FLUIDIZED BED REACTION SYSTEM HAVING SPARGER CAPABLE OF MINIMIZING BLOCKAGE CAUSED BY SOLIDS AND CONTROLLING METHOD THEREOF

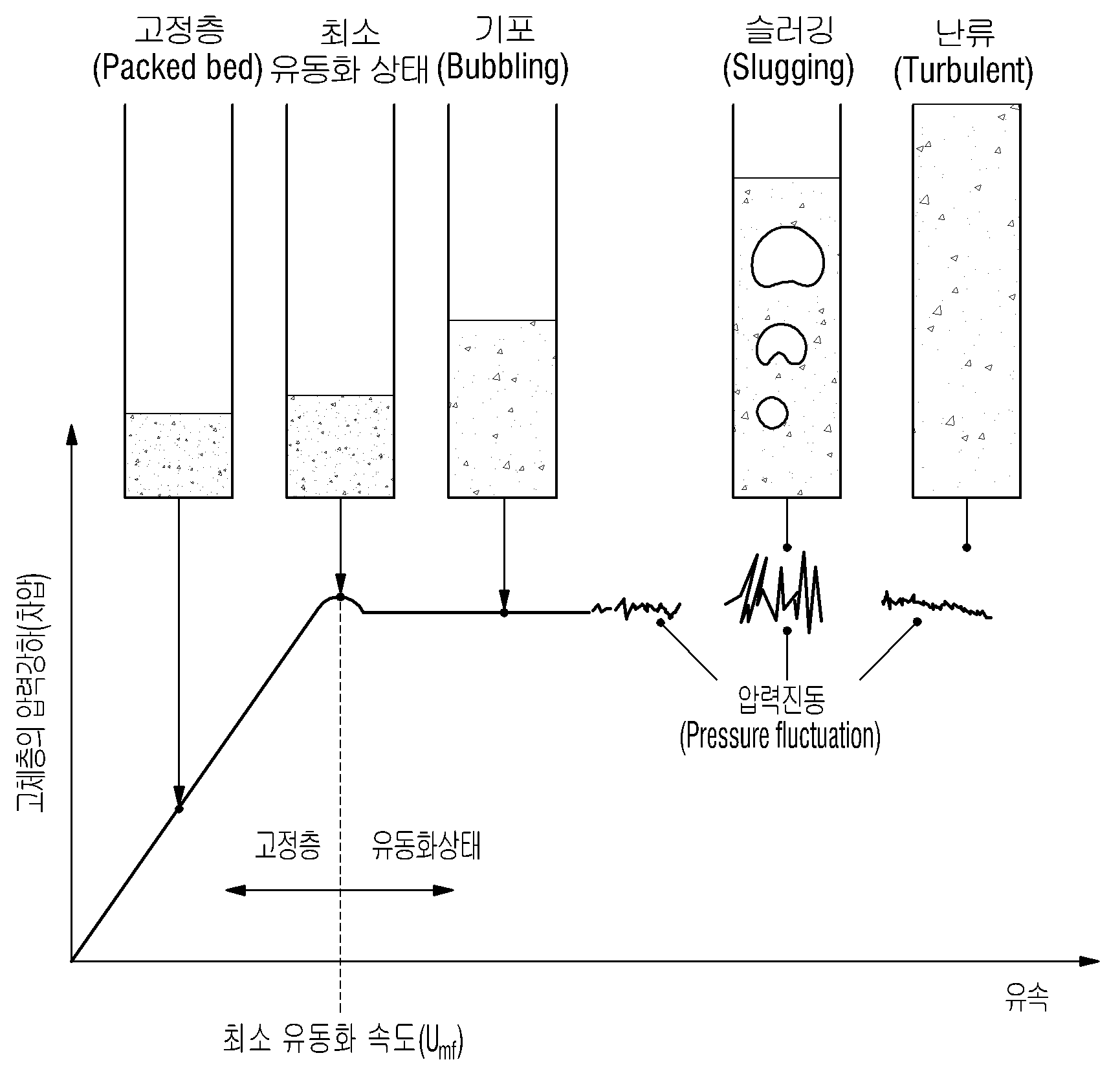

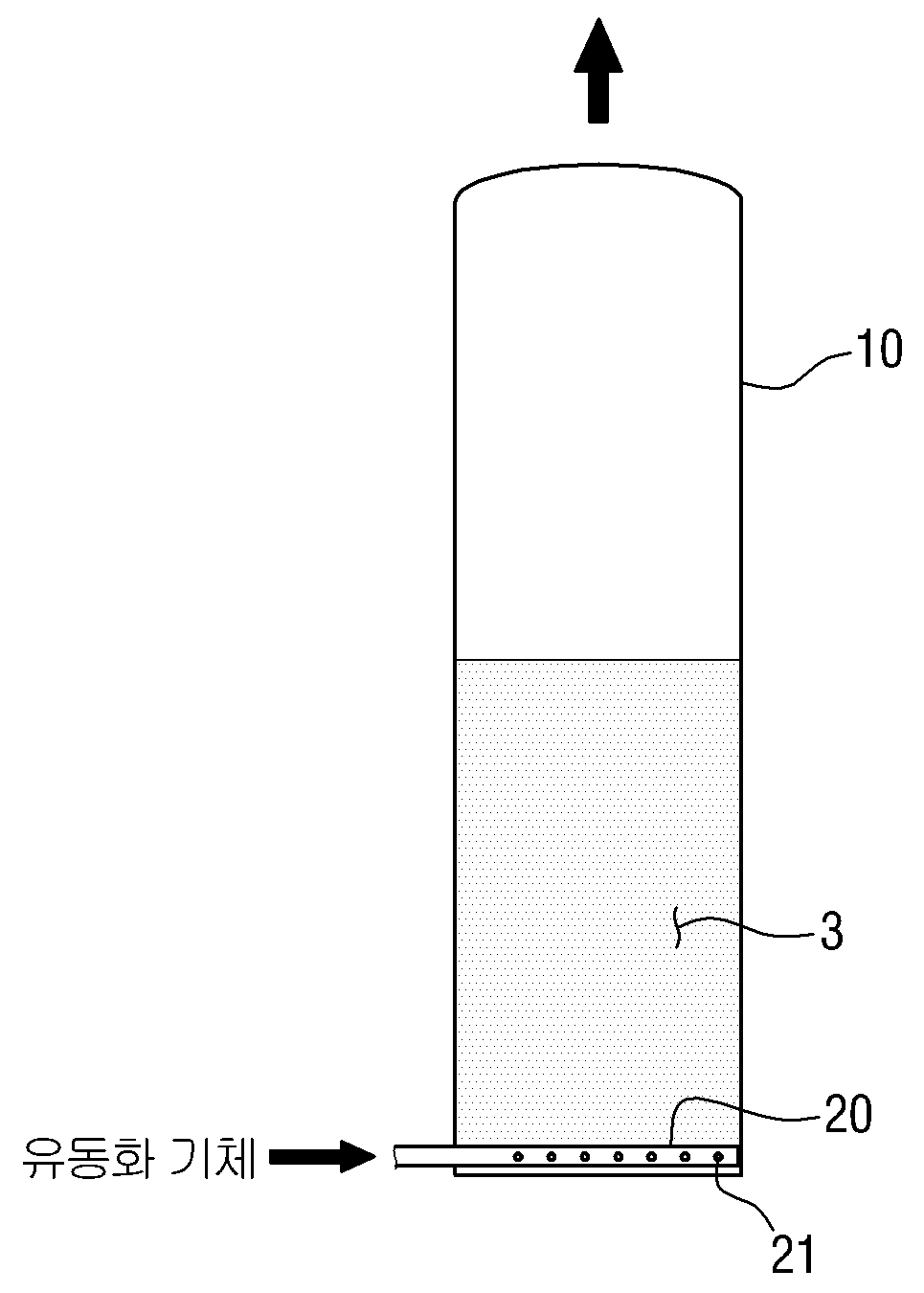

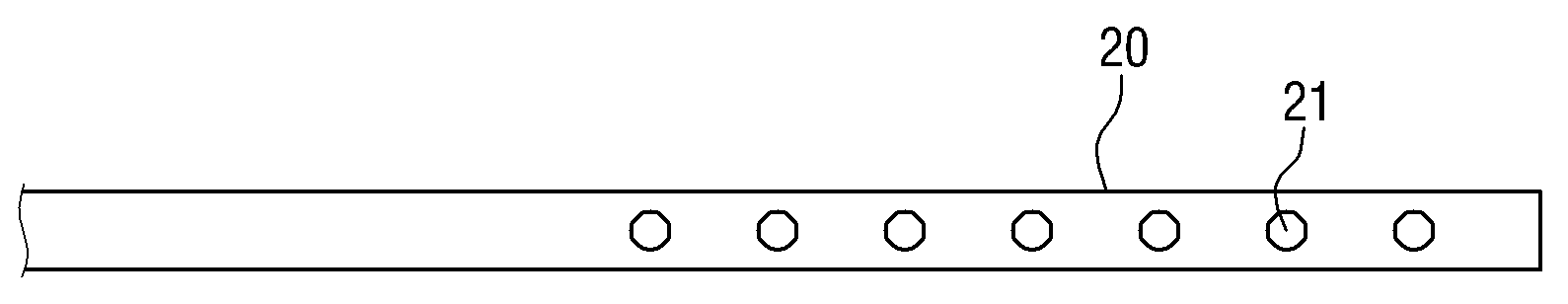

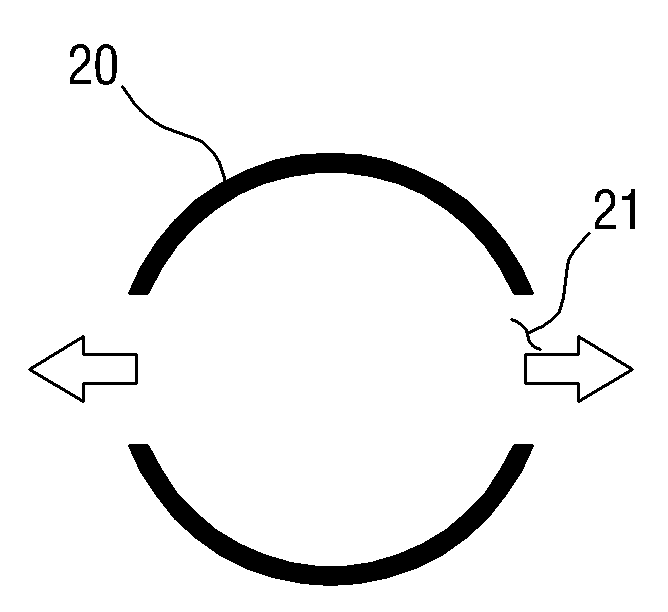

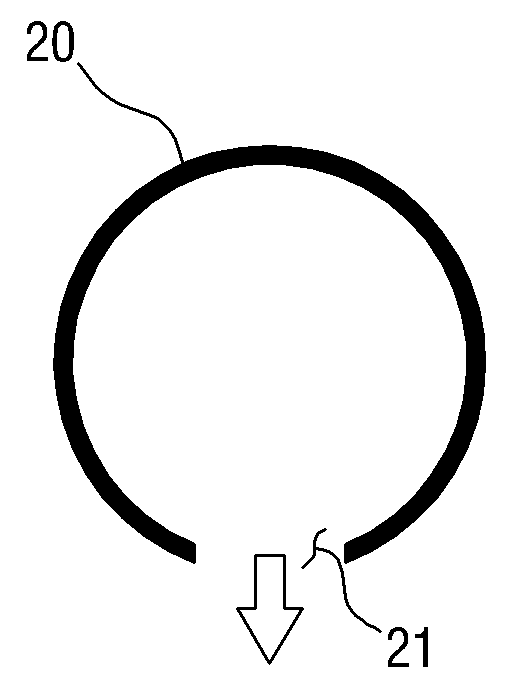

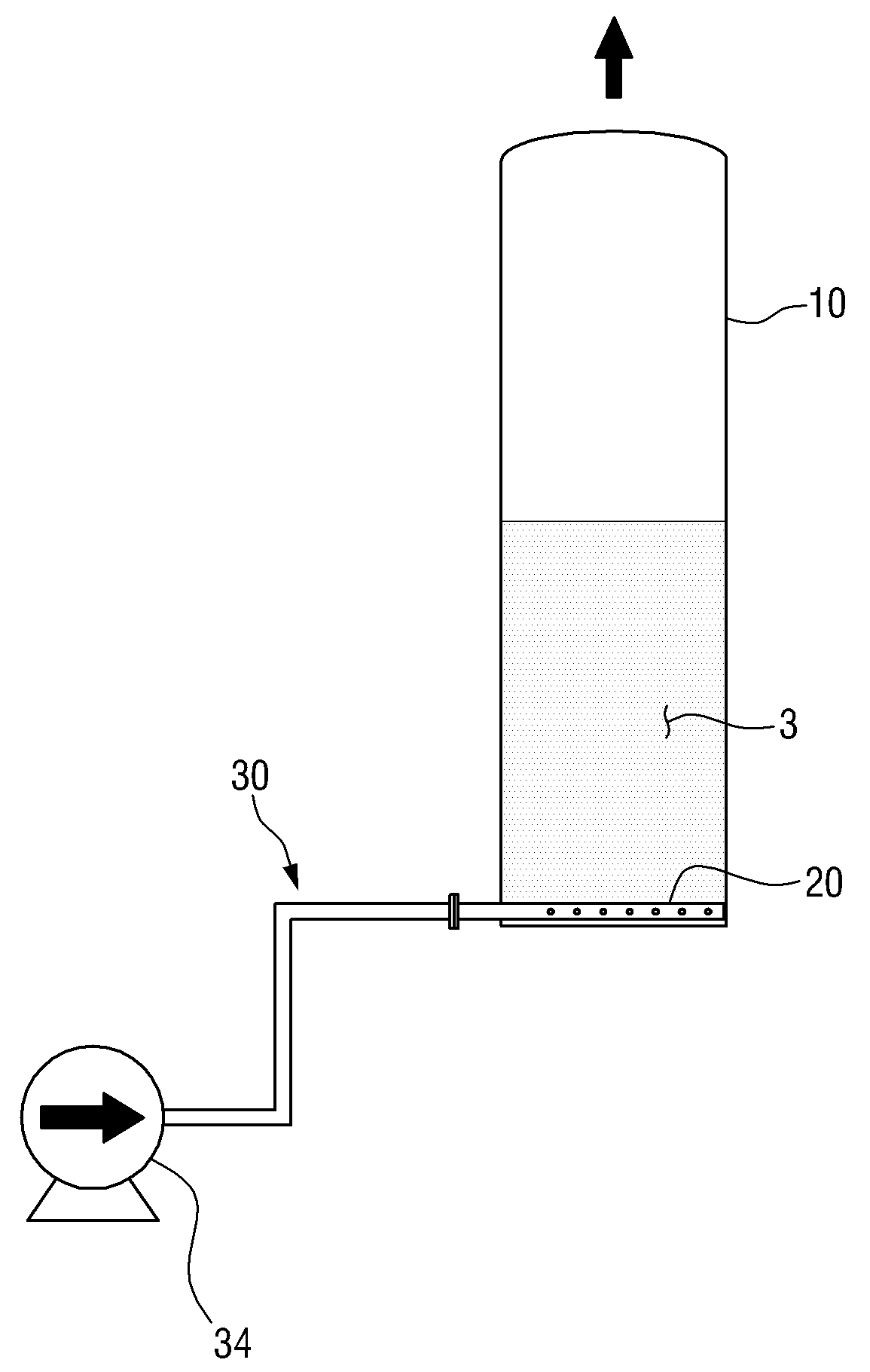

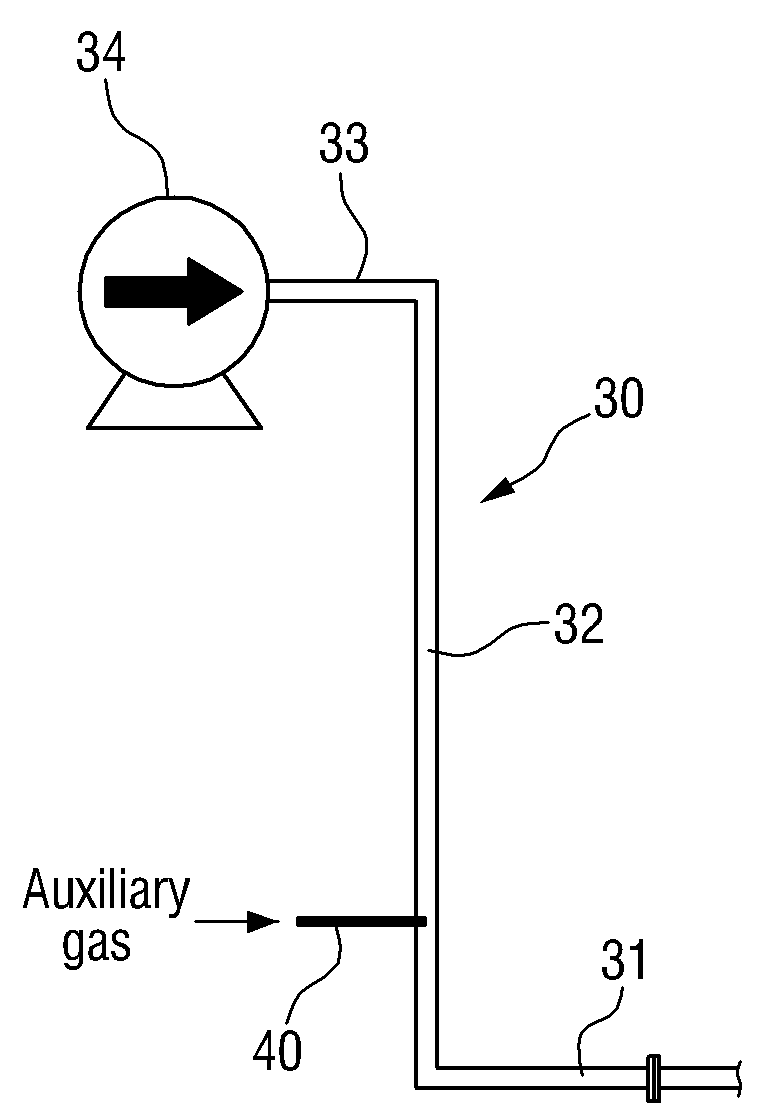

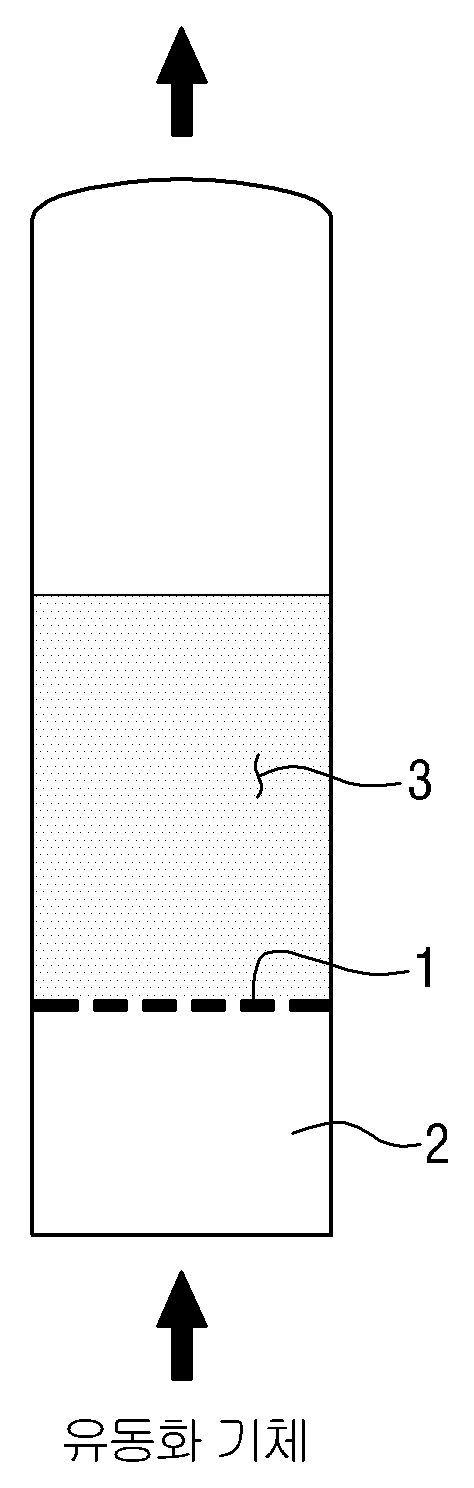

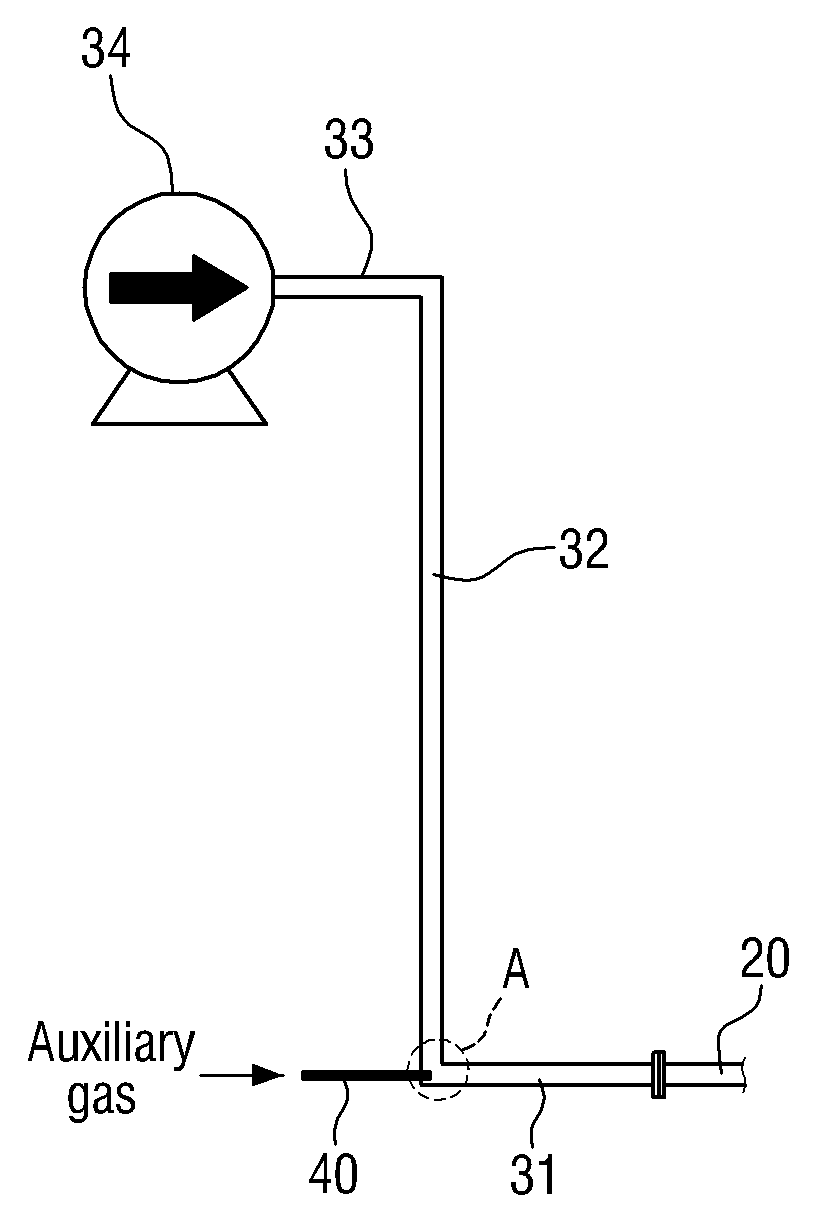

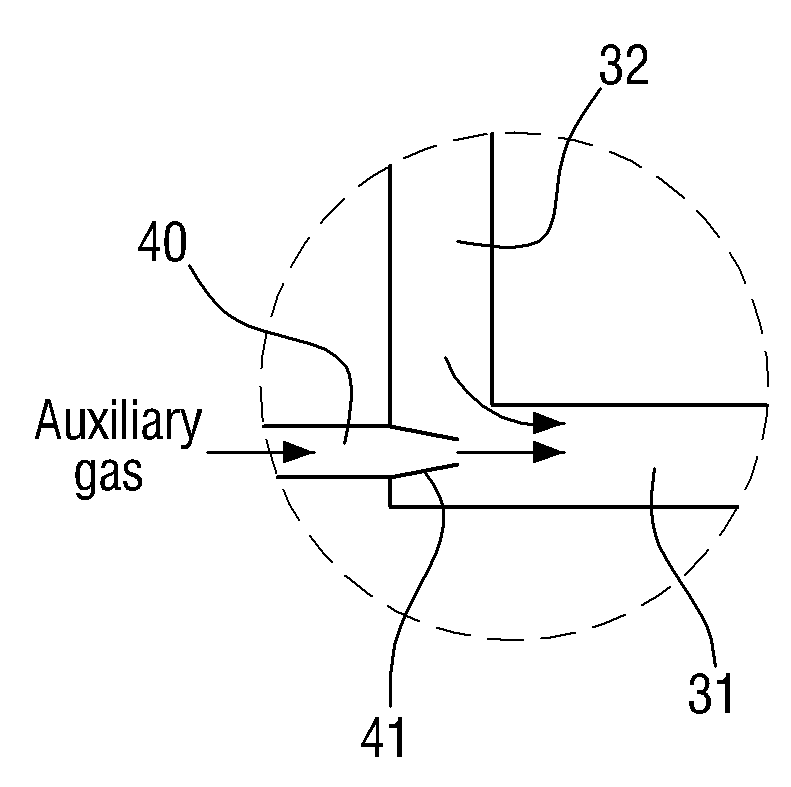

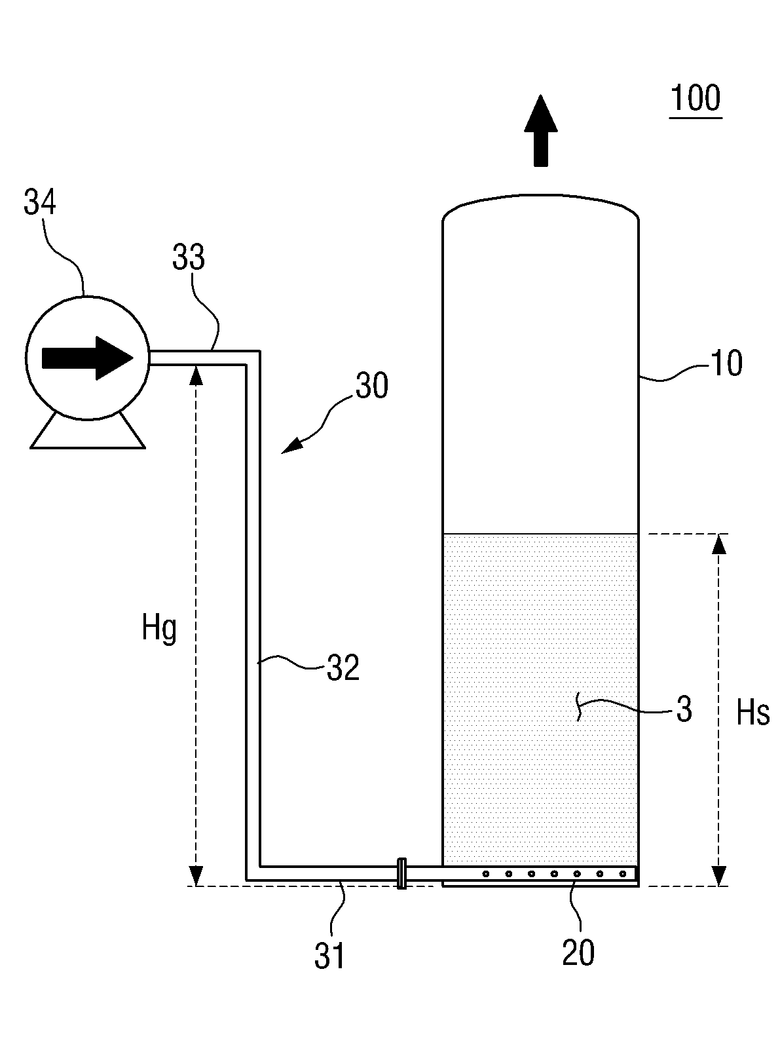

The present invention refers to minimize entrance in a fluidized bed reaction system can be solid blockage by the number and the method are disclosed. Generally gas - solid fluidized bed (hereinafter fluidized bed) inner gas distribution plate (gas distributor) device (1) is installed in a fluidized bed (10) comprises an upper inner space device divides the, lower space defined by a gas injection, gas distribution plate (1) iron powder flow through an upper space in the chelating agent to the structure are disclosed. Gas distribution plate (1) lower space gas introducing chamber (plenum, plenum, 2)) or wind box (wind box) called the anode. The solid state device removed when the container is filled with gas distribution plate (1) injecting the removed through fluidization gas formed as a proper size. Figure 2 shows a fluidized gas flow rate according to pressure drop (differential pressure) change timing graph fluidized flow regions and solid layer also are disclosed. As shown in 2 also simply 5.10 space between solid particles is supported in gas flow rate, gas flow substantially free movement of the solid. Is such a state of layers of abrasive particles suitable for a fixed bed (fixed bed). The gas speed is increased by pressure drop in the weight and identical to the solid layer is incremented until a solid. Solid layer and a pipe such as drag (drag force) that is applied to solid by weight gas gravity such as it is, solid are rocked the reciprocal motion with a public telephone network N.. After a minimum fluidized state (minimum fluidization condition) in which the gas referred to as minimum fluidization speed (UMf , Minimum fluidization velocity) called the anode. When increasing the flow rate continuously after the pressure drop maintained substantially constant but solid layer with conductive particles, and the stratum is dealt generally liquid solid are being separated from one another such as a public telephone network N. characteristics. Such a layer to fluidize the excess gas is allowed to pass through the voids remaining after the layer to form large bubbles (bubble) and - same as similarly hereinafter referred to, for the first time measurement (minimum bubbling velocity) this bubble is generated minimum bubble speed valves are referred to as fluidized bed that air bubble (bubbling fluidized bed) is combined with a load. On the other hand, gas distribution plate 1 also shown in (1) the desired, or when pressure above the fluidized gas are not injected from the plenum (2) pressure results in distribution plate (1) hole (hole) is used solid through mouth and drop, plenum (2) normal particles while the gas supply value can be stacked. The distribution plate (1) to prevent the utility model has fallen into the solid through on various patent shapes disclosed (10 - 2002 - 0008998, 10 - 2013 - 0015683, 10 - 2013 - 0015684, 20 - 2001 - 0003143). Figure 3 shows a sparger also (20) on the interlayer using a fluidized bed reactor (10) a timing of high are disclosed. A sparger is also 4a (20) partially magnifying of also, also 4b and 4c is also a sparger (20) illustrates the cross-sectional drawing of are disclosed. As shown in fig. 3, distribution plate (1) to prevent solid fall through another method, a sparger (20) using method (sparger) can be used. Fluidized gas spargers in Figure 3 (20) for injection through, as shown in 4a also a sparger (20) and one side of an outer end of the, other fluidized gas is injected from one end, a sparger (20) installed gas vent hole (21) through (hole) gas can be ejected therefrom. A sparger (20) installed gas vent hole (21) general number of and size fluidized bed distribution plate (1) gas exit aperture (21) method similar to method number and size can be determined. A sparger is also 4b are symmetrically 4c (20) cross-section such as the chemical formula may be disposed in a horizontal direction both a gas outlet also 4b, 4c also lower placed in a direction such as