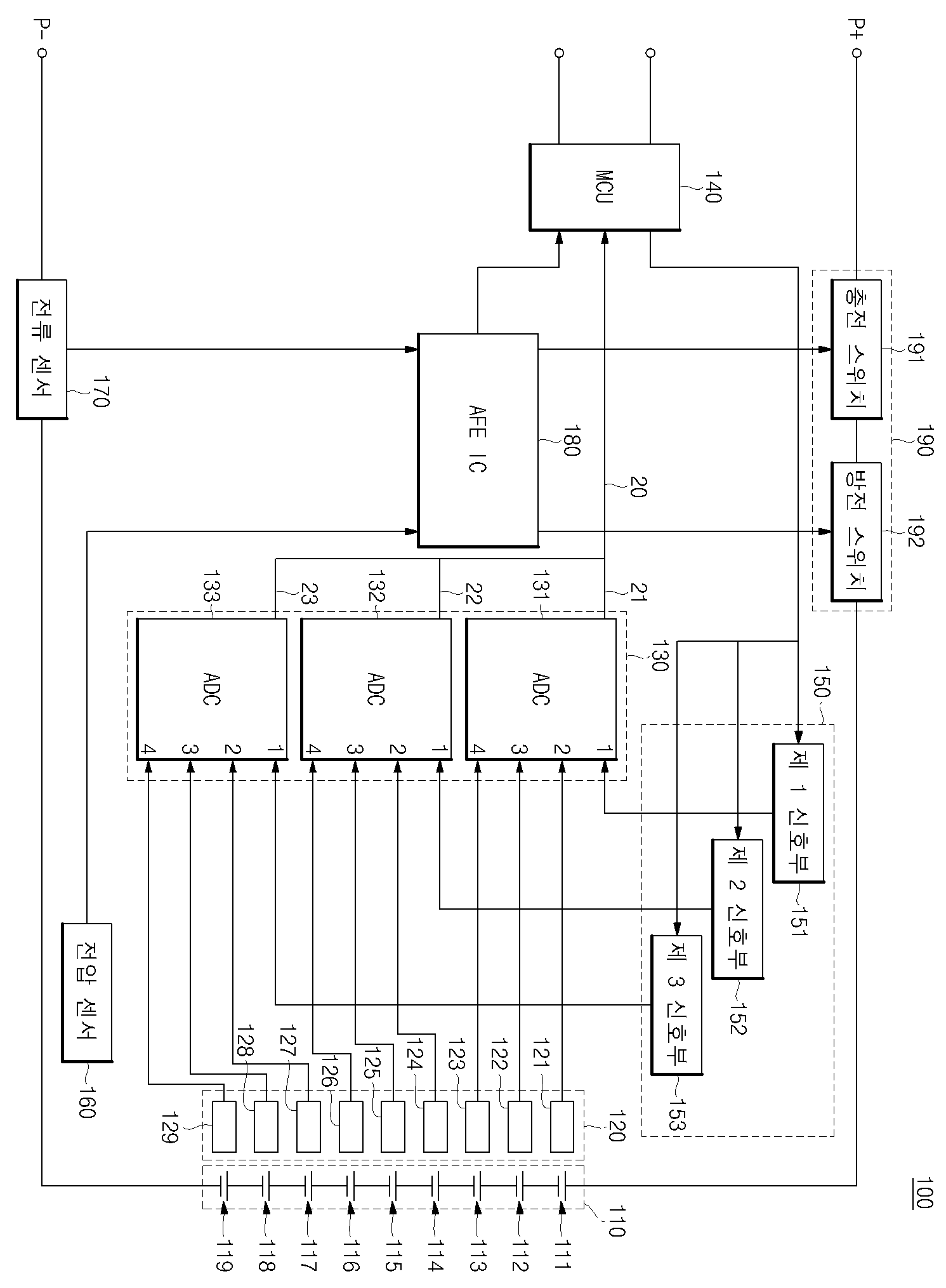

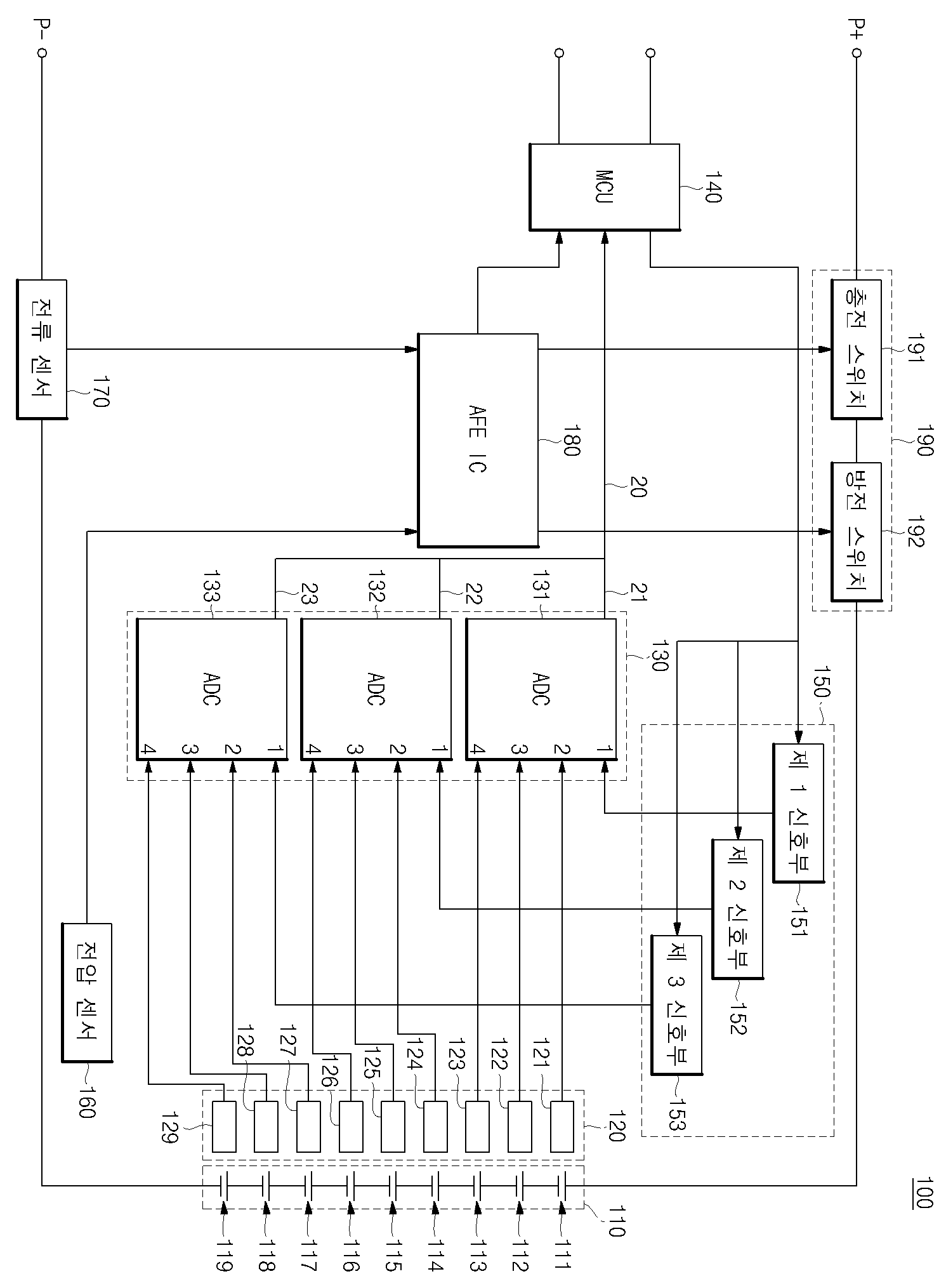

Battery Pack

The present invention refers to relates to battery pack. Generally, notebook, PDA (Personal Digital Assistants) reproduction by providing non-inverted and from portable electronic device such as device (UPS) uninterruptible power supply battery used until to capacitive is battery cells address information and size information of the several battery cells which are serially connected to adaptor prepared of wet liquid to flow down. Plurality of secondary battery cells connected in series a battery pack a secondary for battery pack's capacity and coefficient of the total which it will count to serialization cell because it can be and then voltage is connected to another end of the capacity and voltage output, can produce a contact point is turned off. With such an when battery pack charger to the output terminals of battery pack connected to or loads connected in series a plurality of battery cells is or discharge concurrently filled. Therefore, battery pack to increase stability and reliability of, for battery pack overcharge or overdischarge in battery pack configured for is is required. The present invention refers to plurality of battery cell temperature over control certain interval symmetrically to each measuring method consists in using a battery pack provides. Battery pack the present invention according to a plurality of battery cell; said for battery pack-off of the temperature signal to producing temperature sensor; said temperature sensor and the a plurality of groups so that the, said said temperature signal respectively extending from the group on the LCD converts the signal into a digital signal a plurality of A/D converter; said A/D is connected to converter, said A/D converter by different markers signal identification signal parts that have; and is connected to converter said A/D identification signal and a temperature signal to said transformers, said identifying signals identifying the cells at both said battery through a control unit may comprise an. Wherein, said control and a plurality of said A/D converter 1-wire (1-wire) connected in communication can be. The identification signal and said different voltages divided into a predetermined number of files converter said A/D, current code and electronic Serial number selected from said least one can apply as identification signal. Furthermore, said control unit said A/D converter said identification signal is said identification signal can be control color. Furthermore, the respectively said identification signal is said control electrode to the switching transistor coupled with a microcontroller may be comprised of.. Furthermore, said of switching transistors and is coupled to a source of voltage electrode number 1, number 2 electrode to ground through a resistor voltage divider may be connected to. Furthermore, a switching transistor for high-said distribution voltage by said voltage divider resistance can apply as said identification signal. Furthermore, the identification signal said said voltage divider preceding clause different by converter said A/D through said distribution voltage can apply as identification signal. Furthermore, said identifying signals through said control unit identifies the converter said A/D, through converter said A/D can identify the said temperature sensor. Furthermore, corresponding to the said battery cell are connected in series in charge and discharge switch element to radiate an a analog front end is further can be formed. A plurality of battery pack based on a received of the present invention embodiment connected to temperature sensor 1-a control part, and an converter