Memory device.

[0001] The invention concerns a memory device for a temporary storage of objects, like substrates, planned for the production of semiconductor components, wafer, Reticles, and such a thing, whereby the memory device exhibits a housing, which encloses an interior, which is provided with a lockable opening housings, by the objects into the housing importable and from the housing is executable, with a pure space mechanism for production and maintenance is provided by pure space conditions within the housing, exhibits a handling mechanism within the interior, by means of which objects are manageable in the interior, and a multiplicity of stock piles for the arrangement of objects in open transportable memory means aufweist.

Basis for the production of electronic construction units are in certain way prozessierte substrates, like disks, glass plates or such a thing. Disks, in particular silicon wafers, are usually called in this connection wafer. For the production of electronic elements these substrates must go through different process stages to their surface processing. For example raw wafer (wafer unprozessierte) are manufactured and usually stored temporarily and transported between going through individual process stages in transport containers. So that the individual process stages supply good results of working, it is frequently necessary to stop process parameters. In many cases the optimal process parameters are empirically determined, gone through into first so-called test wafer the treatment processes. On the basis their condition after or the suitable parameters know the repeated going through of the treatment processes under attitude of different values derived and afterwards Produktions-Waferdie of processes durchlaufen.

Both Testals also production wafer must be inserted for transport to the actual treatment process as wafer pile in a transport container. The amount of the wafer planned in a container also “batch” (pile) is called. The batch size is standardized and amounts to usually 25 (or 13) wafer. The Batches is usually arranged for the individual processes and the individual processing units zugeführt.

For this already memory devices with a housing are well-known, which would drive out with at least a lockable opening to Einund from objects, like Wafern, and at least a robot arranged within the housing for handling the wafer is provided. Such memory device exhibit besides in matrix fashion arranged stock piles, in which the objects can be stored temporarily temporarily, until they are again needed in production. There the objects often batch (batchweise) in production to be processed, are already memory devices admit become, with which piles (batches) can be arranged and implemented by objects within the memory device. This possibility exists for example with the WHERE 02/05 320. In such gattungsgemässen memory devices the objects are openly stored and handled. For this reason it is necessary that inside the housing pure space conditions will keep created and upright. Usually large Ventilatorund filter units is intended for this on the roof of the memory device, with which large quantities of air are sucked in and cleaned from above the inside the housing. Since it is aimed at that an air flow flows not several times over stored objects and carries by it particles of an object on the other hand, is necessary extensive gas guidance elements, with those inside the housing pre-determined Luftbzw. Gas flows over the objects to be led. Despite these technically complex air guidance measures a cross contamination cannot be excluded from an object to another. Besides maintenance work requires of the central pure space mechanism a comparatively large expenditure, in particular must measures be met, with it the disconnection of the pure space mechanism not for pollution openly stored objects führt.

In accordance with a first aspect for the invention the task is appropriate at the basis a possibility for a memory device of the kind initially specified to therefore create, by still better the impurities of openly stored objects from the manufacturing of electronic construction units avoids itself leave

This task is solved during a memory device of the initially specified kind-according to invention by the fact that the pure space mechanism is provided by filter ZLüftereinheiten with a majority, which are assigned to only in each case certain stock piles. By the use a multiplicity of individual and in particular autonomous fan/filter units can fail this now clearly smaller than the very voluminösen fan/filter units arranged used so far in a central place. Thus again an arrangement of filter ZLüftereinheiten is in the interior of the memory device and in particular possible with the camp blow-out directly, which the distance, which an air flow shortens needs for reaching camp objects, clearly. From there only small flow rates must be produced and be led only over short distances in pre-determined way compared with past solutions. The shortened distances lower also the probability the fact that the air flow on its way to an object particles take up and then one that object with in such a way taken up particle contaminates kann.

Also decentralized lonisationssysteme can be avoided by such a solution according to invention, since the air flow speeds of produced pure air are kept small due to smaller ways which can be put back and so a loading the washed wafer be avoided can. Possible an in principle avoidance of lonisationssystemen can lead to a substantial reduction of the technical expenditure of gattungsgemässen memory devices. In this connection their automatic exchange can be intended against other memory means also after a pre-determined meter time by memory means. The memory means know e.g. to CH 699,754 Al of their cleaning or, there it preferably around standard carrier act also inclusive. To reload wafer and without these, for bringing into the production process from the memory device implemented werden.

These advantages particularly come in a preferential execution form of the invention to carrying, with which exactly a filter ZLüftereinheit is assigned to each individual stock pile for a memory means. With this execution form thus each stock pile has its own filter ZLüftereinheit for the production of a pure air flow.

A particularly preferred solution according to invention can plan that the fan ZFiltereinheiten behind in each case a stock pile is arranged and flows through these from outside to inside in the direction of a center of the memory device with an air flow, in particular an essentially horizontal aligned air flow. Such a solution presents itself in particular with regarding a sketch a symmetrical, for example, arrangement of stock piles to a circular within the memory device. Since with this solution none of the air flows meets another filter ZLüftereinheit a stock pile, is here a cross contamination of objects with particles from other objects assigned air flows particularly gering.

