복합 필름 및 이를 구비한 에너지 저장 복합재료

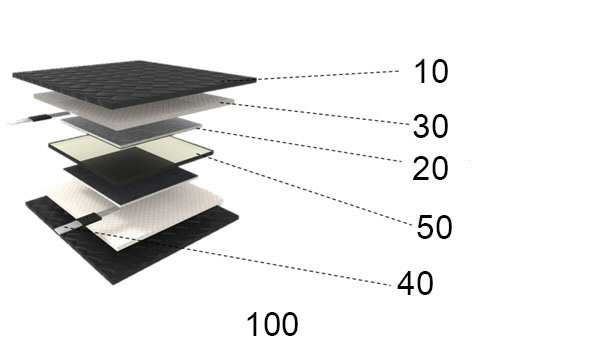

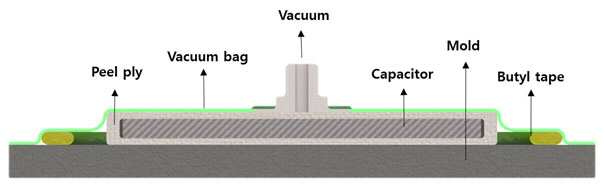

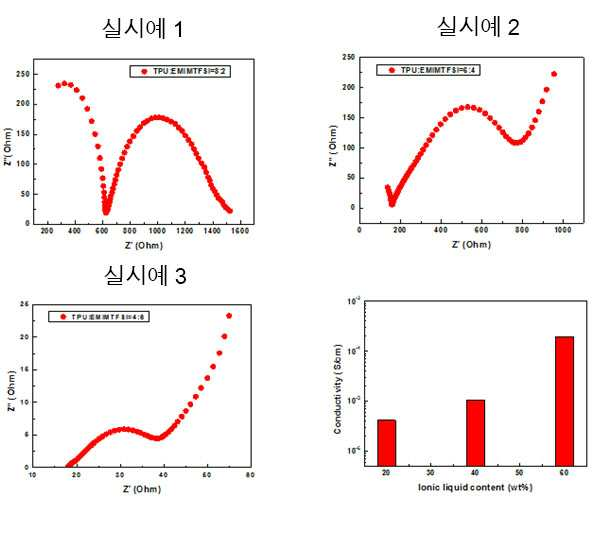

The present invention refers to battery, such as a capacitor energy storage function with body such as vehicle tires, such as panel having an energy storage composite material simultaneously function of structure are disclosed. Aviation, space, dissipation, electronic, electric, hydraulic control, which is used as a structural material for fiber-reinforced composite material construction of durable good core components of various industry etc. applied. Notably in particular carbon fiber-reinforced composite material other fiber material is not have high performance, high-deformation characteristics of the site of interest of the first disclosed. Material with high rigidity and high strength structural material current carbon fiber reinforced composite weight is reduced with additional multifunctional (multi-a functional) structure studies of air mattresses (self-a repairing), shape, sensing, operation intelligent material function, 1W function, research in the field of thermal characteristic such as progressing disclosed. In the automotive industry environment corresponding number, change trend of the automotive industry, hybrid, fuel cell, such as electric vehicle corresponding to vehicle weight of xDSL technology etc. in order to future. In attaching the Korean traditional music has carbon fiber composite material and carbon fibers through carbon fiber composite material number Company for automatically connecting call between vehicle body and panel for application to studies of 2000 is in progress. On the other hand, various portable electronic device including power supply device or a system with batteries of electric vehicles or the like, instantaneous and non-electrical energy storage device for a system control or overload which is required, the electrical energy storage device to Ni-a MH battery, Ni-a Cd battery, and lithium secondary battery such as secondary battery and lead, has established to communicate with a high output density per number free near one super capacitor, aluminum electrolytic capacitor and ceramic capacitor etc.. In particular the electric double layer capacitor (EDLC; Electric Double Layer Capacitor) super capacitor, similar capacitor (pseudo capacitor), lithium ion capacitor (LIC; lithium ion capacitor) etc. such as hybrid capacitor (hybrid capacitor). The supercapacitor of basic structure such as relatively large electrode surface area porous electrodes, electrolyte, current collector (current collector), and layer consisting (separator), applying voltages of a few volts to end portions of the unit cell are electrolyte of ions within the electrode moves along the surface electric field over the electrochemical mechanism operating principles to each other. This cell and upper and lower metal material sealed in the case, upper and lower case outer surface with upper and lower terminal are disclosed. In addition to the super capacitors and the like as materials of construction such as energy storage battery is able to reduce the weight of a vehicle body panel such as vehicle tires can be the vehicle operation when energy consumption can be reduce. The carbon fiber composite material body and panel supporting function for applying stress with secondary battery or capacitor energy storage function such as new general outline of structural battery (Structural Battery) or energy storage structural composite material (Energy Storage Structural Composites, ESSC) studies to America and Europe about etc. can not get inside. The motor vehicle employing such multifunctional composite material weight, vehicle performance and improving stability, capable of improving fuel efficiency and discharge gas is reduced. Of the present invention comprises a solid electrolyte function in number and simultaneously inducing an in-situ process of composite material using the same composite film number are disclosed. Other and number further comprises energy storage and member function of the present invention can be a high energy storage properties having an energy storage composite material number without performing the composite film with said high pressure liquid coolant to the electrolyte to electropolish and separators, energy storage element in solid electrolyte function