A/D wire the controller compares the temperature signal G4, identification signal has been of thee different signal parts that have identification A/D converter by applied to the control unit, control unit and a temperature sensor converter A/D the second filler material containing groove can be, number of temperature sensor control part controls the display element for is increased when sound is used as the port for increasing the extendibility without can be. The present invention technology realizing, in the technical field, to which a mobile station belongs person with skill in the art easily embodiment to sizes to be a preferred embodiment of the present invention thereby, the cold air flows reference to drawing were as follows. rapidly and to reduce a memory space. Hereinafter in battery pack according to an embodiment of the present invention (100) to account for the configuration of. Also according to an embodiment of the present invention Figure 1 shows a battery pack (100) is shown a plurality of applications in a hand. Also Figure 2 shows a battery pack according to an embodiment of the present invention (100) an identification signal parts that have used (150). a circuit it is shown a one example of. Also refers to surface 1 and 2, according to an embodiment of the present invention battery pack (100) a plurality of battery cell (110), said battery cell (110) to measure the temperature of plurality of temperature sensor (120), said temperature sensor (120) A/D converter connected to (130), said A/D converter (130) connected to the control part (140), said control unit (140) identification signal parts that have connected to (150) includes. Furthermore, said battery cell (110) measures a voltage a voltage sensor (160), said battery cell (110) of electric current sensor, sensing the current (170), said control unit (140) connected to analog front end (180), said analog front end (180) is connected to control an electroforming (190) may include further. Said battery cell (110) a plurality of-shaped secondary battery is provided which can be connected in parallel with series and/or. may be in the form. In one example, said battery cell (110) a cylindrical lithium ion battery, prismatic lithium ion battery, pouch-type lithium ion battery but may be in the form of, said battery cell (110) type of. are not limited to. Said battery cell (110) the large current line charges and discharges the electricity by connecting. can be made. Furthermore, in one example said battery cell (110) the number 1 battery cell (111) to number 9 battery cell (119) but can be comprised of, said battery cell (110) number of. are not limited to. Said temperature sensor (120) a plurality further includes a first sub-driving said battery cell (110) of level by measuring a temperature signal to generates. To this end, said temperature sensor (120) the battery cell (110) can be attached to the surface of. Said temperature sensor (120) the battery cell (110) to measure the temperature of TC (Thermal coupler) can be constructed element. On the other hand, said temperature sensor (120) the battery cell (110) further includes a first sub-driving the same number and said battery cell (110) may be formed, said battery cell (110) further includes a first sub-driving small number than constant battery cell (110) may be formed. In one example, said temperature sensor (120) the number 1 temperature sensor (121) to number 9 temperature sensor (129) further includes a first sub-driving, said battery cell (110) respectively coupled to ones of a but is shown, said temperature sensor (120) number of. are not limited to. Said A/D converter (130) a plurality further includes a first sub-driving said temperature