Furthermore it is preferential, if the filter ZLüftereinheiten is designed as autonomous modules, which are fastened to the stock pile solvable and can if necessary independently of remaining components of the respective stock pile be exchanged. An appropriate easy expandability of memory devices according to invention can be obtained thereby if besides a filter ZLüftereinheit as well as one or more stock piles for one or more memory means as exchangeable building group is designed. Likewise it can be intended the fact that several stock piles are assigned exactly to one of several filter ZLüftereinheiten and these several stock piles and some filter ZLüftereinheit is designed as exchangeable building group. Such building groups can be characterised by the fact that they can to accept and for their one or for their several stock piles an individual air supply place standard carrier surely. In addition they can make a mechanical to-ZAbdock-possibility possible between a carrier and the filter ZLüftereinheit with advantage. With such positioning aids the memory means can be positioned also during an automated handling surely and reproducibly in pre-determined positions before the respective filter ZLüftereinheit. By training of such complete stock piles as building group, into which one or more FilterZLüftereinheiten can be also integrated, the thereby developing camp modules can in addition also in another connection than the memory device according to invention be used, for example also for manually fed shelves for memory means, like open Carrier.

In a further favorable execution form the memory device can be with one or more pressure sensors provided, with on the basis of measured printing values within the memory device the controlling of the filter ZLüftereinheiten made wird.

In accordance with a second aspect the task is appropriate for the invention at the basis at as little an expenditure as possible a safe positioning of the handling mechanism before the respective stock piles and their photographs for individual objects too ermöglichen.

This task is solved according to invention during a memory device of the kind initially specified by the handling mechanism provided with detection means, which are intended both for the recognition of position information of the respective stock pile and for the recognition of individual objects in the memory means. In particular with means for the recognition of position information of the stock piles can be made fully automatic Teach in procedure by means of the handling mechanism. Differently than with before-well-known solutions for this no manual interferences of an operator are necessary. Nevertheless surely the positions of the stock piles can determined and in a control put down werden. with the solution according to invention fast, exactly and

From the conditions of the technology hardly memory devices are well-known, which makes inside possible a handling in their by both the memory means and individual objects stored by to be able to arrange for example in order piles of objects. With the well-known memory devices, which make this possible are for this several robots within the memory device intended, what increases however the space requirement (Footprint) of the memory devices in a factory. Besides this increases the volume within the memory device, in that pure space conditions to be created müssen.

In accordance with a further aspect therefore the task is appropriate for the invention at the basis with as small a space requirement of the memory device as possible a large flexibility regarding the handling within the memory device from objects to ermöglichen.

This task is solved during a memory device of the kind initially specified according to invention by the fact that several Endeffektoren at only the handling mechanism are automated exchangeable. By several EndeffektorenZGreifer within the memory device and by of them automated exchange at the handling mechanism further handling mechanisms can be avoided within the memory device, without having to do thereby without functionality of the memory device in surprisingly simply way. On the contrary, by arbitrary extension of the handling mechanism with Endeffektoren their functionality can 699,754 Al be extended soCH like the functionality of memory devices according to invention in a simple manner. So for example different types can be provided with stock by Wafern at the same time in the memory device and handled by means of different grip arms. Thereby a cross contamination of the different wafer types can be avoided. Besides the renouncement of further Handhabungsvorrichtungen reduces the utility space needed by the memory device within a Fabrik.

In a preferential execution form of the invention the handling mechanism can exhibit a Endeffektor, which is provided by stock piles with detection means for detection by position information. With this detection means in particular on the basis a positioning by geometrically pre-determined detection objects of the stock piles in a Teach in step position information about the individual stock piles of the memory device can be communicated and put down to a control. In this way determined position information can be used in the following, in order to start with the handling mechanism the respective stock piles. In a preferential execution form of the invention the detection means can be at a Endeffektor attached, that additionally provided with handling means, as a grip arm, ist.

In a further preferential execution form of the invention the handling mechanism can with a exchangeable Endeffektor for the handling by in each case individual wafer as well as provided with a likewise changeable Endeffektor for the handling by memory means, as a carrier, sein.

Further preferential arrangements of the invention result from the requirements, the description and the Zeichnung.

The invention is more near described on the basis of remark examples represented purely schematically in the figures, it to show:

a memory device according to invention; the memory device from Fig. 1 in a partly cut representation; a part of the stock piles of the memory device with Carriem, arranged planned in rows and columns, therein; two base plates of stock piles as structural unit; the base plates from Fig. 4 also Carriern arranged on it; a stock pile with Carrierund filter ZLüfereinheit in a side view; the stock piles from Fig. 3 in an opinion from the rear; the stock pile from Fig. 6 in a ISO-metric representation; a Teach in Endeffektor with integrated wafer single grip arm; a Endeffektor for a robot for the handling of wafer Carriern; a rack also on, it drive outable from the housing of the memory device, arranged robot and Ein-ZAusgabestationen.

