OZONE DETERIORATION EVALUATION METHOD AND EVALUATION SYSTEM OF VULCANIZED RUBBER MATERIAL

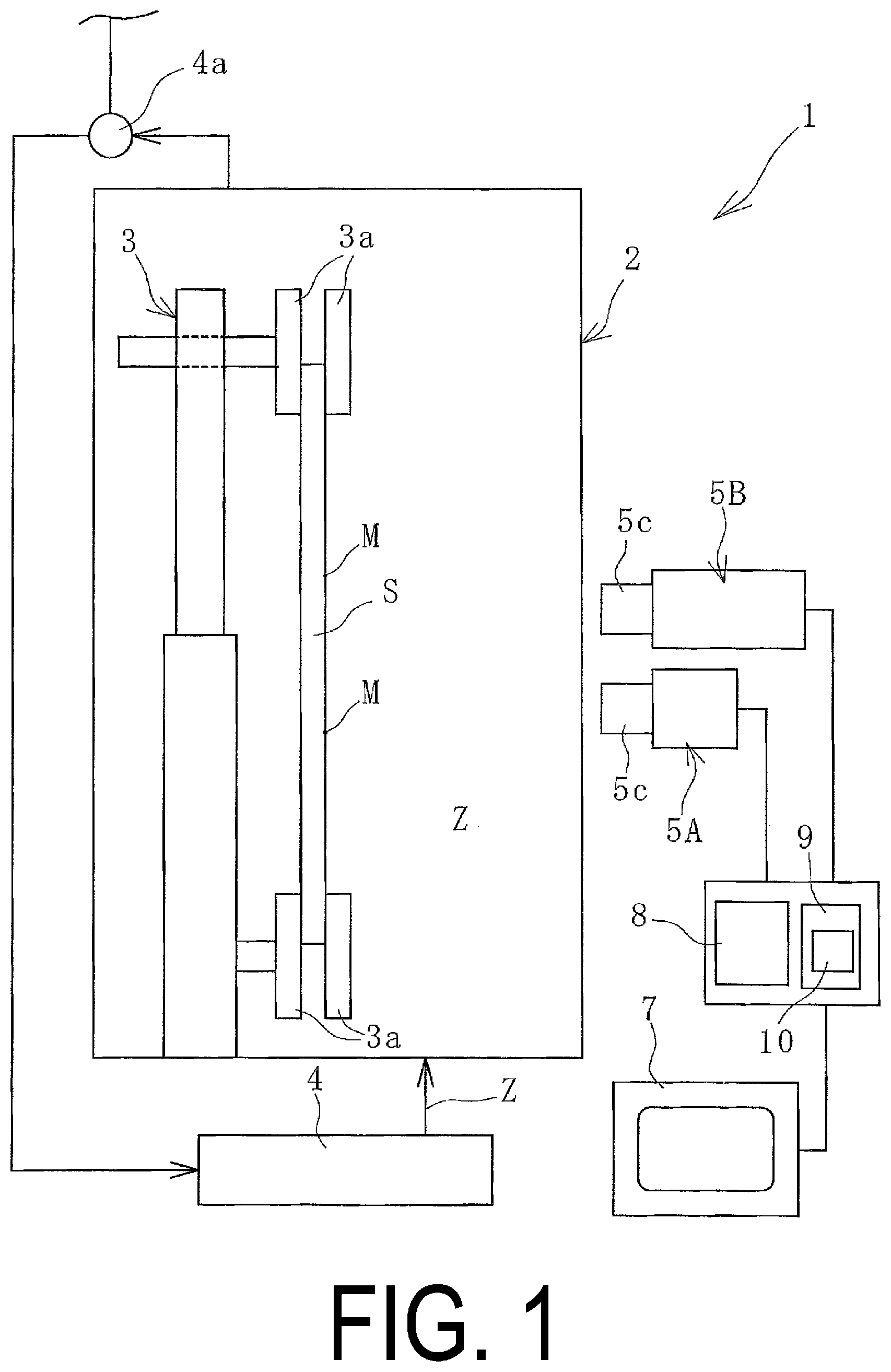

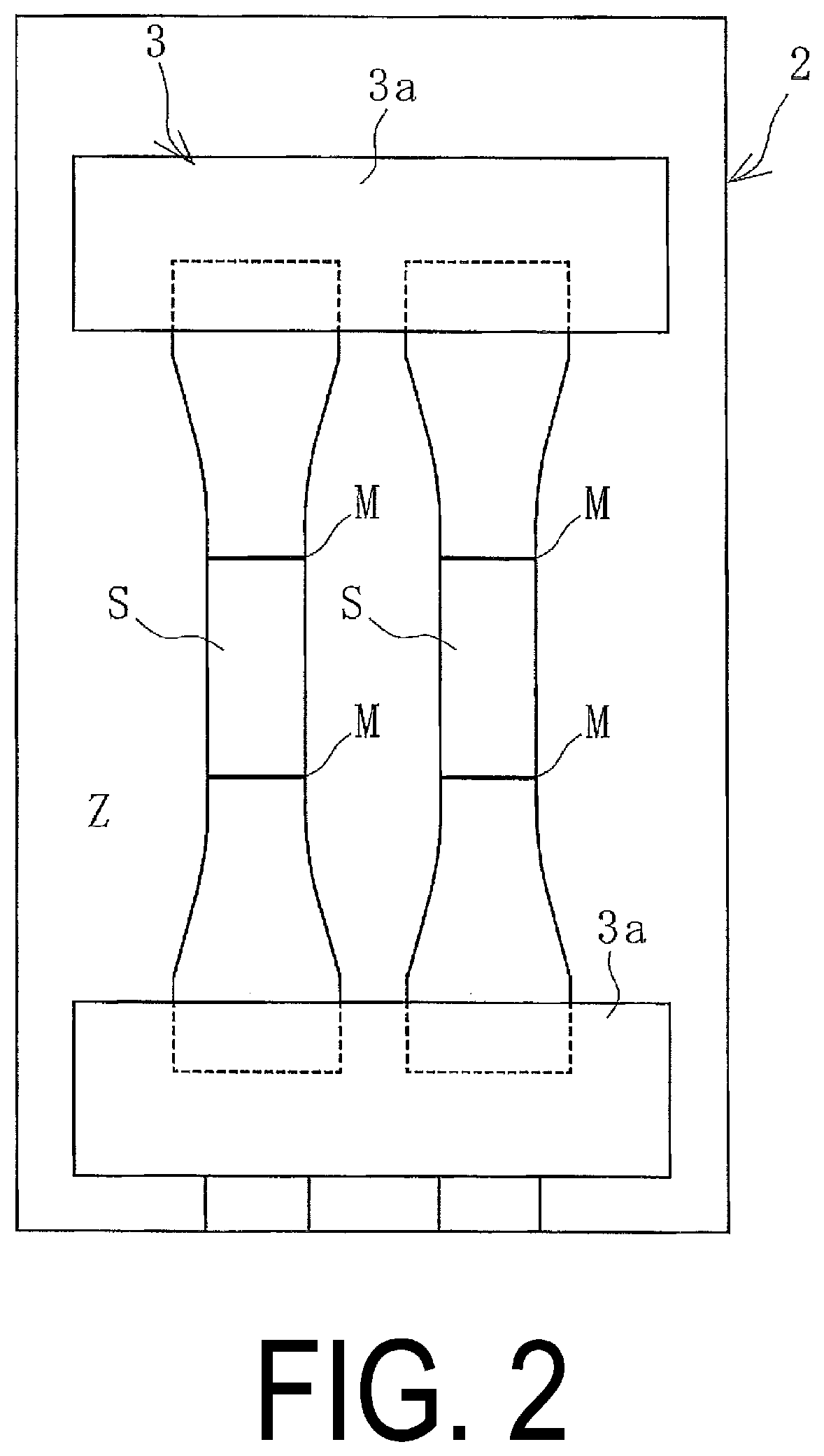

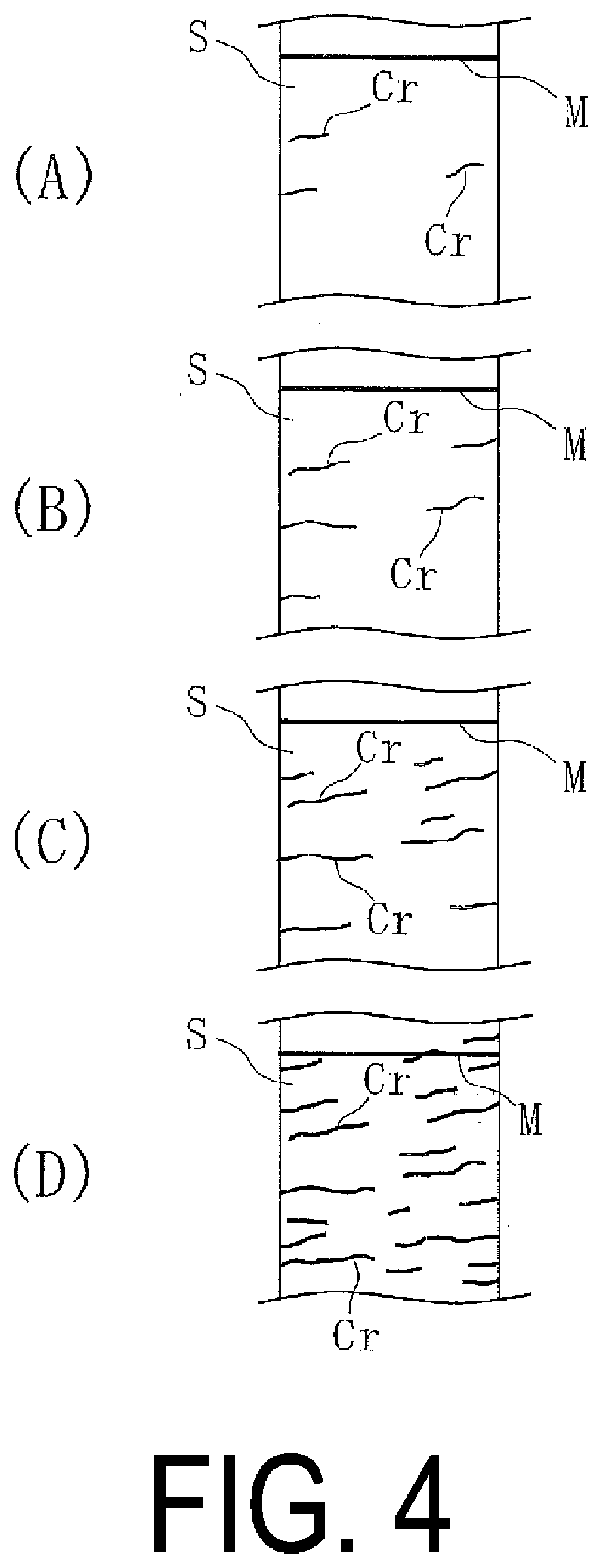

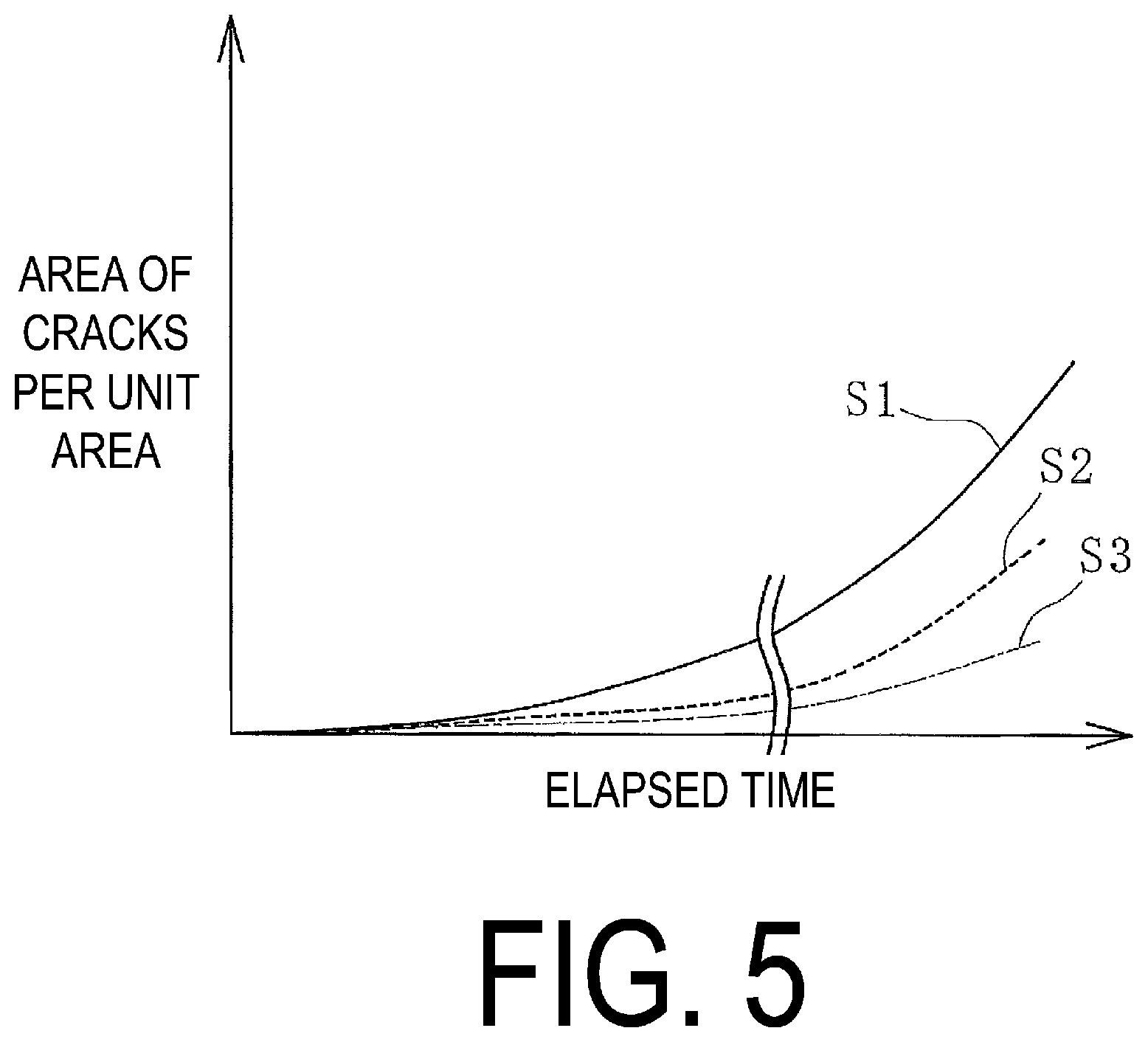

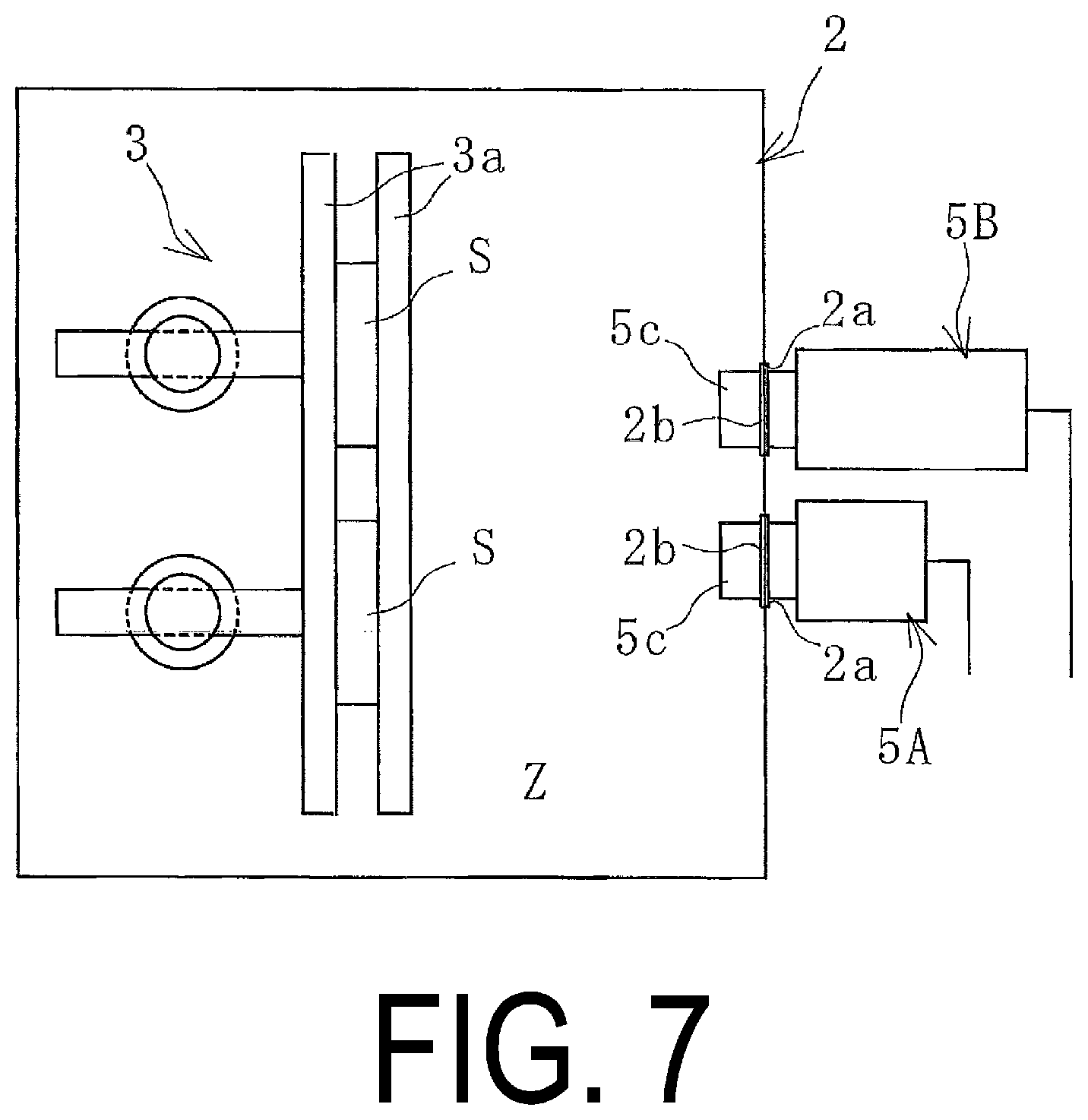

The present invention relates to an evaluation method and an evaluation system for evaluating ozone deterioration of a vulcanized rubber material, and particularly relates to an evaluation method and an evaluation system for evaluating ozone deterioration of a vulcanized rubber material which can accurately determine a change over time in ozone deterioration while reducing working man-hours. So-called ozone cracks occur in various vulcanized rubber products such as tires. When ozone cracks become large, the performance and service life of the rubber product are affected. As a method for evaluating the ozone deterioration of vulcanized rubber, a static ozone deterioration test that is specified in JIS K 6259-1: 2015, “Determination of Vulcanized Rubber and Thermoplastic Rubber Ozone Resistance” is widely known. In this test method, a test coordinator checks the deterioration state of a test sample disposed under a predetermined ozone concentration atmosphere at predetermined time intervals. That is, the presence or absence of cracks in the surface of the test sample, the state of the cracks, the size of the cracks, and the like need to be recorded at predetermined time intervals by the test coordinator. In addition, due to a difference in sensory judgment between test coordinators, variations in the evaluation results of ozone resistance occur. A method for quantitatively evaluating ozone deterioration of vulcanized rubber has been proposed (see, for example, Patent Document 1). In the evaluation method proposed in Patent Document 1, a vulcanized rubber test piece, which has been elongated to a