CENTRIFUGAL FAN

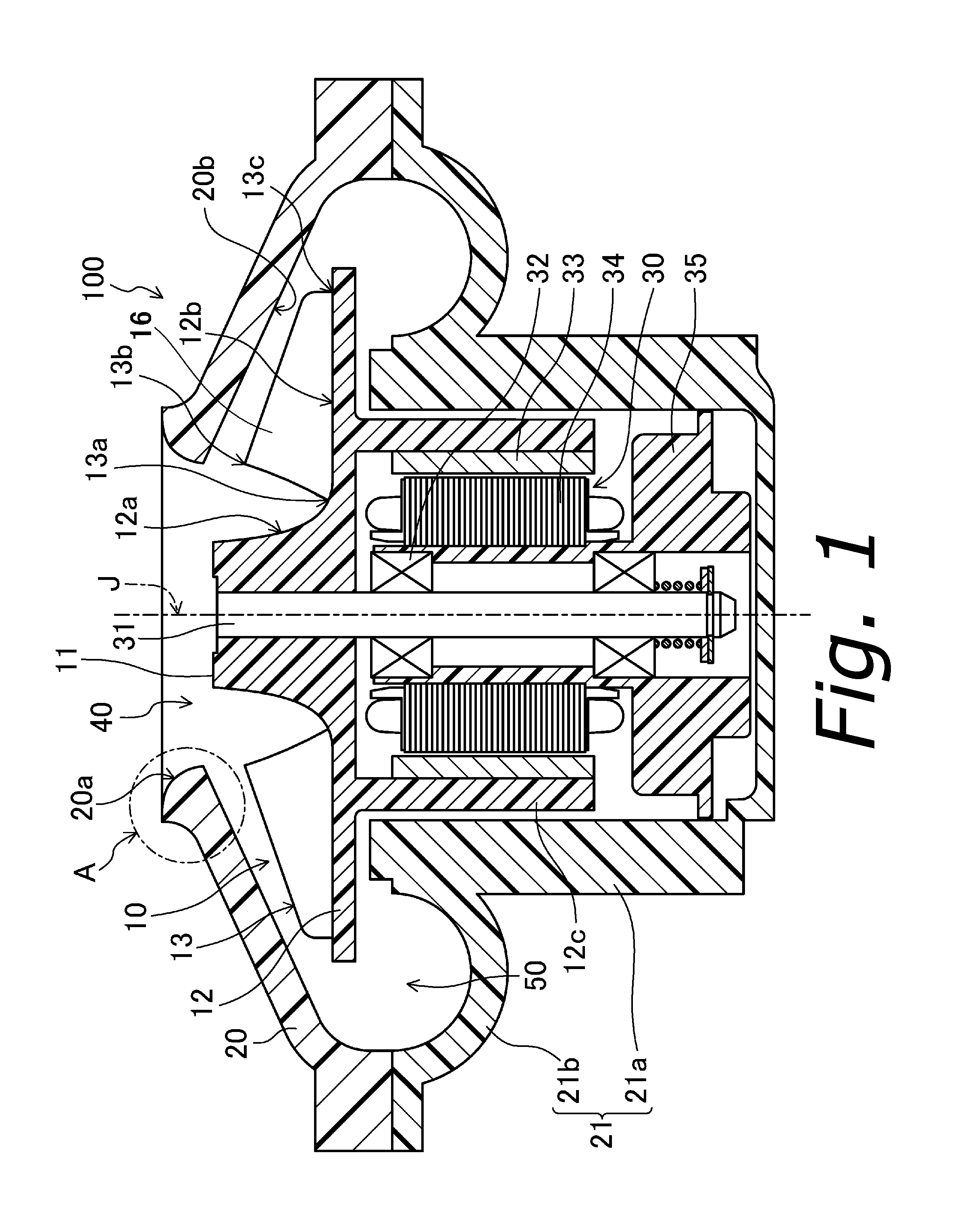

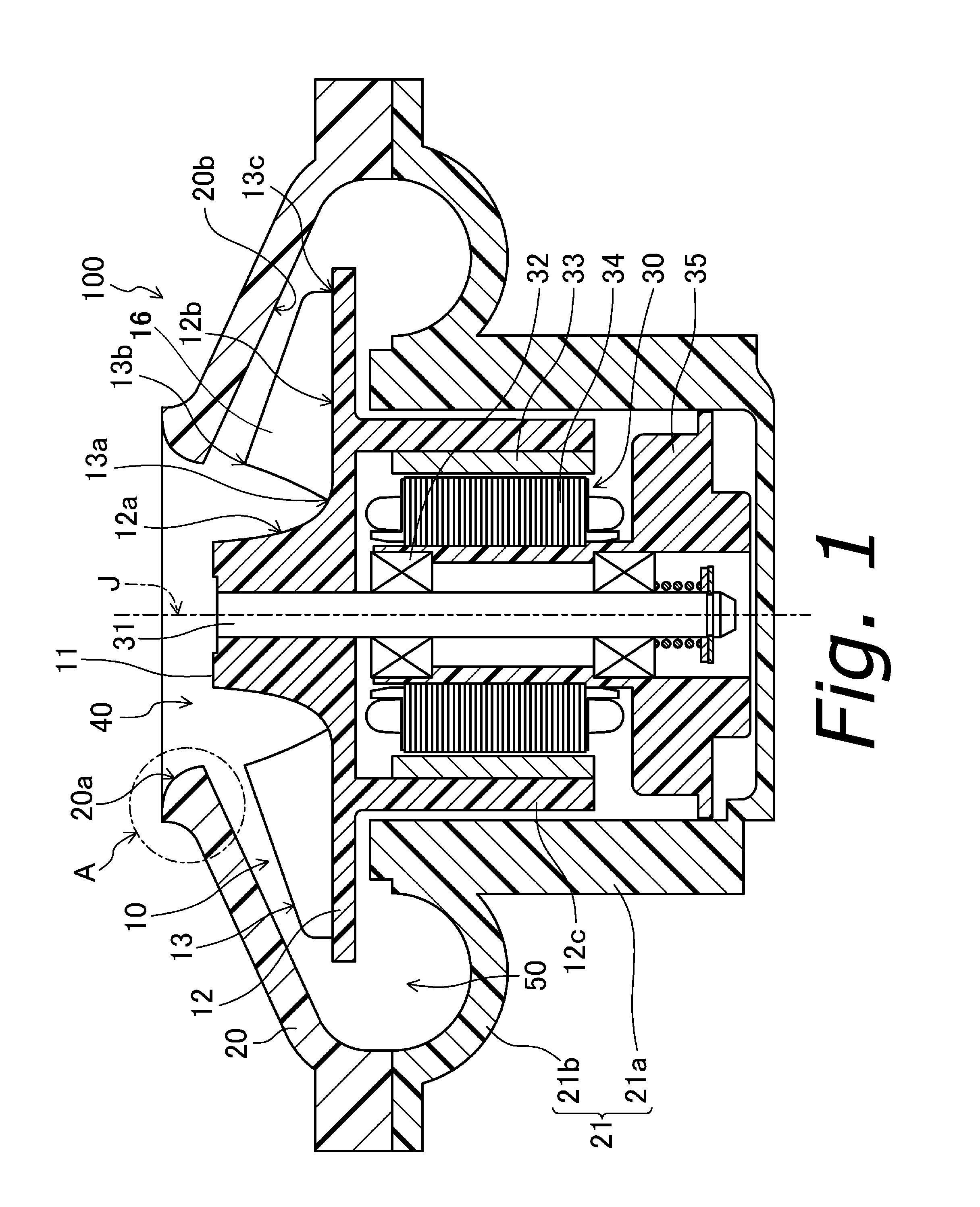

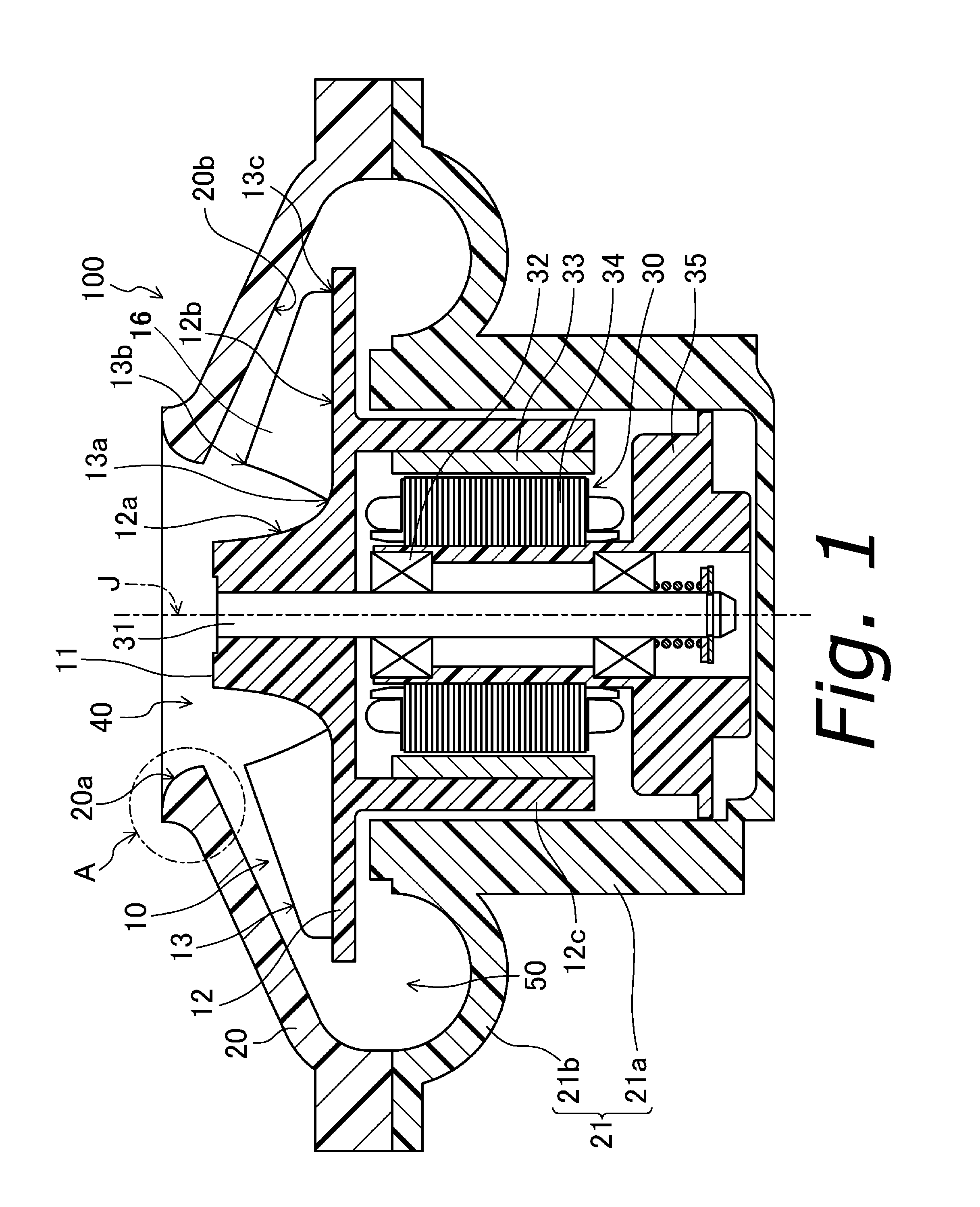

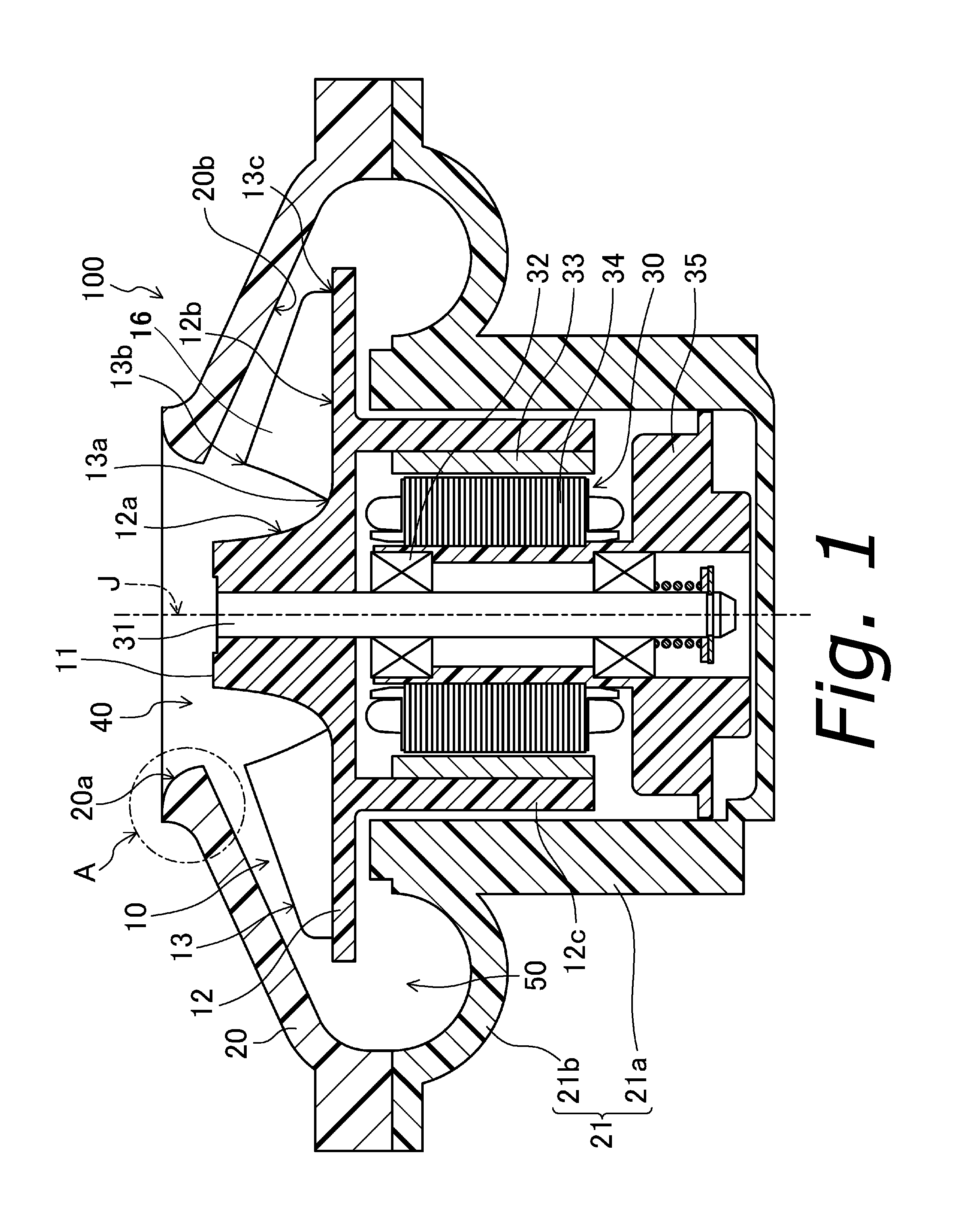

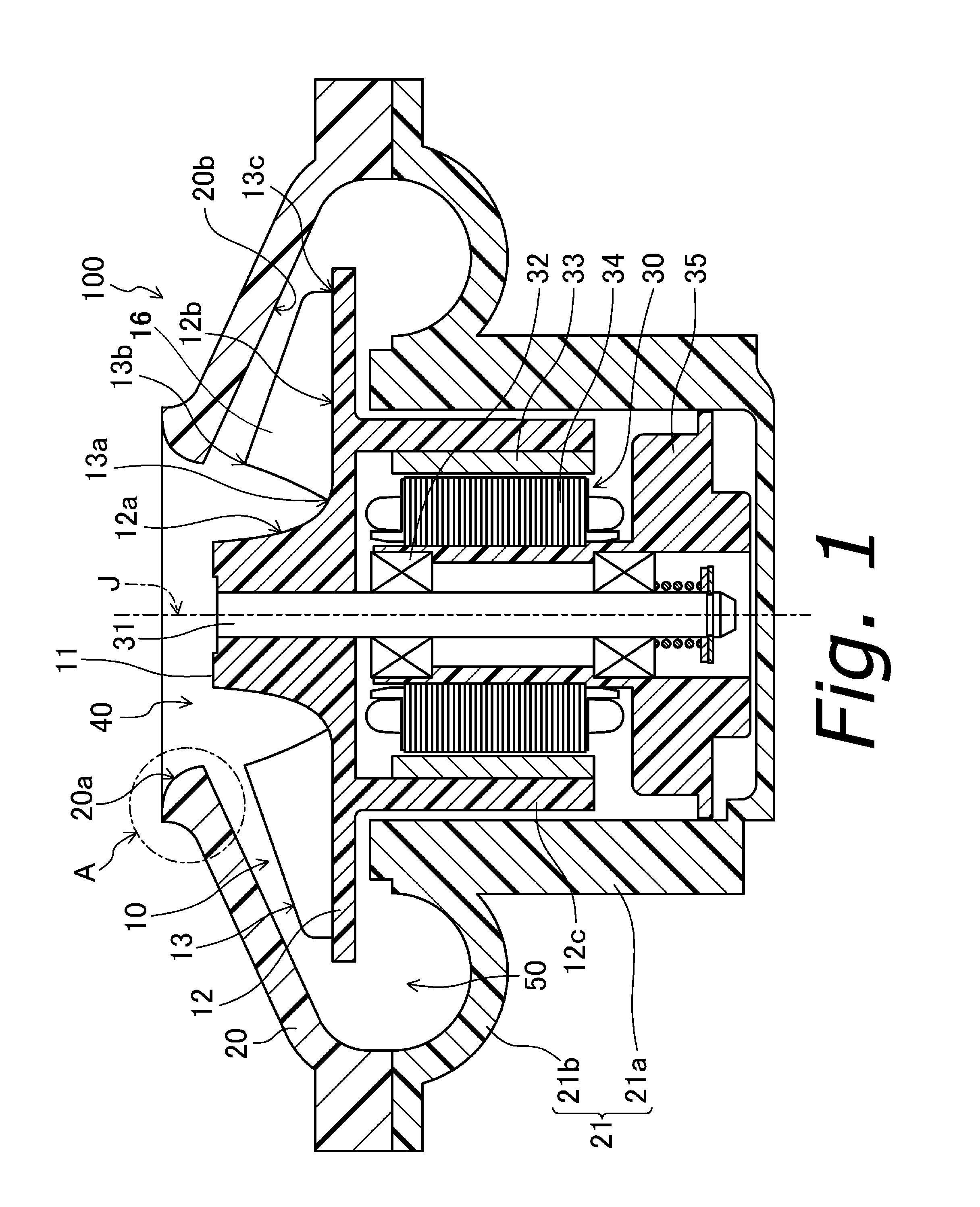

The present application is a continuation application of U.S. patent application Ser. No. 13/781,811, filed on Mar. 1, 2013, the entire contents of which are incorporated herein by reference. The Ser. No. 13/781,811 application claimed the benefit of the date of the earlier filed Japanese Patent Application No. JP 2012-054906, filed Mar. 12, 2012, priority to which is also claimed herein, and the contents of which are also incorporated by reference herein. The present invention relates to a centrifugal fan. In the case of a centrifugal fan, a gas sucked in through an air inlet is pushed radially outward by a centrifugal force produced by rotation of an impeller, and then whirls in a circumferential direction through an annular air channel portion provided around the impeller, and the gas is thereafter discharged outwardly through an air outlet. In a medical appliance such as a respirator or a sputum aspirator, a centrifugal fan generally needs to be used to cause a flow of a gas in order to provide an aid in respiration or to facilitate suction. The centrifugal fan used in such a medical appliance is required to have a high static pressure and a large air volume, and, in addition, to produce little noise in view of an environment in which the medical appliance is used. JP-A 9-14192, for example, describes a centrifugal fan which includes an air current guide at an air inlet, and which thereby achieves reduced noise. In the centrifugal fan described in JP-A 9-14192, the ratio of the area of an imaginary circle joining center-side ends of blades of a centrifugal impeller to the area of an entry of the air inlet is optimized while the air current guide is provided to smoothly guide an air current at the air inlet. In addition, the air current guide is arranged to be in the shape of a circular arc in a cross-section, and a seal member which is in sliding contact with an entry portion defined at a center of a side plate of the centrifugal impeller is attached to an inside of the circular arc so that the air inlet can