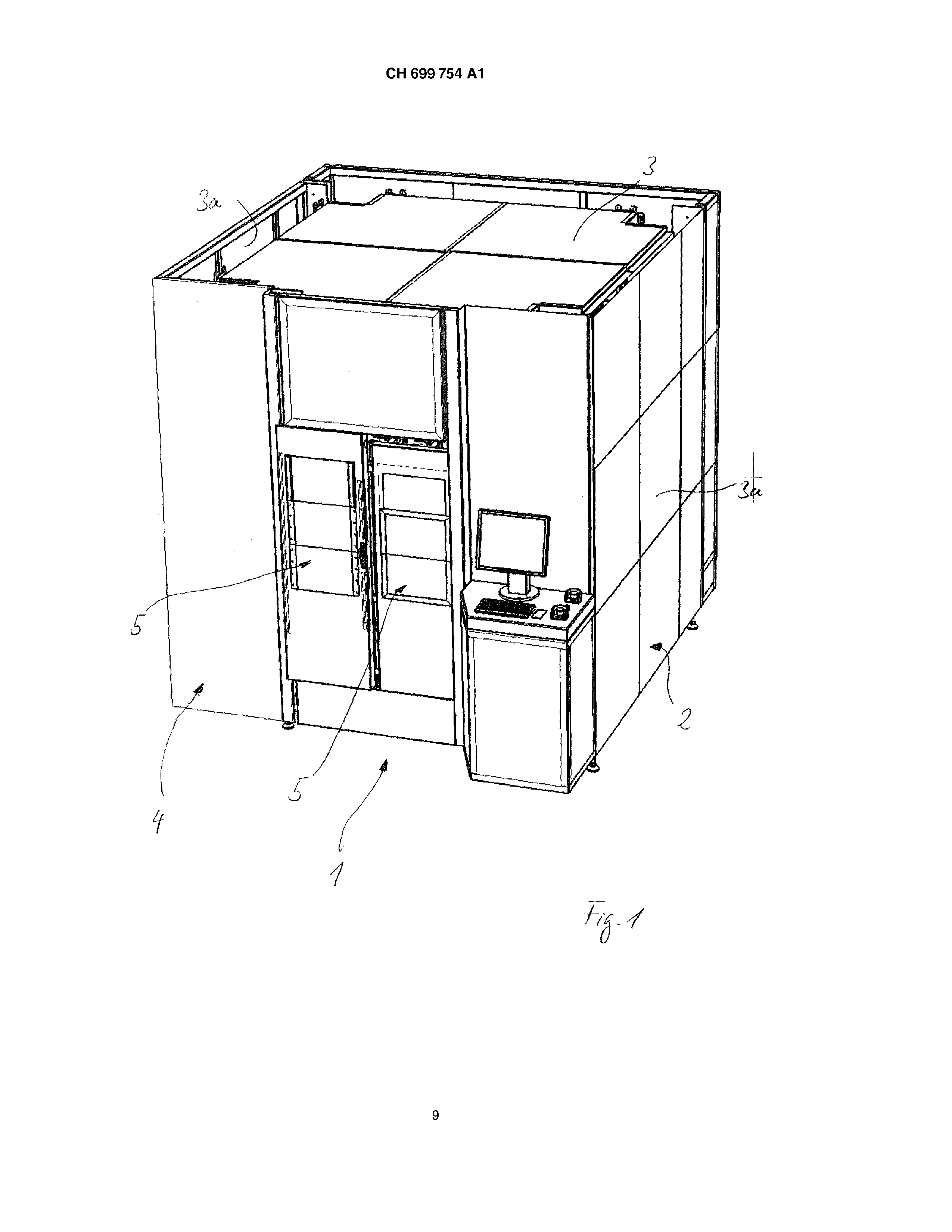

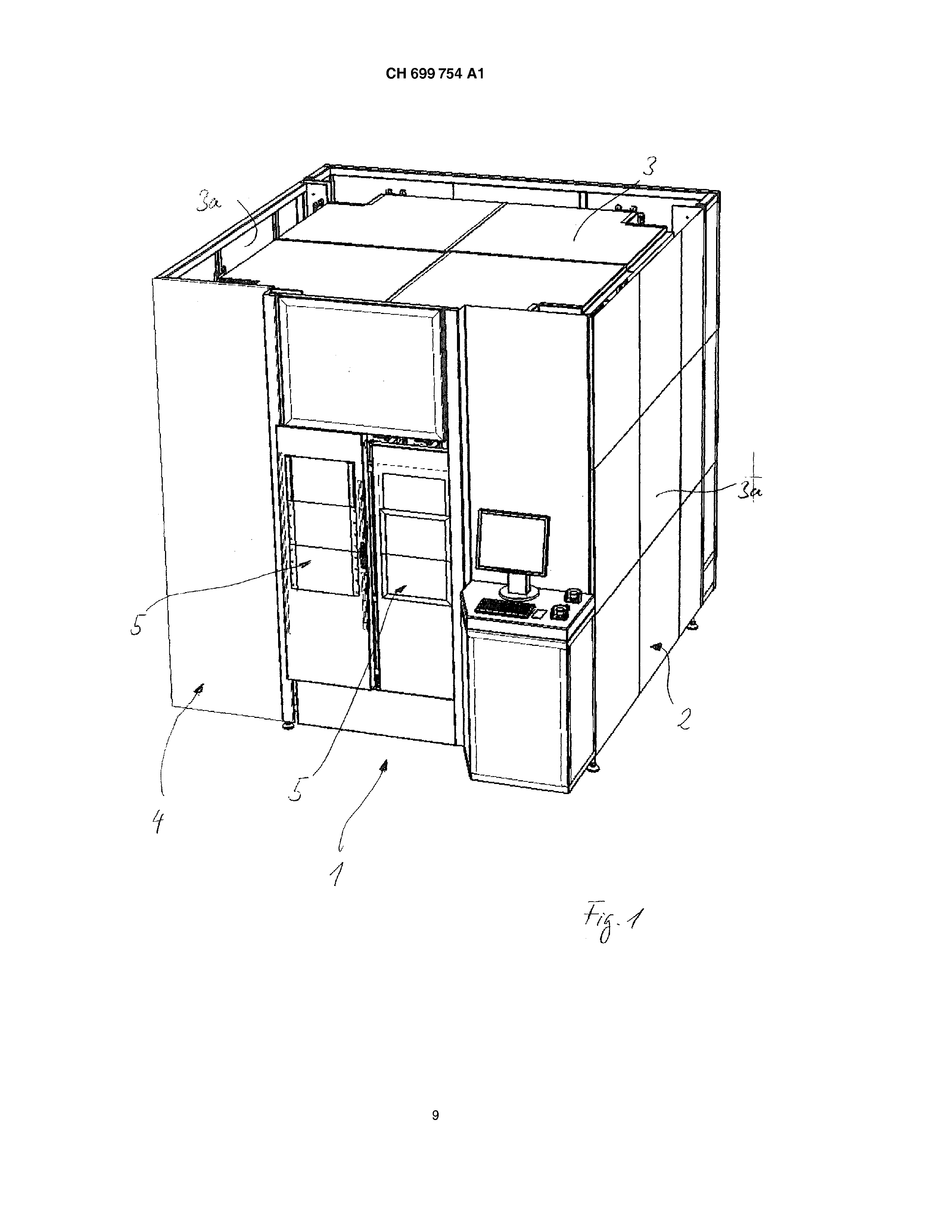

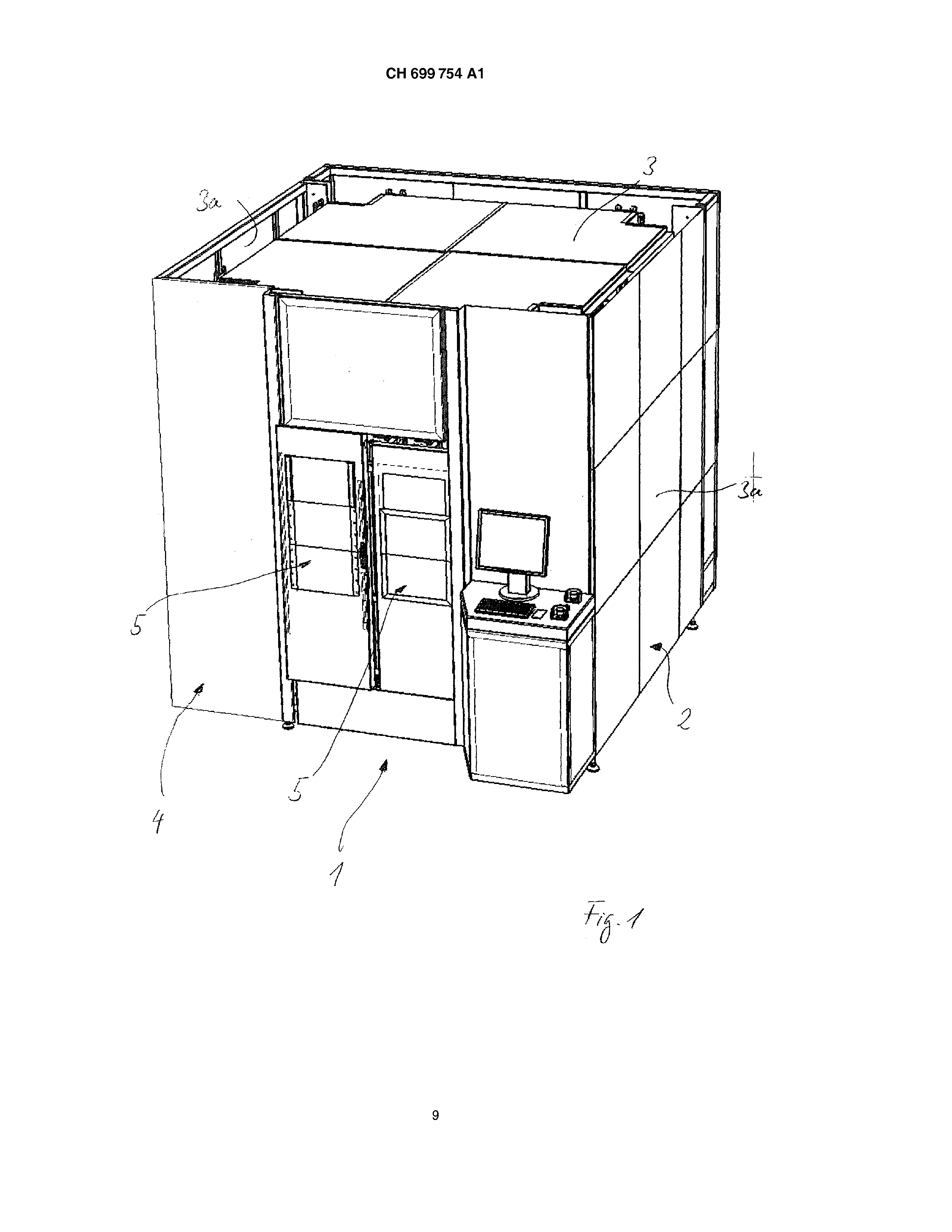

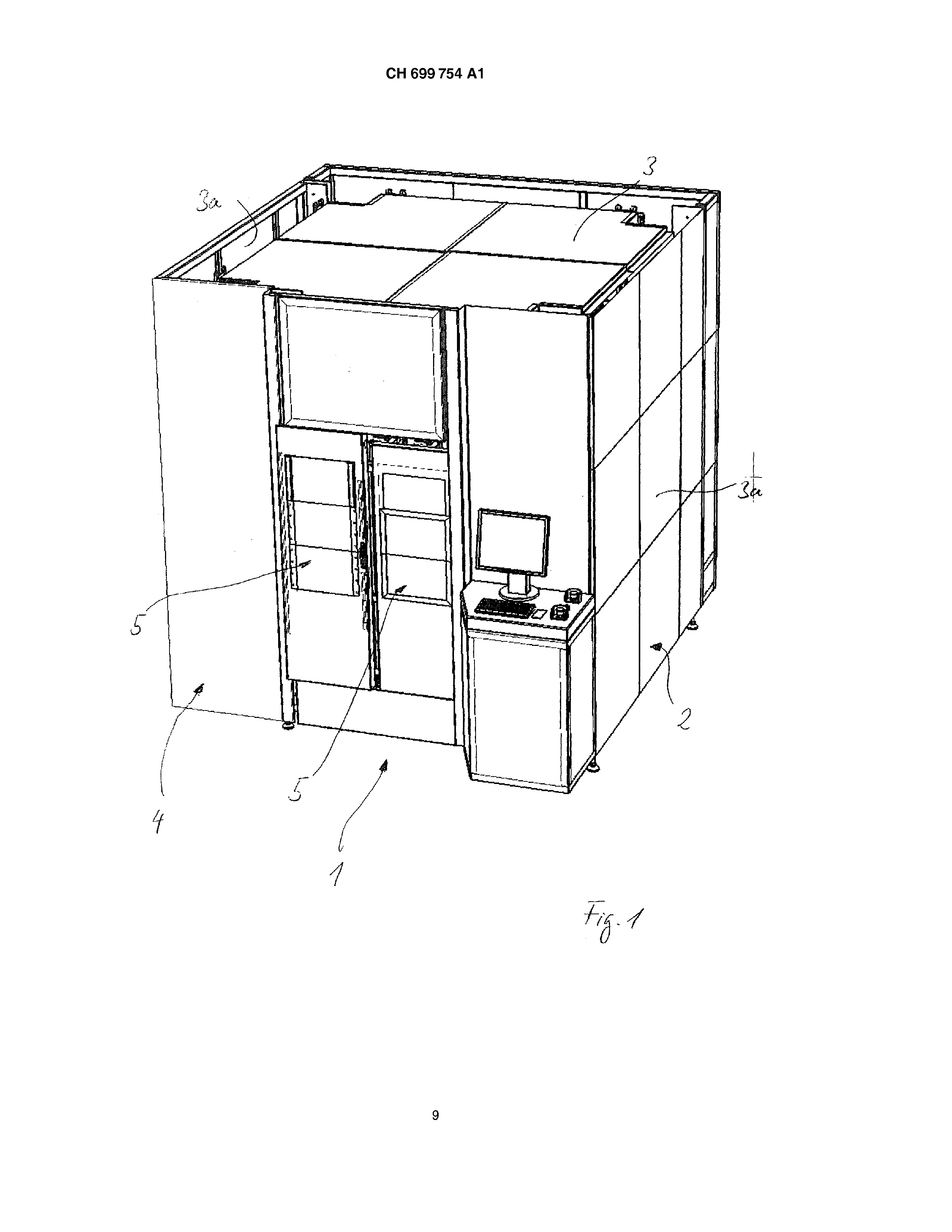

Into the Fig. a memory device according to invention 1 for wafer is shown 1 and 2. This has a housing 2 square in the cross section, which exhibits several sheet metals 3 as upper cover. Contrary to before-well-known memory devices is here no central - FFU attached on the Stocker (fan filter unit) is usually planned, with air from the environment sucked in, cleaned and in the inside of the Stockers led. Three of the four side panels of the housing 2 are likewise formed out of sheet metals 3a. In the front side panel 4 are for Einund would drive out by memory means as well as intended by memory objects arranged in the memory means such as wafer two lockable in/output equipment 5. The remaining surface of the front