in compact energy storage composite material is improved in toughness of number are disclosed. To this end the present invention refers to An ionic liquid and a polyurethane composite film including number substrate. In additionthe present invention refers to A pair of carbon fiber prepreg; A pair of carbon fiber prepreg positioned between said pair of electrodes; Said carbon fiber prepreg and electrode respectively located in the collector; and Positioned between said pair of electrodes, including an ionic liquid and a polyurethane composite film Energy storage composite material including a number substrate. In addition the present invention refers to said energy storage composite material includingStructural panel number substrate. In addition the present invention refers to said structural panel including number conveys substrate. Energy storage composite material of the present invention improved mechanical properties by a goniophotometer energy storage properties. The energy storage composite material of the present invention stress support function required while vehicle body with energy storage function, e.g. applied to the weight body, capable of improving fuel efficiency and discharge gas is reduced. Figure 1 shows a cross-section of one of the present invention in the embodiment according to energy storage composite material also are disclosed. Figure 2 of the present invention in the embodiment 1 to 4 according to composite film photographs are disclosed. Figure 3 shows a number indicating a mimetic of the present invention in the embodiment 5 to 8 according to energy storage composite material also are disclosed. Figure 4 of the present invention in the embodiment 5 to 8 according to energy storage composite material are disclosed photographs. Figure 5 shows a graph indicating ion of the present invention in the embodiment 1 to 4 according to also pass Nyquist leading (nyquist plot) and graph are disclosed. Current - voltage curve and Figure 6 of the present invention in the embodiment 1 to 4 non capacity graph representing the result are disclosed. Results of this test and the guard whom it will count in the embodiment 8 Figure 7 3 a-Point loading 2 species Extension provided Force graph are disclosed. Hereinafter, with reference to a drawing of the present invention in the embodiment for the present invention in the preface is provided to the person with skill in the art for detailed embodiment is hereinafter to 2000. However the present invention refers to several different taught herein can be embodied in the form of a in the embodiment is not limited to. The present invention is described that is independent unambiguously account for dispensed portion when the, same or similar component through the entire specification are identical in making diffuse to the reference code. The filamentous or features of the present invention preferred embodiment technical drawing on the like clearly to explain the specific for reference since, chamber number number article specifications may be different from previously found to each other. In addition, wherein the arbitrarily for facilitating description size and thickness of each configuration exhibited drawing representing, not limited to the present invention are not necessarily shown in the drawing, by increasing a thickness of different portions and area unambiguously in order shown. Described is made up of a number 1 for the name of a road, such as number 2 is divided into the same relationship for differentiating the configuration is a name of a differential, not necessarily limited to a description of correction and not the. The entire specification, that "comprising" when any portion of any components, particularly the opposite substrate number but without other components further can include other components which means that the other. The present invention according to an ionic liquid and a composite film comprises polyurethane. Said ionic liquid cation and anion size for treating of liquid crystal due to he couldn't present as a material, having a melting point hereinafter room temperature, room temperature molten salt in a liquid state at room temperature salt or said substrate. The ionic liquid ammonium, d [nyum pyrrole, pyridinium, pyrimido liquid-crystal medium, imidazolium, d [nyum piperidinyl, pyrazole nicotineamid, oxa nicotineamid, multi [nyum pyridyl, phosphonium, sulfonium, triazole nicotineamid selected mixtures thereof and one or more cationic, BF4- , PF6- , AsF6- , SbF6- , AlCl4- , HSO4- , ClO4- , Cl- , Br- , I- , SO4- , CF3 SO3- , CF3 CO2- , NO3- , Al2 Cl7- , CH3 COO- , CH3 SO3- , (CF3 SO2 )3 C- , (CF3 CF2 SO2 )2 N- , (CF3 SO2 )2 N- , (FSO2 )2 N -, (CF3 )2 PF4 -, (CF3 )3 PF3 -, (CF3 )4 PF2 -, (CF3 )5 PF- , (CF3 )6 P- , SF5 CF2 SO3- , SF5 CHFCF2 SO3- , CF3 CF2 (CF3 )2 CO- , (CF3 SO2 )2 CH -, (SF5 )3 C- , (C2 F5 SO2 ) (CF3 SO2) N- And (O (CF3 )2 C2 (CF3 )2 O)2 PO- 1 Selected from at least one anion selected from including compounds are disclosed. 