Komprimierbares prepreg auf der basis von mit duromeren kunstharzen imprägnierten flächigen trägermaterialien, ein verfahren zu dessen herstellung sowie dessen verwendung

The invention concerns a compressable prepreg on the basis yon with duromeren synthetic resins impr gnierten f chigen Tr germaterialien, a procedure for its production as well as its use.

Such prepregs are used for the production of the electrical Isolationen of Trafowicklungen and consist usually of a Tr germaterial, e.g. a glass fiber fabric, which is gniert synthetic resin rtbaren with one in animal heat h impr. These prepregs are applied now for the production of the electrical Isolationen mentioned for example in volume form on a metal band and applied with application of high tensions to a winding thorn, which into a heated furnace 5bergefi3hrt becomes anschlieBend. With these erh hten temperatures the synthetic resin of the prepreg in the B-condition becomes into the C-condition [Jbergeff3hrt. Since however this MetalI Prepregverbund stands under high tension, it is in particular wegflieBt in uneven metal places the resin before its Aush rtung from the glass fiber fabric m6glich, dab, soda8 unimpr gnierte glass fiber situations between the layers of metal lies.

Thus with the Erstbenutzung of the Tratowicklungen a KurzschluB is already produced.

From there the task is appropriate for the invention to reason to indicate a compressable prepreg of the kind initially specified which does not exhibit the M specified above with its use as electrical insulating material ngel.

Erfindugnsgem f3 the prepreg is characterized by it, dab it a first, directly Tr chigen on the flat steel bar germaterial applied synthetic resin layer in the C-condition and a second synthetic resin layer applied on the first synthetic resin layer in the B-condition exhibits.

A further advantage of the invention consists of it, daf3 the prepreg than flat steel bars of chiges Tr igermaterial a fabric of organic fibers enth lt and these organic fibers aramide fibers is.

A further variant of the invention is lt, dab the prepreg than flat steel bars of chiges Tr germaterial a fabric from inorganic fibers enth, which glass fibers sin& A further advantage of the invention consists of it, daf3 that. Prepreg ats flat steel bar of chiges Tr germaterial a fleece from organic fibers enth lt, the aramide fibers are.

Another variant of the invention is lt, dab the prepreg than flat steel bars of chiges Tr germaterial a fleece from inorganic fibers enth, whereby these organic fibers are glass fibers.

A further advantage of the invention is, dab the duromere synthetic resin a Epoxyharz or a polyester resin is.

Invention in accordance with fuel element the prepreg is manufactured by a procedure, which is characterized by it, dab fi the chige Tr germaterial into one with one aush rtbaren Kunstharzl sung gef [Jllten first Tr nkwanne is gefQhrt, dab this impr gnierte Tr germaterial [Jber several detour rollers a heating zone happened, whereby the synthetic resin into the C-condition L bergef [Jhrt becomes, and dab anschlie8end this group a KunstharzlSsung rtbaren with one aush gefQIIten, second Tr nkwanne happened, whereby a second, sticky resin layer on the group is produced and dab this second synthetic resin layer anschliei3end into the B-condition 5bergeEJhrt becomes.

The invention concerns also the use of a prepreg to the electrical lsolierung the coils of electrical machines, whereby the synthetic resin of the second synthetic resin layer likewise into the C-condition iJbergef (Jhrt becomes.

A way to the production invention in accordance with Ben of the prepreg: The production invention in accordance with Ben of the prepreg takes place for example with devices in accordance with 8 the figures 1 and 2.

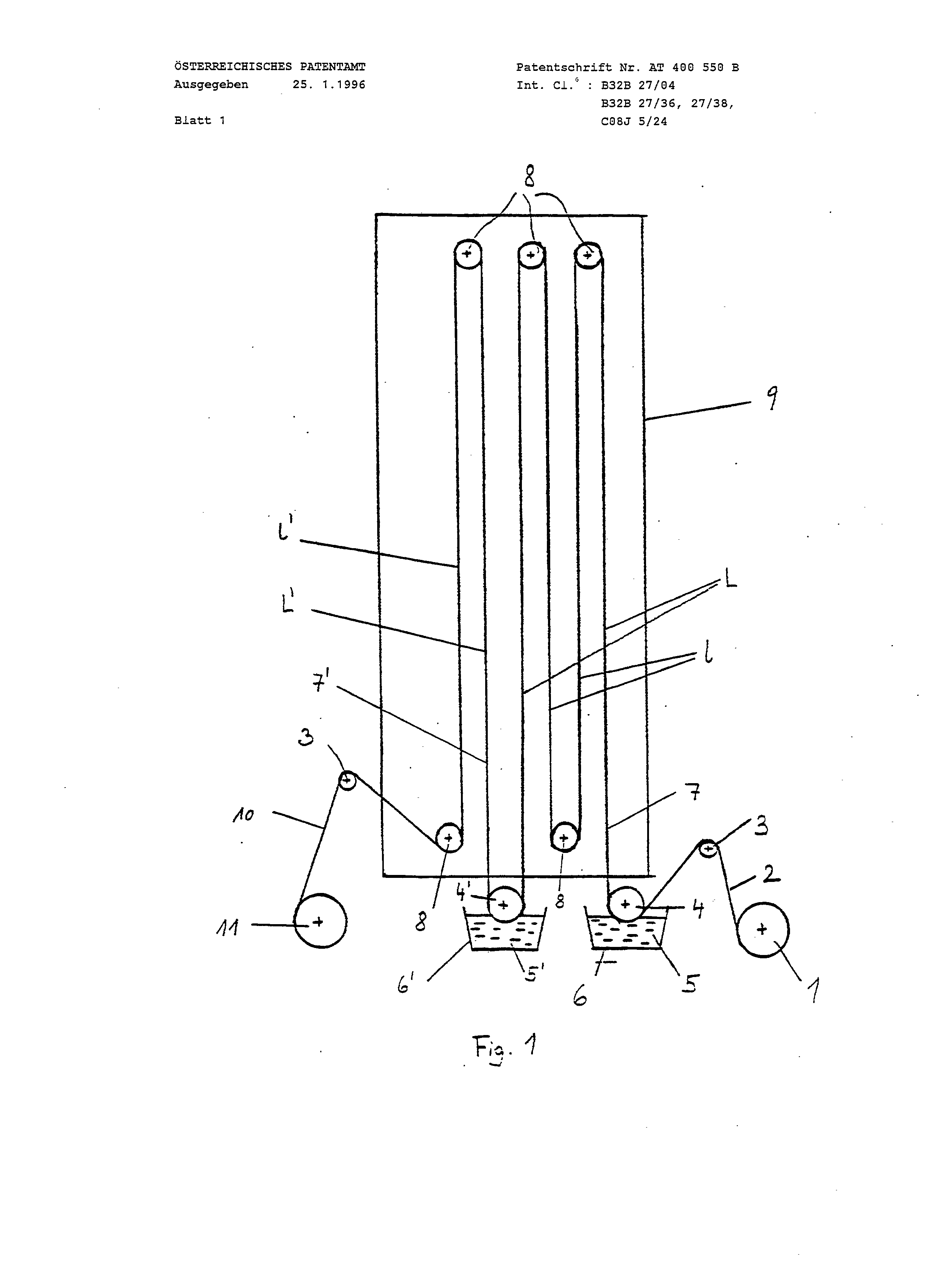

Figure 1 shows a Impr gnieranlage consisting of two Tr nkwannen and a Impr gnierturm.

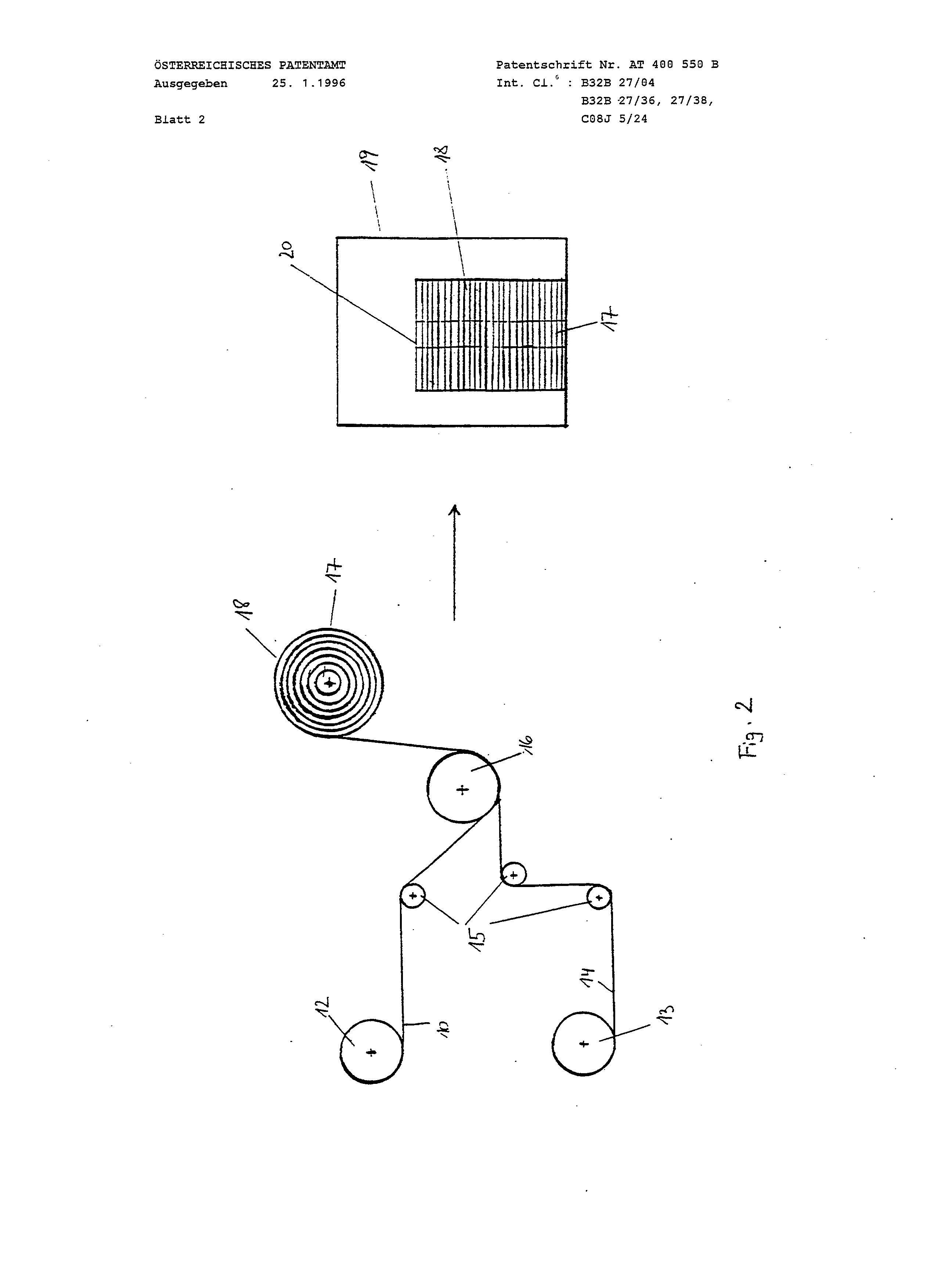

Figure 2 shows a winding device f [Jr a metal foil and invention in accordance with fuel element the prepreg, which a furnace can be connected at the outlet side.

The Impr gniervorgang for the production invention in accordance with Ben of the prepreg can take place for example in accordance with 8 of a device after figure 1.

Of that is taken off from supply role of 1 for example a glass fiber fabric 2 and more fJber the pinchroll 3 of an order roller 4 is zugefShrt. The order roller 4 immerses 5 gefL llte Tr nkwanne 6 into a KunstharzlSsung rtbaren with one aush. The Kunstharzl6sung 5 can exist for example out in Ketonen gel6sten Epoxyharzen, whereby its temperature w is held hrend the Impr gnierung ambient temperature o. AnschlieBend becomes the group 7 [Jber several detour rollers 8 in the Impr, consisting of glass fiber fabric and synthetic resin, gnierturm 9, its temperature held approximately 120 ° to 130 ° C, is led, whereby the group 7 the Wegl ngen Lund the Wegl formed formed between the order rollers and the guide rollers between two order rollers ngen 1 durchl uft. Furthermore the synthetic resin penetrates the glass fiber fabric and becomes due to the erhShten temperature in the Impr gnierturm into the B-condition [Jbergef [Jhrt. To AnschlieJ] end this group more cuber a further order roller 4 ', which immerses 5 ' gefUIIte Tr nkwanne 6 ' into a KunstharzlSsung rtbaren with one aueh, gefL one hrt. This KunstharzI6sung is held ambient temperature and can exhibit the same concentration as those the KunstharzlSsung in addition, one to this different concentration. Furthermore the KunstharzlSsung can exhibit 5 ' RKs 400,550 B also to into the Kunstharzl6sung 5 different synthetic resin, for example a polyester resin. AnschlieBend durchl uft the group 7 ' the L' nge between the order roller 4 ' and a guide roller 8 lying Wegi and the 1 nge between two guide rollers 8 lying Wegl '. Due to the erh6hten temperature in the Impr gnierturm is in the finalmanufactured prepreg 10 the synthetic resin layer applied in form of the first Kunstharz16sung 5 into the C-condition 0bergef0hrt, w hrend synthetic resin layer applied in form of the second Kunstharzl sung 5 the ' still in the B-condition is. This prepreg is rolled up now on a supply role, on which his to subsequent treatment will be stored can.

A mSgliche subsequent treatment of the prepreg 10 can take place with the help of a device after figure 2. Vorratsrolte 12 invention in accordance with fuel element the prepreg 10 and of that are taken off from of that supply role of 13 a metal foil 14, for example a Kupferfolie, and to 0ber pinchrolls 15 of the detour roller 16 zugef0hrt with one another, brought at that the materials 10 and 14 at ambient temperature in contact and anschliel end on the Wicke [thorn! 7 to be rolled up, whereby a tension affects the materials. This MetalI Prepregwicklungen 18 standing under tension is anschlieSend abgel#.ngt anschlieSend and in one on for instance 130° to 160°C heated furnace 19 0bergef0hrt, whereby also zweite.im the B-condition becomes synthetic resin layer present into the C-condition 0bergef0hrt. With well-known prepregs, which exhibit only a synthetic resin layer, it showed, dab starting from a certain tension the resin with the Aush rten themselves by the Tr germaterial was away-squeezed, sodaB that not impr gnierte Tr germaterial directly on the Metatlfolie rested upon, which during the far idiom for example as windings in transformers to Kurzschl0ssen f0hrte.

After the Aush it rten the face of the coil 20 is poured and the winding thorn 17 removed whereby a Ger0st is produced, which can be used as coil in transformers.

PatentanspdJche 1, compress-cash prepreg on the basis of flat steel bar chigen Tr gnierten with duromeren synthetic resins impr germaterialien. in it characterized, dab it a first, directly Tr chigen on the flat steel bar germaterial applied synthetic resin layer, consisting of a Epoxyoder polyester resin in the C-condition and a second synthetic resin layer applied on the first synthetic resin layer, consisting of a Epoxyoder polyester resin in the B-condition exhibits.

2. Prepreg according to requirement 1, Tr chiges thereby characterized, dab it as f germaterial a fabric from organic fibers enth Et.

3. Prepreg according to requirement 2, by it characterized, dab the organic fibers aramide fibers sin& 4. Prepreg according to requirement 1, by it characterized, dai3 it as flat steel bar of chiges Tr germaterial a fabric from inorganic fibers enth as per.

5. Prepreg according to requirement 4, by it characterized, daf the inorganic fibers glass fibers are.

6. Prepreg according to requirement 1, by it characterized, dab it as flat steel bar: chiges Tr germaterial a fleece from organic fibers enth as per.

7. Prepreg according to requirement 6, by it characterized, dab the organic fibers aramide fibers are.

8. Prepreg according to requirement 1, Tr chiges thereby characterized, dab it as flat steel bar germaterial a fleece from inorganic fibers enth as per.

9. Prepreg according to requirement 8, by it characterized, dab in organic fibers the glass fibers are.

Procedure for the production of a prepreg after one the Anspr0che 1 to 9 assistance of a Zweibadimpr gnierverfahrens, thus gekennzeiohnet, dab the flat steel bar the chige Tr germaterial into a Kunstharzl sung on basis of Epoxyoder polyester resin gef011ten first Tr nkwanne 0ber an order roller 4 gef0hrt, rtbaren with one aush, is passed, dab this impr gnie.rte Tr igermaterial 0ber several detour rollers a heating zone, whereby the synthetic resin becomes into the C-condition 0bergef0hrt, and dab anschlieBend this group passes a Kunstharzl6sung on basis of Epoxyoder polyester resin gef011ten, rtbaren with one aush, to second Tr nkwanne 0ber the order roller 4 ', whereby second, PCT No. PCT/AT93/00082 Sec. 371 Date Jan. 5, 1994 Sec. 102(e) Date Jan. 5, 1994 PCT Filed May 13, 1993 PCT Pub. No. WO93/23461 PCT Pub. Date Nov. 25, 1993.The invention concerns a compressible prepreg based on flat substrates impregnated with thermosetting synthetic resins, characterized in that it comprises a first, C stage synthetic-resin layer directly deposited on the substrate and a second, B stage synthetic-resin layer deposited on the first synthetic-resin layer. exhibit also to into the Kunstharzl6sung 5 different synthetic resin, for example a polyester resin. AnschlieBend durchl uft the group 7 ' the L' nge between the order roller 4 ' and a guide roller 8 lying Wegi and the 1 nge between two guide rollers 8 lying Wegl '. Due to the erh6hten temperature in the Impr gnierturm is in the finalmanufactured prepreg 10 the synthetic resin layer applied in form of the first Kunstharz16sung 5 into the C-condition 0bergef0hrt, w hrend synthetic resin layer applied in form of the second Kunstharzl sung 5 the ' still in the B-condition is. This prepreg is rolled up now on a supply role, on which his to subsequent treatment will be stored can.

A mSgliche subsequent treatment of the prepreg 10 can take place with the help of a device after figure 2. Vorratsrolte 12 invention in accordance with fuel element the prepreg 10 and of that are taken off from of that supply role of 13 a metal foil 14, for example a Kupferfolie, and to 0ber pinchrolls 15 of the detour roller 16 zugef0hrt with one another, brought at that the materials 10 and 14 at ambient temperature in contact and anschliel end on the Wicke [thorn! 7 to be rolled up, whereby a tension affects the materials. This MetalI Prepregwicklungen 18 standing under tension is anschlieSend abgel#.ngt anschlieSend and in one on for instance 130° to 160°C heated furnace 19 0bergef0hrt, whereby also zweite.im the B-condition becomes synthetic resin layer present into the C-condition 0bergef0hrt. With well-known prepregs, which exhibit only a synthetic resin layer, it showed, dab starting from a certain tension the resin with the Aush rten themselves by the Tr germaterial was away-squeezed, sodaB that not impr gnierte Tr germaterial directly on the Metatlfolie rested upon, which during the far idiom for example as windings in transformers to Kurzschl0ssen f0hrte.

After the Aush it rten the face of the coil 20 is poured and the winding thorn 17 removed whereby a Ger0st is produced, which can be used as coil in transformers.

PatentanspdJche 1, compress-cash prepreg on the basis of flat steel bar chigen Tr gnierten with duromeren synthetic resins impr germaterialien. in it characterized, dab it a first, directly Tr chigen on the flat steel bar germaterial applied synthetic resin layer, consisting of a Epoxyoder polyester resin in the C-condition and a second synthetic resin layer applied on the first synthetic resin layer, consisting of a Epoxyoder polyester resin in the B-condition exhibits. 2. Prepreg according to requirement 1, Tr chiges thereby characterized, dab it as f germaterial a fabric from organic fibers enth Et. 3. Prepreg according to requirement 2, by it characterized, dab the organic fibers aramide fibers sin& 4. Prepreg according to requirement 1, by it characterized, dai3 it as flat steel bar of chiges Tr germaterial a fabric from inorganic fibers enth as per. 5. Prepreg according to requirement 4, by it characterized, daf the inorganic fibers glass fibers are. 6. Prepreg according to requirement 1, by it characterized, dab it as flat steel bar: chiges Tr germaterial a fleece from organic fibers enth as per. 7. Prepreg according to requirement 6, by it characterized, dab the organic fibers aramide fibers are. 8. Prepreg according to requirement 1, Tr chiges thereby characterized, dab it as flat steel bar germaterial a fleece from inorganic fibers enth as per. 9. Prepreg according to requirement 8, by it characterized, dab in organic fibers the glass fibers are.

Procedure for the production of a prepreg after one the Anspr0che 1 to 9 assistance of a Zweibadimpr gnierverfahrens, thus gekennzeiohnet, dab the flat steel bar the chige Tr germaterial into a Kunstharzl sung on basis of Epoxyoder polyester resin gef011ten first Tr nkwanne 0ber an order roller 4 gef0hrt, rtbaren with one aush, is passed, dab this impr gnie.rte Tr igermaterial 0ber several detour rollers a heating zone, whereby the synthetic resin becomes into the C-condition 0bergef0hrt, and dab anschlieBend this group passes a Kunstharzl6sung on basis of Epoxyoder polyester resin gef011ten, rtbaren with one aush, to second Tr nkwanne 0ber the order roller 4 ', whereby second, RK 400,550 B sticky resin layer on the group is produced and dab this second synthetic resin layer anschlieBend into the B-condition one iJbergefiJhrt. 11. Use of a prepreg in accordance with B one the AnsprSche 1 to 9, by it characterized dab one the prepreg for the electric insulation of the coils of electrical machines begins, whereby the synthetic resin of the second synthetic resin layer becomes likewise in the C-Zu.stand QbergefShrt.