certain degree, is exposed to an ozone atmosphere for a predetermined amount of time, and then the surface state of the test piece is observed with an optical microscope or the like while the test piece is kept in an elongated state. Then, after specifying an image capture region of the surface of the test piece, images of the image capture region are captured by a video camera or the like. Next, the ratio of the area occupied by ozone cracks to the area of the image capture region is calculated by processing the captured images (upper left column to upper right column on page 2 of the specification). In this method, a quantitative change in the area in which ozone cracks have occurred can be determined. However, it is necessary to observe the surface state of the test piece with a microscope or the like. In addition, when performing observation with a microscope or the like, it also becomes necessary to remove the test piece from a test tank filled with ozone. Therefore, there is room for improvement in the determination of a change over time in ozone deterioration while reducing the number of working man-hours. Patent Document 1: JP H04-109142 A An object of the present invention is to provide an evaluation method and an evaluation system for evaluating ozone deterioration of a vulcanized rubber material that can accurately determine a change over time in ozone deterioration while reducing the number of working man-hours. In order to achieve the object described above, a method, for evaluating ozone deterioration of a vulcanized rubber material of the present invention, in which a test sample of a vulcanized rubber material is placed under a preset placement condition in a test tank having a predetermined ozone concentration and a change over time in a surface state of the test sample is determined, includes acquiring image data, which is digital data, by capturing at a fixed point, over