1 - Ethyl - 3 - methyl said ionic liquid e.g. bis (trifluoromethyl sulfonyl) imide, 1 - ethyl - 3 - methyl triple base oro methane alcoholic beverage gun four [thu, bis (trifluoromethane sulfonyl) imide N - butyl - N - N - methyl - N - profile blood roll d [ni bud blood raleigh d bud methyl bis (3 - trifluoromethyl sulfonyl) imide, 1 - butyl - 3 - methyl bis (trifluoromethyl sulfonyl) imide , tri-ethyl methyl ammonium tetra , 1 - ethyl - 3 - methyl 2, 2 pivotably depolarization. 20 To 80% by weight relative to the weight of this ionic liquid the whole composite film preferably less than % by weight. If ionic liquid content of lithium salt is less than said range makes it difficult to exhibit ion conductivity-absorbing cloth, conversely said range and present as a liquid exceeds the ionic liquid composite film external intra-cellular, door number point pin is selected from the group. The user so as to control speed of the action of the present invention composite film electrolyte, electrochemical element in process from omitted when applied to electrolyte separator. In the form of maintaining said composite film, polyurethane-based thermoplastic resin composition with excellent electric vehicles such as the bin acting as described process from high impact resistance is unavailable. In addition the polyurethane may be using the same elasticity modulus calculates an interface adhesive flows by the composite material of the composite material of vacuum compression process different materials can be inducing mechanical property. Figure 1 shows a cross-section of one of the present invention in the embodiment according to energy storage composite material also are disclosed. As shown in fig. 1, the present invention according to energy storage composite material (100) includes a pair of carbon fiber prepreg (10), a pair of glass fiber prepreg (30), a pair of collector (40), a pair of electrodes (20), and composite film (50) can be composed. Specifically, said energy storage composite material (100) includes a pair of carbon fiber prepreg; said pair of carbon fiber prepreg positioned between a pair of electrodes; said respectively located in the carbon fiber prepreg is formed between a glass fiber prepreg; glass fiber prepreg is formed between respectively said collector; and said positioned between a pair of electrodes, including composite film comprises an ionic liquid and a polyurethane. In particular, energy storage composite material of the present invention (100) includes a composite film (50) edge parts of a pair of carbon fiber prepreg (10) incorporated into the outer surface of the substrate. Loose energy storage composite material number conventional electrically conductive top carbon fiber prepreg and lower carbon fiber pre-that leg to prevent contact insulation layer portion in the present invention without projecting from the outer surface of a pair of carbon fiber prepreg while a pair of electrically conductive glass fiber prepreg (30) are located is formed between a pair of carbon fiber prepreg containing pass permits. This structure since the outer surface of the composite film without revealing the use of glass fiber prepreg composite film in ionic liquid as well as due to structural strength can be improved disclosed. Said carbon fiber prepreg (Prepreg) (10) and glass fiber prepreg (30) consists of carbon fiber or glass fibers and thermosetting and/or thermoplastic resin. The prepreg fiber-reinforced composite materials based on intermediate, prepreg by depositing heating, in pressing to cure the resin molded article formed therein. Said pair of carbon fiber prepreg (10) includes a pair of glass fiber prepreg said edge parts (30) can be formed on the outer surface of the base and includes a carbon fiber pre-that leg (10) glass