be kept airtight. That is, provision of the air current guide and the seal member is necessary to achieve a high static pressure and low noise, and this leads to a complicated structure. A centrifugal fan according to at least an embodiment of the present invention includes an impeller arranged to rotate about a rotation axis, an impeller case arranged to accommodate the impeller, a motor arranged to rotate the impeller, and a motor case joined to the impeller case and arranged to accommodate the motor. The impeller includes a boss portion joined to a shaft arranged to rotate about the rotation axis, a hub arranged to extend radially outward from an outer circumferential surface of the boss portion, and a plurality of blades arranged on an upper surface of the hub. Each blade is arranged to extend radially outward away from the rotation axis. An inner wall of the impeller case is arranged to cover the blades, and includes an inside surface extending radially outward along an upper end portion of each blade. The impeller case includes an air inlet defined in a central portion thereof, with a side end portion of the air inlet including a curved surface projecting radially inward. At least an embodiment of present invention is able to provide a centrifugal fan which is excellent in a static pressure characteristic and an air volume characteristic and which produces relatively little noise. The above and other elements, features, steps, characteristics and advantages of the present invention will become more apparent from the following detailed description of the preferred embodiments with reference to the attached drawings. Embodiments will now be described, by way of example only, with reference to the accompanying drawings which are meant to be exemplary, not limiting, and wherein like elements are numbered alike in several Figures, in which: Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the following description of some embodiment examples, it is assumed that a direction parallel to a rotation axis is referred to by the term “axial direction”, “axial”, or “axially”, that radial directions centered on the rotation axis are referred to by the term “radial direction”, “radial”, or “radially”, and that a circumferential direction about