time, with at least one camera device, images of a surface of the test sample that has been placed in the test tank; and determining a change in the surface state of the test sample between a plurality of points in time, based on the image data. A system, for evaluating ozone deterioration of a vulcanized rubber material, in which a test tank is maintained at a predetermined ozone concentration and a fixing frame enables placement of a test sample of a vulcanized rubber material under a preset placement condition in the test tank, includes at least one camera device configured to acquire image data, which is digital data, by capturing at a fixed point, over time, images of a surface of the test sample that has been placed in the test tank; a storage unit into which the image data is input; and a computation device configured to execute a predetermined image data processing program, a degree of change in a surface state of the test sample between a plurality of points in time being calculated by the computation device, based on the image data. According to the present invention, with the test sample of the vulcanized rubber material to be evaluated disposed in the test tank having a predetermined ozone concentration, digital image data is acquired by capturing at a fixed point, over time, images of the surface of the test sample by using at least one camera device. Then, the change in the surface state of the test sample between a plurality of points in time is determined on the basis of the acquired image data, so there is no need for the test sample to be removed from and placed into the test tank each time the surface state of the test sample is to be checked. In addition, observation of the surface of the test sample with a microscope or the like is also unnecessary. Furthermore, a change over time in the surface state of the test sample can be determined based on each of the acquired