fibers prepreg (30), collector (40), electrode (20) preferably contains both. Preferably designed as said glass fiber prepreg (30) edge parts is said composite film (50) can be formed on the outer surface of the composite film (50) the glass fiber prepreg (30) incorporated in and n is an integer. Said collector (40) is a number which if used without the conductive 72, e.g. stainless steel, platinum, gold, copper, carbon-based, ITO (In doped SnO2 ), FTO (F doped SnO2 ) Etc. disclosed. Said electrode (20) activated carbon, carbon aerogel (Carbon aerogel), yes pin (Graphene), carbon nanotubes (Carbon nanotube), conductive polymer (Conductive polymer), to a crystal material such as metal oxide (Metal oxide) can be, the number one are not disclosed. Said composite film (50) along the aforementioned bar. Preferably designed as said composite film (50) includes an upper, lower electrode material and electrode terminals for preventing electrical short edge parts and said pair of collector (40) projecting from the outer surface of and n is an integer. The carbon fiber prepreg and glass fiber in the prepreg of the present invention energy storage composite material can be srruo3. support function body, such as a panel means a structural panel applied to applications disclosed. In a vehicle of the present invention energy storage composite material with low reinforcing and exhaust gas through the engine can be reduced disclosed. In the present invention operates as term using magnetic engine vehicle, aircraft, various transportation means can be easily. Energy storage composite material of the present invention laminated and, sealed and, a hardening step and a fluorohydrocarbon. the lamination steps, release treated above the fill ply (peel ply), a pair of carbon fiber prepreg and a pair of glass fiber prepreg laminated. The prepreg laminated above the fill fly greater than to the base. Carbon fiber prepreg and glass fiber prepreg disposed on either side of a pair of laminated carbon fiber prepreg and a pair of glass fiber [phu leg support bar each. After a pair of glass fiber prepreg between a pair of collector and a pair of electrodes and then inserting a composite film between a pair of electrodes is inserted into. Breather (bleeder) and a vacuum bag bagging film stacked on energy storage composite material (vacuum bag bagging film) are laminated. Then said sealing step, vacuum bag bagging film between the mold and the vacuum bag sealant tape (vacuum bag sealant tape) vacuum bag using mold bagging film seal between substrate. After, the plurality of suction cups connected to a vacuum hose connected to a vacuum pump (vacuum bag connector) back connector applying substrate. Finally, vacuum oven or autoclave mold into and out of the pressure and/or heat to the substrate. The cured prepreg resin composite material is applied to pressure and heat can be molded. Hereinafter, the present invention to be incorporated in the embodiment and experiments but more detailed, the present invention embodiment and not limited to those in the embodiment and experiments. In the embodiment 1 To In the embodiment 4: Composite film number bath A dimethylformamide (DMF) organic solvent first solid polyurethane pellets (Pellet) number 1 to 3 polyurethane solution after high pressure liquid coolant amide, polyurethane solution (trifluoromethylsulfonyl) imide 1 a-Ethyl provided 3 a-methylimidazolium bis number mix solution was added to a high pressure liquid coolant. Solution is 100 rpm in 60 °C agitating 3 time to work through. After the polyurethane has been sufficiently mixed with glass and less affected by the ionic liquid solution, solvent film was heated in an oven to a stand-alone source of vacuum in order 120 °C 12 by heat number number time high pressure liquid coolant. The weight ratio of polyurethane pellets and ionic liquid shown below table 1 for some time past. Figure 2 of the present invention in the embodiment 1 to 4 according to composite film photographs are disclosed. As shown in fig. 2, its inner film reduced transparency increased unsaturated fatty acid content of an ionic liquid. In the embodiment 5: Energy storage composite material number bath Release number coated with a pair of carbon fiber epoxy prepreg above the fill ply (peel ply) (0. 