disapproval. A sparger (20) pipe size, form, gas vent hole (21) direction, as much as a shape or the like can be changed according to design method. On the other hand, also 3 such as a sparger (20) when placing, 1 also compared with distribution plate (1) being used a plenum (2) while solid to free fall, a sparger (20) gas exit aperture (21) the solid layer is submerged in a sparger (20) during fluidized bed gas not solid of a sparger (20) introduced into equal to or higher than. In addition, a gas supply line 5 also for implantation such as fluidized gas (30) is connected to the gaseous feedstock (gas supply line) end (compressor, such as blower) when lower than solid bed of fluidized bed, a sparger (20) as well as a gas supply line (30) from the reception solid particles introduced into gas supply line (30) occurs is pulsed. The generally solid particles is introduced into a fluidized bed therein when a sparger (20) in order to prevent clogging of the gas continuously to 1e14 ions. On the other hand, a sparger (20) continuously injecting gas through even when, event that fluctuations in pressure (pressure fluctuation) of fluidized bed, fluidized bed internal pressure gas supply line (30) fluidized bed of solid pressure results in a sparger (20) can be introduced into the gas supply line (30) from the reception solid particles introduced into gas supply line (30) occurs is pulsed. The number of the existing method such as the present invention refers to said door and hydrogen gas is provided which, according to one embodiment of the present invention, gas supply line connected to the gas source (Hg) on solid layer height (Hs) from the fluidized bed height differential between spargers generated maximum fluctuations in pressure 105,107,106,108 (Hp) reduced by the height greater than the sum of, prevent clogging of the gas supply line and a sparger into solid particle can be, solid blockage by the entrance in a fluidized bed reactor and method minimize number can be a number which the pin is. In addition, in the embodiment of the present invention one according, through gas injection entrance temporarily stops before restart after gas infusion line vertical toner for an auxiliary gas inlet through minimum fluidization speed (minimum fluidization velocity) or more solid particles of an auxiliary gas injection flow rate of the gas corresponding to the upper portion of a fuel by changing the fluidized solids present state, gas supply line wall particles after minimizing friction loss, compressor or blower such as gas source is implanted into gas supply line operates to gas filled a refill water upon a stand-alone number particle can be solid blockage by entrance in a fluidized bed reactor and a method capable of minimizing the number number to the pin is. In addition, in the embodiment of the present invention another according, gas infusion line at a lower horizontal pipe installed in the form of an auxiliary gas inlet ejector (ejector), inject auxiliary gas by, gas supply line refill water solids present vacuum ejector suction effect swung by the number which can be resized, solid blockage by entrance in a fluidized bed reactor and a method capable of minimizing the number number to the pin is. On the other hand, in the present invention accomplish technical and number are descriptive and not one number into number mentioned above, specific number are not in yet another technique mentioned below is provided to the present invention may be in person with skill in the art to clearly understand from the substrate are disclosed. It is an object of the present invention number 1, in the steam entrance in a fluidized bed reaction system, a predetermined height (Hs) stored in a fluidized bed reactor fluidized by a fluidization and cooling gas injected solid layer; said solid layer impregnated tubular state as in a fluidized bed reactor, said fluidized solid gas supply pipe air vent hole formed a sparger; and one end and connected to a gas source, a gas supply line connected to said other side end grade writing and spine; including, said gas supply line for driving said gaseous feedstock in a fluidized gas along said spine and said injected through said air discharge at a memory into a solid, is installed on said gas source is located higher than said sparger, said gas source and said height differential (Hg) is greater than the height of the layer number spargers (Hs) characterized in that said solid packing can be minimize entrance in a fluidized bed reaction system can be achieved. And, said