring. The transmission path may comprise a driven ring located between the friction clutch and the one-way clutch, preferably wherein the driven ring is positioned concentrically between the drive ring and the piston. The disc brake may further comprise a resilient element for applying a load to the friction clutch. The disc brake may further comprise a return spring for returning the operating shaft to its rest position when the operating shaft is not being actuated. The return spring may be concentric with the piston. The return spring may further act as the resilient element, thereby further reducing the part count. The inner portion of the piston may be coupled with the first brake pad to restrain the inner portion from rotation. The one-way clutch may be a wrap spring, and a first end of the wrap spring may encircle the outer portion of the piston and a second end of the wrap spring may encircle an outer surface of the driven ring and engage the outer surface of the driven ring, such that rotation of the driven ring in one direction is transmitted to the outer piston via the wrap spring. Encircling the wrap spring around an outer surface of the driven ring helps to minimize any potential backlash that may occur between the driven ring and the wrap spring, which can help to reduce wear of the components. A second aspect of the present invention provides a rewind mechanism for a brake adjuster, the mechanism comprising a rewind shaft arranged to drivingly engage an adjuster mechanism and a head accessible on a brake caliper for engagement by a user to permit the shaft to be turned either directly or by use of a tool, the shaft being supported for rotation on a bearing support, the bearing support being formed from sheet metal material, the sheet metal material having a cylindrical section to engage a face of a bore of the caliper and a radial portion comprising a bore to receive the shaft. The second aspect may optionally have sealing material on an outer face of the cylinder, preferably overmolded thereon. Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings, in which: As required, detailed embodiments of the present invention are disclosed herein; however, it is to be understood that the disclosed embodiments are merely exemplary of the invention that may be embodied in various and alternative forms. The figures are not necessarily to scale; some features may be exaggerated or minimized to show details of particular components. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a representative basis for teaching one skilled in the art to variously employ the present invention. Actuation Various orientations of the disc brake are described. In particular the directions inboard and outboard refer to the typical orientation of the disc brake when fitted to a vehicle. In this orientation the brake pad closest to the center of the vehicle is the pad directly actuated by an actuation mechanism and being the inboard pad, and the outboard pad being one mounted to a bridge portion of the caliper. Thus inboard can be equated with an actuating side of the disc brake, and outboard with a reaction side. The terms radial, circumferential, tangential and chordal describe orientations with respect to the brake rotor. The terms vertical and horizontal describe orientations with the disc brake mounted uppermost on an axle, whereas it will be appreciated that in use such a disc brake may adopt any axle orientation depending upon packaging requirements of the vehicle. The disc brake 2 comprises a caliper 3 having a housing 6 to accommodate the actuation mechanism and which is slideably mounted on a carrier 4 for movement in an inboard-outboard direction. An inboard brake pad 11 Suitable means are provided to urge an outboard brake pad 11 With reference to In order to urge the piston assembly in the direction of arrow 14, the operating shaft 21 is pivoted about a transverse axis 22 within a saddle on a single bearing surface 27 of the caliper. The operating shaft 21 supports a roller 23 whose axis 28 is parallel and offset from the axis 22 and couples with a follower 20 in a semi-circular recess thereof. A surface 19 of the follower 20 opposing the recess is in slideable contact with an inboard end face of the piston 15 so that no transverse movement of the piston is required. The operating shaft 21 further comprises a lever 24 having a pocket 25 adapted to receive an output push rod (not shown) of a brake actuator (e.g., an air chamber). The lever 24 is, in this embodiment, shaped as an inverted “U” (see In other embodiments, another form of cam surface instead of roller 23 may be employed (e.g., a plain bearing) and/or the arrangement may be reversed with the follower 20 or roller 23 being in contact with the caliper housing 6. Application of a force in the direction of arrow 26 ( Wear Adjustment A wear adjuster mechanism 30 to maintain a desired running clearance between the rotor 10 and pad 11 In this embodiment, the drive ring further comprises two opposing recesses 37 which face inboard and are arranged to accommodate a corresponding pair of lugs provided on input plates of a friction clutch 39. In other embodiments alternative arrangements for driving the clutch input plates are contemplated e.g., a different number of recesses, projections rather than recesses, or arm 33 being extended to directly drive the input plates. The friction clutch further comprises output plates positioned between the input plates. The output plates of the clutch 39 have a number of radially inwardly facing lugs 40 (not present on the input plates) that engage in corresponding recesses 