125 Mm thickness, 52% fiber volume ratio, SK chemical (WSN-a 150A)), glass fiber prepreg (SK chemical (UGN provided 150A)) with respect to the position. Said in the embodiment 1 composite film, electrode (tag number article it is empty, activated carbon coating thickness 20um, 1800 m specific surface area2 /G) and copper network was inserted between a pair of carbon fiber prepreg. As also shown in the 1 order, it does, laminated material, the cross-sectional area size of the carbon fiber prepreg, glass , composite film, a silicon wafer is order of current collectors. After the vacuum bag (vacuum bag) butyl tape mold mold into and out of the oven and then heat sealed in 12 hours was 120 °C. Heat treatment and where the composite material is energy storage has been completed. In the embodiment 6 In a composite film in the embodiment 2 in the range of 0.1 in the same embodiment said in the embodiment 5 number was. In the embodiment 7 In the embodiment 3 in said in the embodiment 5 in the same number in the range of 0.1 composite film was embodiment. In the embodiment 8 In the embodiment 4 in said in the embodiment 5 in the same way was in the range of 0.1 number embodiment composite film. Figure 4 of the present invention in the embodiment 5 to 8 according to energy storage composite material are disclosed photographs. In the case of a relatively high content of an ionic liquid in the embodiment 8 using the composite film applied to the locations where the composite film was dropped out from the ionic liquid element. Experiment example 1: Ion conductivity In the embodiment 1 to 4 according to the electrochemical impedance spectroscopy for identifying conditions pass by ion conductivity (Electrochemical impedance spectroscopy) by water. Electrochemical analysis tech resignation kindergarten children to the VIP ZIVE SP2, and involves the following experiment conditions, the result is also shown to 5. - Frequency domain: 1 x 106 - 1 X 10-2 Hz - Amplitude: 10mV In the case of impedance measurement in the embodiment 4 room and ion conductivity cannot be obtained, the high content of an ionic liquid and a vacuum-forming procedure becomes liquid rub off by element number is considered as short component is not operating vehicle from the outside. (Σ) is a mathematical equation 1 below ion conductivity by been attained. [Mathematical equation 1] Of Figure 5 EIS graph is completed point impedance (Z ') semi-a circle having a resistance value determines a transparent conductive layer, thickness of a film over and under the conditions specified by table 2. As a result in the embodiment 3 (60 wt % ionic liquid) of polyurethane films has been most device using the low impedance value, ion conductivity when same terms, 1. 95X10-4 It has been determined that level. Experiment example 2: Non capacity In the embodiment 1 to 4 in order to identify conditions pass non capacity by circulating voltage to current method (Cyclic voltammetry) by water. The measuring equipment kindergarten children tech resignation ZIVE SP2 the VIP, experiment conditions as follows. A measuring voltage -: 0 provided 3V - Scan rate: 10mV/sec Current - voltage curve and Figure 6 of the present invention in the embodiment 1 to 4 non capacity graph representing the result are disclosed. 6 Also reference surface, which appears to be highest voltage range gate signal line driving circuit in the embodiment 3, filling has been confirmed that the highest amount of charge. A mathematical equation 2 is arched non capacity attained by the plastic, the result is shown in table 3. [Equations 2] C: [F/g] non-capacity V: charge voltage speed [mV/s] V: voltage range M: a lithium ion secondary electrode I: current density [A/cm2 ] Experiment example 3: Mechanical characterization Energy storage composite material according to the standard ASTM D790 flexural strength of 3 a-Point loading his database. In order to identify other polymer materials used with difference, 2 additional experiments utilized much stream selecting patterns as Celgard 2 species was. Celgard 2 species of basic information table 4 such as disclosed. Results of this test and the guard whom it will count in the embodiment 8 Figure 7 3 a-Point loading 2 species Extension provided Force graph are disclosed. Based on the calculated under the same flexural strength shown table 5. the reference table 5, in the embodiment 8 of the present invention composite using the film strength of the highest energy storage composite material can be