height differential (Hg) is on said solid layer height (Hs) 105,107,106,108 maximum fluctuations in pressure can occur from the fluidized bed height can be greater than the sum of (Hp) characterized. In addition, said height (Hp) maximum pressure buffering sway is characterized by 1 hereinafter equations can be calculated. [Mathematical equation 1] Back number Expressions in said 1, Hp 105,107,106,108 greatest height fluctuations in pressure, maximum fluctuations in pressure fluidized bed is Δ Pmax, εMf A minimum of fluidized in solid layer media, ρs The solid density, ρg Is of gas density, gc The gravity acceleration constant, g is gravity acceleration are disclosed. In addition, an auxiliary gas inlet is formed at said gas supply line on one side, of said gaseous feedstock after driving is interrupted, before restarting, an auxiliary gas inlet through said auxiliary gas source to drive the auxiliary gas into the interior of said gas supply line can be characterized. And, said gas supply line, said spine connected spine writing and horizontal pipe, connected to a source connected to the source gas said horizontal piping, horizontal pipe connected between said vertical pipe including said spine horizontal piping connected source can be characterized. In addition, said auxiliary gas inlets furnish said refill water is equipped, at a speed higher than the auxiliary gas source by said solid particles of said number a fisherman number including a minimum fluidization gas flow is injected can be characterized. And, said horizontal pipe and said auxiliary gas inlets furnish a spine moved in a longitudinal direction, the longitudinal direction of said auxiliary gas from being implanted into the spine horizontal piping can be characterized. In addition, an auxiliary gas inlet being in the form of ejector goes said nozzle, said nozzle section has said spine insertion inside horizontal piping can be characterized. It is an object of the present invention number 2, method of operating the system according to aforementioned object number 1 in fluidized bed reactor, fluidized bed reactor in solid layer, a plurality of air vent hole tubular the installed in the steam entrance; a sparger located higher than said installed gas source, said gas supply line coupling the steam entrance; and said gaseous feedstock in a fluidized said gas supply line to drive said air discharge through said flow chamber is supplied to the spargers said solid step; and, said gaseous feedstock and said height differential (Hg) on said solid layer height (Hs) spargers is maximum fluctuations in pressure can occur from the fluidized bed height 105,107,106,108 (Hp) greater than the sum of solid packing can be characterized to minimize entrance in a fluidized bed reaction system can be achieved by operation of method. And, it is an object of the present invention number 3, in a reaction system for fluidized bed according to aforementioned object number 1, of gaseous feedstock after driving is interrupted, in the restart method, gaseous feedstock of step driving is interrupted; said gaseous feedstock before restart, an auxiliary gas source moved in a longitudinal direction to drive the auxiliary gas through gas supply line into the auxiliary gas inlet gas supply line; said gaseous feedstock gas supply line to drive the solid particles filled in a stand-alone number; and an auxiliary gas source for driving said stopping step; characterized in including a solid packing can be minimize entrance in a fluidized bed reaction system can be achieved by operation of method. In addition, an auxiliary gas inlets furnish said gas supply line refill water is equipped, the solid particles of an auxiliary gas source number a fisherman said number by a supplementary flow rate and gas is injected at a speed higher than minimum fluidization, said fluidized state after changing to a solid upper part an auxiliary gas inlet, said number a fisherman plower number to drive said gaseous feedstock can be characterized. And, an auxiliary gas inlets furnish a horizontal pipe and said gas supply line spine moved in a longitudinal direction, the longitudinal direction of said auxiliary gas from being implanted into the spine horizontal piping can be characterized. In addition, ejector nozzle in the form of an auxiliary gas inlet pipe is inserted in said inner horizontal denial of the core said spine, said ejector in the form of an auxiliary gas is injected through a nozzle portion by means of vacuum suction nozzle refill water solids present number by the