sensor (120) is connected to. Said A/D converter (130) the temperature sensor (120) for rising temperature signal of converts the form of digital signals. At this time, said A/D converter (130) the temperature sensor (120) is made from number less than the number of. Said temperature sensor (120) a plurality of group which are separated from one, each said A/D converter each group on the LCD (130) and a are connected. Therefore, said A/D converter (130) each plurality of temperature sensor (120) inversely proportional to the level change of temperature signal to from. In one example, said A/D converter (130) the number 1 converter (131) to number 3 converter (133) is made from. And said number 1 converter (131) sequentially number 1 temperature sensor (121) to number 3 temperature sensor (123), number 2 converter (132) sequentially number 4 temperature sensor (124) to number 6 temperature sensor (126), number 3 converter (133) sequentially number 7 temperature sensor (127) to number 9 temperature sensor (129) can be degraded and is connected, .are not limited to content of the present invention. Furthermore, said A/D converter (130) each identification signal parts that have (150) and a are connected. Said A/D converter (130) each of (131 to 133) said identification signal parts that have the (150) from two opposite inversely proportional to the level change of identifying signals. Eventually, said A/D converter (130) each of (131 to 133) and is converted into a digital signal with through the, said control unit (140), and transmitted to said identification signal temperature signal are distinguishable in a radio cell by expansion. Furthermore, said A/D converter (130) the control unit (140) and a 1-wire (1-wire, 20) performs communication. Therefore, said A/D converter (130) each of (131 to 133) the one wire (20) through said control unit (140) and a sequentially is to conduct communications. And said A/D converter (131 to 133) duplex communication a display electrode line group and the temperature signal to the identification signal of the control unit (140) is applied to. Therefore, said control unit (140) through the identifying signals said A/D converter (131 to 133) can be identified and, applied sequentially after said A/D converter an identified temperature signal (131 to 133) a temperature sensor connected to can be identified as temperature signal. Said control unit (140) the A/D converter (130) is connected to. Said control unit (140) the A/D converter (130) and a 1-wire (20) are connected to. Well as, said 1-wire (20) is provided at its end with an branched with the wire (21 to 23) through said converter (130) each of (131 to 133) and may be connected to. Said control unit (140) the A/D converter (130) each of (131 to 133) identified from temperature signal and signal applied to it. Said control unit (140) first controls the 1-wire (20) inversely proportional to the level change of signal identified through the use. Through identifying signals and said said A/D converter (130) each of (131 to 133) which in said control unit (140) identifies whether the content is being communicate with an. Furthermore, said control unit (140) is said A/D converter (131 to 133) after identifying an, said temperature signal to sequentially applied identified A/D converter (131 to 133) temperature sensor connected to (121 to 129) identifies the signal temperature of.. In one example, said control unit (140) is said 1-wire (20) through identifying signals applied through the, said number 1 converter (131) is said control unit (140) provided an opening connected to id.. And said control unit (140) of an identification signal the temperature signal to applied sequentially after