the rotation axis is referred to by the term “circumferential direction”, “circumferential”, or “circumferentially”. It is also assumed that an axial direction is a vertical direction, and that a side on which an impeller is arranged with respect to a motor is defined as an upper side. The shape of each member or portion and relative positions of different members or portions will be described based on the above assumptions. Note that the present invention is not limited to the embodiments described below. It is to be understood by those skilled in the art that variations and modifications can be made appropriately as long as desired effects of the present invention are not impaired. Also note that the embodiments described below may be modified and/or combined with other embodiments of the present invention and that the embodiments below should not be considered to limit the scope of the invention. Referring to The impeller 10 includes a boss portion 11 joined to a shaft 31 arranged to rotate about the rotation axis J, a hub 12 arranged to extend radially outward from an outer circumferential surface of the boss portion 11, and a plurality of blades 13 arranged on an upper surface of the hub 12. The boss portion 11 is substantially tubular, and is joined to an outer circumferential surface of the shaft 31, which extends in the vertical direction along the rotation axis J, on an upper side of the motor 30. The shaft 31 is thereby supported with increased strength, and the likelihood that rotation of the impeller 10 will cause the shaft 31 to be shaken is reduced. Note that the boss portion 11 may include a cover portion arranged to project upward while covering an upper end portion of the shaft 31. The cover portion includes a curved surface. This enables a gas sucked in through a side end portion 20 The upper surface of the hub 12 includes a slanting surface 12 Note that the slanting surface 12 A periphery of the flat surface 12 Moreover, the hub 12 may include a slanting surface radially outside the periphery of the flat surface 12 Referring to In addition, referring to An inner wall of the impeller case 20, which is arranged to cover the blades 13, includes an inside surface 20 The impeller case 20 includes the air inlet 40 in a