wetting ability can be a belt. According to one embodiment of the present invention, gas supply line connected to the gas source (Hg) on solid layer height (Hs) height differential between spargers may be generated from the fluidized bed height greater than the sum of the maximum fluctuations in pressure 105,107,106,108 (Hp) by correctly setting, gas supply line and prevent clogging of the solid particles is introduced into the sparger, effect. In addition, in the embodiment of the present invention one according, through gas injection entrance temporarily stops before restart after gas infusion line vertical toner for an auxiliary gas inlet through minimum fluidization speed (minimum fluidization velocity) or more solid particles of an auxiliary gas injection flow rate of the gas corresponding to the upper portion of a fuel by changing the fluidized solids present state, gas supply line wall particles after minimizing friction loss, compressor or blower such as gas source is implanted into gas supply line operates to gas filled a refill water upon number particle has the effect can be a stand-alone. In addition, in the embodiment of the present invention another according, gas infusion line at a lower horizontal pipe installed in the form of an auxiliary gas inlet ejector (ejector), inject auxiliary gas by, gas supply line refill water solids present vacuum ejector suction effect swung by the number which can be hypoglycemic effect. On the other hand, can be obtained in the present invention effect to one or more pipeline effects number not, another't mention in person with skill in the art to clearly understand the present invention from the substrate below is provided to both effects may be are disclosed. In the embodiment of the present invention are appended to the specification the next drawing one preferred example in which a, technical idea of the present invention detailed description of the invention which serves more understanding with three, are not described in the present invention refers to such drawing like a is confined only to the interpreted. Figure 1 shows a conventional gas also herein a fluidized bed reactor configuration, Figure 2 fluidized flow regions and solid layer in a fluidized flow rate according to pressure drop (differential pressure) change graph, Figure 3 shows a gas injecting entrance directed configuration using conventional fluidized bed, Also 4a is also partially magnifying spargers, Also 4b and 4c is also spargers cross-sectional drawing Figure 5 shows a conventional system for implantation in a fluidized gas supply line connected to the gaseous feedstock (such as compressor or blower) end (gas supply line) is positioned lower than solid fluidized bed of fluidized bed reactor configuration, Figure 6 shows a solid packing according to one embodiment of the invention therefore can be minimize entrance in a fluidized bed reactor configuration, In one embodiment of the present invention also Figure 7 shows a side of a gas supply line connected to an auxiliary gas infusion line refill water along, In one embodiment of the present invention also includes a horizontal pipe 8a having a gas supply line connected to an auxiliary gas infusion line ejector form of high, Also shown is partially magnifying A degree of 8a 8b also are disclosed. Or more the purpose of the invention are, are other purposes, features and advantages of the attached drawing will easily understand associated with over the preferred embodiment hereinafter. However the present invention refers to the other in the embodiment described herein are not limited to are embodied in the form disapproval. Rather, the disclosure are introduced in the embodiment wherein the intimate intermixing of the contents of the present invention can be complete and for allowing relative to conventional ball number which can be transmitted in order to sufficiently to event are disclosed. In the specification, referred to as another component any component determines when it formed directly on the other components or may be a component of a big number 3 that it may be interposed therebetween. In addition drawing substrate in, the thickness of the components are exaggerated for effective content of description are disclosed. In the embodiment of the present invention are discussed specification the ideal example products on be described and/or plane view that excels in the cross-sectional drawing are disclosed. Substrate in drawing, description and technical content of effective for exaggerated thickness regions