41 in a driven ring 42 that in this embodiment is nested concentrically between the drive ring and the piston 15. The piston 15 comprises an outer piston 15 On the outboard facing edge of the driven ring 42, a relatively small notch 43 is provided that connects to one free end of a wrap spring 44. The wrap spring 44 is arranged to frictionally wrap around an outer portion 15 The components above between the operating arm and inner and outer piston define a transmission path of the wear adjuster mechanism. The wear adjuster mechanism 30 additionally comprises a washer 45 retained by a circlip 46 held in an annular recess of the outer piston 15. An outboard face of the washer 45 is acted on by a return spring 47, the return spring being arranged to retract the piston 15, and therefore the brake pad when a brake actuation cycle ceases. The inboard face of the washer 45 supports a compression spring 48 arranged concentrically between the drive ring 35 and driven ring 42 in order to load the clutch 39 and generate the required amount of friction that controls, the torque at which it slips. The inboard end of the outer piston portion 15 The inner piston portion 15 In order to maintain a desired running clearance between the brake pads and rotor the wear adjuster mechanism is required to periodically advance the inboard brake pad 11 In a normal braking operation in which the running clearance is within the desired parameters, as the operating shaft 21 pivots, the operating arm 33 causes the drive ring to rotate. However, a predetermined amount of play or backlash is provided in the system between the recesses 37 and corresponding lugs 38 on the clutch, and as such the drive plates of the clutch do not rotate and no adjustment will occur. If the running clearance is however greater than the desired range, the aforesaid play is taken up and rotation of the drive plates on the friction clutch 39 will occur. Whilst there is excess running clearance to be taken up, this rotation is transmitted via the driven plates and driven ring to the wrap spring 44, causing the wrap spring to rotate around the outer piston portion 15 Since the inner piston portion 15 The co-axial mounting of the adjuster mechanism 30 around the piston 15 minimizes the space required by the mechanism within the housing, resulting in a lighter, more compact housing. The use of the outer surface of the piston as a barrel for the wrap spring, obviates the need for the separate barrels and gears of the prior art and minimizes the number of components required for the brake to function. The outer piston 15 An alternative wear adjuster mechanism 130 is described below. Like features are indicated in the figures with like reference numerals, but with the prefix ‘1’. With particular reference to In this embodiment, the drive ring further comprises an axially extending outer lip having two opposing recesses 137 which face outboard and are arranged to accommodate a corresponding pair of radially outward extending lugs 138 provided on input plates 139 The friction clutch 139 further comprises output plates 139 In this embodiment, the friction clutch 139 is made up of two input plates 139 The piston 115 comprises a hollow outer piston 115 A plurality of projections 141 In this embodiment, the outer portion 115 The components above, between the operating arm and inner and outer piston, define a transmission path of the wear adjuster mechanism. In this embodiment, the wear adjuster mechanism also includes thrust bearings 163. A first thrust bearing 163 engages an outboard surface of the friction clutch 139, and a second thrust bearing 163 engages an inboard surface of the drive ring 135. The thrust bearings 163 are annular, and include circumferentially distributed spherical rolling elements 163′, which assist with free rotation of the clutch mechanism and drive ring 135, to help reduce friction within the system and wear of the components. The wear adjuster mechanism 130 additionally comprises a washer 145 that engages the first thrust bearing 163 that is located adjacent the clutch 139. An outboard face of the washer 145 is acted on by a return spring 147, the return spring 147 being arranged to retract the piston 115, and therefore the brake pad when a brake actuation cycle ceases. The force applied by the return spring 147 to the inboard face of the washer 145 also acts to load the clutch 139 (via the thrust bearing 163) and generate the required amount of friction that controls the torque at which it slips. The inboard end of the outer piston portion 115 The operation of the wear adjustment mechanism is as described above (previously with reference to This helps to minimize any potential backlash that may occur between the driven ring and the wrap spring, which can help to reduce wear of the components. Uncontrolled unwinding of the spring is minimized, which provides a more predictable, and hence controllable, friction level. The wear on the outer surfaces of the piston and driven ring is also reduced. This could, for example, obviate the need to heat treat these outer surfaces, reducing manufacturing costs. The arrangement also helps to remove any uncertainties that may arise after manufacturing of the components, for example unpredictable tolerances, which may affect the function of the system. The co-axial mounting of the adjuster mechanism 130 around the piston 115 minimizes the space required by the mechanism within the housing, resulting in a lighter, more compact housing. The use of the outer surface of the piston 115 Rewind Mechanism Once the friction material 13 has worn to its design limit, it is