central portion thereof, and a curved surface projecting radially inward at the side end portion 20 The motor 30 includes a bearing 32 arranged to support a rotor magnet 33 such that the rotor magnet 33 is rotatable about the rotation axis J, a bearing support portion 35 arranged to support the bearing 32, and a stator 34 supported by the bearing support portion 35. The hub 12, which is fixed to the shaft 31 arranged to rotate about the rotation axis J, includes a substantially cylindrical rotor support portion 12 As a result of supply of a drive current to the stator 34, a torque is generated between the rotor magnet 33 and the stator 34. The impeller 10, which is fixed to the shaft 31, is thereby caused to rotate about the rotation axis J. The motor case 21 includes a motor accommodating portion 21 The recessed portion 21 In the present embodiment, the radially inner end 13 In short, the present embodiment is directed to the centrifugal fan in which the radially inner end 13 Moreover, in the present embodiment, each blade 13 extends radially outward away from the rotation axis J, and at the same time the inner wall of the impeller case 20 includes the inside surface 20 Note that the boss portion 11, the hub 12, and the blades 13 of the impeller 10 according to the present embodiment may be defined integrally with one another. For example, the boss portion 11, the hub 12, and the blades 13 may be molded by an injection molding process as a single continuous member. Here, the amount of the gas sucked in through the air inlet 40 (i.e., the air volume) depends on the size of the opening of the air inlet 40. Therefore, the air volume characteristic can be improved by securing a wider channel for the gas sucked in. Note that the size of the opening of the air inlet 40 does not simply refer to the radial dimension of the side end portion 20 The amount of the gas sucked in through the air inlet 40 (i.e., the air volume) depends not only on the size of the opening of the air inlet 40 but also on the shape of the side end portion 20 Hereinafter, the shape of the side end portion 20 Referring to In addition, the radially innermost end P includes a minute round portion. This enables the gas to be sucked in more efficiently along the round