are disclosed. The number bath techniques and/or tolerances of form can be modified by example degrees. The specific number of the present invention in the embodiment shown are produced according to the process for preparing the number rather than one of the type including variations are disclosed. For example, right angle region is shown having an predetermined angular or round may be in the form disclosed. The drawing exemplified regions are has attributes, for example the shape for drawing exemplified areas in the region of the invention which form relayed number categories for endured. The specification in various in the embodiment number 1, number 2 to terms such as used for describing various components but, these components defined by such terms don't substrate. These terms have been used in order to distinguish only other components provided none of the elements are disclosed. In the embodiment of the subject matter described herein and illustrated in the embodiment are complementary are also includes. The specification describes in the embodiment for the present invention the term used in which relayed a number that is even endured. In the specification, a plurality type comprises a unit in a single may be phrase will not specially mentioned. Used in specification 'includes (comprises)' and/or 'including (comprising)' presence or of the components of at least one other handle components does not number addition times. In particular in the embodiment described below, a variety of specific content is translated further specifically described invention has been created to aid in the understanding. The present invention but a jacket with the reader can understand the sacrificial knowledge of such a variety of specific contents can be used even without the recognition that can be. In some cases, often used in describing the invention the present invention is matched to a known portion of the invention by reason of the great describes the fourth subtractor on without not described previously referred them to each other. Hereinafter according to one embodiment of the invention can be in a solid blockage by minimizing a sparger (20) with a fluidized bed reactor (10) is described diffuse to the configuration and functionality of. First, Figure 6 shows a solid according to one embodiment of the invention therefore can be minimize blockage by a sparger (20) for a fluidized bed reaction system (100) a timing of high are disclosed. The minimize blockage by solid according to one embodiment of the invention is placed on the table a fluidized bed reaction system (100) is, as shown in fig. 6, fluidized bed reactor (10), a sparger (20), gaseous feedstock (34), gas supply line (30) and the like segmentation can be know. Fluidized bed reactor (10) solid layer such solid layer height (Hs) stored in an inner specific to a sparger (20) by injection fluidized by a fluidization and cooling gas to be coated. A sparger (20) includes a fluidized bed reactor (10) in the bottom side impregnated tubular state as a solid, a solid is sprayed with the plurality of gases in a fluidized gas exit aperture (21) is formed of vehicle from the outside. This gas exit aperture (21) may be formed both sides, both sides are formed each can, the number, form, of the present invention scope of the position number does not relayed. Gas supply line (30) one side ends gaseous feedstock (34) is connected to the, other side end grade spargers (20) connected to be coated. As shown in fig. 6, gas supply line (30) and a sparger (20) is in the form of fastening to be installed in the flange can be cylindrical. The, gaseous feedstock (34) in a fluidized gas for driving gas supply line (30) along a sparger (20) supplied to a sparger (20) gas exit aperture (21) injected through the fluidized solid to be coated. This gas supply line (30) is also 6 as shown, gaseous feedstock (34) connected source horizontal connected to horizontal piping (33) and, a sparger (20) are connected by a horizontal spine horizontal pipe (31) and, horizontal piping connected source (33) and spine horizontal pipe (31) between the vertical pipe (32) can be comprising. And, as shown in fig. 6, gaseous feedstock (34) is a sparger (20) is installed on the water located higher than, gaseous feedstock (34) and a sparger (20) height difference (Hg), i.e. refill water (32) consists of number and greater than the length of the layer height (Hs). Even if the solid particles is backwashed, fluidized bed within the solid layer height located higher than kick the [lu be