side panel 4 is likewise covered by sheet metals. In/the output equipment can exhibit a file not represented more near, on which transportable memory means for wafer, in the remark example carrier can be set off, outside of the interior. The carrier here memory means can be, like them in lockable transport containers are intended, with those the memory objects, as are transported wafer, within a manufacturing plant by electronic construction units. Besides a ZAusgabeeinrichtungen is 5 with closing means, like vertically displaceable windowpanes versehen.

Like this in the sectional view of Fig. 2 to recognize is, is more mehrachsiger within the housing 2 - robot 6 arranged, hands its range among other things up to the not represented file outside of the housing 2. Thus the robot kinetics is to be taken up in the position carrier 7 (without transport containers) of the file and be introduced the inside the housing. Likewise it in the position carrier 7 from the housing 2 is to be implemented and on the file Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig.

Fig. 6 Fig. 7 Fig. 8 Fig. 9 Fig.

Fig. To set off 11 CH 699,754 Al. Such Kinematiken, as for example 6-Achsen-Roboter, becomes including robotic control for example of the enterprise Stäubli of tea system GmbH (www.staeubli.de) under the designation series of TX angeboten.

The moreover one, actually a well-known mechanism not represented more near is for aligning Wafern on the basis of notches (Notch), recognizing Wafern in the photograph positions the carrier including possible false positionings, as well as arranged for reading from identification markings (ID) at the Wafern inside the housing 2 in direct proximity to a ZAusgabeeinrichtung (wafer Aligner map by & ID reader mechanism) vorgesehen.