said number 1 converter (131) number 1 connected to temperature sensor (121) to number 3 temperature sensor (123) can be identifies the of. As a result, said control unit (140) through the identifying signals said number 1 converter (131) when identifying an, sequential said temperature signal to said number 1 battery cell (111) to number 3 battery cell (123) in a signal produced to measure the temperature of can be identified as. Furthermore, the operation said control unit (140) converter said number 2 signal is identified (132) or number 3 converter (133) when identifying an dispersed form and transmitted to the other 2000. I.e., said number 2 converter (132) is identified when, said temperature sensor said number 4 a temperature signal (124) to number 6 temperature sensor (126) identified a signal of the number 4 battery cell (114) to number 6 battery cell (116) is the temperature of is identified as. Furthermore, said number 3 converter (133) is identified when, said temperature sensor said number 7 a temperature signal (127) to number 9 temperature sensor (129) identified a signal of the number 7 battery cell (117) to number 9 battery cell (119) is identified as is the temperature of. Therefore, said control unit (140) the 1-wire (20) plurality of said A/D converter (131 to 133) is connected, said 1-wire (20) and identification signal parts that have (150) is surface allocating a BPDU to. I.e., plurality of A/D converter (131 to 133) and joined with the plurality of temperature sensor (121 to 129) the control unit (140) to 1-wire (20) may be connected to one of ports. Furthermore, said control unit (140) has an identification signal for A/D converter rotates in the opposite direction (131 to 133) and temperature sensor (121 to 129) can identify the. Therefore, battery cell (110) thereby open of temperature sensor (120) even when the second insulating layer is number of said control unit (140) do not need add for recording and reproducing, battery cell (110) and temperature sensor (120) for being easily expanded. can be obtained. Said identification signal parts that have (150) the control unit (140) and a A/D converter (130) is connected to between. Said identification signal parts that have (150) the control unit (140) control signals from the transformers, each said A/D is operated according to the is (131 to 133) asserts different markers to. Also the identification signal parts that have 2 (150) is one example of showing. Also 1 and 2 a together, said identification signal parts that have (150) each of the A/D converter (131 to 133) of a bearing member corresponding to the number 1 signal parts that have (151) to number 3 signal parts that have (153) consists of to. Said number 1 signal parts that have (151) a control electrode is said control unit (140) is connected connected to won (Vcc) voltage number 1 number 1 electrode (SW1) switching element number 1, number 2 electrode and said number 1 number 2 of a proportional to absolute temperature voltage source switching element (SW1) formed between the resistance number 1 number 2 (R1) and (R2) may include a resistance. At this time, the won (Vcc) voltage said number 1 said control unit (140) can link section 125b voltage applied from a carbon-, said number 2 can be ground (ground) voltage source. Furthermore, said switching element can be the switching transistor (SW1). Said number 1 signal parts that have (151) to said control unit (140) lower the application of control signals of turn-on time of a parasitic, turn-on time of a switching element is said number 1 (SW1). Furthermore, said number 1 number 2 and won (Vcc) voltage won voltage is path is formed, the air flow of current between the, said resistance (R1) and (R2) route on the number 1 number 2 are connected serially-resistance. At this time, resistance (R1) (R2) resistance number 2 number 2 and said number 1 end amount of resistance (R2) according to a resistance value of the divided voltage with is formed. Said number 1 and number 2 (R1) and (R2) resistance resistance (V1) potential at a contact of the number 1 converter (131) to are applied to identification signal number 1. Said number 2 signal parts that have (152) also said number 1 signal parts that have (151) such as and operates in method. Said number 2 switch (SW2) is connected, said number 3 and number 4 resistance resistance (R3) (R4) according to a resistance value of the at a contact potential (V2) is said number 2 converter (132) is applied as identification signal number 2 to. Furthermore, said number 3 signal parts that have (153) also in addition said number 1 signal parts that have (151) such as and operates in method. Said number 3 switch (SW3) is connected, said number 5 and number 6 resistance resistance (R5) (R6) (V3) potential at a contact according to a resistance value of the is said number 3 converter (133) to number 3 is applied as identification signal. When and, said number 1 signal parts that have (151) to number 3 signal parts that have (153) a the identification signal of the number 1 resistance (R1) to number 6 according to a resistance value of the resistance (R6), can take the different values. In one example, said number 1 voltage won (Vcc) is 5 of constant voltages circle and , said number 1 are 20 resistance (R1), (R2) are 30 said number 2 resistance when, the 3 said number 1 identification signal (V1) is. Furthermore, said number 3 resistance (R3) are 30, said number 4 resistance (R4) are 20 when, said number 2 identification signal (V2) is the 2. Furthermore, said number 5 40 are (R5) resistance, said number 6 resistance (R6) are 10 when, said number 3 identification signal (V3) is the 1. I.e., said number 1 converter (131) to number 3 converter (133) to said identification signal (V1 to V3) is 3, 2, 1 can be applied to the information related to, said control unit (140) is said identification signal (V1 to V3) through said number 1 converter (131) to number 3 converter (133) can identify the. And in this case, if said control unit (140) identification signal has been applied to 3 when, said control unit (140) has the identification signal identifying with number 1 (V1), said number 1 converter (131) line is busy, the method identifies to. Applied and then said number 1 temperature signal to temperature sensor (121) to number 3 temperature sensor (123) is measured at the temperature signal, the. recognize a. Furthermore, said control unit (140) applied to when said identification signal has been 2, said control unit (140) identification signal identifying with the number 2 (V2), said number 2 converter (132) identifies to line is busy, the method. Applied and then said number 4 temperature signal to temperature sensor (124) to number 6 temperature sensor (126) is measured at the temperature signal, the. recognize a. Furthermore, applied to said control unit when said identification signal has been 1, said control unit (140) identification signal identifying with the number 3 (V3), said number 3 converter (133) line is busy, the method identifies to. Applied and then said number 7 temperature signal to temperature sensor (127) to number 9 temperature sensor (129) is measured at the temperature signal, the. recognize a. On the other hand, said identification signal (V1 to V3) the voltage but also described, are not limited to, current or unique number type. Said voltage sensor (160) the battery cell (110) is connected to. Said