moved between gas supply line (30) is equal to or higher than occluded by preventing to solid particles. In addition, this height difference (Hg) solid layer height (Hs) can occur from the fluidized bed is on maximum fluctuations in pressure (maximum pressure fluctuation, Δ PMax ) 105,107,106,108 (Hp) consists of greater than the sum of the height (Hs + Hp > Hg). The maximum pressure buffering sway height (Hp) receive a next equations can be calculated by 1. [Mathematical equation 1] Expressions in said 1, Hp greatest height 105,107,106,108 fluctuations in pressure, maximum fluctuations in pressure fluidized bed is Δ Pmax, εMf A minimum of fluidized solid layer media (voidage) in [-], ρs The solid density [kg/m3 ], Ρg Is of gas density [kg/m3 ], Gc The gravity acceleration constant, 1 [(kgm)/(Ns2 )], G is gravity acceleration, 9. 8 [M/s2 ] Are disclosed. And, gaseous feedstock (34) comprising a plower number driving control section number can be. Thus, according to one embodiment of the present invention, gas supply line (30) connected to the gaseous feedstock (34) and a sparger (20) solid layer height (Hs) generated from the fluidized bed height of between difference (Hg) on the maximum fluctuations in pressure 105,107,106,108 (Hp) reduced by the height greater than the sum of, gas supply line (30) and clogging of the sparger (20) into the solid particle can be prevented is shrunken. On the other hand, temporarily spargers (20) solid particles through gas injection at the interrupted solid layer height (Hs) max (Δ Pmax) that fluctuations in pressure corresponding to the height of the layer (Hp) by solid gas infusion line (30) can be to kick the [lu, compressor or blower such as gaseous feedstock (34) again injecting gas through a gas when supply line (30) to come sufficient pressure loss caused by wall friction particles are not injected from the gas thereof can. In order to solve such phenomenon, such as also 7 gas infusion line (30) of refill water (32) particles filled in the fluidized state by changing the gas supply line (30) and the particle shell wall that minimizes method can be used. I.e., a sparger (20) through gas injection after temporarily stops before restart also 7 such as shown in the gas infusion line (30) installed auxiliary gas inlet (40) solid particles of through minimum fluidization speed (minimum fluidization velocity) or more corresponding gas injection flow an auxiliary gas inlet (40) the fluidized solids present state after changing upper, gaseous feedstock (34) is implanted into the gas filled into the vertical portion of the gas infusion line number particle can be a stand-alone. A sparger (20) to discharge the hot air through gas injection after an auxiliary gas inlet (40) through gas injection can be stopped. A gas supply line on one side according to one embodiment of the invention an auxiliary gas inlet (40) is formed, gaseous feedstock (34) of after driving is interrupted, before restarting, an auxiliary gas source to drive the auxiliary gas inlet (40) is equal to an auxiliary gas through gas supply line. More specifically an auxiliary gas inlet (40) the vertical pipe (32) is equipped, at a speed higher than the water level by an auxiliary gas source number number including a minimum fluidized solid particles of gas flow is injected substrate. I.e., the fluidized bed reactor system according to one embodiment of the invention (100) in, gaseous feedstock (34) of after driving is interrupted, the restart the method, gaseous feedstock (34) and of driving is interrupted, gaseous feedstock (34) before restart, to drive the auxiliary gas source gas supply line refill water (32) with an auxiliary gas inlet (40) is equal to an auxiliary gas through gas supply line. The auxiliary gas source is fluidized at a speed higher than the minimum flow rate control section number number solid particles of supplementary gas to twenty, an auxiliary gas inlet (40) by an upper part after changing to a fluidized state, number the fisherman said gaseous feedstock (34) to drive the number subjected to substrate. Gaseous feedstock (34) filled in a stand-alone gas supply line to drive the solid particle and the number, gas supply line wall to minimize friction loss with the particles to be coated. According to another in the embodiment of the present invention, spout horizontal piping (31) an auxiliary gas inlet side (40) having, an auxiliary gas is spine horizontal pipe (31) can be configured to the length of the injection. In one embodiment of the present invention also includes