portion. This leads to an additional increase in the static pressure of the centrifugal fan 100. The gas sucked in through the air inlet 40 experiences flow separation at the radially innermost end P with a high probability. Once the gas experiences the flow separation, turbulence occurs to interfere with efficient suction of the gas. The minute round portion included in the radially innermost end P contributes to preventing the gas from experiencing the flow separation at the radially innermost end P, and promoting efficient suction of the gas. Note that it is easy to define the above-described curved surface of the side end portion 20 In addition, referring to Note that the axial dimension L1refers to the shortest distance between the radially innermost end P and a point of intersection of a line perpendicular to the rotation axis J and passing through the axially uppermost end Q with a line parallel to the rotation axis J and passing through the radially innermost end P. Meanwhile, the radial dimension L2refers to the shortest distance between the axially uppermost end Q and the aforementioned point of intersection. Moreover, the radially innermost end P including the minute round portion is may be arranged on a lower side of a tangent to the side end portion 20 Furthermore, an upper end portion of the boss portion 11 is arranged at a level lower than that of the radially innermost end P of the side end portion 20 Furthermore, each main blade 15 is arranged to extend radially outward from a point radially inward of the radially innermost end P of the side end portion 20 The distance between each main blade 15 and the inside surface 20 The structure of an impeller 10 according to the present embodiment is different from the structure of the impeller 10 illustrated in The impeller 10 according to the present embodiment includes a boss portion 11 joined to a shaft 31 arranged to rotate about a rotation axis J, a hub 12 arranged to extend obliquely downward and radially outward from a portion of an outer circumferential surface of the boss portion 11, and a plurality of blades 13 arranged on the hub 12. Each of the blades 13 and an inner wall of an impeller case 20 is arranged to extend obliquely along the slanting hub 12. That is, each blade 