To the execution of these tasks the respective carrier, in whom the wafer are arranged, is brought by means of the robot 6 to the mechanism and set off there to pre-determined position. After the functions mentioned at the Wafern arranged in the carrier accomplished are fetched and either to a ZAusgabeeinrichtung or one that in the following discussed storage locations brought can the respective carrier with the robot from the mechanism werden.

The memory device is provided in its interior with a multiplicity of for instance storage locations 10 arranged in a square sketch, whereby the storage locations 10 are in matrix fashion in columns and rows arranged, like this in Fig. 2 and in Fig. 3 to recognize is. Each storage location 10 is here with a base plate 11 (Fig. 4 and 5) provided, which is solvable fastened to a rack, for example by means of plug connectors. In the remark example of the Fig. 4 is summarized in each case two base plates 11 as structural unit. The memory device 1 points both individual base plates and such, like it in Fig. 4 is shown, up. By means of the base plates 11 autonomous are trained, i.e. by other storage locations or structural units of several storage locations independent camp units for carrier. Everyone of the base plates 11 exhibits positioning aids to the pre-determined positionexact arrangement of only one carrier. With the positioning aids it acts over in a SEMI standard defined interfaces. At a front face of the base plates 11 each of the base plates exhibits in each case two in their dimensions and positions pre-determined geometry (e.g. pins or reaming). All base plates always exhibit these geometry in the same place. Optionally the stock piles can be provided also with level setters, with which a tilting angle for the carrier 7 can be planned and stopped. By means of the level setters in particular a pre-determined inclination the carrier can be achieved by 5° - regarding a horizontal - to the rear, like this in Fig. 6 for a camp unit also on it is represented to arranged carrier 7. This inclination guarantees that wafer of its photographs in the carrier 7 cannot slip out unintentionally. Besides thereby an air flow becomes that in the following filter ZLüftereinheiten 12 described still more near more effectively over the wafer surface geleitet.

As in Fig. , refers to Einschubund withdrawal openings all carrier 7 thus to the robot 6 is shown 2, which is about centrically arranged regarding the square sketch of in matrix fashion arranged storage locations. With the individual Carriem 7 of the represented remark example it acts over by the organization SEMI standardized standard carrier. The carrier 7 are at the inside of their two walls with itself opposite in each case bars provided, which train in pairs in each case an admission for individual wafer. This carrier 7 are open also at their back. At the top side of the carrier a grasp is intended, with which the carrier 7 can be carried manually. Besides the carrier is reciprocally provided at its top side with a shaping, which can be used for the automated handling of the carrier 7 by means of the robot 6. Such a handling can consist for example of transferring filled or empty carrier 7 from a ZAusgabeeinrichtung 5 to a base plate 11 to or carrier from a base plate to the mechanism already mentioned for aligning, recognizing and for the identification from Wafern to bringen.

Within the range of the back of each position plate and thus in the interior of the memory device - a FilterZLüftereinheit (FFU) is arranged 12 in each case, whose width about the width of the base plate 11 and its height corresponds about to the height the carrier 7. Each storage location 10 of the remark example is provided with its own filter ZLüftereinheit in each case, which is assigned to this a storage location only in each case. Each filter ZLüftereinheit is solvable fastened to the respective stock pile, so that it can be exchanged independently of other filter ZLüftereinheiten 12 and independently of her assigned the base plate 11 if necessary against another filter ZLüftereinheit 12. As in Fig. , arises due to this allocation of in each case a filter ZLüftereinheit 12 to each storage location also a matrix-like arrangement is represented to 7 filter ZLüftereinheiten 12.

Each filter ZLüftereinheit sucks in from the rear by means of its exhaust and thus by the FFU air, cleans it by means of in their contained filter and addresses the cleaned air flow on the rear opening of the carrier 7th that only in each case a Carriem assigned air flow of these in each case a filter ZLüftereinheit 12 flows through the respective carrier 7, paints here approach parallel to the horizontal adjustment of the wafer surfaces over these and steps to a front opening of the respective carrier. In remark variations in type a building group by stock piles a filter ZLüftereinheit could be assigned in each case in each case. On the wafer surfaces arranged particle is carried away by in this way aligned air flow and the file of particles on the wafer surfaces is possibly prevented. Thus is each carrier? and each storage location 10 preferably an own air flow assigned, which is produced directly behind the respective storage location 10. The respective air flow is approximately diametrically directed toward the side panel facing in each case the memory device 1 in. Within the range of the robot 6 those meet one another them assigned Carriem 7 already flowed through air flows, so that they are braked at the latest here and in the memory device facing carrier not to reach. Thus each air flow flows through only one carrier and/or only the carrier in a building group by camp units to be stored. In the CH thus a lighter positive pressure prevails to 699,754 Al inside of the memory device. Air becomes from here by a defined discharge possibility (for example downward) outward abgeleitet.

In the memory device can besides a part of the memory device 1 as Bufferbereich be planned to store for example in order straight imported carrier temporarily directly and/or to the expenditure planned carrier until in/the output equipment for a further handling is free. This Bufferbereich can preferably cover stock piles in the proximity of a ZAusgabeeinrichtung, in order to keep handling ways of the robot short. The constructional structure of the Bufferbereichs does not differ thus in this remark example from other storage locations for carrier. Only in the function of the Bufferplätze, i.e. for a short term temporary storage from Carriern to the robots for their handling free, is present in the comparison to the remainder of the storage locations a difference is. It can be also intended therefore that by means of a software allocation freely assignable and also changeable is, which stock piles are intended as Bufferbereich. Besides coherent ranges can be assigned to different memory objects by storage locations, for example (production) wafer and test wafer or silicon wafer and kupferbeschichtete-Wafer.