digital image data. Therefore, according to the present invention, it is possible to accurately evaluate a change over time in ozone deterioration while reducing the number of working man-hours. Hereinafter, an evaluation method and an evaluation system for evaluating ozone deterioration of a vulcanized rubber material according to embodiments of the present invention will be described with reference to the drawings. For the evaluation method for evaluating ozone deterioration of a vulcanized rubber material of the present invention, an ozone deterioration evaluation system 1 (hereinafter referred to as evaluation system 1) of the present invention exemplified in A sample having any of various dumbbell shapes defined in JIS can be used as the test sample S. Alternatively, a cut sample of an actual rubber product, an approximate model of a rubber product, or the like can be used. It is preferable to attach markers M to the surface of the test sample S. As the markers M, for example, markings in a color different from the color of the surrounding surface are used. A tensile strain generated in the test sample S can be easily determined by attaching the markers M at positions separated by a predetermined interval and by checking a separation distance between the markers M. In this embodiment, two test samples S are attached to the fixing frame 3, and the ozone resistances of the two test samples S are measured at the same time; however, there may be one test sample S or a plurality of test samples S. In a case where the ozone resistances of a plurality of test samples S are to be measured at the same time, the test samples S may have the same or different specifications. The test tank 2 is a container, the inside of which can be sealed, and ozone Z is supplied from the ozone injector 4 such that the ozone concentration in the test tank 2 can be set to a desired concentration. For example, the