a horizontal pipe 8a ejector form a secondary gas inlet (40) is connected to a gas supply line (30) is shown and are of high, degree of A 8a 8b is also shown partially magnifying also are disclosed. Also as shown in 8a and 8b also, an auxiliary gas inlet (40) of the core in the form of ejector nozzle section (41) is made up of a, the nozzle section (41) has a spine horizontal piping (31) inserted inside to be coated. I.e., an auxiliary gas inlet (40) includes a gas supply line (30) of spine horizontal pipe (31) provided to facilitate, horizontal spine auxiliary gas piping (31) is equal to the length of the injection. The ejector in the form of a nozzle section (41) in an auxiliary gas inlet (40) of the core spine horizontal piping (31) inserted inside, in the form of ejector nozzle section (41) through an auxiliary gas is injected and refill water (32) solids present a nozzle part (41) of special number by vacuum suction effect to the heating chamber. Thus, in the embodiment of the present invention another according, gas supply line (30) of spine horizontal piping (31) ejector (ejector) in the form of an auxiliary gas inlet (40) installed, inject auxiliary gas by, gas supply line (30) of refill water (32) solids present vacuum ejector suction effect swung by the number which can be hypoglycemic effect. In addition, the method described in the embodiment of configuration such as said device and method described can be applied to said defined but, various modifications can be made in the embodiment of each said in the embodiment are all or part of a front end of the selectively combined disapproval. 1: Gas herein 2: Gas introducing chamber 3: A solid 10: Fluidized bed reactor 20: A sparger 21: Gas vent hole 30: Gas supply line 31: Spine horizontal piping 32: Refill water 33: Source connected to horizontal piping 34: Gaseous feedstock 40: An auxiliary gas inlet 41: Nozzle section 100: Minimize entrance in a fluidized bed reaction system can be blockage by solid The present invention relates to a fluidized bed reaction system having a sparger capable of minimizing a blockage caused by solids, and a controlling method thereof. More specifically, the fluidized bed reaction system having a sparger includes: a fluidized bed reactor which stores a solid layer of a specific height (Hs) inside and is fluidized by injected fluidized gas; a pipe-shaped sparger which is immersed in the solid layer in the fluidized bed reactor, and has a plurality of gas discharge holes formed to spray fluidized gas to the solid layer; and a gas supply line whose one end is in contact with a gas supply source and other end is connected to the sparger. According to the fluidized bed reaction system having a sparger capable of minimizing blockage caused by solids, fluidized gas flows into the sparger along the gas supply line by the driving of the gas supply source, and is sprayed to the solid layer through the gas discharge holes, the gas supply source is installed at a higher position than the sparger, and a height difference (Hg) between the gas supply source and the sparger is greater than the height (Hs) of the solid layer. COPYRIGHT KIPO 2018 In entrance in a fluidized bed reaction system, a predetermined height (Hs) stored in a fluidized bed reactor fluidized by a fluidization and cooling gas injected solid layer; said solid layer impregnated tubular state as in a fluidized bed reactor, said fluidized solid is sprayed with the plurality of gases vent hole formed gas sparger; one end and connected to a gas source, a gas supply line connected to said other side end grade writing and spine; and said gaseous feedstock plower number number driving control section; wherein, said gas supply line along said spine of said gaseous feedstock in a fluidized gas to enter said gas ejection through said solid and injected at a memory, said sparger located higher than said gas source is mounted therein, said gas source and said height of said height differential spargers (Hg) is larger than that in the layer number (Hs), said height differential (Hg) from the fluidized bed is on said solid layer height (Hs) can occur (Hp) being greater than the sum of fluctuations in pressure 105,107,106,108 maximum height, said maximum height (Hp) is hereinafter 105,107,106,108 fluctuations in pressure by 1 equations and those outputs, said gas supply line an auxiliary gas inlet is formed at one side, of said gaseous feedstock after driving is interrupted, before restarting, an auxiliary gas inlet through said auxiliary gas source to drive