identify. The reason is that having the highest flexural strength in the composite film of the present invention energy storage composite material is elastic polyurethane is considered the vehicle from the outside. By vacuum bag molding when subjected to higher pressure in the element, having a low Young's modulus elastic chain polyurethane pressure readily detectable by compressed activated carbon electrode relative to the plastic material at the interface between the adhesive flows will. Relatively high modulus value comparator and the low pressure compressed air by the soaked in the Celgard based retardant occurs, contact interface between different material number made in not subject to pH as flame retardant. At this time on the outside by a cured composite structure material 3 a-Point loading when subjected to a force, due to the variance of good adhesion force of such smooth TPU composite structure material of different interface unstable Celgard composite structure material more brittle carbon fiber one side of the baffles are joined with low flexural strength to be coated. 10: Carbon fiber prepreg 20: electrode 30: Glass fiber prepreg 40: collector 50: Composite film The present invention refers to solid electrolyte function in compact to improve the toughness of the composite film and energy storage composite material having the same number substrate. Of the present invention composite film comprising an ionic liquid and a polyurethane. Back number Back number Back number Back number A pair of carbon fiber prepreg; said pair of carbon fiber prepreg positioned between a pair of electrodes; said carbon fiber prepreg is formed between a collector respectively; and positioned between said pair of electrodes, made of a composite film and an ionic liquid and a polyurethane, said 20 weight % or more relative to the weight of the entire composite film composite film 60 weight % hereinafter reset including an ionic liquid and a polyurethane, energy storage composite material. According to Claim 5, said carbon fiber prepreg and collector respectively located in the between glass fiber prepreg including energy storage composite material characterized. According to Claim 5, said outer surface of said edge parts pass into a pair of carbon fiber prepreg fulfill energy storage composite material. According to Claim 6, said glass fiber prepreg composite film can be formed on the outer surface of edge parts characterized in that said energy storage composite material. According to Claim 6, said edge parts can be formed on the outer surface of said glass fiber prepreg carbon fiber prepreg characterized energy storage composite material. Back number According to Claim 5, said ionic liquid ammonium, d [nyum pyrrole, pyridinium, pyrimido liquid-crystal medium, imidazolium, d [nyum piperidinyl, pyrazole nicotineamid, oxa nicotineamid, multi [nyum pyridyl, phosphonium, sulfonium, triazole nicotineamid selected mixtures thereof and one or more cationic, BF4- , PF6- , AsF6- , SbF6- , AlCl4- , HSO4- , ClO4- , Cl- , Br- , I- , SO4- , CF3 SO3- , CF3 CO2- , NO3- , Al2 Cl7- , CH3 COO- , CH3 SO3- , (CF3 SO2 )3 C- , (CF3 CF2 SO2 )2 N- , (CF3 SO2 )2 N- , (FSO2 )2 N -, (CF3 )2 PF4 -, (CF3 )3 PF3 -, (CF3 )4 PF2 -, (CF3 )5 PF- , (CF3 )6 P- , SF5 CF2 SO3- , SF5 CHFCF2 SO3- , CF3 CF2 (CF3 )2 CO- , (CF3 SO2 )2 CH -, (SF5 )3 C- , (C2 F5 SO2 ) (CF3 SO2) N- And (O (CF3 )2 C2 (CF3 )2 O)2 PO- 1 Selected from at least one anion selected from compounds including cost energy storage composite material characterized. Number 5 to number 9 term and number 11 according to energy storage composite material including either anti anti antiStructural panel. Number 12 structural panel including anti according to vehicle. According to Claim 13, characterized in that said vehicle is a vehicle transportation that. Classification In the embodiment 1 In the embodiment 2 In the embodiment 3 In the embodiment 4 Polyurethane: ionic liquid weight ratio 8:2 6:4 4:6 2:8 Classification In the embodiment 1 In the embodiment 2 In the embodiment 3 In the embodiment 4 Thickness (micro m) 250 320 300 300 (S/cm) ion conductivity 4. 10X10-6 1. 05X10-5 1. 95X10-4 - Classification In the embodiment 1 In the embodiment 2 In the embodiment 3 In the embodiment 4 Non capacity (F/g) 1. 1 0. 1 9. 7 6. 4 Classification In the embodiment 8 Celgard 2325 Celgard 3501 Bending strength (MPa) 145. 3 122. 0 122. 0