The robot 6 is provided with three different Endeffektoren/grip arms, which it can alternating at its grip arm interface arrange and for in each case another that three Endeffektoren/grip arms themselves exchange. The robot 6 exhibits for this an actually well-known grip arm alternating system. With first, in Fig. it acts 8 represented Endeffektor in a Teach in the Endeffektor 15, with which the spatial positions of the individual storage locations 10 are determined and stored regarding the spatial coordinate system of the robot 6. The Teach in Endeffektor 15 (also at the same time as Carrieroder the wafer Endeffektor trained to be can) exhibits for this as possible suitable sensor system a light barrier 16, with which the robot the spatial position of the lower and upper outline as well as the face of position pins of the base plates misses and stores these item data in its control. This is made uniquely for all stock piles of the memory device. As long as the memory device is not taken out of operation and changes are not made regarding the stock piles, this completely independently accomplished Teach in procedure does not have to be repeated. Since the spatial relative relative of a carrier on a base plate is pre-determined regarding the two Positonsstifte of the respective base plate 11 and the photographs the carrier with a pre-determined pitch distance are arranged, the robot is now able the carrier and the wafer arranged in the photographs aufzufinden.

As in Fig. , is trained at the Endeffektor 15 of the robot also a wafer single grip arm 17 is shown 9 as the handling of individual wafer. In remark variations in type this could be trained also than separate grip arm, which can be attached then just like the Teach in Endeffektor over a defined interface automated at the robot. For the admission of a Endeffektors the robot 6 proceeds to a place in the memory device, at that the Endeffektoren is put down and takes up the respective Endeffektor, for example the Teach in Endeffektor with integrated wafer single grip arm 17. The latter is grip arm-trained, trained at that an edition for wafer as forked ist.

Can for it be also used a to-ZAbwesenheit of wafer in Carriern and/or false positionings from Wafern exhibits sensor system of the Teach in Endeffektors trained in the remark example as light barrier 16 in the range of the fork ends of the grip arm 17, some light emitter and a photosensor to recognize. With this light barrier 16 the wafer single grip arm drives off a carrier, if it is to access at least one the wafer of the appropriate carrier. Here by means of the light barrier 16 within the range of a front opening of the respective carrier the Anoder absence is examined by Wafern in the individual photographs of the carrier. Likewise it is detected whether in an admission in actually inadmissible way more than one wafer or however a wafer is arranged crosswise in two photographs. These information is put down in the controlling of the robot and/or in the controlling of the memory device. Subsequently, the grip arm 17 accomplishes the lining up task of handling using the allocation information about the carrier, now the available, for example a withdrawal of a wafer from the carrier from a certain admission of the carrier. With the wafer single grip arm 17 it is in particular possible to arrange in a carrier a new wafer pile. For this can be taken from wafer by means of the wafer single grip arm 17 out of different Carriern and be arranged in one the carrier in its photographs. Also for this allocation information from the Carriern concerned determined and with the handling procedures can considered werden. by means of the light barrier

If in the memory device different objects, for example silicon wafer copper-coated and wafer at the same time is stored can it be meaningful to have several wafer single grip arms available 17 in the memory device. By changes of the wafer single grip arms 17 and a use of the respective wafer single grip arms for always only the same type of wafer thereby a cross contamination can avoided by Wafern werden.

In Fig. a third Endeffektor of the robot is finally pointed 10, i.e. a carrier grip arm 20 to the handling of Carriern 7. with this grip arm 20 can the robot carrier 7 on base plates to their pre-determined position set off, for example after a carrier with the grip arm from in/the output equipment 5 transferred wurde.

In the same way an empty or occupied carrier from the memory device can led out werden. with the carrier grip arm 20

Besides CH 699,754 Al is within the range of an admission for the Endeffektoren at the robot one in Fig. 9 represented camera 18 together with a lighting for the camera picture arranged. The picture taken up by the camera 18 can be used outside at the memory device or in an other suitable place on a monitor for the monitoring of the handling procedures in the memory device. Besides finds above the camera 18 lonisationsmittel 19, with in the range of the grip arm static loadings to avoid itself sollen.

As in Fig. , is the handling mechanism as well as in/the output equipment 5 of the memory device on one, designed as robot 6, is shown 11 verschiebbzw. displaceable rack 22 arranged. This can be removed for maintenance purposes of the memory device from the housing 2. Thus the robot from the sensitive storage area of the Wafern stored openly in the memory device is shifted out and can be waited outside of the memory device. With such a solution it can besides is avoided that for maintenance of the memory device these are opened at other side panels than the front side panel and from these sides be accessible must. This reduces likewise the necessary utility space of the Speichervorrichtung.