13, the inner wall of the impeller case 20, and the hub 12 are arranged to extend substantially parallel to one another and obliquely. This arrangement enables a gas sucked in through an air inlet 40 to efficiently flow into an air channel portion 50. The hub 12 is may be arranged to extend obliquely downward and radially outward from an upper end portion of the outer circumferential surface of the boss portion 11. This arrangement contributes to more effectively preventing rotation of the impeller 10 from causing a shake of the shaft 31. Note that the upper end portion of the outer circumferential surface of the boss portion 11 refers to a portion of the outer circumferential surface of the boss portion 11 which is above a midpoint between an upper end and a lower end of the boss portion 11. The present embodiment may also be directed to the centrifugal fan in which a radially inner end 13 Moreover, referring to While the description above refers to particular embodiments of the present invention, it will be understood that many modifications may be made without departing from the spirit thereof. The accompanying claims are intended to cover such modifications as would fall within the true scope and spirit of the present invention. The presently disclosed embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims, rather than the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. A centrifugal fan may include an impeller arranged to rotate about a rotation axis, an impeller case arranged to accommodate the impeller, a motor arranged to rotate the impeller, and a motor case arranged to accommodate the motor. The impeller may include a boss portion joined to a shaft arranged to rotate about the rotation axis, a hub arranged to extend radially outward from the boss portion, and a plurality of blades. Each blade may be arranged to extend radially outward. An inner wall of the impeller case may include an inside surface extending radially outward along an upper end portion of each blade. A side end portion of an air inlet defined in a central portion of the impeller case may include a curved surface projecting radially inward. 1. A centrifugal fan comprising:

an impeller arranged to rotate about a rotation axis; an impeller case arranged to accommodate the impeller; a motor arranged to rotate the impeller; and a motor case joined to the impeller case and arranged to accommodate the motor; wherein

the impeller comprises:

a boss portion joined to a shaft arranged to rotate about the rotation axis; a hub arranged to extend radially outward from an outer circumferential surface of the boss portion; and a plurality of blades arranged on an upper surface of the hub; each blade is arranged to extend radially outward away from the rotation axis; an inner wall of the impeller case is arranged to cover the blades, and comprises an inside surface extending radially outward along an upper end portion of each blade; the impeller case comprises an air inlet defined in a central portion thereof, with a side end portion of the air inlet comprising a curved surface projecting radially inward; and the each blade has an axially upper end projecting upward and positioned radially outward of a radially innermost end of the curved surface of the air inlet; and a distance between the each blade and the inside surface of the impeller case is arranged to be shortest at the axially upper end of the each blade. 2. The centrifugal fan according to 3. The centrifugal fan according to 4. The centrifugal fan according to 5. The centrifugal fan according to 6. The centrifugal fan according to the upper surface of the hub further comprises a flat surface arranged to extend from a radially outer end of the slanting surface substantially perpendicularly to the rotation axis; and a periphery of the flat surface is arranged to project radially outwardly relative to a periphery of each blade. 7. The centrifugal fan according to 8. The centrifugal fan according to 9. The centrifugal fan according to 10. The centrifugal fan according to a main blade arranged to extend radially outward from a point radially inward of a radially innermost end of the curved surface of the air inlet; and an auxiliary blade arranged to extend radially outward from a point radially outward of the radially innermost end of the curved surface of the air inlet. 11. The centrifugal fan according to 12. The centrifugal fan according to 13. A centrifugal fan comprising:

an impeller arranged to rotate about a rotation axis; an impeller case arranged to accommodate the impeller; a motor arranged to rotate the impeller; and a motor case joined to the impeller case and arranged to accommodate the motor; wherein

the impeller comprises:

a boss portion joined to a shaft arranged to rotate about the rotation axis; a hub arranged to extend radially outward from an outer circumferential surface of the boss portion; and a plurality of blades arranged on an upper surface of the hub; each blade is arranged to extend radially outward away from the rotation axis; an inner wall of the impeller case is arranged to cover the blades, and comprises an inside surface extending radially outward along an upper end portion of each blade; and the impeller case comprises an air inlet defined in a central portion thereof, with a side end portion of the air inlet comprising a curved surface projecting radially inward; and the each blade has a radially outer end at a radially outermost point of an upper end portion thereof; and a distance between the each blade and the inside surface of the impeller case is arranged to be shortest at the radially outer end of the each blade. 14. The centrifugal fan according to 15. The centrifugal fan according to 16. The centrifugal fan according to 17. The centrifugal fan according to 18. The centrifugal fan according to 19. The centrifugal fan according to the upper surface of the hub further comprises a flat surface arranged to extend from a radially outer end of the slanting surface substantially perpendicularly to the rotation axis; and a periphery of the flat surface is arranged to project radially outwardly relative to a periphery of each blade. 20. The centrifugal fan according to 21. The centrifugal fan according to 22. The centrifugal fan according to 23. The centrifugal fan according to a main blade arranged to extend radially outward from a point radially inward of a radially innermost end of the curved surface of the air inlet; and an auxiliary blade arranged to extend radially outward from a point radially outward of the radially innermost end of the curved surface of the air inlet. 24. The centrifugal fan according to CROSS REFERENCE TO RELATED APPLICATIONS

FIELD OF THE INVENTION

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION