Vorrichtung zum Aufnehmen einer Person und zur teilweisen Einschränkung ihrer Bewegungsfreiheit

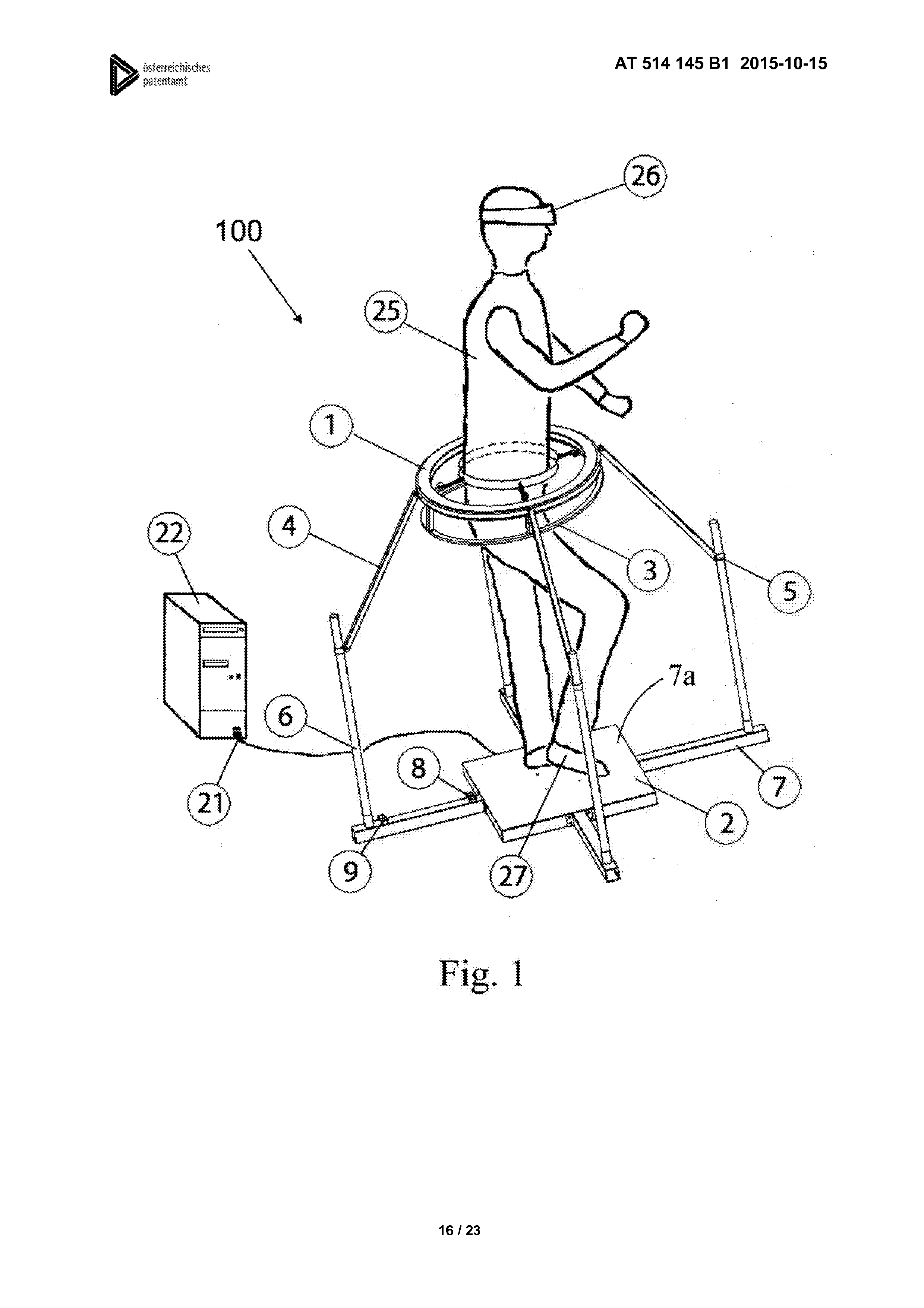

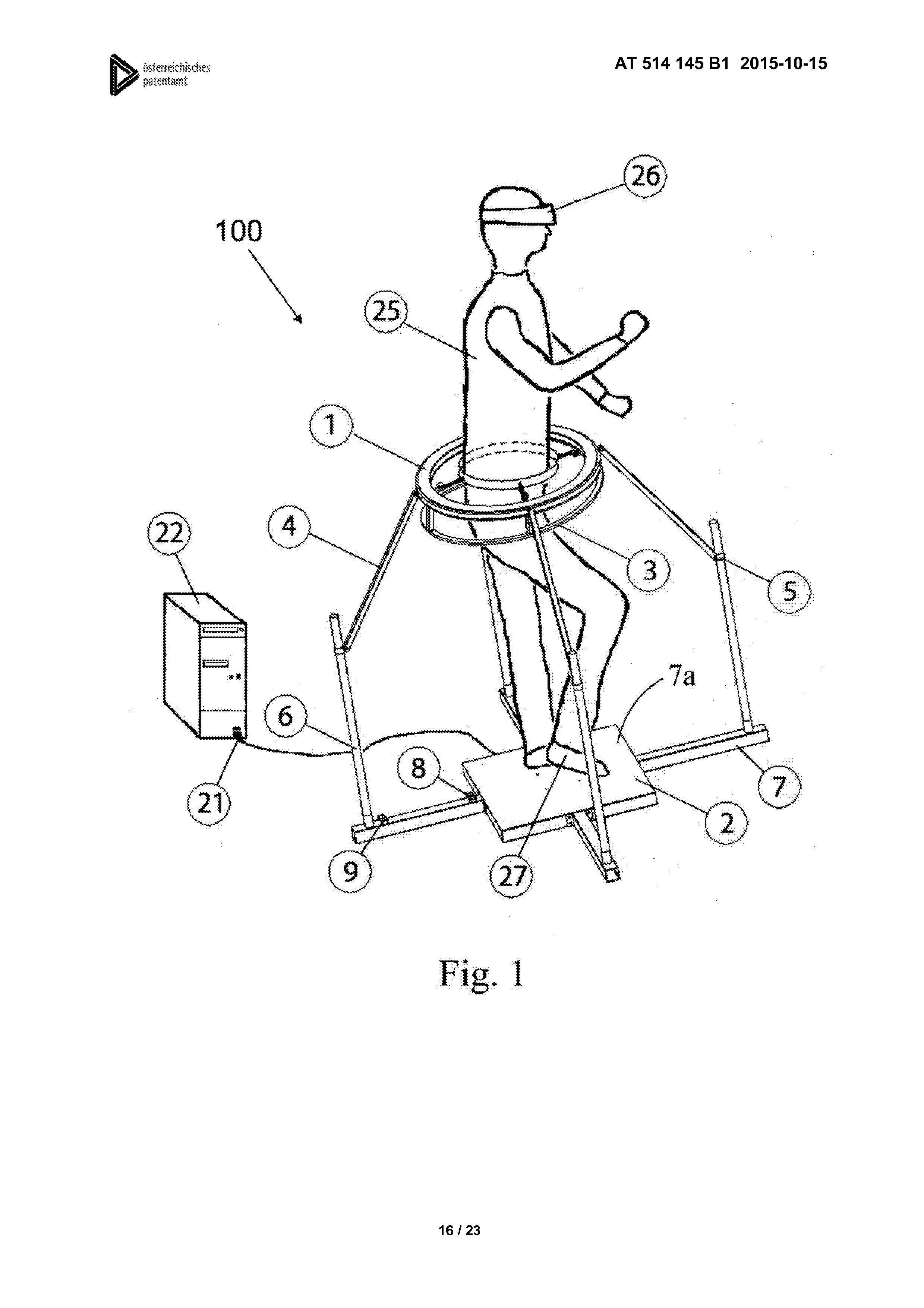

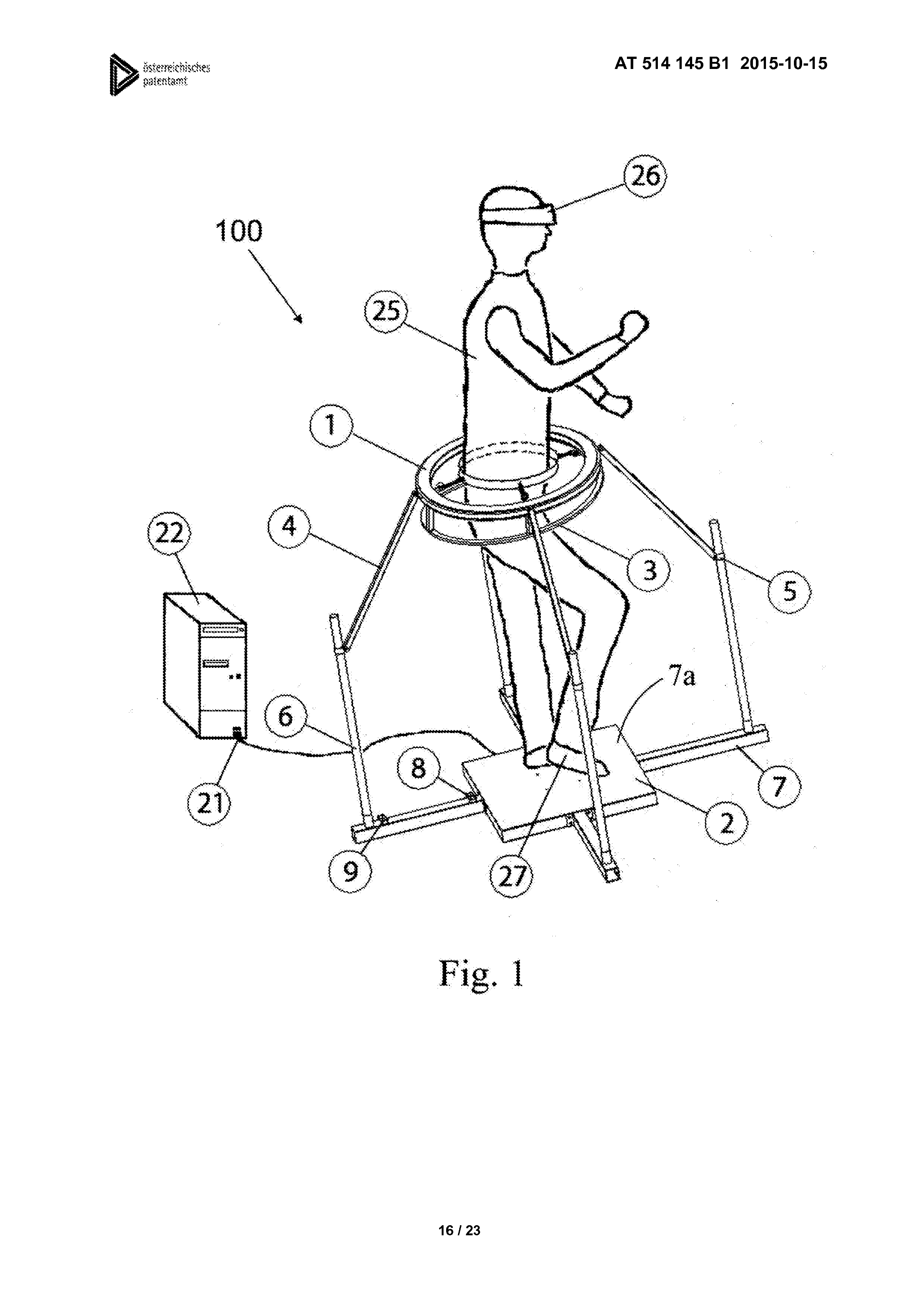

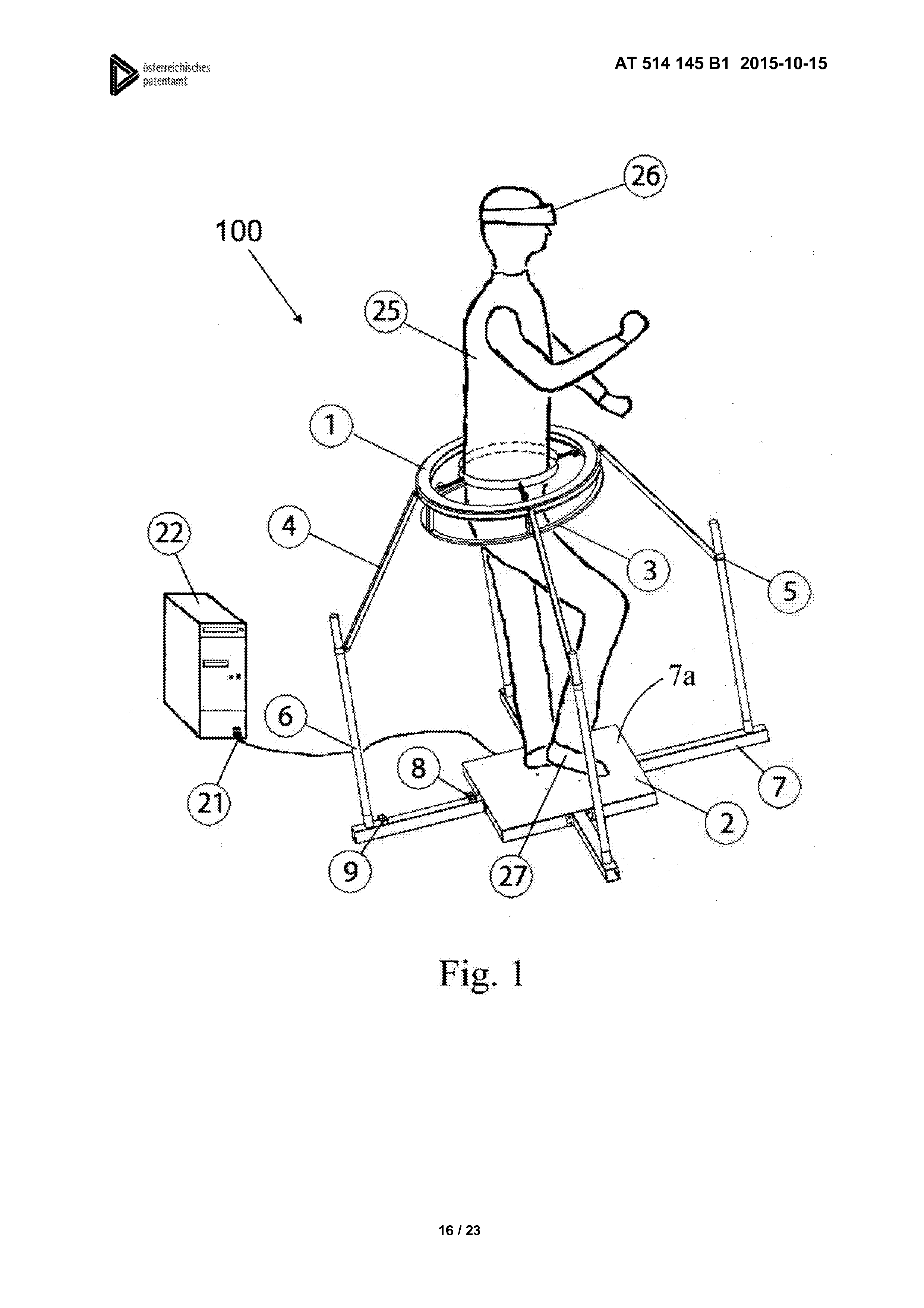

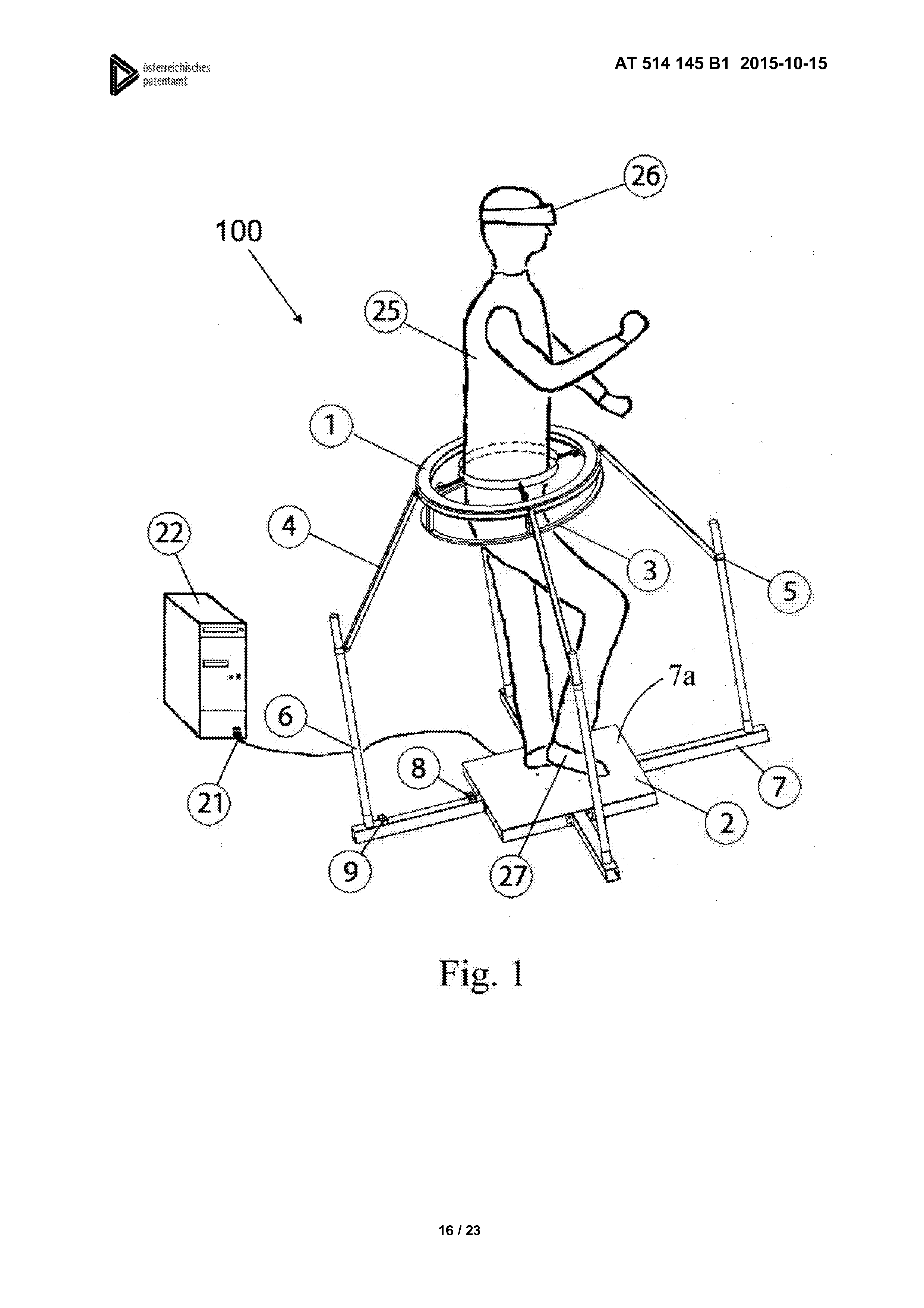

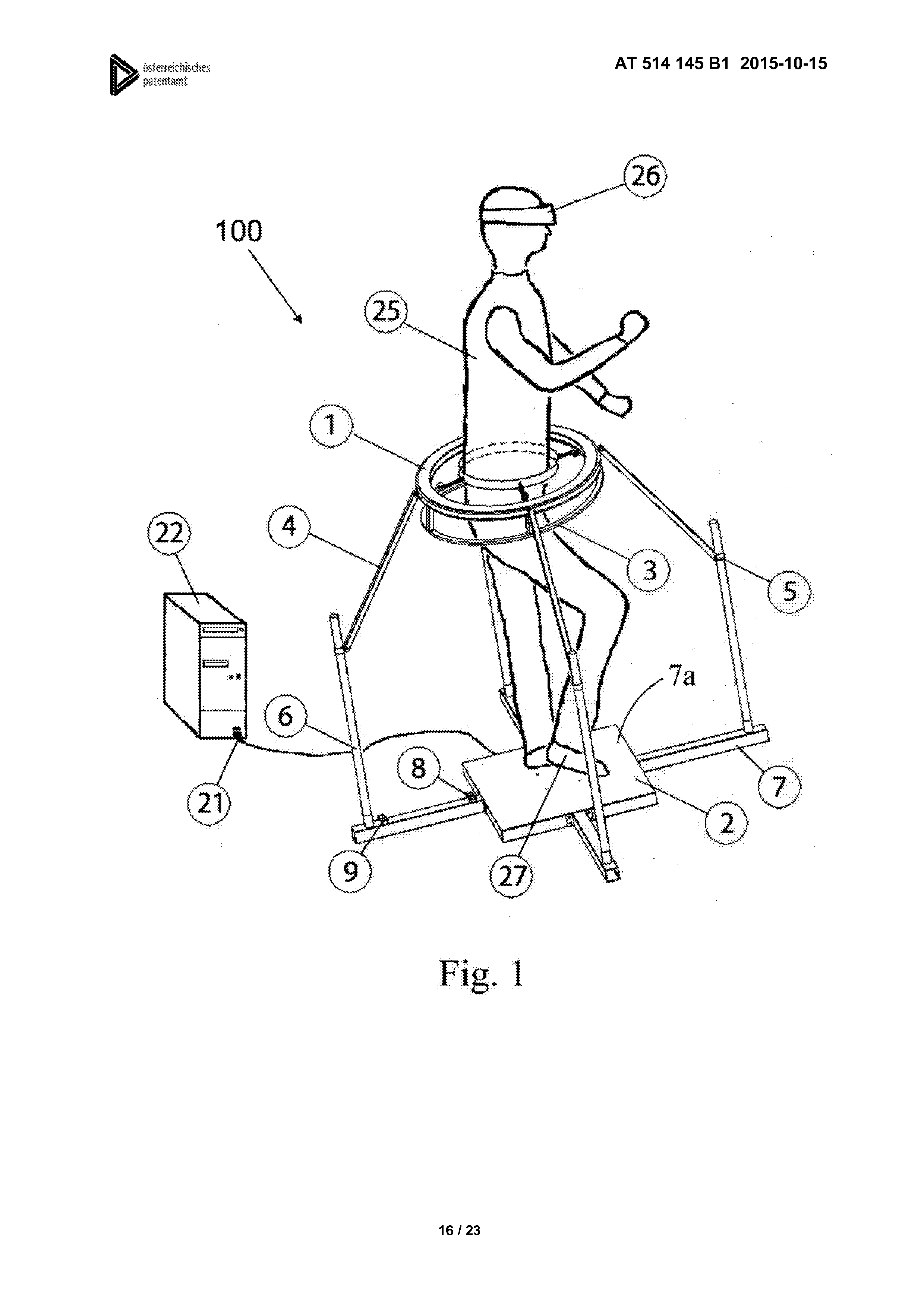

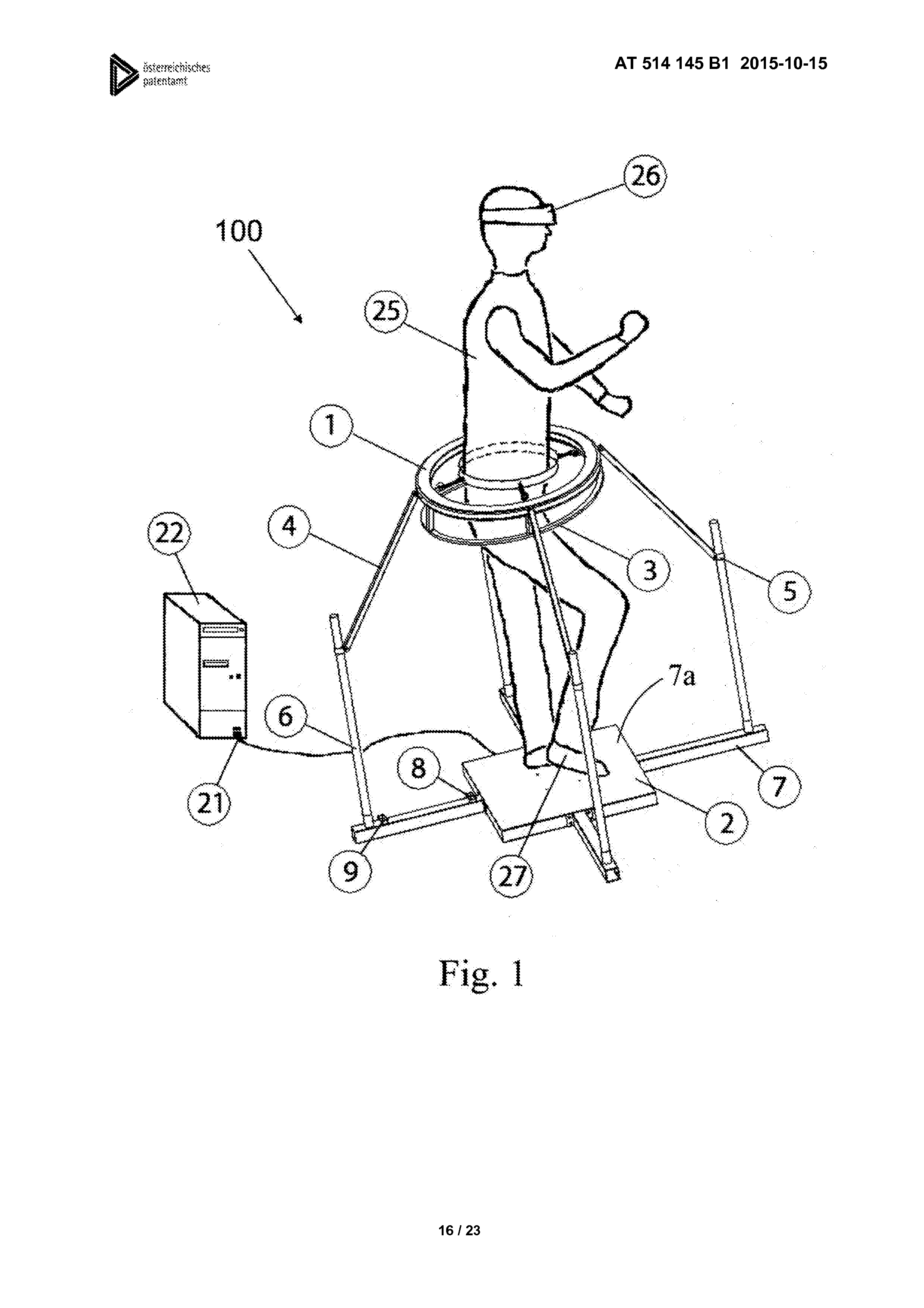

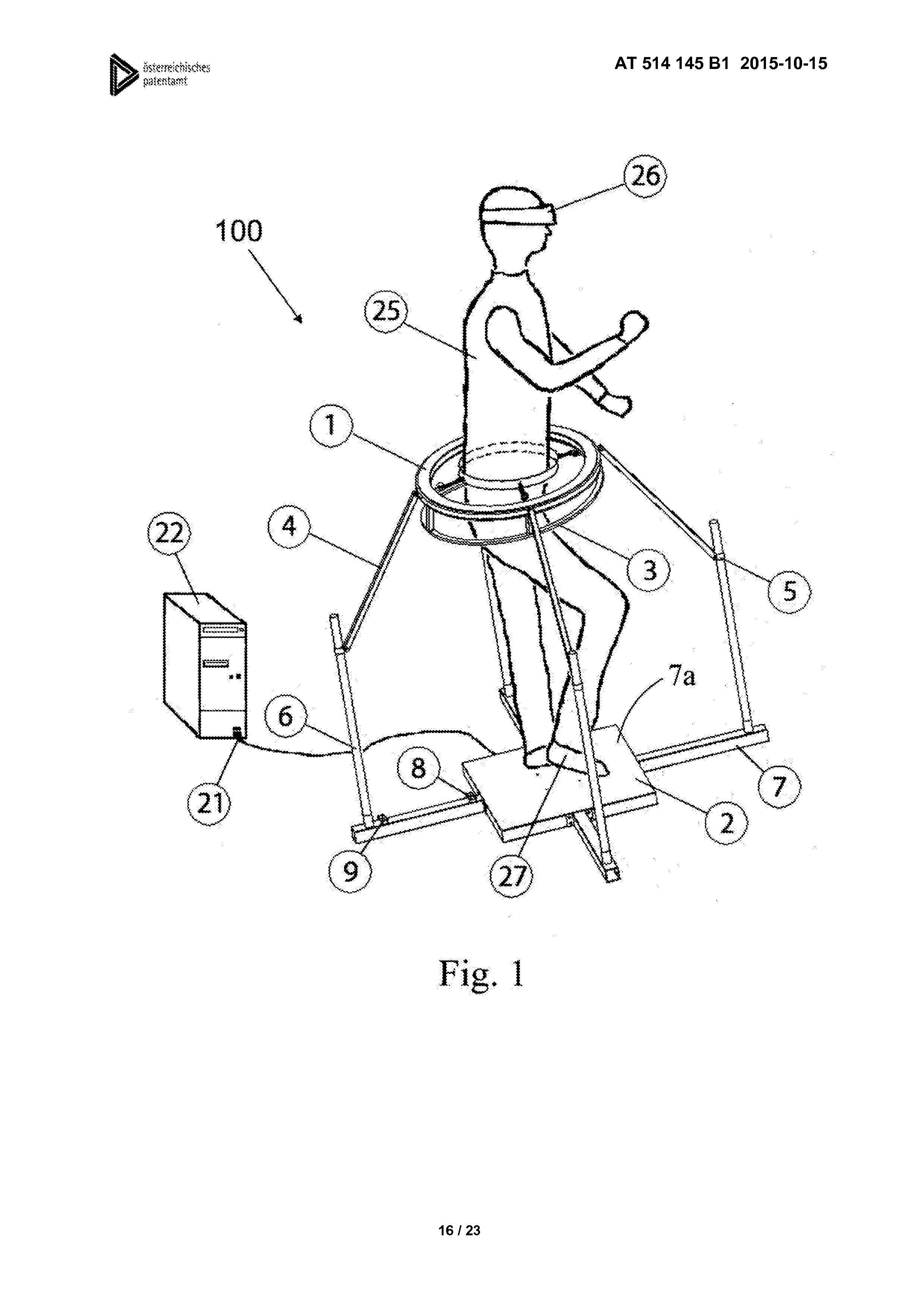

[...] [0001] The invention relates to a device for receiving at least one person and to partially restrict the movement of the person received by the device, with a platform and a platform arranged above the first annular member for surrounding the at least one person, wherein said circumferential portion is rotatable relative to the platform. The invention refers in particular to [...] -devices, moving means, (Reality) Simulation device, sport devices[...] /or. [0002] Such devices are also known under the name of " [...] devices" and "head mounted display" find particularly in connection with a use as Simulation tool, a piece of sports equipment and Amusement apparatus. One can use such a device also Virtual "sight [...] ", if the necessary virtual environment has available for it. If is a kind of controller is additionally in the hand so that play " [...] has can games", without a mouse or a keyboard to be dependent on. Through suitable software it is possible to realize even, the viewing direction, the weft direction and the direction of movement to decouple and to let " [...] " still be thus the real. [0003] Themovement cage Reality W02002059853A2 discloses a system with a simulation movement ring surrounding and a the user, has a rotational degree of freedom with respect to the the movement cage. Over relatively long User is, compliant fixing feathers/springs , are secured by the user to be worn on a belt, at the coupled movement ring. Such a construction requires a lot of room due to the large diameter and long fixing feathers/springs , the stands in particular in the private sphere not available. Moreover, fixing feathers/springs are expensive and the wear-susceptibly. Restricting the freedom of movement is not given to the extent, in the this is desired for many applications, give plenty of room in all directions but the fixing feathers/springs. [0004] a device is described in the[...] , which consists of a hollow sphere, and is mounted on rollers in the busiest then brings the can move, by introducing this hollow sphere to rotate. The rotation of the ball is detected via sensors and forwarded to a computer. This computer calculated rotation values and sets the movement of the user in the now a virtual Figure to the movement. Therefore one can move by virtual spaces. This hollow sphere must have a diameter, which is larger than the body height of the person, wishes to use the equipment. Therefore one needs plenty of space, so as to be able to use this device. Since the hollow sphere also has inertia, the abrupt stall is only conditionally possible in the apparatus. [0005] From the US7470218 is a device known, which consists of a curved base platform, on which it executes with special shoes sliding movements. This not the natural walking movements and sliding movements are similar to the movement of the forward movement is equal to the backward movement, therefore the apparatus does not recognise, in which direction it is willing to move. [0006] Further of the present invention are following booklets to extract further remote constructions: US 6135928 A, US5372561A, GB2312273A, US5702307A, [...] and CN201871178 U. [0007] Therefore, the invention is, to provide a device, the the disadvantages of known [...]. Moving means and which extends in said device moving person has not restrict the movement of as much as possible allows latitude of movement despite partial. Space-saving design and simple construction is to be routed through such device A. A reliable and defined connection of the person to the device is to be guaranteed, while at the same time is to be minimized the injury risk. [...] [0008] This problem is solved with a device of the aforementioned type which that the annular part with respect to the platform is movable up and down. [0009] In addition to the degree of rotational freedom of the annular part shall receive a translatory degree of freedom, whereby the applications due to enhanced freedom of movement in the vertical direction will be expanded and at the same time a space saving construction is in particular possible. The first annular part rotates with the person with, i.e. the rotational movements of the person Transferring on the annular portion. The first annular part is dimensionally stable, in particular of rigid material, e.g. a metal or rigid plastic, formed, whereby the necessary stability is achieved. A continuous ring is Preferably, the annular part. However, it would be conceivable also a ring interrupted at a location, e.g. an annular clasp. The first annular member is adapted, to enclose the torso of a person, and serves therefore the coupling of the person to the device. [0010] The first annular member is indirectly connected to the platform, and at these points, and to be movable up and down relative to the latter, so that also the vertical movements of the person, in particular upon erection and jumping, on the annular portion can be transmitted. [0011] Preferably, the device a second annular part on, wherein the plane defined by the first annular portion and the plane defined by the second annular member are substantially parallel to each other and the first annular member within the second annular member about an axis of rotation and attached to, the plane defined by the first annular portion is substantially normal to the is mounted rotatably. In this embodiment, the first (inner) (outer) annular portion rotatably mounted in the second part is annular. This the rotational degree of freedom is achieved of the first annular member relative to the platform on reliable, simple and space saving manner. This means that the second (inner) (outer) ring member surrounds the first annular part and here as a bearing or holder for the first (inner) ring part serves immediate. Even the second (outer) annular part is dimensionally stable, in particular of rigid material, e.g. a metal or rigid plastic, formed, whereby the necessary stability is achieved. Is held by the second (inner) annular part the first Prefers (outer) annular part axially, so that mutual displacement of the two annular parts is blocked in the direction parallel to the axis of rotation. The two annular parts are together to be movable up and down relative to the platform. [0012] Preferably, the second annular part non-rotatably relative to the platform, whereby the first annular part relative to the platform shown clearly defined degrees of freedom for. These degrees of freedom are rotation about an axis of rotation and a translatory movement in the Preferably, substantially parallel to the rotational axis, wherein all other degrees of freedom are blocked. [0013] Preferably, the annular portion rotatably about an axis of rotation relative to the platform, the stands is substantially normal to the plane spanned by the annular part surrounds, whereby rotations of the person about their body axis are possible, the torso of the person when the ring or respectively of the first annular member. [0014] Preferably, substantially parallel to the plane defined by the annular part is the surface of the platform or the angle is at most 45° or a possible angular variation between said planes, preferably at most 30 °, particularly preferably at most 15°. The device can therefore be used in the standing position, and at most during sporting Training body-stressed[...] what is desired. Even the training with respect to the ring plane is possible on a inclined plane. [0015] Preferably, the annular part movable substantially in the vertical direction with respect to the platform movable up and down, wherein preferably the annular part is connected to the platform via a substantially vertical guide. Through this degree of freedom is the jumping and Crouch makes it possible, in particular. A compact construction is ensured. [...] [0016] Preferably, the first annular part relative to the platform in the horizontal fixed with respect to a translatory movement, whereby a spatial displacement of the person in the horizontal direction is prevented. This embodiment is particularly suited in cases where there is little available space requirements. [0017] Preferably, the first annular member for connecting to the first annular part at least on the person a hitch bar. This, for example, can be constructed in the form of a hook. Located on the can by means of a belt the person itself Towing device, rope, belt, a chain or the like. belay. [0018] Preferably, the device to the first annular part on a waist belt for connecting the person, wherein preferably the hip belt comprises at least one length-adjustable connecting strap, which is connected with the first annular part transmits, so that the force caused by the movement of the person on the connecting strap the first annular part. This constitutes a particularly simple solution, since hip straps are obtainable on the market in all arbitrary sizes. connecting belt any suitable connecting means may be used instead of a, e.g. a rope, a chain, a tape etc. [0019] the ring inner diameter of the first annular member is at least 300 mm Prefers, so as to allow a surrounding the hull, in particular of the waist region are gathered breast range a person and/or of the. [0020] the ring inner diameter of the first annular member at most 800 mm is preferred, preferably at most 600 mm. Through this limitation allows upwardly will ensure that the required connections between person and the first annular part not too much room to maneuver. It itself has shown that the most direct transmission of the movement of the person by a short connection on the annular portion is beneficial. Also this solution advantageously acts on the space requirement is from. [0021] at least one sensor device for detecting the movement Preferably, the device and/or the movement sequence and/or the amount of motion of the person picked up from the device on. The by the sensor device can be associated with and evaluated or are processed by a received measurement data or a software for virtual Games training software. The thereby allows e.g. an effective training or a particularly close-to-reality Feedback reached " [...] ". [0022] the device also preferably includes a visual display, particularly a display, a screen or a video eyeglasses , wherein the sensor signals received by the sensor device can be transmitted to a data processing device, which in turn communicates with the visual display (cable-linked or wirelessly). [0023] Preferably, at least along the upper side of the first annular member extends an annular disc and is located in the cavity formed between the annular parts and of the annular disk a bearing, preferably a ball bearing. The disc prevents a contamination of the bearing, and an axial displacement between the annular parts injury risk reduced the blocked at least in one direction. [0024] Preferably, extends along the underside of the annular part an annular disc, which together with the annular disc, the extends along the upper side of the first annular member, bounds the cavity. This the bearing can prevent an axial displacement is even better protected between the annular parts also in the other direction. [0025] Preferably, the annular disc with the first annular part fixedly connected. Preferably, the bearing comprises a plurality of ball bearings, wherein [0026]- at least one ball bearing on the inner side of the second annular member is mounted in such a way that the axis of the ball bearing is substantially parallel to the axis of the annular parts, and the ball bearing contacts the outer side of the first annular member, and [...] [0027]- at least one ball bearing on the inner side of the second annular member is mounted in such a way that the axis of the ball bearing is substantially radially perpendicular to the axis of the annular parts, and the ball bearing the lower side of the annular disc, the extends along the upper side of the first annular member, contacts. [0028] (inner) can move the first part of the ring construction is This with respect to the second (outer) part not axially. Between the annular disk and the second (outer) is Preferably, (seen in the direction of the axis of rotation) a gap formed annular part. [0029] It is preferable for the at least one ball bearing on the inner side of the second annular member mounted in such a way that the axis of the ball bearing is substantially radially perpendicular to the axis of the annular parts, and the ball bearing the upper side of the annular disc, the extends along the underside of the first annular member, contacts. This (inner) can move the first part of the ring construction is with respect to the second (outer) part not axially. Between the annular disk and the second (outer) is Preferably, (seen in the direction of the axis of rotation) a gap formed annular part. [0030] Preferably, on the underside of the annular disk is mounted a spiral having a turn, which has a diameter, which is substantially as large as the diameter of the second annular member. [0031] Preferably, to the second annular member is fixed at at least one point a linkage, the runs obliquely to the plane defined by the second annular member has downwardly and at its outer end a guide structure, preferably a pipe holder, , on an elongated guide, preferably a steel tube is guided. [0032] the guide structure preferably includes a sliding bush of the linkage, the enclosing the elongate guide, wherein the guide takes the form of substantially vertically upwards and secured to the platform is formed tube. [0033] ground stand welded-on sleeve is inserted in the tube a with a Preferably, and are preferably screwed. [0034] ground stand formed on a platform is preferably, from square, equal length forming tubes of steel, which are welded to each other are square is formed, wherein in the center of the square ground stand in addition, shaped tubes, which are arranged in the manner of a cross and are welded to the inner side of the square ground stand centrally, and are preferably centrally on the outside of the shaped tubes of the square shaped tubes screwed equal length ground stand additional, form a flat plane wherein all upper sides of the shaped tubes of the ground stand. [0035] Preferably, the platform by a with PTFE-spray sprayed plate, preferably a stainless steel plate formed, and preferably the plate is screwed on a ground stand. [0036] Preferably, the platform holes for the passage of light rays from optical sensors on. [0037] the apparatus preferably includes a person received from the device for the footwear, which has a low coefficient of friction in conjunction with the platform. [0038] Preferably, the coefficient of friction between the shoe and the platform adapted, so that the person has to utilise for the movements little, but a rotary movement of the person remains possible. [0039] the sensor device preferably includes at least one optical sensor is disposed below the platform, wherein the optical sensor is preferably a computer mouse is directed upwardly at its base. [0040] Preferably, optical sensors of the sensor device arranged in such a way that each [...] Foot motion in each direction of rotation of at least one optical sensor can be identified as the person, and preferably the sensor signal over a USB hub and one Sending USB host Shield to a microcontroller. [0041] preferably includes the sensor device preferably optical distance sensors, are arranged in the region of the platform are formed and for this purpose the, the height of the annular parts and/or the angle of rotation of the first annular part relative to the second annular member to measure. [0042] preferably includes the device for evaluating the sensor signals at least a microcontroller is connected to the at least one sensor device, and that preferably the device has a data processing device, in particular a computer, comprises is connected to the microcontroller. This the sensor data into a corresponding application software can by this be taken into account and fed (training software , computer games). [0043] Preferably, the absolute angle measurement of the first annular part relative to the second annular member by means of a spiral, with a first sensor is detected, and a formed between the sensor signal of the first sensor and the sensor signal is measuring difference of a second sensor, which measures the height of the annular parts, so that this measurement does not affect the axial vertical movement of the annular parts. [0044] In one implementation the invention concerns a device for detecting movements without spatial locomotion for virtual reality systems and exercise (also known as [...] device) consisting of a rotatable and vertically movable ring construction, which a user over a with sensors equipped ground stand fixed. [0045] A embodiment also relates to the fixing process of the user to the inner ring (first annular part) of the ring construction, an absolute angle measuring method of the inner ring of the ring construction, a method for implementation of sliding movements on the base platform and a measurement method for the sliding movements of the feet of the user. [0046] The first annular part of the ring construction is increasing (inner ring) 360 preferably ° about the vertical axis rotate the entire move up and down vertically in a specific range can be axially movable up and ring construction. [0047] A fundamental objective of the present invention is in particular, to describe the necessary system components and their interaction, with which this device can be used as a sports apparatus. Special focus was on the enabling Sport in virtual environments. [0048] A central importance also carries the underlying purpose, to allow a user to be able to carry out certain movements permanently, without via sensors to detect the type of movement and move is situated in a space. [0049] Another objective it was, so to reduce the coefficient of friction between the footwear and the base platform, so that the movements are possible without great effort of the user, but also the rotational movement is possible, which, in turn, at least a slight degree of friction required. [0050] The general possible movements are: move forward, forward skulk, run ahead, sideways skulk, go sideways, run sideways, backwards skulk, go backwards, run backwards, rotate, duck, and combinations of these movements Jump. [0051] A local movement will be realized, by the belt prevents the user, in the space of the engine, and its feet therethrough for a populated with sensors slide base platform. The force, which is needed to prevent the user thereto is received over the connecting belts, with the inner ring (first annular part) of the ring construction which are connected. On the feet of the user specific Footwear, which has very low frictional resistance in combination with the base platform. [...] [0052] it was also important, the movements, which are detected via the sensors to calculate, directly into the device and to transmit to the driver software on the computer. [0053] These is achieved by means of a microcontroller, which the signals of the sensors processed. [0054] Another task it was, to find a way, so as to detect the direction of movement of the hip of the user and to compare with the direction of movement of the user's foot motion. [0055] So that the direction of the hip can be detected with respect to a fixedly defined direction of the device, it was necessary, to find a method, which measures the angle of the inner ring of the ring construction absolutely. [0056] These is realized via an additional ring, which is bent radially on one side is cut through and as a spiral. The bottom of the rotatable inner ring of the ring construction is This spiral mounted by a distance measurement from a and enabling ground stand firmly mounted to the distance sensor, assigning each rotation a distance. Each angle of the inner ring will therefore lead to a variation in distance between spiral and sensor. Here the resolving power of the sensor and the offset of the ends of the spiral is important. So that the vertical movement of the entire ring construction does not affect this angle measurement, provides a second distance sensor, which measures only the height of the ring construction, for a correction of the measurement value. These it is achieved by a subtraction of the measured values of both sensors. [0057] The detecting the foot motion takes place over several mice, directed upwards to the underside of the foraminous base platform are mounted. [0058] It it was, to reduce the weight of the ring construction on the user. This has been achieved via suitable friction against the slide bushes and the vertical sliding rods. By tightening the screw the pipe holder can increase the force, with which the sliding bush presses on the sliding rods. [0059] In the following a preferred embodiment is described more detail with reference to the drawing of the invention. Indeed [0060] Fig. 1 one apparatus of the present invention with a person received therein, [0061] Fig. 2 the first annular member having a hooked strap thereto, [0062] in an exploded view the parts formed by the annular ring construction 3 Fig., [0063] Fig.ground stand without platform 4 the, [0064] the fastening of the connecting rods with the pipe holders 5 Fig., [0065] Fig.ground stand 6 the fastening of the sliding rods with the bushes of the, [0066] Fig. 7 the apparatus of the present invention from the side, and [0067] 9 alternative embodiments of the invention 8 and Fig.. [0068] Fig. 100 1 shows an apparatus of the present invention, e.g. a training device or (Reality) Simulation device or. Moving device for virtual Games is formed. The apparatus 100 serves for receiving at least one person in the device 25 and to partially restrict the movement of the 25 and 7a comprises a platform 100 captured person, the person is on the 25, and a first annular member disposed above the platform 13 or 7a. Ring for enclosing the at least one person is relative to the platform 25 13 rotatably and 7a. The annular part 7a wound onto and downwardly movable with respect to the platform. [...] [0069] In the shown embodiment, the device 100 has a second annular part 12 on, wherein the plane defined by the first annular part 13 and the plane defined by the second annular member 12 are substantially parallel to each other and the first annular member 13 within the second annular member 12 and attached to about an axis of rotation 13a, the stands is substantially normal to the plane defined by the first annular member 13 is mounted rotatably. The second annular part 7a is substantially non-rotatably relative to the platform 12. [0070] The first annular part 7a relative to the platform 13 is 13a rotatably about an axis of rotation, substantially normal to the plane spanned by the annular part 13 stands (Fig. 2). In the shown embodiment, by the first annular part 13 stands in Fig. 1 substantially parallel to the surface of said platform plane spanned 7a. [0071] The annular part 7a substantially in the vertical direction with respect to the platform 13 is wound onto and downwardly movable, wherein the annular part 13 via a substantially vertical guide in the form of sliding rods 7a is connected to the platform 6. The first annular member 13 is thereby relative to the platform with respect to a translatory movement in the horizontal fixed 7a. [0072] The apparatus 100 has at least one sensor device (e.g. distance sensors 8, 9 and/or optical (Moving) sensors in the region of the platform and/or laterally positioned sensors 7a) for detecting the movement and/or of the movement sequence and/or the amount of motion of said 25 100 captured person from the device on. [0073] Furthermore, are in the preferred embodiment of 1 to see Fig.: the ring construction with which the person 25 fixed 1, the spiral 3 for measuring the angle of the first annular part 1 (inner ring) of the ring construction 13, the connecting rods or. Linkage 4, which connects with the pipe holders 1 5 the ring construction, the presses the slide bushings 16 to the vertical sliding rods 6 in turn, the sliding rods 6 via a welded-on sleeve 7 on which the vertical ground stand or. Sleeve 17 are connected, the base plate 2, which is screwed to the 7a forms ground stand and the platform 7, on which it will then moved, the optical distance sensor 8, which measures the height to the worm 3, the optical distance sensor 9, which measures the height of the ring construction (e.g. with respect to the platform) 1, the special shoes 27, which are disposed on a low friction on the bottom plate 2, the USB cable 22 21 for connection of the device to the computer, and a display in the form of a 26 [...] displays. [0074] 23 connected to the rotatable inner ring 2 shows the belt Fig. 13 of the ring construction 1, which the person 100 fixed with the device 25. Here are highlighted: The belt 23, 24 via the connecting belts 13 is connected with the hooks 15 of the inner ring, the ball bearings 14, which enable the rotation of the first annular member (inner ring) 13 (outer ring) 12 within the second annular member. [0075] 3 shows an exploded view of the ring construction are highlighted Fig. 1st Here: the inner ring 13, and a lower disc 10 to which a upper disc 11 are mounted, the ball bearings 14, 15 in the form of hooks for attaching the person the Towing device 25, and the outer ring 12 by the rings 12 are ball bearings in the. The, 13 and the discs 10, 11 formed annular cavity. [0076] Fig.ground stand 4 shows the 7 without-mounted base platform. The ground stand 7 is screwed to the base platform and has holes for the optical sensors, which measure the foot movements. Here emphasised: the ground stand 7, the optical distance sensor 8 for measuring the height to the worm 3, the optical distance sensor 9 for measuring the height of the ring construction 1, the optical sensors 19 for measuring the movements of the feet, a USB-stroke 18, which forwards the signals of the optical sensors 20 19 to a microcontroller, a USB cable 21 for connecting the device to a computer 22. [0077] Fig. 5 shows the connecting rods, which by means of a screw having the [...] lha are connected 5. This pipe holders fix the slide bushes 6 5 16 to the vertical sliding rods emphasised. Here: the connecting rod or. Linkage 4, the pipe holder 5, the sliding bush 6 and the slide bar 16. [0078] 6 shows the fastening of the sliding rods 6 with the 7 ground stand Fig.. The sliding rods into the sockets or 6 in this case are. Sleeves 17 inserted, which are welded to the 7 ground stand , and there additionally fixed with a screw. Here are highlighted: the slide bar 6, the bushing or. Sleeve 17, the ground stand 7. [0079] Fig. 7 shows the device 100 from the side and the measuring beams of the sensors, which measure the height of the ring construction 3 to the worm 1 and the height. Here are highlighted: 1 the ring construction, the spiral 3, 4 the connecting rods, the sliding rods 6, 7 the ground stand , the optical distance sensor 8 for measuring the height to the worm, the optical distance sensor 1 9 for measuring the height of the ring construction. [0080] Below this embodiment, a detailed description is carried out: [0081] The apparatus 100 consists of a (Subtle) belt 23, a platform 1 7a and a ring construction, which preferably are connected with each other via sliding bushings and/or hooks. [0082] base platform: [0083] Theground stand 7 comprises a base platform, a bottom plate 2, and the electronics of the device 100. The bottom plate 2, the the platform consists of square stainless flat steel 7a forms, which has four small holes. The diameter of these holes is preferably about 4 mm, just enough that the optical sensors 25 can detect the person's feet under said table. The placement of these holes is at a distance of about 130 mm square, so that at each direction of movement is detected always at least one foot. This the coefficient of friction between the plate and the shoe of the user is reduced, the plate is still sprayed with PTFE-spray. The ground stand 7 is screwed with screws at the corners to the plate. The ground stand 7 consists of square equal length forming tubes of steel, which are welded each other square. In use, not too much to make the bottom plate are located in the center of the square ground stand bends in addition, shaped tubes are arranged as a cross. 7 and, to the inner side of the shaped tubes This ground stand 7 centrally welded square. Align Middle on the outside of the shaped tubes 7 are screwed four additional ground stand of the square shaped tubes of equal length. All upper sides of the shaped tubes ground stand form a flat plane at the top of the. 17 which are welded to the four short sleeves are upwardly directed outer forming tubes. Those four sleeves 17 round steel tubes are of equal length and be stuck 6 6. This tubes 17 additionally screwed to the sleeves. In the inner forming tubes, which are arranged as a cross, four optical functional (e.g. by the company A4Tech; model N -350) are mice square mounted arranged. The bottom side is directed upwards and forms these mouses ground stand a flat surface with the upper side of the. The arrangement is so adapted that the optical light beam through the holes of the bottom plate is lit the clickers. 18 and 20 are still a USB-stroke in addition a microcontroller 7 (e.g. [...] microcontroller), to the inner side of the mounted ground stand. The four mice connected to the USB-stroke be 18 via a USB host 18 and the USB-stroke Shield to the microcontroller. On one of the four outer shaped tubes 7 are located two optical distance measuring sensorsground stand of the 8, 9 (e.g. distance-sensor GP [...] Sharp 2 Y0A 02), which are evaluated by means of triangulation principle or work. One of these sensors is directed vertically upwards just before the sleeve 17 and the other mounted in the vicinity of the connection with the square frame of the forming pipe. Also this is directed vertically upwards. This two sensors are connected to the microcontroller also. In the microcontroller 20 and this cable is then used for a USB is connected-cable communication with the computer 22. [...] [0084] 1 ring construction: [0085] The 1 consists of an inner rotatable part 13 and an outer ring construction fixed part 12. [0086] The inner rotatable part preferably consists of a aluminium ring and two annular disks 13 10, 13 and 11. The inner diameter of the first or inner ring the inner diameter of the two annular disks 10, 11 is the same size. The outer diameter of the two discs 10, 11, however is larger than that of the ring. The cross-section of the inner ring 13 is rectangular, wherein the shorter side is at the top and bottom. The two discs 10, 11 are screwed to the inner ring 13 at the top and bottom, respectively. The outer part of the ring construction 12 (outer) ring 1 consists of a second, at which are located outside and inside, for example fifteen ball bearing 14 are fixed at four points square aluminum-around-shaped tubes. The cross-section of the outer ring 12 is preferably square, wherein the side length of the square is shorter than the vertical longer side of the cross-section of the inner ring 12 of the outer ring 13 is for example by about. The inner radius 20 mm greater than the outer radius of the inner ring 13, 14 of an external diameter so that ball bearing 19 mm place in the space of the rings 12, 13 have. This that the side length of the cross-section of the outer ring 12 is shorter than the side length of the long side of the cross-section of the inner ring 13, the outer ring 12 fits between the two discs 10, 11, which have been screwed on the inner ring 13. [0087] 12 is welded to the inner side of the outer ring a round steel. This serves as fixing for the ball bearings 14 is round steel round steel welded in three different ways. The, so that three positioning possibilities for the ball bearings 14 result. At the first type of round steel is welded to the inner side of the outer ring 12 so that the axis of the ball bearing 14 parallel to the axis of the rings 12, 13 and 14 the outer side of the inner ring is 13 contacts the ball bearing. This operation is at six points over the entire circumference of the ring 12 distributed carried out. These allows the rotation of the inner ring 13 now. [0088] In order with respect to the outer part 13 of the ring construction the inner portion 1 12 cannot move axially is welded to, for example, nine locations on the inner side of the outer ring 12 of the round steel so that the axis of the perpendicular to the axis of the outer ring 14 radially mounted ball bearing 12 shows. These posts are also uniformly distributed over the circumference. At e.g. six of these points, it welded to the inner side of the outer ring 12 so the round steel that the ball bearings contact the internal face of the upper disc 14 10 10 and upper side of the outer ring contact and a gap between disc is 12, so that disc 10 and ring 12 not. At e.g. three of these locations is so welded the round steel, so that the ball bearings 11 14 the upper side of the lower disk 12 is a gap between disc 11 and ring contact and contact, so that disc 11 and ring 12 and bottom of not. [0089] The four square shaped tubes at the outer side of the outer ring with the outer ring 12 are rigidly connected by a screw 12. 45 degrees in about an angle of downward are shaped tubes This inclined and at the outer ends of these shaped tubes are 5 screwed pipe holders. This pipe holders are mounted on the four round steel tubes 5 via a PTFE sliding bush 6 the base platform 16. The pipe holders 16 on the PTFE sliding bushes 5 press, which press on the round steel tubes 6 in turn. By varying the pressing force of the tube holders 16 and the friction between the PTFE sliding bushes 5 can be 6 vary the steel pipes. The shaped tubes are exactly as long that, in the lowermost position of the slide bushings 16 and 17 where the PTFE ring construction the sleeves contact 1, a height for the lower disc 13 of about 550 mm yields 11 of the inner part. [0090] On the inside of the inner portion 1 are screwed four hooks 13 of the ring construction, which are distributed uniformly over the circumference and serve as Towing device. 23 serve for fixing the hook (Subtle) belt. This At the lower side of the [...] ren disc 1 is located a spiral 11 of the inner member 13 of the ring construction (e.g. plastic) 3 whose outer diameter as large as the diameter of the disc 11 has exactly one turn and was talking about a 3. The spiral 160 mm offset of say. The spiral 11 is screwed at four points to the disk 3 by suitable connector fittings from aluminum round steel. [0091] Thespecial belt : [0092] Thespecial belt is made additionally have been sewn to the four connecting belts on a commercially available Climbing harness 24. The length of these connecting belts and at their ends is located a steel ring 24 can be vary. The placing of the four connecting belts 23 24 is distributed uniformly over the circumference of the belt. The (climbing) [...]shoulder adjustmentleg adjustment but no 23 has only one and a belt. Zum connecting the person 100 with the device 25, the belt 23 is tightened, the steel rings are mounted to the respective hook 24 the connecting belts and the length of the four connecting belts 24, which connect the belt 1 23 with the ring construction, shall be reduced in such a way that the connecting belts are tensioned firmly 24. Now the connecting belts 24 can receive the forces, which arise during the movement in the device 100 by the user. [0093] measuring technique: [0094] This user can make best use of the apparatus with different body height 100, one must the apparatus, in particular the sensor device together with the evaluation device as a first calibrate. [0095] foot movements: [0096] If the user wants on the base platform Getting Around, it prevent the four tensioned connecting belts 24 thereto, so that its feet are scheduled to start, to slide on the bottom plate. This that small holes are arranged on this plate and including the optical mouses is recognized at least one foot on said sliding on these holes through the clickers. The signals the clickers, which movements have registered, Sending 20 to the microcontroller. This calculates a direction and speed of movement now. This data is transmitted over the USB cable to the driver software of the computer 22. [0097] position of the inner part 13 of the ring construction 1: [0098] The outer distance sensor 1 measures the distance to the base platform for forming tube 9 the ring construction, which is connected with the pipe holder 5, and the signal gives the microcontroller 20 further. This signal is used, to register ducking movements[...]. This movements of arrival by axial upstream and down-displacement of the ring construction is a certain height value 1st After the calibration established and by comparing the value with the height value is detected from the outer distance sensor 9, whether the user thinks or jumps. The inner distance sensor 3 measures the distance to the worm 8 and the signal gives the microcontroller 20 further. [0099] By rotation of the inner part 13 of the ring construction is changing the distance between the inner 8 and distance sensor 1 3 of the spiral; thus one can measure the angle of the inner member 13 to the outer part 12 of the ring construction absolutely 1. In order to take into account an optionally is formed due to the axial booms and 8 1 corrupted measured value of the downlink movements of the ring construction with respect to the worm distance sensor inner 3, a difference of the values between the two distance sensors 8, 9. That assembly will ensure can be detected that each angle, wherein each possible height position of the entire ring construction 1. [00100] The microcontroller 20 transmits these values to the driver software on the computer 20 from driver software evaluates the data of the microcontroller 22. The the set and then presents further commands to the software, which is reacted together with 100 wishes to use the device. [...] [00101] 8 and 9 show alternative embodiments of the invention's Fig.. (Outer) ring of the first annular part is instead a second annular segments 28 and rotatably mounted 13 held by parts. [00102] Fig. 8 shows a construction with two parts in the form of a ring segment 28, the receiving face each other and said first annular part 3 between them. The 13 is T-shaped cross-section of the first annular member, while the cross-section of the part in the form of a ring segment 28 is U-shaped the annular portion (13) surrounds. [00103] Diversely oriented bearing (B-B A-A and cut cut), i.e. with differently oriented axes, 13 and 18 to prevent or restrict a mutual displacement in the axial direction and in the radial direction of the parts. [00104] The plane defined by the first annular portion and the plane defined by the form of a ring segment parts 13 28 are substantially parallel to each other and the first annular member 13 is in the form of a ring segment 28 about an axis of rotation to the parts 13a, the stands 13 is substantially normal to the plane defined by the first annular member, rotatably supported. Here the form of annular segments 28 relative to the platform part is non-rotatably and 7a to be movable up and down together with the first annular part 13 (not shown in 8 Fig.). [00105] In Fig. 9 of the first annular member has a 13 H-shaped cross-section and it is only [...] part 28 provided. As A-A from the cuts, are three differently oriented bearing B-B and C-C to see, i.e. with differently oriented axes necessary, in order to prevent a mutual displacement of the parts 13 and 28/limit. [00106] To 9 with respect to the part in the form of a ring segment 28 from Fig. a rotation of the platform to prevent the case of only one (vertical) guide rod 7a also, an elongated groove (milled) could be introduced in the guide rod, the co-operates with a projection extending into the groove (non-rotatably) a slide bushing. Possible would also be the providing a second guide rod, wherein the two associated slide bushes are connected rigidly to each other. [00107] 8 and 9 are made in The benefits to the variants represented in particular in the material saving Fig. and the associated weight reduction for the user. [00108] It is pointed out expressly thereon that the with respect to the second annular member 12 disclosed characteristics, in particular its connections with the platform 7a, can be applied also for the ring segment-like member 28 applies or analogously. [00109] The described device is only one of many possible variants of the invention constitute. The invention is by no means limited to the described embodiments and aspects highlighted by the therein. invention thought a plurality of modifications possible within the Rather, the professional action fall within the limits. Also it is possible, by combining the above-mentioned means and characteristics to realize further embodiment variant, without the scope of the invention to leave. The invention relates to a device (100) for accommodating a person (25) and for partially limiting the freedom of movement of the person (25) accommodated in the device (100), comprising a platform (7a) and a first annular part (13) arranged above the platform (7a) for surrounding the at least one person (25), wherein the annular part (13) can be rotated in relation to the platform (7a), wherein the annular part (13) can be moved up and down in relation to the platform (7a). 1. device (100) for receiving at least one person (25) and for partial Restricting the freedom of movement of the in the device (100) received person (25), with a platform (7a) and a above the platform (7a) arranged first annular part (13) for enclosing the at least one person (25), wherein the first annular member (13) relative to the platform (7a) is rotatable, characterized in that the first annular part (13) indirectly with the platform (7a) is connected with respect to the platform and (7a) is movable up and downwardly movable. 2. apparatus according to claim 1, characterized in that the device (100) a second annular part (12) has, wherein by the first annular part (13) and the plane defined by the second annular member (12) substantially parallel to each other and the plane spanned first annular member (13) within the second annular member (12) and attached to about an axis of rotation (13a), the stands from the first annular portion is substantially normal to the (13) plane spanned is mounted rotatably. 3. apparatus according to claim 2, characterized in that the second annular part (12) relative to the platform (7a) is prevented from rotating. 4. device according to one of the preceding claims, characterized in that the first annular part (13) relative to the platform (7a) about an axis of rotation (13a) is rotatable, the stands from the first annular portion is substantially normal to the (13) plane spanned. 5. device according to one of the preceding claims, characterized in that the from the first annular part (13) substantially parallel to the surface of said platform plane spanned (7a) is. 6. device according to one of the preceding claims, characterized in that the first annular part (13) with respect to the platform (7a) is movable substantially in the vertical direction wound onto and from, wherein preferably the first annular member (13) to the platform via a substantially vertical guide (7a) is connected. 7. device according to one of the preceding claims, characterized in that the first annular part (13) relative to the platform (7a) is fixed with respect to a translatory movement in the horizontal. 8. device according to one of the preceding claims, characterized in that the first annular part (13) at least one Towing device (15) for connection of the person against the first annular part (13) has. 9. device according to one of the preceding claims, characterized in that the device (100) a waist belt (23) for connection of the person (25) to the first annular part (13) has, wherein preferably the hip belt (23) at least one longitudinally adjustable connecting means, in particular a connecting strap (24), comprises, which transmits to the first annular part (13) is connected, so that the connecting means (24) by the motion of the person (25) on the first annular member force caused (13). 10. device according to one of the preceding claims, characterized in that the ring inner diameter of the first annular member (13) is at least 300 mm. 11. device according to one of the preceding claims, characterized in that the ring inner diameter of the first annular member (13) at most 800 mm, preferably at most 600 mm is. [...] 12. device according to one of the preceding claims, characterized in that the device (100) at least one sensor device for detecting the movement and/or of the movement sequence and/or the amount of motion of said from the device (100) received person (25) has. 13. device according to one of claims 2 to 12, characterized in that at least along the upper side of the first annular member (13) an annular disc (10) extends between the annular parts and that, in the (12, 13) and the annular disc (10) cavity formed a bearing, preferably a ball bearing (14) is located. 14. device according to claim 13, characterized by that extends along the underside of the annular part (13) an annular disc (11) extends, which together with the annular disc (10), the extends along the upper side of the first annular member (13), bounds the cavity. 15. apparatus according to claim 13 or 14, characterized in that the annular disc (10, 11) with the first annular part (13) is connected fixedly. 16. device according to one of claims 13 to 15, characterized in that the bearing more ball bearing (14) comprises, wherein -at least one ball bearing (14) are mounted on the inner side of the second annular member (12) is mounted that the axis of the ball bearing (14) substantially parallel to the axis of the annular parts (12, 13) is, and the ball bearing (14) the outer side of the first annular member (13) contacts, and -at least one ball bearing (14) are mounted on the inner side of the second annular member (12) is mounted that the axis of the ball bearing (14) substantially radially perpendicular to the axis of the annular parts (12, 13) is, and the ball bearing (14) the lower side of the annular disc (10), the extends along the upper side of the first annular member (13), contacts. 17. device according to claim 16, characterized in that the at least one ball bearing (14) are mounted on the inner side of the second annular member (12) is mounted that the axis of the ball bearing (14) substantially radially perpendicular to the axis of the annular parts (12, 13) is, and the ball bearing (13) the upper side of the annular disc (11), the extends along the underside of the first annular member (13), contacts. 18. device according to one of claims 14 to 17, characterized by that on the underside of the annular disk (11) a spiral (3) mounted with a single turn coil, which has a diameter, which is substantially as large as the diameter of the second annular member (12). 19. apparatus according to one of claims 2 to 18, characterized in that at the second annular part (12) at at least one point a linkage (4) is fixed, extends from the second annular member has the oblique to the (12) downwardly and at its outer end a guide structure plane spanned, preferably a pipe holder (5), , on an elongated guide, preferably a steel tube (6) is guided. 20. device according to claim 19, characterized in that the guide structure of the linkage (4) a sliding bush (16) comprises, the enclosing the elongate guide, wherein the guide takes the form of substantially vertically upwards and to the platform (7a) fixed tube (6) is formed. 21. apparatus according to claim 20, characterized in that the tube (6) into a with a ground stand (7) welded-on sleeve (17) is screwed and preferably plugged. [...] 22. apparatus according to any one of the preceding claims, characterized in that the platform (7a) on a ground stand (7) is formed, from square, equal length forming tubes of steel, which are welded to each other are square is formed, wherein in addition, in the center of the square shaped tubes ground stand (7), which are arranged in the manner of a cross and, to the inner side of the square ground stand (7) are welded centrally, and that preferably centrally on the outside of the shaped tubes ground stand of the square (7) additional equal length are screwed shaped tubes, wherein all upper sides of the shaped tubes of the ground stand (7) form a flat plane. 23. apparatus according to any one of the preceding claims, characterized in that the platform (7a) by a with PTFE-spray sprayed plate (2), preferably a stainless steel plate formed is, and preferably the plate (2) on a ground stand (7) is screwed. 24. apparatus according to any one of the preceding claims, characterized in that the platform (7a) has holes for the passage of light rays from optical sensors. 25. apparatus according to any one of the preceding claims, characterized in that the device (100) for the from the device a Footwear (100) received person comprises, which in conjunction with the platform (7a) has a low friction coefficient. 26. apparatus according to claim 25, characterized in that the coefficient of friction between the shoe and the platform (7a) is adapted in such a way, so that the person (25) little has to utilise for the movements, but a rotary movement of the person (25) remains possible. 27. apparatus according to one of claims 12 to 26, characterized in that the sensor device at least one optical sensor (19) comprises, below the platform (7a) is arranged, wherein preferably the optical sensor is a computer mouse is directed upwardly at its base. 28. apparatus according to one of claims 12 to 27, characterized by that optical sensors (19) of the sensor device are arranged in such a way that each foot motion of the person (25) in each direction of rotation of at least one optical sensor (19) is recognizable, and that preferably the sensor signal over a USB-stroke (18) and a USB host to a microcontroller Shield (20) is sent. 29. apparatus according to one of claims 12 to 28, characterized by that the sensor device preferably optical distance sensors (8, 9) comprises, in the region of the platform (7a) are arranged are formed and for this purpose, the height of the annular parts (12, 13) and/or the angle of rotation of the first annular member (13) relative to the second annular member (12) to measure. 30. device according to one of claims 12 to 29, characterized by that the device (100) for evaluating the sensor signals at least one microcontroller (20) comprises, with the at least one sensor means is connected comprises the, and that preferably the device (100) a data processing device, in particular a computer (22), , to the microcontroller (20) is connected. 31. apparatus according to one of claims 12 to 30, characterized by that the absolute angle measurement of the first annular part relative to the second annular member by means of a spiral (3) takes place and that is formed with the sensor signal of a second sensor a measuring difference , which measures the height of the annular parts (12, 13), so that the axial vertical movement of the annular parts (12, 13) does not affect this measurement. [...]" [...] 32. apparatus according to any one of the preceding claims, characterized in that the device (100) at least one ring segment-like member (28) has, wherein by the first annular part (13) and the plane defined by said at least one ring segment-like member (28) substantially parallel to each other and the first annular member plane of the cutting edge (13) to the at least one ring segment-like member (28) about a rotation axis (13a), the stands from the first annular portion is substantially normal to the (13) plane spanned is mounted rotatably, and that preferably the ring segment shaped portion (28) relative to the platform (7a) is prevented from rotating. 33. apparatus according to claim 32, characterized by that the first annular part (13) at two parts in the form of a ring segment (28) is mounted, the part-parts (28) are opposed to each other. 34. apparatus according to any one of the preceding claims, characterized in that the first annular part (13) T-shaped cross-section. 35. apparatus according to any one of the preceding claims, characterized in that the first annular part (13) H-shaped cross-section. 36. apparatus according to one of claims 32 to 35, characterized in that said at least a segment of a ring part (28) U-shaped cross-section, and the first annular member (13) at least in part by the form of a ring segment [...] of the part (28) is surrounded. 37. apparatus according to one of claims 32 to 36, characterized by that the bearings, in particular ball bearings, between the first annular part (13) and ring segment-like member (28) a mutual displacement in the axial direction and in the radial direction prevent or at least limit. Description