Reference symbol list 1 memory device of 2 housings 3 sheet metals 4 front side panel in/output equipment of 6 robots 7 carrier storage location 11 base plate 12 filter ZLüftereinheit Teach in Endeffektor 16 light barrier of 17 wafer single grip arms 18 camera of 19 lonisationsmittel carrier grip arms 22 rack In a storage apparatus for temporarily storing objects intended for the production of semiconductor components, such as substrates, wafers, reticles, and the like, wherein the storage apparatus comprises a housing enclosing an interior space through which the objects can be introduced into the housing and removed from the housing, said apparatus being provided with a clean room device for producing and maintaining clean room conditions within the housing, and said apparatus comprising a handling device inside the interior space by means of which the objects can be handled in the interior space and a plurality of storage spaces for arranging objects in open transportable storage means, a storage apparatus having the smallest design possible is to be implemented with the least design complexity possible, wherein even when the number of storage spaces of the storage apparatus is varied, secure positioning of the handling device in front of the respective storage spaces and the receptacles thereof for individual objects is ensured. For that purpose, the handling device is equipped with detection means, which are provided both for detecting position information of the respective storage space and for detecting individual objects in the storage means. Furthermore, only one handling device may be provided, having exchangeable end effectors. 1. Memory device for a temporary storage of objects, like substrates, planned for the production of semiconductor components, wafer, Reticles, and such a thing, whereby the memory device exhibits a housing, which encloses an interior, which is provided with a lockable opening housings, by the objects into the housing importable and from the housing is executable, with a pure space mechanism for production and maintenance is provided by pure space conditions within the housing, exhibits a handling mechanism within the interior, by means of which objects are manageable in the interior, and a multiplicity of stock piles for the arrangement of objects in open transportable memory means exhibits, in it characterized that the pure space mechanism is provided by fan/filter units with a majority, those in each case to only are assigned certain stock piles. 2. Memory device according to requirement 1, by the fact characterized that by the majority of fan/filter units a fan/filter unit is assigned to one stock pile for only one memory means only in each case. 3. Memory device according to requirement 1 or 2, by the fact characterized that itself at least some the fan ZFiltereinheiten completely in the interior of the memory device befinden.

CH 699,754 Al 4. Memory device after at least one of the preceding requirements, by the fact characterized that the stock piles are arranged in rows and columns and at least some the fan ZFiltereinheiten itself directly with the respective stock pile befinden.

Memory device after at least one of the preceding requirements, characterized by fan ZFiltereinheiten, which are arranged within the range of a stock pile in each case and which are essentially horizontal into the center of the memory device of arranged pure air flow intended for production one in each case. 6. Memory device according to requirement 5, characterized by an arrangement of a fan ZFiltereinheit by of their produced air flow within the range a back of a transportable memory means enters, which flows through memory means and within the range of a front of the memory means from the latter withdraws. 7. Memory device after at least one of the preceding requirements, characterized by module-like FanZFiltereinheiten, which are independently and separately of other fan ZFiltereinheiten of the memory device exchangeable. 8. Memory device after at least one of the preceding requirements, characterized by module-like stock piles, which is provided with a fan ZFiltereinheiten with a camp means for the arrangement of a memory means as well as. 9. Memory device for a temporary storage of objects, like substrates, planned for the production of semiconductor components, wafer, Reticles, and such a thing, whereby the memory device exhibits a housing, which encloses an interior, which is provided with a lockable opening housings, by the objects into the housing importable and from the housing is executable, with a pure space mechanism for production and maintenance is provided by pure space conditions within the housing, exhibits a handling mechanism within the interior, by means of which objects are manageable in the interior, and a multiplicity of stock piles for the arrangement of objects in open transportable memory means exhibits, characterized in the handling mechanism provided with detection means, both for the recognition of position information of the respective Stock pile and for the recognition of individual objects in the memory means intended sind.

Memory device according to requirement 9, characterized by an automatic determination of position information from at least a multiplicity of stock piles by means of the detection means using in the stock piles planned detection objects and placings of the position information in a control. 11. Memory device for a temporary storage of objects, like substrates, planned for the production of semiconductor components, wafer, Reticles, and such a thing, whereby the memory device exhibits a housing, which encloses an interior, which is provided with a lockable opening housings, by the objects into the housing importable and from the housing is executable, with a pure space mechanism for production and maintenance is provided by pure space conditions within the housing, exhibits a handling mechanism within the interior, by means of which objects are manageable in the interior, and a multiplicity of stock piles for the arrangement of objects in open transportable memory means exhibits, characterized in several Endeffektoren, which are automated exchangeable at only the handling mechanism. 12. Memory device according to requirement 11, characterized by a Endeffektor, which is provided by stock piles with detection means for the position determination. 13. Memory device according to requirement 11 or 12, characterized by final result order handling mechanism trained as wafer single grip arms. 14. Memory device according to requirement 13, characterized by detection means of the Wafer-Einzel-Greifers.

Memory device after at least one of the requirements 11 to 14, characterized by a Endeffektor of the handling mechanism trained as memory central grip arms, which for the handling is intended by memory means. 16. Memory device for a temporary storage of objects, like substrates, planned for the production of semiconductor components, wafer, Reticles, and such a thing, whereby the memory device exhibits a housing, which encloses an interior, which is provided with a lockable opening housings, by the objects into the housing importable and from the housing is executable, with a pure space mechanism for production and maintenance is provided by pure space conditions within the housing, exhibits a handling mechanism within the interior, by means of which objects are manageable in the interior, and a multiplicity of stock piles for the arrangement of objects in open transportable memory means exhibits, characterized in open transportation magazines from transport containers as memory means, which are executable into the memory device einund. 17. Memory device according to requirement 16, by the fact characterized that the open transportation magazines without their transport containers are executable into the memory device einund. 18. Memory device according to requirement 16 or 17, characterized by only one handling mechanism, with which both individual objects from the memory means and the memory means themselves are manageable.