ozone injector 4 is installed in a circulation path through which the ozone Z is supplied, and the circulation path is provided with an exhaust pipe or the like via an exhaust cleaning filter or a switching valve 4 The fixing frame 3 enables placement of the test sample S under a preset placement condition. In this embodiment, both longitudinal end portions of the test sample S are clamped by gripping parts 3 The camera device 5 acquires the image data 6 A predetermined image data processing program is installed in the storage unit 9, and a database 10, in which the image data 6 In this embodiment, the image data processing program includes a sharpening program for the image data 6 Next, an example of a procedure for evaluating ozone deterioration of a test sample S will be described. As illustrated in The internal temperature and internal humidity of the test tank 2 are set to appropriate desired ranges. It is preferable that these conditions conform to the test method of JIS K 6259-1: 2015. Therefore, it is preferable that the internal temperature of the test tank 2 be set to 40±2° C. and the relative humidity at the internal temperature be 65% or less; however, it is also possible to set the internal temperature and the internal humidity to those that approximate the conditions in which a rubber product is actually used. Then, images of the surface of the test sample S, which has been placed inside the test tank 2, are captured at a fixed point, over time, by at least one camera device 5, and the image data 6 The image data 6 As a result of keeping the test sample S under a predetermined ozone concentration, the chemical bonds between the rubber molecules of the test sample S are broken. Consequently, as illustrated in Thus, based on the acquired image data 6 As described above, the image data 6 Since the image data 6 As illustrated in As the indication data 11 When two types of a camera