necessary for the brake pads 11 To this end, a rewind shaft 51 is provided, having a bevel gear 52 mounted at an inner end thereof to mesh with the gear wheel 49. A hex head 53 or other suitable interface is provided at the outer (user accessible) end to which a spanner, wrench or other suitable tool may be attached to effect the rewinding operation. In one embodiment, the shaft 51 is mounted within a transverse cylindrical opening 57 cast or machined in the caliper. A support 54 including a plain bearing rotatably supports the shaft. In this embodiment the support 54 is formed in a sheet metal e.g., sheet steel having a cylindrical portion, a truncated cone portion and a disc shaped portion all formed monolithically from a single piece of metal in a drawing or pressing operation. A peripheral seal (not shown) may be bonded to the outer face of the cylindrical section without the use of adhesive, due to it being formed as an overmolding, causing it to be secured thereto by solidification of the sealing material when liquid during the molding operation. In other embodiments a separate sealing component, such as an O-ring, may be used. Additionally, in some embodiments the shaft may have multiple supports along its length. In this embodiment, a helical spring 55 may be provided between the support 54 and hex head of 53 of the rewind shaft 51 so as to bias the bevel gear 52 out of engagement with the gear wheel 49, to reduce the risk of accidental rewinding of the wear adjuster mechanism 30. It will be appreciated by those skilled in the art that the mounting arrangement for the rewind shaft 51 maintains effective sealing of the caliper whilst reducing the amount and mass of the parts required. Further the opening 57 may additionally be utilized to provide access for machining of the bearing surface 27. Piston Guidance Referring now in particular to In certain embodiments the cavity may be formed by casting using suitable cores and little or no machining, in other embodiments the cavity may be formed solely by machining from the rotor side inboard to form cylindrical opening 56 and transversely to form the opening 57. In other embodiments a combination of casting and machining may be used. In all of these embodiments, it will be apparent however that the cavity 56, 57 is a simple shape compared with those of the prior art resulting in simplified manufacturing of the caliper 3. Additionally, since the bore 56 is cylindrical, the complex cast and machined cover plates of the prior art are no longer required to close off the rotor side of the cavity and prevent the ingress of foreign matter. In place of cover plates, a pre-machined cylindrical guide insert 60 is utilized, which is provided with a machined bore 61 to guide the piston 15. The guide insert 60 further comprises an annulus 62 closed at an outboard end to act as a pocket for receiving and guiding the return spring 47. With reference to The guide insert 60 may further comprise a circumferential recess 67 in the outer circumferential surface thereof to accommodate a circlip/snap ring 68, as well as a further annular recess to accommodate an O-ring type seal 59 in order to prevent foreign matter from entering the join between the guide insert 60 and caliper. The bore 56 is, in this embodiment, provided with a circumferential groove 59 at an appropriate location into which the circlip/snap ring can relax and hold the guide insert 60 into place. Various arrangements are contemplated for mounting the guide insert 60 into the caliper 3. These arrangements include mounting the guide insert 60 via a taper fit, interference fit or threaded fit to the caliper 3, or by using an additional fastener such as the aforementioned circlip/snap ring or a canted clip, or a radially oriented bolt as a set screw. In one embodiment, as shown in However, with reference to The metal insert 65 is shaped such that it is keyed into the cast metal once solidified and is malleable such that it is able to be peened over a lip the outboard face of the guide insert so as to hold the insert 60 in place. In preferred embodiments, the metal insert 65 extends around the entire periphery of the bore 56 (i.e., it is substantially circular). In In a preferred embodiment a secondary means of securing the guide insert 60 is preferably provided. In order to remove and replace the guide insert 60, for example during a maintenance or a remanufacturing operation, the peened material needs to be permanently removed. Consequently it cannot be used for retaining a replacement guide insert 60. Therefore, as mentioned above, the circlip/snap ring 68 may be utilized as such a secondary retaining arrangement when a replacement guide insert is fitted. Thus, whilst It will be appreciated that part or all of the actuation and adjustment mechanism may be advantageously be fitted to the caliper 3 as a pre-assembled unit, together with the guide insert 60 via the cylindrical opening 56. This assembly method is possible due to the compact nature of the actuation mechanism, and in particular the operating shaft with a single central bearing surface facing the inboard face of the housing 6. One advantage of the peening approach or circlip/snap ring mounting is that assembly of the insert, together with the piston 15, operating shaft 21 and wear adjuster mechanism 30 is easier to achieve with the fit between the insert and caliper being relatively loose, in order that the parts may be aligned in the correct location for subsequent operation. This may be easier to achieve with these mounting methods, than with alternative threaded or interference fits. Brake Carrier