voltage sensor (160) the battery cell (110) each is arranged parallel in relation to cell voltage measurement of said battery cell (110) is connected are formed of liquid pack is connected in parallel to measure the a pack voltage. And said voltage sensor (160) the cell voltage or pack voltage generates a voltage signal to a corresponding to. Said voltage sensor (160) the analog front end (180) applies said voltage signal is connected to. Said current sensor (170) the battery cell (110) is connected to. Said current sensor (170) the battery cell (110) composed are connected in series with all the sheet pack. I.e., said current sensor (170) connected to the entire pack is connected to large current line, large current said detector measures a current passing through the line, corresponding generates a current signal. Furthermore, said current sensor (170) the analog front end (180) is connected to said applies a current signal. Said analog front end (180) the control unit (140), voltage sensor (160) and a current sensor (170) is connected to. Said analog front end (180) the voltage sensor (160) of voltage signals and the current sensor (170) current signals to said control unit (140) applies. Furthermore, said analog front end (180) the control unit (140) inversely proportional to the level change of signals from. Said control unit (140) the A/D converter (130) from licensee temperature signal or is over a specific reference temperature, said analog front end (180) from licensee voltage signal is reference voltage or exceeds, or current signal is reference current converter converts a current, said analog front end (180) is the application of control signals to. And said analog front end (180) the control unit (140) controlled by a control signal of the switching element (190) by controlling the switching a large current line. Eventually, said analog front end (180) the control unit (140) controlled by a control signal of the battery cell (110) filling and/or discharge an input rate which controls the output is. Said switching element (190) the battery cell (110) are connected in series. I.e., said switching element (190) stores a current line are connected in series. Said switching element (190) the battery cell (110) for controlling charge path of charging switch (191), said battery cell (110) for controlling discharge switch discharge path (192) includes. Furthermore, said charging switch (191) and/or discharge switch (192) the analog front end (180) said controlled at the contact hole by large current line by controls the opening and closing of, said battery cell (110) controls the Vref value and/or connector of an automobile. the, according to an embodiment of the present invention battery pack (100) a plurality of temperature sensor (120) A/D converter connected to (130) to a control section (140) and a 1-wire (20) as a temperature signal G4, identification signal parts that have (150) of thee different identification signal has been A/D converter (130) for the control unit (140) to be applied to a. Therefore, according to an embodiment of the present invention battery pack (100) the control section (140) the identification signal A/D converter (140) and temperature sensor (121 to 129) can be uniquely identifies that base station facilitate, temperature sensor (120) number of control unit is increased (140) do not need add for recording and reproducing for the color temperature. expanding characteristics. Figure 1 shows a configuration of battery pack according to an embodiment of the present invention is also. Also Figure 2 shows a used battery pack according to an embodiment of the present invention one example of an identification signal parts that have a circuit it is shown a.. <Description of the sign for major part of the drawings > 100 ; battery pack 110 ; battery cell 120 ; temperature sensor 130 ; A/D converter 140 ; control unit 150 ; identification signal parts that have 160 ; voltage sensor 170 ; current sensor 180 ; 190 analog front end; charge/discharge switching element Plurality of battery cell in the present invention certain interval symmetrically to measuring each temperature over control method consists in using a battery pack is disclosure. In one example, plurality of the battery cell, said for battery pack-off of the temperature signal to producing temperature sensors and a, a plurality of groups so that the temperature sensor and the, said said temperature signal respectively extending from the group on the LCD converts the signal into a digital signal a plurality of A/D converter and, is connected to converter said A/D said A/D converter by different markers signal identification signal and, is connected to converter said A/D said identification signal and a temperature signal to said transformers said identifying signals through a control block for identifying temperature for battery pack including battery pack is disclosure. Plurality of battery cell; Said for battery pack-off of the temperature signal to producing temperature sensor; A plurality of groups so that the temperature sensor and the, said said temperature signal respectively extending from the group on the LCD converts the signal into a digital signal a plurality of A/D converter; Said A/D is connected to converter, said A/D converter by different markers signal identification signal parts that have; and Is connected to converter said A/D identification signal and a temperature signal to said transformers, said through said identifying signals the control unit identifying temperature for battery pack including battery pack. According to Claim 1, Said control and a plurality of said A/D converter 1-wire (1-wire) are connected in communication by performing a characterized by battery pack. According to Claim 1, The identification signal said divided into a predetermined number of files converter said A/D different voltages, current code and electronic Serial number selected from said least one battery pack characterized by applying as identification signal. According to Claim 1, Said identification signal is said A/D said control unit said converter control signal to control the color identification signal characterized by battery pack. According to Claim 1, Said identification signal is said control electrode the respectively to the switching transistor coupled with a microcontroller comprises characterized by battery pack. According to Claim 5, Said switching transistor and is coupled to a source of voltage electrode number 1, number 2 through the opposition of voltage divider electrode is connected to the ground characterized by battery pack. According to Claim 6, A switching transistor for high-resistance voltage divider said distribution voltage by said identification signal characterized by applying as said battery pack. According to Claim 6, Said identification signal through the voltage divider preceding clause distribution voltage different by converter said A/D said battery pack characterized by applying as identification signal. According to Claim 1, Said identifying signals through said control unit identifies the converter said A/D, through converter said A/D identifying temperature sensor characterized by said battery pack. According to Claim 1, Said corresponding to the battery cell are connected in series in charge and discharge switch element to radiate an a analog front end is further of the link is characterized by battery pack.