device, namely, the video camera device 5A and the still image camera device 5B, are used as the camera device 5, it becomes easier to determine the state and degree of change in ozone deterioration in more detail. Similarly, in order to determine the state and degree of change in ozone deterioration in more detail, the degree of change in the surface state of the test sample S between a plurality of points in time is preferably determined using processed data obtained by performing sharpening processing on each of the image data 6 In a case where a wall surface of the test tank 2 is interposed between the camera device 5 and the test sample S, noise may be included in the image data 6 In this embodiment, the body of the camera device 5 is not disposed inside the test tank 2. This is advantageous in that sharper image data 6 The image data 6 A test sample of a vulcanized rubber material is placed under a preset placement condition in a fixing frame in a test tank having a predetermined ozone concentration, and digital image data is acquired by capturing at a fixed point, over time, with at least one camera device, images of a surface of the test sample that has been placed in the test tank; and determining a change in a surface state of the test sample between a plurality of points in time by analyzing, with a computation device, the image data that has been acquired. Such evaluation method for evaluating ozone deterioration of a vulcanized rubber material can accurately determine a change over time in ozone deterioration while reducing working man-hours. 1. A method, for evaluating ozone deterioration of a vulcanized rubber material, in which a test sample of a vulcanized rubber material is placed under a preset placement condition in a test tank having a predetermined ozone concentration and a change over time in a surface state of the test sample is determined, the method comprising:

acquiring image data, which is digital data, by capturing at a fixed point, over time, with at least one camera device, images of a surface of the test sample that has been placed in the test tank; and determining a change in the surface state of the test sample between a plurality of points in time, based on the image data. 2. The method for evaluating ozone deterioration of a vulcanized rubber material according to 3. The method for evaluating ozone deterioration of a vulcanized rubber material according to 4. The method for evaluating ozone deterioration of a vulcanized rubber material according to storing each of the image data in a database of a storage unit; and automatically determining, by comparing indication data indicating a degree of progression of ozone deterioration stored in the storage unit and each of the image data by using a computation device, the degree of progression of ozone deterioration with respect to the surface state of the test sample in each of the image data, based on the indication data. 5. The method for evaluating ozone deterioration of a vulcanized rubber material according to 6. The method for evaluating ozone deterioration of a vulcanized rubber material according to 7. A system, for evaluating ozone deterioration of a vulcanized rubber material, in which a test tank is maintained at a predetermined ozone concentration and a fixing frame enables placement of a test sample of a vulcanized rubber material under a preset placement condition in the test tank, the system comprising:

at least one camera device configured to acquire image data, which is digital data, by capturing at a fixed point, over time, images of a surface of the test sample that has been placed in the test tank; a storage unit into which the image data is input; and a computation device configured to execute a predetermined image data processing program, a degree of change in a surface state of the test sample between a plurality of points in time being calculated by the computation device, based on the image data.TECHNICAL FIELD

BACKGROUND ART

CITATION LIST

Patent Literature

SUMMARY OF INVENTION

Technical Problem

Solution to Problem

Advantageous Effects of Invention

BRIEF DESCRIPTION OF DRAWINGS

DESCRIPTION OF EMBODIMENTS

REFERENCE SIGNS LIST