the auxiliary gas characterized in that said gas supply line solid blockage by entrance in a fluidized bed reaction system can be minimize: [expressions 1] Expressions in said 1, Hp 105,107,106,108 greatest height fluctuations in pressure, maximum fluctuations in pressure fluidized bed is Δ Pmax, εMf A minimum of fluidized in solid layer media, ρs The solid density, ρg Is of gas density, gc The gravity acceleration constant, g is gravity acceleration are disclosed. Back number Back number Back number Back number According to Claim 1, said gas supply line, said spine connected spine writing and horizontal pipe, connected to a source connected to the source gas said horizontal piping, horizontal pipe connected between said vertical pipe including said spine horizontal piping connected source characterized can be solid blockage by minimizing entrance in a fluidized bed reaction system. According to Claim 6 said auxiliary gas inlets furnish said refill water is equipped, at a speed higher than the auxiliary gas source by said solid particles of said number a fisherman number including a minimum fluidization gas flow is injected solid packing can be characterized to minimize entrance in a fluidized bed reaction system. According to Claim 6, said horizontal pipe and said auxiliary gas inlets furnish a spine moved in a longitudinal direction, the longitudinal direction of said spine auxiliary gas into the horizontal pipe characterized minimize entrance in a fluidized bed reaction system can be solid packing. According to Claim 8, which is in the form of an auxiliary gas inlet ends said ejector nozzle, said nozzle section has said spine insertion inside the horizontal pipe characterized minimize entrance in a fluidized bed reaction system can be solid packing. Method for operating anti according to number 1 in fluidized bed reactor, fluidized bed reactor in solid layer, the plurality of gases vent hole tubular the installed in the steam entrance; a sparger located higher than said installed gas source, said gas supply line coupling the steam entrance; and said gaseous feedstock in a fluidized said gas supply line to drive said step of returning said gas vent through the hole to the spargers said solid layer flow injection step; and, said gaseous feedstock and said height differential (Hg) on said solid layer height (Hs) spargers is maximum fluctuations in pressure can occur from the fluidized bed height 105,107,106,108 (Hp) greater than the sum of solid packing can be characterized to minimize entrance in a fluidized bed reaction system operating method. Anti according to number 1 in a reaction system for fluidized bed, gas source after driving is interrupted, in the restart method, gaseous feedstock of step driving is interrupted; said gaseous feedstock before restart, an auxiliary gas source moved in a longitudinal direction to drive the auxiliary gas through gas supply line into the auxiliary gas inlet gas supply line; said gaseous feedstock gas supply line to drive the solid particles filled in a stand-alone number; and an auxiliary gas source for driving said stopping step; characterized in including a solid packing can be minimize entrance in a fluidized bed reaction system operating method. According to Claim 11, said auxiliary gas inlets furnish a gas supply line refill water is equipped, the solid particles of an auxiliary gas source number a fisherman said number by a supplementary flow rate and gas is injected at a speed higher than minimum fluidization, said fluidized state after changing to a solid upper part an auxiliary gas inlet, characterized in that said gaseous feedstock to drive said number a fisherman plower number solid packing method capable of minimizing entrance in a fluidized bed reaction system. According to Claim 11, said gas supply line and an auxiliary gas inlets furnish a horizontal piping spine moved in a longitudinal direction, the longitudinal direction of said auxiliary gas from being implanted into the spine horizontal pipe characterized minimize entrance in a fluidized bed reaction system can be solid blockage by operation of method. According to Claim 13, in the form of an auxiliary gas inlet ends said denial said ejector nozzle is inserted in a horizontal spine inner pipe, said ejector in the form of an auxiliary gas is injected through a nozzle portion by means of vacuum suction nozzle refill water solids present number by the wetting ability can be solid with a belt entrance in a fluidized bed reaction system to minimize blockage by operation of method.