Referring now to A significant difference between the carrier 4 of the present invention and those of the prior art is that the carrier is formed from two portions 4 A further significant difference between the present carrier 4 and prior art carriers is that the carrier does not include a support for the outboard pad. Rather, the outboard pad 11 Considering the carrier 4 in more detail, in this embodiment, the carrier portions 4 The main body 71 An L-shaped profile is additionally formed in the portion 4 A wing 70 It will be appreciated that in prior art carriers, the beam interconnecting the horizontal abutment surfaces 76 The present applicant has recognized that maintaining this spatial relationship is beneficial for transportation of a carrier and caliper combination, during installation on a vehicle. However a number of benefits accrue to the separation of the carrier into the two portions 4 Secondly, it will be appreciated that the abutment surfaces 75 Thirdly, the portions 4 It would be appreciated that some of the aforementioned benefits will continue to be present when the carrier portions are used in conjunction with an outboard carrier portion that is bolted to the inboard portion, or otherwise secured thereto, and takes the load from the outboard pad. It will additionally be noted that the guide pin 73 The absence of the beam may also enable, in some embodiments, the brake pads to be restrained from radial outward motion due to a suitable “dovetail” (undercut) formation on the radially inner edge of the friction material, backplate (if present) and/or a spreader plate such that the usual pad strap may not be needed for this purpose. To release a worn pad, bolts may be removed from one or both of the portions 4 In variants, the first and second portions may differ in the shape and/or materials used. For example, the portion that supports the trailing edge of the pad in the usual direction of rotation may be stronger than the portion supporting the leading edge, either due to a stronger material being used, the portion being subjected to a different treatment, or to the portion having a different shape to impart more strength. Further the guide sleeve may be integrally formed with the main body or each portion as part of one single casting, or the guide sleeve may be press-fitted or friction welded therein. Due to the simpler overall shape of each portion as compared to a conventional carrier, integral casting of the guide sleeves may be easier to achieve. Brake Pads Turning now to A support surface 80 is provided in the bridge 5 in a spaced parallel relationship with the rotor 10, and facing the rotor. In this embodiment the surface 80 has a key formation for the pad in order to mechanically restrain the pad from motion in a circumferential direction and in a radial direction. In this embodiment the formation comprises a series of circular depressions 81 which mate with complimentary circular projections 82 on a support face 93 of the pad. In other embodiments other suitable key formations may be utilized. Conventionally, brake pads for air actuated disc brakes of the type used in heavy vehicles are typically provided with a metallic backplate that imparts additional strength, rigidity and toughness to the pad as a whole and is fused and/or mechanically connected to the friction material. The backplate also typically enables a pad spring to be mounted to the brake pad in order to resiliently restrain the pad from radially outward motion in use. However, the present applicant has recognized that backplates add to the weight, volume and cost of brake pads and in certain situations may not be required. Therefore, as in the present instance where it is possible to support the friction material across its entire surface area on the bridge 5, and where impact loads to abutment surfaces of a carrier will not be experienced, it is possible to dispense with the backplate. Nevertheless, in order to ensure the outboard pad 11 To that end, in this embodiment, the outboard pad 11 As can be seen in To hold the outboard pad 11 The friction material 13 itself is intended to act as the bearing surface (tongue) having sufficient mechanical strength to be held to the support surface 80. However friction material is a composite material and typically has a low tensile strength. It is nevertheless desirable for the bearing surface to be as thin as possible so as to minimize the amount of friction material that cannot be utilized and remains unworn because the prongs 89 are in contact with the rotor 10. Therefore, the tongue portions 83 and the surrounding sections of the main body of the outboard brake pad may be strengthened by utilizing an increased proportion of steel fibers, or the like within the composite material to improve its performance in tension. In other embodiments, the bearing surface may be formed by a bore extending through some or all of the height of the pad parallel to the bore 85. In this embodiment, the inboard pad 11 Channels 91 are provided in the rear (inboard) face of the spreader plate to accommodate and hold one of the prongs 89 of the retainer 86, the other being in engagement with the tongue 83 of the pad 11 Fitting of the pads 11 In this embodiment, pads 11 In other embodiments, the dimensions of the pads 11 In embodiments where multiple discrete pads are to be mounted, additional clips (optionally without the pad spring portion) may retain these pads in additional bores or channels provided in the caliper or spreader plate respectively. In alternative embodiments the retainer clips described above may be utilized with pads that do have a metallic backplate, which backplate forms the tongues. It is however anticipated that the backplate would be significantly thinner than those of the prior art, leading to many of the benefits outlined above. Alternative forms of pad retainer clip may be used which do not include the pad spring section, and so are separate for each circumferential end, or which clip the pad to the support in a different manner, such as being clipped together in a circumferential direction rather than a radial direction. In variants only a single retainer clip may be required, e.g., at one circumferential end of the pad, with the tongue at the other end fitting into a complementary fixed slot. Spreader Plate Guiding In a further development of the spreader plate illustrated in As noted above one potential problem with single piston brakes, as compared to twin piston brakes, is that of uneven or so-called “taper wear” caused by the greater tendency of the pad to pivot relative to the rotor, due to reduced support from the piston head at the rear thereof. In this embodiment, the spreader plate 12′ is reconfigured to include first and second guide bars 95′ that are secured in a radially outward position to the main body of the spreader plate 12′ which is intended to transmit load to the friction material. The guide bars 95′ extend outboard over the inboard pad 11 The guide bars 95′ are spaced from each other by slightly more than the width of the pad strap 92. The guide bars in this embodiment have radially extending abutment surfaces 96′ facing inwardly towards the pad strap 92 that are machined to a smooth finish to assist in sliding along the corresponding radially orientated surfaces of the pad strap, both during braking operations, and as the inboard brake pad 11 Due to the relatively close running fit between the guide bars 95′ and pad strap 92, and the increased depth of the bars compared to the spreader plate 12, it will be appreciated that the degree to which the spreader plate 12, and therefore the inboard brake pad 11 It will be appreciated that the spreader plate 12′ may be guided on the pad strap 92 by use of other guide formations. For example, the pad strap may be formed with one or more longitudinal slots within it into which a suitable portion projecting from the spreader plate may fit, or the guide bars may be shaped so they at least partially encircle the pad strap, and the spreader plate is lifted out together with the pad strap. In other brakes, the backplate of a pad itself may be provided with a similar guiding arrangement, instead of a spreader plate. It will be appreciated that numerous changes may be made within the scope of the present invention. For example, certain aspects of the invention may be applicable to other types of brake, such as twin piston or electromechanically actuated brakes (e.g., the brake pads and the carrier aspects). While exemplary embodiments are described above, it is not intended that these embodiments describe all possible forms of the invention. Rather, the words used in the specification are words of description rather than limitation, and it is understood that various changes may be made without departing from the spirit and scope of the invention. Additionally, the features of various implementing embodiments may be combined to form further embodiments of the invention. A disc brake having a caliper, a piston, an operating shaft, a wear adjustment mechanism, and a transmission path. The caliper may straddle a rotor and may retain first and second brake pads. The piston may be slidable within the caliper. The operating shaft may apply an actuating force to advance the piston when the operating shaft is actuated. The transmission path of the wear adjustment mechanism may include a one-way clutch. 1. A disc brake comprising:

a caliper configured to straddle a rotor and retain first and second brake pads in at least an inboard-outboard direction; a piston slidable within the caliper for applying a force to the first brake pad to move the first brake pad towards the rotor during a brake operation, the piston including an inner portion restrained from rotating and a rotatable outer portion, the inner and outer portions being in threaded engagement such that rotation of the outer portion of the piston causes the inner portion of the piston to move axially relative to the outer portion of the piston; an operating shaft for applying an actuating force to advance the piston when the operating shaft is actuated; a wear adjustment mechanism for adjusting a clearance between the first brake pad and the rotor to account for wear of the first and second brake pads and the rotor; and a transmission path of the wear adjustment mechanism that extends from the operating shaft to the outer portion of the piston, wherein the transmission path comprises a one-way clutch that directly engages the outer portion of the piston such that when the clearance is adjusted application of the actuation force by the operating shaft causes the one-way clutch to engage the outer portion of the piston, causes the outer portion of the piston to rotate, and causes the inner portion to advance in the direction of the rotor. 2. The disc brake of 3. The disc brake of 4. The disc brake of 5. The disc brake of 6. The disc brake of 7. The disc brake of 8. The disc brake of 9. The disc brake of 10. The disc brake of 11. The disc brake of 12. The disc brake of 13. The disc brake of 14. The disc brake of 15. The disc brake of 16. The disc brake of 17. The disc brake of 18. The disc brake of 19. The disc brake of TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION