Improved interbody spinal fusion implants

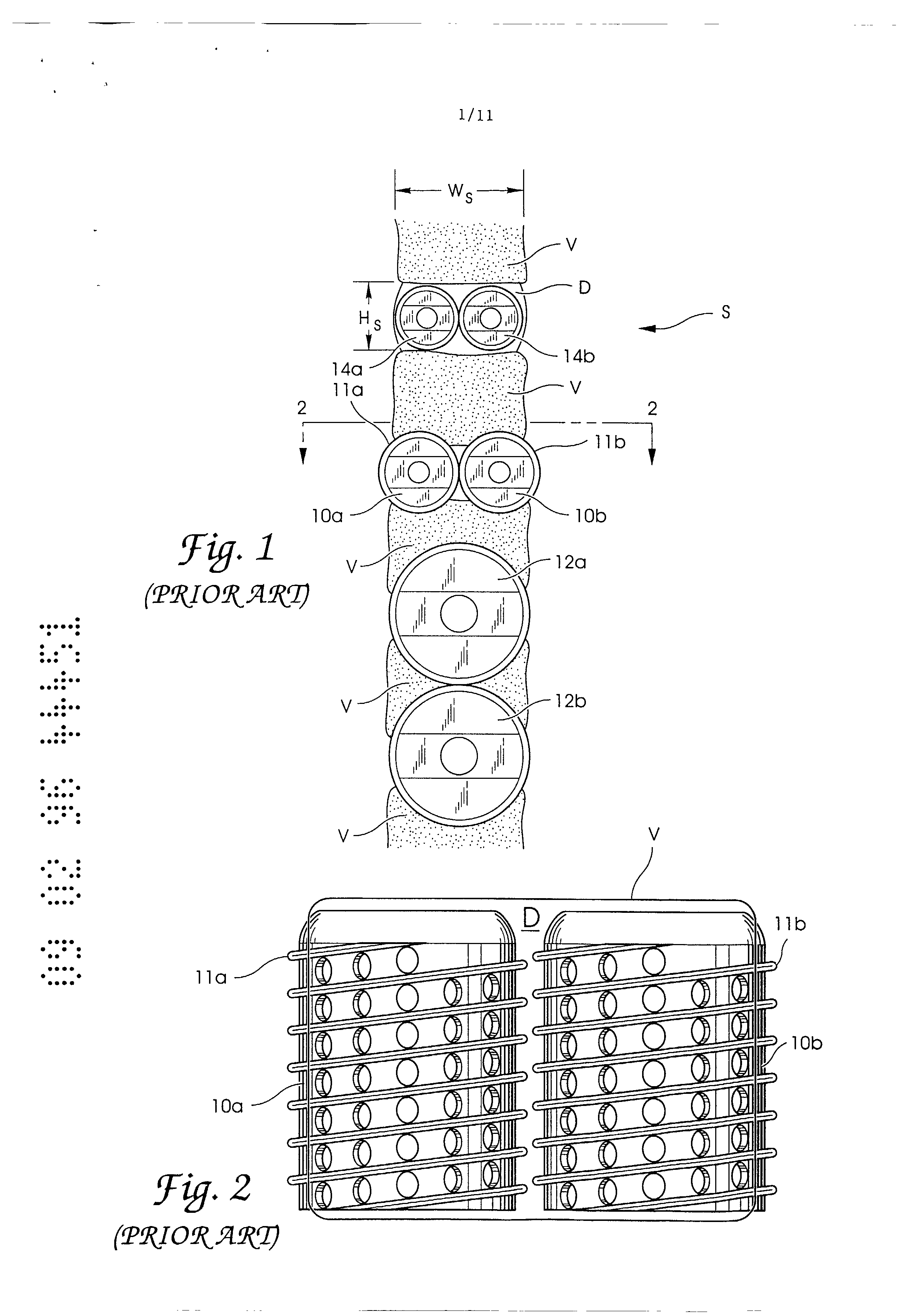

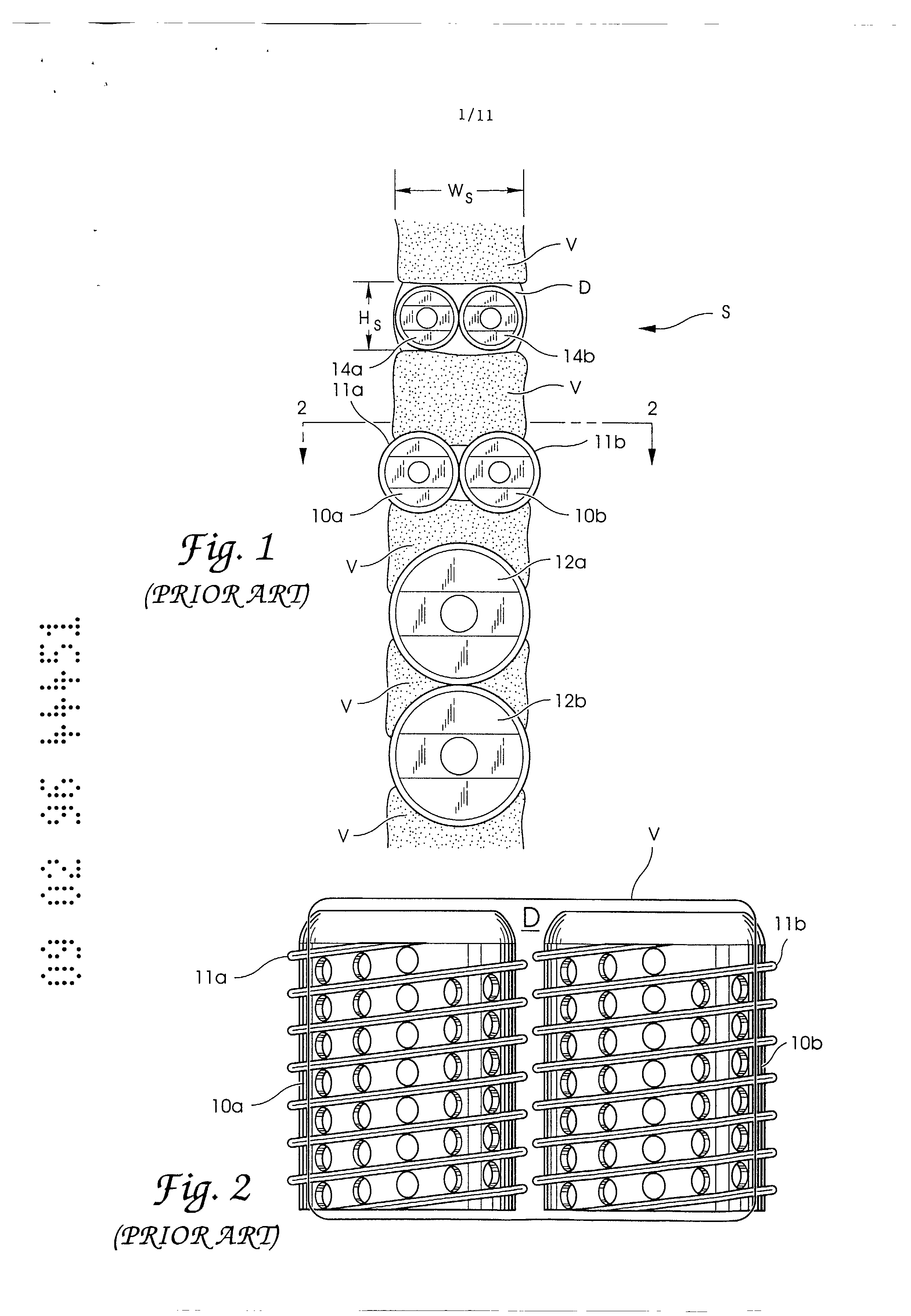

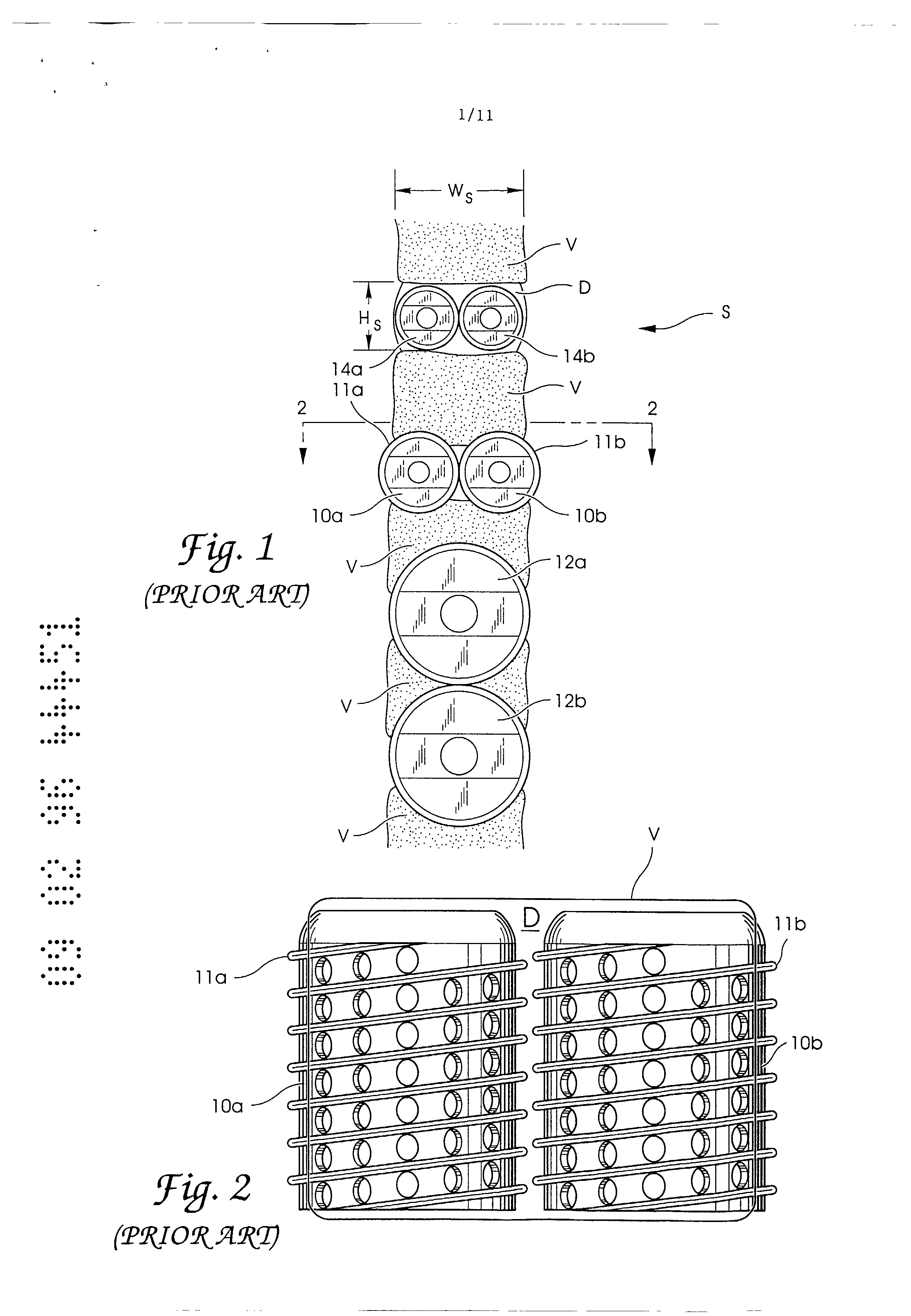

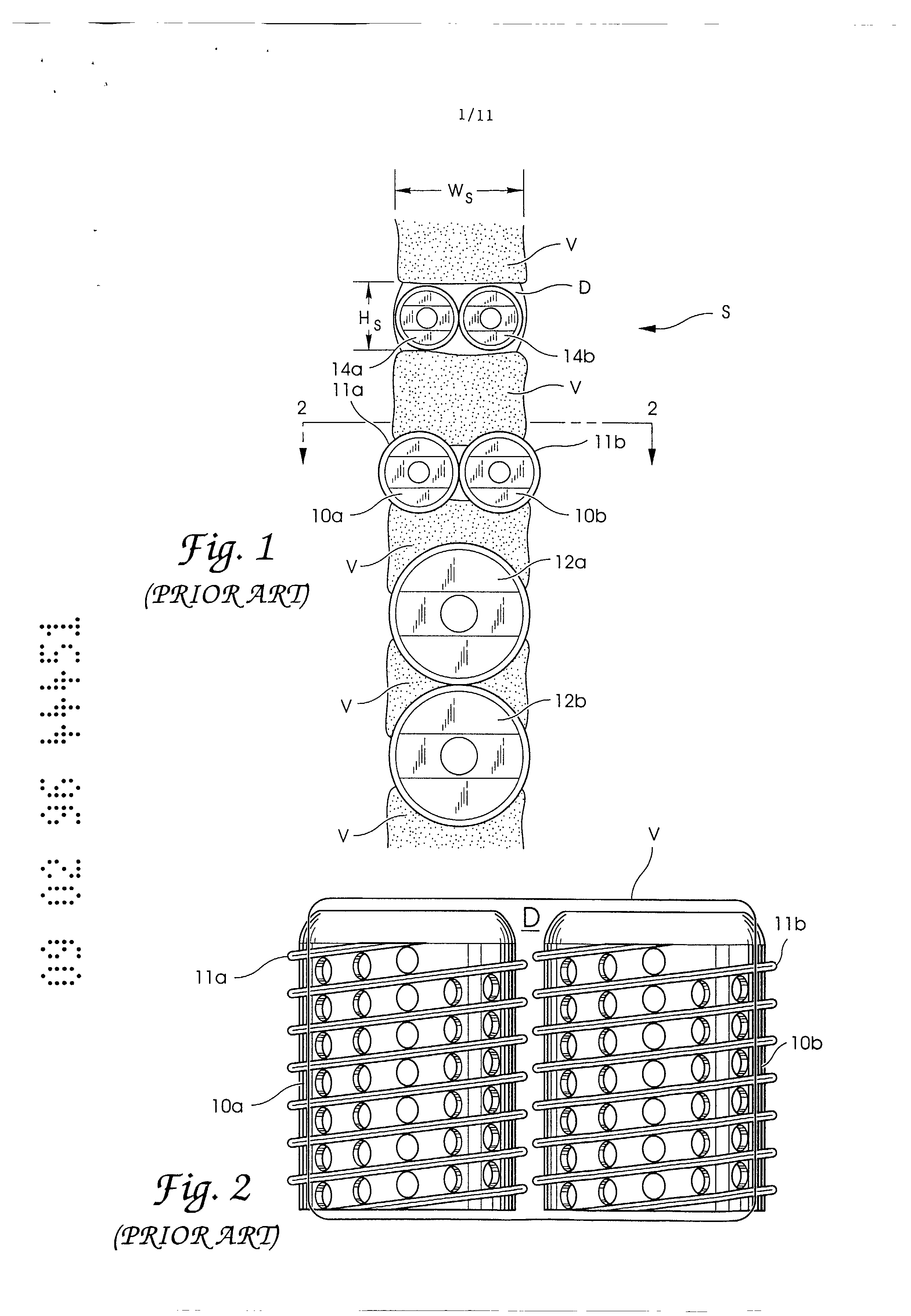

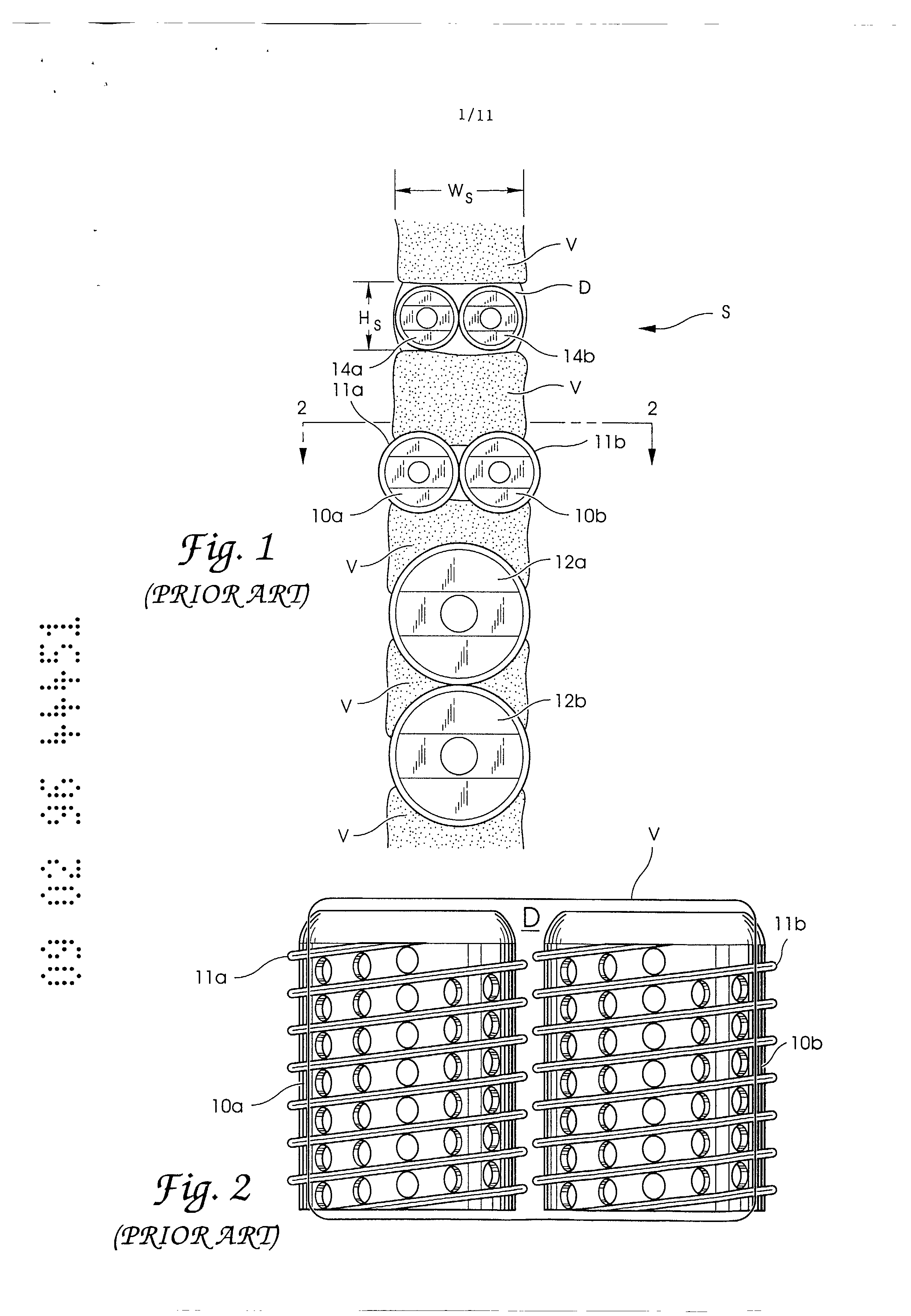

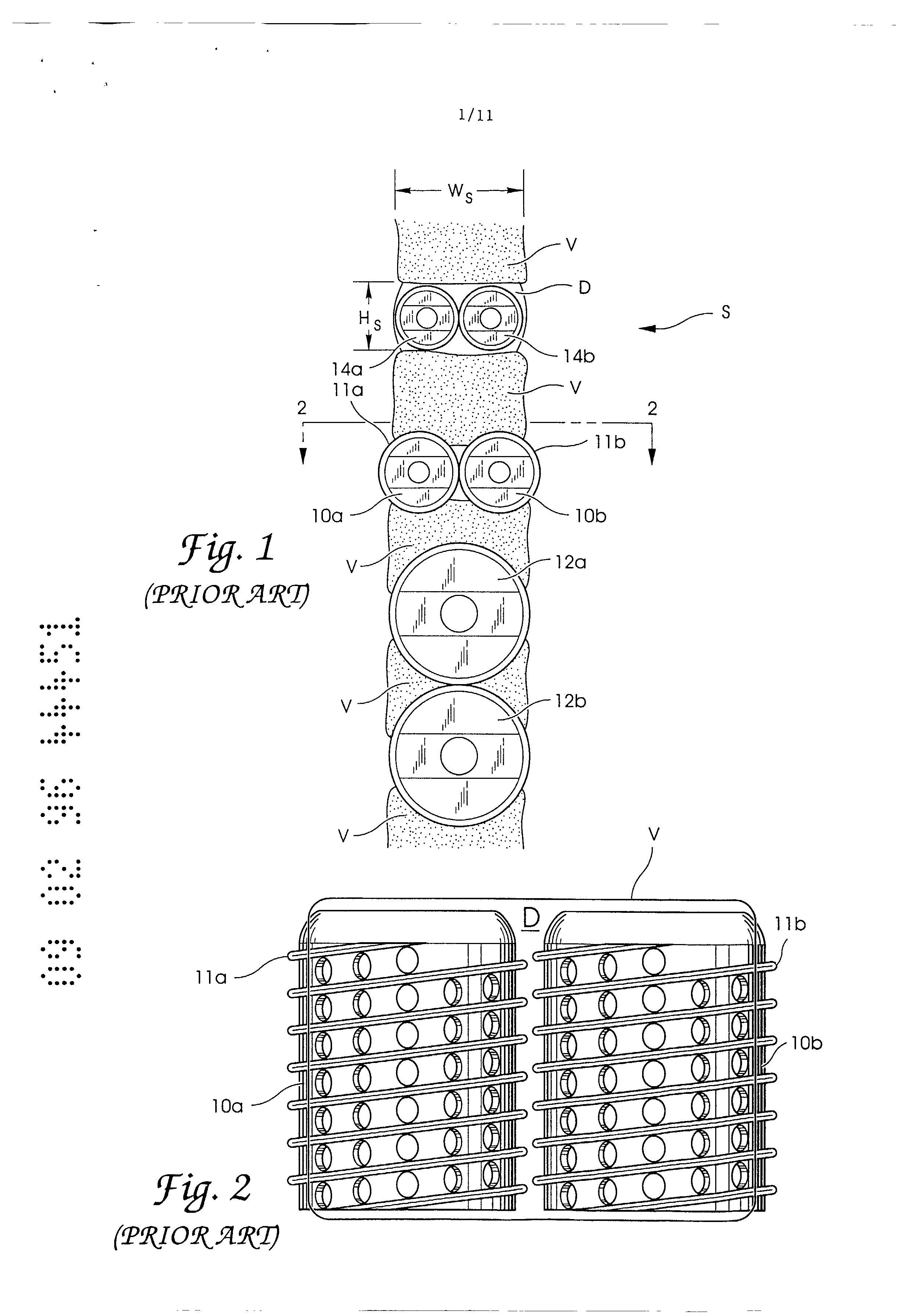

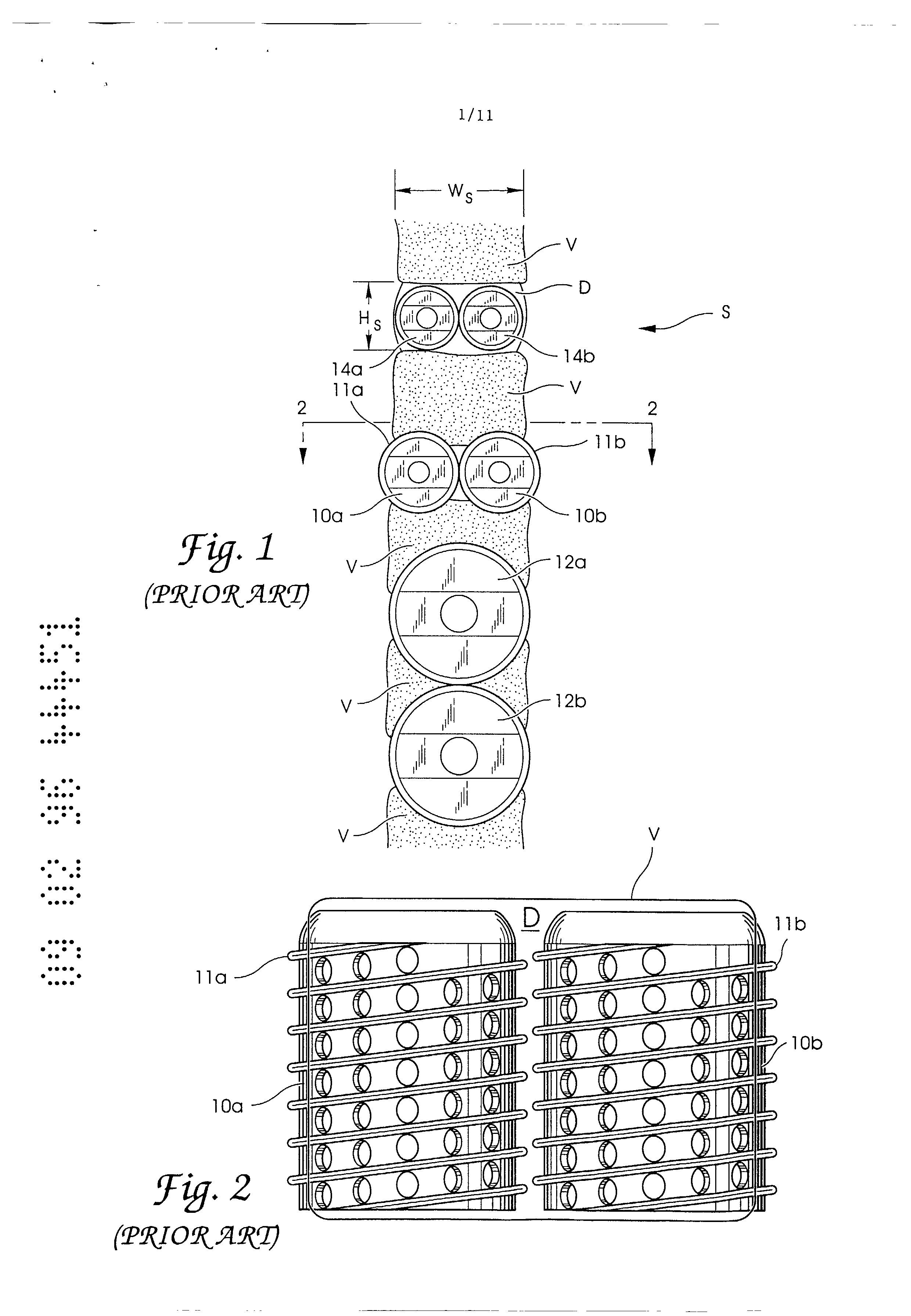

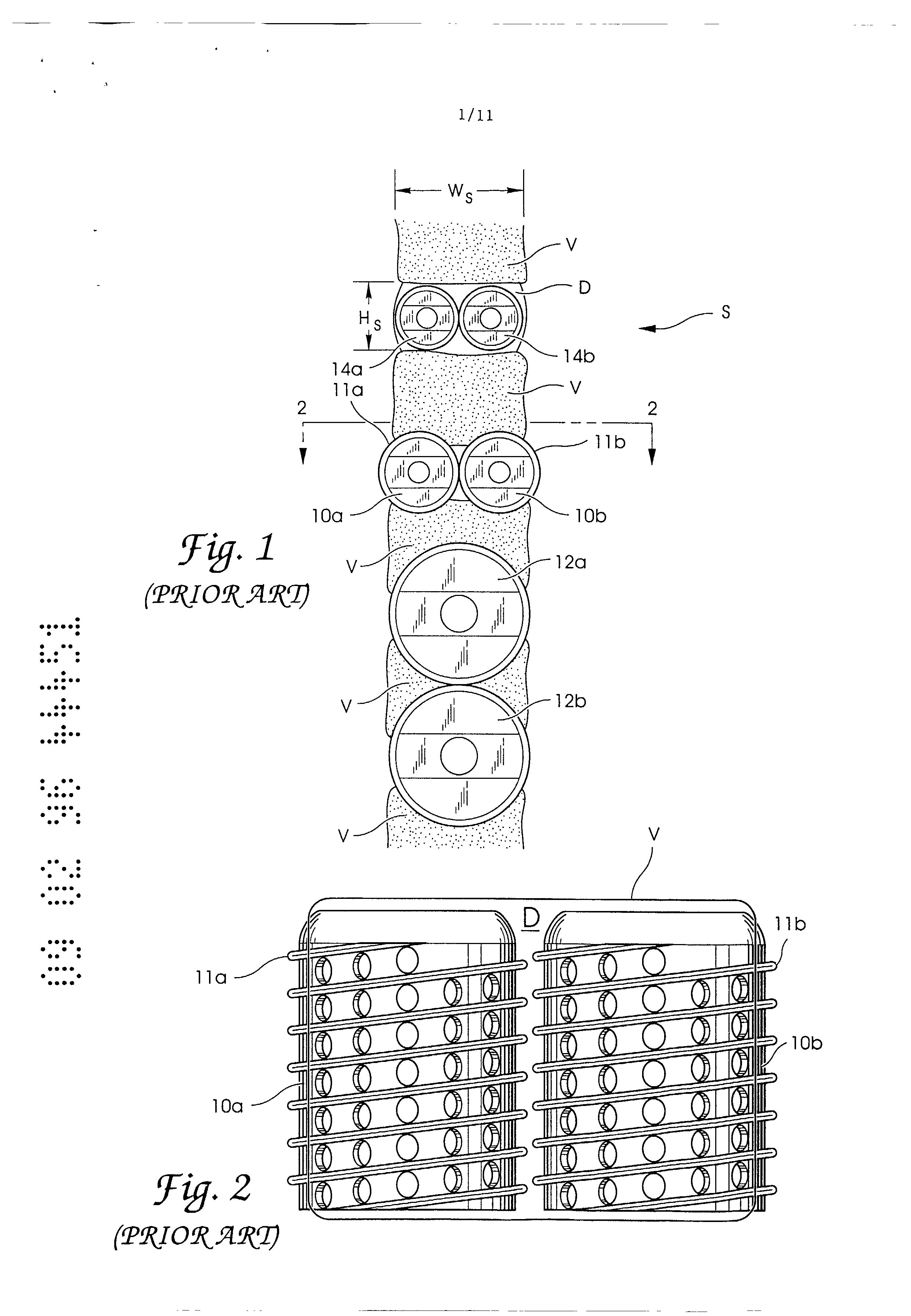

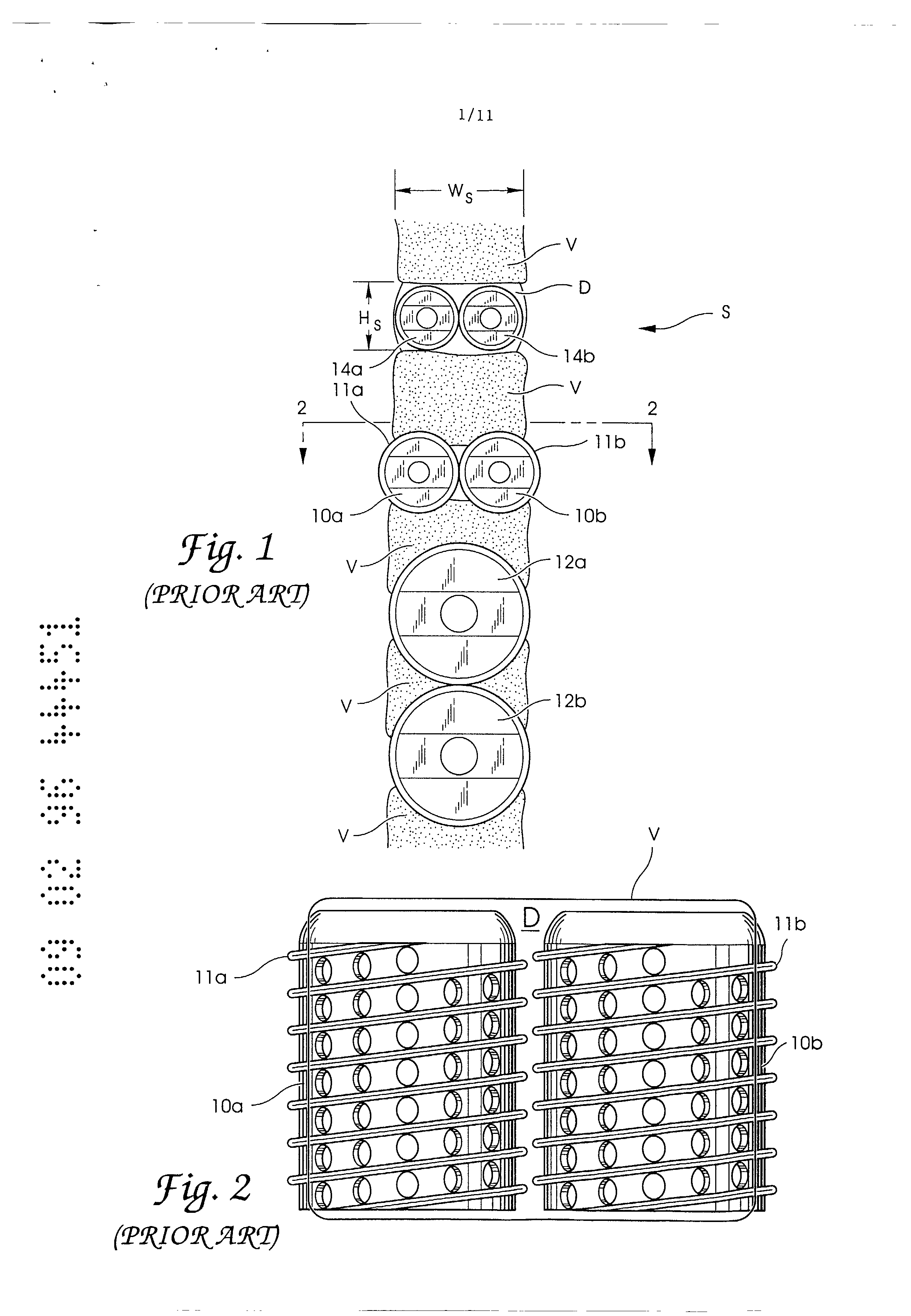

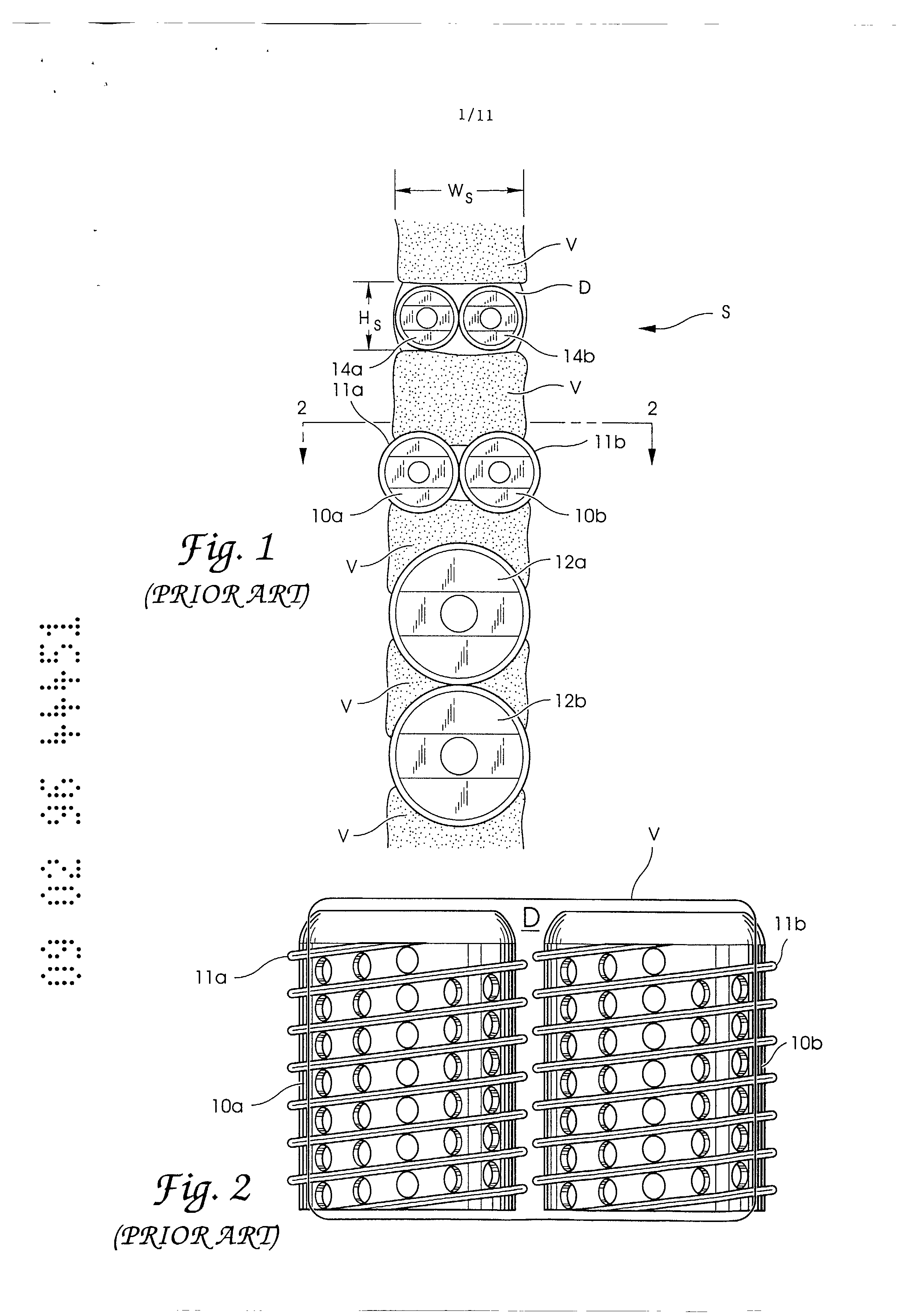

uosn ds:BD&AJBS 0 ssaJppv U&Lae ae9 "(S)JO UBAUI L n Dv (]3J.IN aassauuai s qdmaN P m'e Ed 0081 Jom os: u 3&[ddv o ssaJppv pu ameN IMPROVED INTERBODY SPINAL FUSION IMPLANTS This application is a continuation in part of copending application Serial No. 07/968,240 filed on October 29, 1992 which is a continuation of application Serial No. 07/698,674 filed on May i0, 1991 which is a division of application Serial No. 07/205,935 filed on June 3, 1988, now U.S. Patent No. 5,015,246 issued on May 14, 1991. This application is also a continuation in part of copending design patent application Serial No. 29/023,926 filed on June 3, 1994 and design patent application Serial No. 29/023,923 filed on June 3, 1994. Field of the Invention The present invention relates to artificial spinal fusion implants to be placed across tile intervertebral space left after t]le removal of a damaged spina! disc, and in particular to an improved, at least partially cylindrical, spinal fusion implant for implantation where two threaded cylindrical implants of requisite height would not fit within tile transverse width of the spine. Description of the Related Art In the past, Coward, Wilterberger, Crock, Viche, Bagby, Brantigan, Michelson and others have taught various methods involving the drilling of holes across the disc space between two adjacent vertebrae of the spine for the purpose of causing an interbody spinal fusion. Cloward taught placing a dowel of bone within that drilled hole for the purpose of bridging the defect and to be incorporated into the fusion. Viche taught the threading of that bone dowel. Bagby taught the placing of the bone graft iilto a metal bucket otherwise smooth on its surface, except for rows of radially placed holes communicative to the interior of the basket and to the bone graft. The Bagby device was disclosed as capable of being used in a horse. Brantigan taught the use of inert blocks preferably made of metal and having that metal at its external surface imitate the porosity of bone. Brantigan theorized that the bone dowel could be replaced entirely with a metal plug, that, while not itself active in the fusion, would nevertheless serve to support the vertebrae from within the disc space while allowing fusion to occur around it. U.S. Patent No. 3,844,601 issued to Ma et al. on November 19, 1974, teaches a method and instrumentation for preparing rectangular spaces across the disc space into tile adjacent vertebrae and for prepar'i.Hg a rectangular graft of the bone itself that is inserted in the rectangular spaces. U.S. Patent No. 4,743,256 issued to Brantigan on May i0, 1988 teaches the use of an inert artificial spacer in the shape of a rectangle in place of using a rectangular bone graft as taught by Ma et al. U.S. Patent No. 4,878,915 issued to Brantigan on November 7, 1989, teaches tile use of fully cylindrical inert implants for use in interbody spinal fusion. Such implants do not participate in the bone fusion process but act as inert spacers a id allow for the growth of bone to the outer surfaces of the implants. U.S. Patent No. 4,834,757 issued to Brantigan on May 30, 1989, teaches a rectangular shaped, hollow spinal fusion implant for use in lieu of a rectangular bone graft or Brantigan's earlier artificial inert spacer. U.S. Patent No. 5,015,247 issued to Michelson on May 14, 1991, teaches the use of a thin-walled, highly perforated, threaded, hollow cylindrical impla,lt closed or closable at both ends, so as to be compressably loaded with bone or other fusion promoting materials. Additionally, the Michelson device may then be coated with a bone production inducing chemical suc]l as hydroxyapatite. The Mic]lelson patent also discloses an improved method of drilling holes across the disc space and into the two adjacent vertebrae and safely installing cylindrical implants such that the entire surgical procedure may be conducted through a hollow cylindrical tube. Tl e hollow cylindrical tube may be left in place throughout the surgical procedure and serves to hold the adjacent vertebrae in place relative to each other, permits the guarded drilling of the holes across the disc space, and permits tile insertion of the implant through that same tube into the hole drilled across the disc space and into the adjacent vertebrae. As regards this method of performing interbody spinal fusion using essentially cylindrical threaded implants, a special problem arises (see Figure i) when an attempt is made to place two cylindrical implants (considered to be the preferred number as it is a much more stable construct and has more surface area than a single implant placed celltrally) side-by-side across a disc space and into the two adjacent vertebrae where the height of the disc space is such that it requires an implant of a diameter so large to penetrate into and significantly engage each of the adjacent vertebrae that it is no longer possible to place two such implants side-by-side and to still have them contained within the transverse widtl 1 of tile spine. If an attempt is made to remedy the problem by using smaller diameter implants placed side-by-side such that both would then be able to fit within the transverse width of the spine, then the implants would be of insufficient height to adequately engage the bone. If an attempt is made to remedy the problem by abandoning t:he side-by-side double implant construct in favor of a single, centrally placed implant, then where the implant is sufficiently large enough to occupy a sufficient portion of the transverse width of the disc space to promote firm stability, its vertical height and excursion into tile vertebrae would be so severe that if any two consecutive disc spaces were to be operated upon, the vertebrae in between would be cut in half. U.S. Patent No, 5,055,104 issued to Ray on October 8, 1991 ("Ray Patent") discloses an implant comprising a helical coil without wall members that is assembled after the coils are placed ill the disc space between the vertebrae, which supposedly can then be removed after the vertebrae have become fused together. The Ray implant is defective and unworkable in that it is incapable of being used in the manner in which it is described as it is not possible to insert into hard bone an isolated helical coil without any wall members to support such a coil, which could would be analogous structurally to a slinky, (See Ray Patent, Figures 1 and 7). Further, the Ray implant is unduly complex, because it would require the difficult, if not impossible, task of assembly within the disc space. Figure 3 of the Ray Patent clearly reveals that Ray does not teach the use of a truncated cylindrical implant, but merely teaches the use of a truncated, helical coil appearing as a sharpened spring totally lacking any wall member which could be considered cylindrical. Therefore, Ray teaches only the use of an isolated thread which can only be inserted by rotation and cannot be linearly advanced. If the overwhelming obstacles of the impossibility of inserting an isolated thread without wall members and the problem of the assembly within the disc space could be overcome, then the Ray imp].ant would still be unsafe for its intended purpose as it would be at high risk of spontaneous disassembly and mechanical failure. Further, there would be insufficient room to safely rotate such a device for insertion as it is the very lack of such room that requires the use of a device having a decreased transverse width. There is therefore, the need for a spinal fusion implant that is capable of being inserted into a hole drilled across the disc space between two adjacent vertebrae and partially into the two adjacent vertebrae such that the spinal fusion implant is capable of fitting within the transverse width the spine when placed side-by-side next to a second of its It is an object of the present invention to overcome or ameliorate some of the disadvantages of the prior art, or at least to provide a useful alternative. Summary of the Present Invention Accordingly, in a first aspect the invention provides a spinal fusion implant made of a material appropriate for human implantation across a disc space between adjacent vertebral bodies, said implant comprising: a non-threaded member having a leading end, a trailing end, and a length therebetween, said non-threaded member having a longitudinal axis and an exterior with at least in part opposed arcuate portions adapted to penetrably engage the adjacent vertebral bodies when inserted between the vertebral bodies and across the disc space, said non-threaded member having a height passing perpendicularly through said opposed arcuate portions and the longitudinal axis of said non-threaded member, at least two portions of the length of said non-threaded member having the same height, each of said opposed arcuate portions having at least one opening passing therethrough to allow bone growth from adjacent vertebral body to adjacent vertebral body through said implant; and surface roughenings protruding from said exterior of said non-threaded member for engaging the vertebral bodies to maintain said implant in place, said surface roughenings configured to resist expulsion of said implant from between the vertebral bodies. In a second aspect, the invention provides a spinal fusion implant made of a material appropriate for human implantation between two adjacent vertebral bodies, said implant comprising: a non-threaded member having a leading end, a trailing end, a length therebetween, and a hollow interior, at least one of said leading end and said trailing end having an access opening in communication with said hollow interior and being configured to cooperatively engage an end cap to at least in part close a portion of said access opening, said non-threaded member having a longitudinal axis and an exterior with opposed arcuate portions adapted to penetrably engage the two adjacent vertebral bodies, each of said opposed arcuate portions having at least one opening passing therethrough to allow bone growth from one of the adjacent vertebral bodies to another adjacent vertebral body through said implant; and07795 doc:KEH surface roughenings protruding from said exterior of said non-threaded member for engaging the vertebral bodies to maintain said implant in place, said annular ratchetings being defined around the circumference of said non-threaded member to resist expulsion of said implant from between the adjacent vertebral bodies. The present invention, at least in a preferred embodiment, is an improved interbody spinal fusion implant that is capable of being inserted into a hole drilled across the disc space between two adjacent vertebrae and into the two adjacent vertebrae such that the spinal fusion implant is capable of fitting within the transverse width of the spine when placed side-by-side next to a second of its kind. The spinal fusion implant of the present invention preferably comprises a thinwall, multi-perforate, cylinder or partial cylinder, made of material appropriate for human implantation and having preferably, but not necessarily, one closed end and one end capable of being closed, such that an internal chamber can be filled and hold any natural or artificial osteoconductive, osteoinductive, osteogenic, or other fusion enhancing material. The spinal fusion implant of the present invention preferably relies on roughenings of the outer surface to enhance its stability. Depending on the dimension of the transverse width of the spine in which the spinal fusion implant is being inserted, the spinal fusion implant of the present invention may have one or more flat sides to reduce the width of the spinal fusion implant. The spinal fusion implant of the present invention preferably incorporates at its rear end, an engagement means to facilitate insertion or extraction of the implant, preferably at its rear end. The implant of the present invention may be made of, filled with and/or coated with fusion promoting substances. Further, the spinal fusion implant of the present invention does not require rotation for its insertion and can be seated by linear advancement. The spinal fusion implant of at least a preferred embodiment of the present invention is generally effective, and is safer and more effective than the cylindrical implants of the prior art for the special instance when it is desirable to insert two implants side-by-side into cylindrically prepared channels, and where the height of the disc space between two adjacent vertebrae is so great relative to the transverse width of the spine, [R: LIBLL]07795 doc:KEH that two implants of the requisite height will not fit within the transverse width of the spine. Prior art has taught those knowledgeable in the art of spinal surgery, that the likelihood of obtaining a spinal fusion is proportionate to three factors: 1) the surface area of the implant 2) the quality and quantity of the graft material and 3) the stability of the fusion construct. The spinal fusion implant of the present invention preferably increases each of these three factors by making it possible to use two implants side-by-side across a disc space that would otherwise lack sufficient width to accept more than one. The spinal fusion implant of the present invention is preferably more efficacious than the prior art on an individual implant basis for the following reasons: 1. Increased surface area. The spinal fusion implant of at least a preferred embodiment of the present invention, because of its surface roughenings has greater surface area for engaging the adjacent vertebrae than an implant with smooth external surfaces. The presence or absence of holes does not materially affect this, so far as the holes are filled with material effectively contributing to the area of contact at the surface. The arced portions of the partially cylindrical implant of the present invention are in contact with the adjacent vertebrae and provide a greater surface area than is possible with a flat portion from a non-cylindrical implant. 2. The quantity and quality of graft material presented. As the spinal fusion implant of at least a preferred embodiment of the present invention is not screwed in, it need not be constructed to resist the torquing therewith associated. Thus, the implant may be thinner walled and thereby, for a given diameter, have greater internal volume. The spinal fusion implant has arced portions making the implant stronger in compression than an implant lacking upper and lower curved supporting surfaces such that the wall of the implant can be relatively thinner than such implants. A thinner wall is easier for bone to grow through. Also, the interpore bridges may be smaller allowing for greater porosity and thereby greater exposure to the internal graft material. Further, the spinal fusion implant of the present invention may be constructed of and/or coated with, and/or loaded with a variety of materials and/or chemical substrates known to actively participate in the bone fusion process. As the spinal fusion implant of at least a preferred embodiment of the present invention offers greater surface area, and greater internal volume for its outside diameter, it offers the opportunity for presenting a greater surface area and volume of these fusion materials. 3. The implant of the present invention preferably offers greater stability than the prior art implants. The least stable implants are the implants lacking surface roughenings. Surface holes increase implant stability by increasing the interference of the implant to the opposed surfaces. The spinal fusion implant of the present invention is a further improvement over the prior art in that the surface roughenings of the spinal fusion implant of at least a preferred embodiment of the present invention resist motion in all directions. Further, all implants are subject to the possibility of backing out, by retracing the path by which they were inserted. However, the spinal fusion implant of the preferred embodiment of the present invention can have a surface configured to urge the spinal fusion implant forward as to offer increased resistance against such undesirable backward migration. Further, the arced portions of the implant provides a greater support area to better distribute the compression forces through the vertebrae. The spinal fusion implant of at least the preferred embodiment of the present invention is easier to use as it occupies less space, does not require pre-tapping, and can be inserted without the need to rotate an instrument within the closed confines of the spinal wound. Further, the spinal fusion implant of the present invention is preferably easier to insert than implants lacking upper and lower curved supporting surfaces that are arcs of the same circle and which implants are to be inserted across the disc space and into the adjacent vertebrae as it is easier to prepare a round hole than a square hole, as a round hole can be drilled in a single step. The present invention, at least in a preferred embodiment, provides an improved interbody spinal fusion implant such that it is possible to place two such implants side-byside across a disc space and into two adjacent vertebrae in close approximation to each other and within the transverse width of the spine, where the transverse width of the spine would have otherwise been insufficient relative to the required implant height to have allowed for the accommodation of two prior art cylindrical threaded implants. The present invention preferably provides a spinal fusion implant that is easier to insert, and does not require tapping prior to implantation. The present invention further preferably provides a spinal fusion implant that is safer, in which there is no need to run sharp threads near delicate structures. The present invention yet further preferably provides a spinal fusion implant that is faster to implant between adjacent vertebrae via linear advancement as opposed to rotational advancement. The present invention further preferably provides a method for implanting partially cylindrical implants having at least one fiat side. A preferred embodiment of the invention will now be described, by way of example only, with reference to the accompanying drawings in which: BRIEF DESCRIPTION OF THE DRAWINGS Figure 1 is a diagrammatic representation of a segment of the human spinal column comprising several vertebrae with various cylindrical threaded implants inserted across the disc space and into the two adjacent vertebrae to illustrate the problems encountered by those implants. Figure 2 is a top plan view along lines 2--2 of Figure 1 with the top vertebrae removed, of two cylindrical threaded implants illustrating the minimum distance possible between the two threaded implants when placed beside each other across the disc space. Figure 3 is a perspective side view of an embodiment of the spinal fusion implant of the present invention having surface roughenings in the form of ratchetings. Figure 4 is a first side elevational view of the spinal fusion implant of Figure 3. Figure 5 is a top plan view of two spinal fusion implants of Figure 3 illustrating the minimum distance possible between the two implants when placed beside each other across the disc space. Figure 6 is a second side elevational view of the spinal fusion implant of Figure 3. Figure 7 is a cross sectional view along lines 7--7 of the spinal fusion implant of Figure 6. Figure 8 is a cross sectional view along lines 8--8 of the spinal fusion implant of Figure 6. Figure 9 is a top end view of the spinal fusion implant of Figure 3. Figure i0 is a bottom end view of the spinal fusion implant of Figure 3. Figure ii is a side perspective view of an alternative embodiment of the spinal fusion implant of the present invention. Figure 12 is a first side elevational view of the spinal fusion implant of Figure ii. Figure 13 is a second side elevational view of the spinal fusion implant of Figure Ii. Figure 14 is a cross sectional view along lines 14--14 of tile spinal fusion implant of Figure 13. Figure 15 is a perspective side view of an alternative embodiment of tile spinal fusion implant of the present invention having surface roughenings in the form of knurling. Figure 16 is a first side elevational view of the spinal fusion implant of Figure Figure 17 is a top plan view of two spinal fusion implants of Figure 15 illustrating the minimum distance possible between the two implant when placed beside each other across the disc space. Figure 18 is an enlarged fragmentary view along line 18 of Figure 16 showing the surface configuration of the implant of Figure Figure 19 is a second side elevational view of the spinal fusion implant of Figure Figure 20 is a cross sectional view along lines 20--20 of the spinal fusion implant of Figure 16. Figu -e 21 is a top end view of the spinal fusion implant of Figure Figure 22 is a bottom end view of the spinal fusion implant of Figure Figure 23 is a perspective side view of an alternative embodiment of the spinal fusion implant of the present invention i,aving flat sides and surface roughenings in the form of ratchetings. Figure 24 is a first side elevational view of the spinal fusion implant of Figure 23. Figure 25 is a diagrammatic representation of a segment of the human spinal column showing two implants of Figure 23 the present invention inserted within the spine. Figure 26 is a top plan view along lines 26--26 of Figure with the top vertebrae removed, illustrating the minimum distance possible between two spinal fusion implants of Figure 23 placed beside each other across the disc space. Figure 27 is a top end view of the spinal fusion implant of Figure 23. Figure 28 is a bottom end view of the spinal fusion implant of Figure 23. Figure 29 is a second side elevational view of the spinal fusion implant of Figure 23. Figure 30 is a cross sectional view along lines 30--30 of tile spinal fusion implant of Figure 29. Figure 30A is a cross sectional view of an alternative embodiment of the spinal fusion implant of the present invention having only one flat side. Figure 31 is a perspective side view of an alternative embodiment of the spinal fusion implant of the present invention |laving flat sides and surface roughenings in the form of ratchetings. Figure 32 is a first side elevational view of the spinal fusion implant of Figure 31. Figure 33 is a second side elevational view of the spinal fusion itnplat]t of Figure 31. Figure 34 is a cross sectional view along lines 34--34 of the spinal fusion implant of Figure 33. Figure 35 is a cross sectional view along lines 35--35 of the spinal fusion implant of Figure 33. Figure 36 is a perspective side view of an alternative embodiment of the spinal fusion implant of the present invention having flat sides arid having surface rougher tings in the form of knurling. Figure 37 is a first side elevational view of the spinal fusion implant of Figure 36. Figure 38 is a second side elevational view of tile spinal fusion implant of Figure 36. Figure 39 is a cross sectional view along lines 39--39 of the spinal fusion implant of Figure 38. Figure 40 is an enlarged fragmentary view along line 40 of Figure 37 showing the surface configuration of the spinal fusion implant of Figure 36. Figure 41 is a perspective side view of an alternative embodiment of the spinal fusion implant of the present invention having surface roughenings comprising of a blasted extertlal surface. Figure 42 is a perspective side view of an alternative embodiment of the spinal fusion implant of the present inve,ltion having flat sides and openings in the form of vertical and horizontal slots. Figure 43 is an elevational side view of a segment of the spillal column with an alternative embodiment of two spinal fusion implants of the present invention having corresponding concave and convex sides inserted across one disc space and an alternative embodiment of a single spinal fusion implant of the presellt invention having a two cylindrical portions inserted across one disc space. DETAILED DESCRIPTION OF THE DRAWINGS The Previous Devices Referring to Figure i, a diagrammatic representation of a segment of the human spinal column generally referred to by the letter S is shown. T e segment of the spinal column S comprises several vertebrae V alld a disc space D between two adjacent vertebrae V. Various cylindrical threaded spinal fusion implants, each ]laving different diameters, are shown inserted across tJ1e disc space D. When the height H s of the disc space D is so large that two cylindrical implants, such as spinal fusion implants 10a and 10b, each having a sufficient diameter to cross the disc space D and sufficiently e11gage i11to the bone of adjacent vertebrae V, are placed across the disc space D, the combined overall width of the two special implants 10a and 10b exceeds the transverse width w of the spinal column S As a result S " ' a portion of each implant 10a and 10b protrudes from the sides of the spinal column S and could cause severe and perhaps mortal damage to the patient as delicate and vital structures lie adjacent to that area of the spinal column S such that the use of two cylindrical spinal fusion implants 10a arid 10b would not be desirable. If instead of two spinal fusion implants 10a and 10b, a single implant, such as spinal fusion implant 12a were to be used having a sufficiellt diameter to provide for stability arid fusion, then the implant would penetrate deeply into the adjacent vertebrae V. The spinal fusion implant 12a would |]ave a diameter that is significantly greater than the heigllt H s of the disc space D, such that the vertebrae V would have to be substantially bored out to accommodate the large diameter of the spinal fusion implant 12a. As a result, a large part of the vertebrae V would be removed, and thus the overall structural int:egrity of the vertebrae V would be substantially weakened. This is especially a problem when a second spinal fusion implant 12b identical to spinal fusion implant 12a is placed across disc space D on the other side of the same vertebrae V such that two spinal fusion implants 12a and 12b are placed across the disc spaces D on either side of the vertebrae V. As a result, the vertebra V is cleaved into a "butterfly" configllration as shown in Fiiure l, and the structural integrity and strength of the vertebrae V is further diminished such that the effectiveness of the spinal fusion process is substantially reduced, and the vertebrae V are at high risk of devascularization and fracture. Conversely, if two cylindrical implants such as spinal fusion implants 14 a and 14b, each having a sufficiently sized diameter such that when placed side-by-side in the disc space D, the combined overall width of the spinal fusion implants 14a and 14b just fills the transverse width W s of the spinal column S, the diameter of each of the spinal fusion implants 14a and 14b will not be sufficient to cross the disc space D to eT1gage the vertebrae V. Therefore, while the spinal fusion implants 14a and 14b will not protrude from the sides of the spinal column S, the spinal fusion implants 14a and 14b cannot reach and engage the bone of t-he vertebrae V and thus cannot function to stabilize the adjacent vertebrae V. Referring to Figure 2, a top plan view, taken along line 2--2 of Figure 1 with the upper vertebrae V removed, of two cylindrical threaded i,nplallts 10a and 10b placed across the disc space D is shown. The threaded implants 10a and 10b ]lave an external thread lla and llb which must have a minimum height that is proportional to the size of the threaded implant to be effective. The thread lla and llb of the threaded implants 10a and 10b converts torque to linear motion, such that the threads lla and llb need to be of a sufficient height to overcome the resistance of the material, such as bone, in which the th,'eaded implants 10a and 10b are being inserted, such resista ice being proportional to the surface area and diameter of each of threaded implant 10a arid 10b. Thus, the difference between the major diameter (including the threads) and the root diameter (minus tile threads) of each threaded implant 10a and 10b is such that when two threaded implants 10a and 10b are implanted across tile disc space D and into the adjacent vertebrae V, there must be a minimum distance between the two threaded implants 10a and 10b to allow for the height of the threads lla and llb. This would be true even if the threads lla and llb were interdigitated the threaded implants 10a and 10b would still be offset by at least the height of the thread of at least one of the threaded implants 10a and 10b. Such a minimum distance between the two threaded implants 10a and 10b increases the combined overall width of the two threaded implants 10a and 10b when inserted. Therefore, in order for a cylindrical spinal fusion implant to be used in the spinal fusion process where the heigllt H s of the disc space D between two adjacent vertebrae V is large relative to its width w s, it is necessary to have an implanl: that can be implanted adjacent to a second of its kind in closer contact than is possible with threaded implants, while still providing for an implant surface that will provide mechanical stability in engagement to the adjacerJt vertebrae V. The use of a cylindrical implant is desirable as it is easy to prepare the recipient site by drilling a cylindrical llole across the disc space D and into the adjacent vertebrae V, The curved surface of the cylindrical holes drilled into tile vertebrae V have increased surface area compared to a flat surface and also provides for tile possibility of tight congruency when the cylindrical hole is fitted with an implailt having corresponding cylindrical poL'tions of matched diameter. T_JLe __Pr_e s e n tin v e n _i o n Referring to Figures 3-10, an embodiment of the spinal fusion implant of the present invention, is shown and generally referred to by the numeral i00. The spinal fusion implant i00 has a substantially cylindrical configuration having a thin outer wall 112 surrounding an internal chamber 114 and a longitudinal central axis L. The exterior of tile spinal fusion implant 100 comprises surface roughenings that provide a surface suitable for engaging the vertebrae V to stabilize the spinal fusion implant 100 across the disc space D and into the adjacent vertebrae V once surgically implant In one embodiment of the spinal fusion implant 100, the surface roughenings comprise a plurality of ratchetings 120 along the circumference of said spinal fusion implant. Each of the plurality of ratchetings 120 has a bone engaging edge 122 and an angled segment 124. F.ach of the plurality of ratchetings 120 has a hei<jht that is substantially less than Lhe heigl,t of a requisite thread for a cylindrical threaded implant of the same size. As a thread is a simple device for convertin<3 torque to linear advancement, the requisite height of the thread is proportional to the surface area and diameter of the implant and must be sufficient to pull a cylindrical implant t,aving a diameter sufficient to cross the disc space D through a material as dense as bone. In contrast, the ratchetings 120 have a height tllat is significantly less than tile requisite height of a thread of a same sized threaded implant since the spinal fusion implant i00 is implanted across the disc space D and into the adjacent vertebrae V by linear advancement. The spinal fusfon implant i00 may be pushed into the cylindrical disc space D by direct, linear advancemezlt since it requires no thread to pull it forward through the spine. As no torque is required to advance the spinal fusion implant i00 there is no minimum requisite height of the surface roughenings. The only surface feature necessary is that which gives the spinal fusion implant i00 stability once implanted. Moreover, the ratchetings 120 may face in one direction, the direction in which the spinal fusion implant i00 is inserted, and function to prevent the spinal fusion implant i00 from backing out of the disc space D in a direction opposite to the direction of insert*or, once inserted between the two adjacent vertebrae v. The ratchetings 120 urge the spinal fusion implant 100 for-ward against the unremoved bone of the ve,:tebrae V. Since implants generally want to back out along the same path in which they are inserted, such as repeated moveme,lt of the patient's body ove - time and which would cause some other design of implant to come loose (e.g. cause a threaded cylindrical implant to possibly unscrew), the ratchetings 120 tend to urge the spinal fusion implant i00 forward against the solid unremoved bone further resisting dislodgement and controlling motion resulting in an exceedingly stable implantation. The bolle engaging edges 122 of the ratchetings 120 that have a height at a highest point measured from the root diameter of the spinal fusion implant 100 that is approximately 0.35 ram. In this manner the spinal fusion implant I00 may be placed beside a second of its kind at a distance of 8ppl-oximately 0.7 mm apart or if offset even closer, substantially reducing the combined overall width of the two spinal fusion implants i00 once surgically il0planted. The ratchetings 120 may have a height in the range of 0.25 - 1.5 ram, with the preferred height range being 0.35 - 0.75 mr0. Referring to Figure 5, two spinal fusion implants 100a as,d 100b are shown inserted across the disc space D having the same dimensions of the disc space D shown in Figure 2. The two spinal fusion implants 100a and 100b ],ave a decreased overall combined width when compared to two threaded spinal fusion implants placed side by side previously described and illustrated in Figure 2. The decreased combined overall width of the two spinal fusion implants 100a and 100b is the difference between the root and major diameters of the spinal fusion implants 100a and 100b and is achieved by utilizing surface roughenings such as ratchetings 120 for stability. The surface roughenings allow the two spinal fusion implants 100a and 100b to cone into considerably closer approximation to one another and require less total transverse width for their insertion than is possible for two threaded cylindrical implants having identical root diameters because of the requisite thread height of such threaded implants. Reducing the offset between implants allows for the uses of larger diameter implants which can then still fit within the transverse width W of the spinal column and achieve more s substantial engagement into the adjacent vertebrae v. Referring to Figure 7, a cross section of the spinal fusion implant i00 is shown wherein the wall 112 has openings 128 passing therethrough to communicate with the iilter 11 al chamber 114. The internal chamber 114 may be filled with bone material or any natural or artificial bone growth material or fusion promoting material such that bone growth occurs from the vertebrae V through the openings 128 to the material within internal chamber 114. While the openings 128 [lave been shown in the drawings as being circular, it is appreciated that the openings 128 may have any shape, size, or form suitable for use in a spinal fusion implant without departing from the scope of the present invention. Also, the number of openings may be varied or no openings may be presezlt on the spinal fusion imp I ant. Referring to Figures 8 and 9, the spinal fusion implant i00 has a cap 130 with a thread 132 that threadably attaches to one end of the spinal fusion implant i00. Once the cap 130 is attached to the spinal fusion implant i00, the edge 136 acts as an additional ratcheting 120 to further stabilize the spinal fusion implant i00 once it is implanted across the disc space D. The cap 130 is removable to provide access to the internal chamber 114, such that the internal chamber 114 can be filled and hold any natura[ or artificial osteoconductive, osteoinductive, osteogenic, or other fusion enhancing material. Some examples of such materials are bone harvested from the patient, or bone growth illducing material such as, but not limited to, hydroxyapatite, hydroxyapatite tricalcium phosphate; or bone morphogenic protein. The cap 130 and/or the spinal fusion implaut i00 itself is made of material appropriate for human implantation such as titanium and/or .nay be made of, and/or filled and/or coated with a bone ingrowth inducing material such as, but not limited to, hydroxyapatite or hydroxyapatite tricalcium phosphate or any other osteoconductive, osteoinductive, osteogenic, or other fusion enhancing material. Referring to Figure 4, alternatively the cap 130a may be "bullet"-shaped to facilitate insertion. The cap 130a has at its greatest diameter a diameter equal ho the root diameter of the spinal fusion implant 100 such that no additional ratchetings 120 are formed. Referring to Figure i0, the spinal fusion implant i00 has ar engagement means at one end in the form of a rectangular slot 140 for engaging a driver instrument having a removable engagement means for intimately engaging the rectangular slot 140. A threaded portion of tile driver instrument, which in one embodiment extends as a rod through a hollow tubular member and car] be rotationally controlled, screws into a threaded aperture 142 In the slot 140 and binds the implant i00 and tile driver instrument together. Once affixed to the implant driver instrument, the spinal fusion implant 100 may be then introduced through a hollow cylindrical tube and driven into the cylindrical hole that has been drilled across the disc space D. The impla,lt driver instrument may then be impacted lay a mallet, or similar device, to linearly advance the spinal fusion implant 100 across the disc space D. Once the spinal fusion implant i00 is inserted across the disc space D, the ratchetings 120, engage the bone of the vertebrae V and the implant driver instrument is detached from the spinal fusion implant 100. The procedure for drilling the holes across the disc space D and instrumentation pertaining thereto are described in copending Application Serial No. 08/074,781 filed on June i0, 1993, incorporated herein by reference. Referring to Figures 11-14, atl alternative embodiment of the spinal fusion implant of the present invention, generally referred to by the numeral 200 is shown. Tile spinal fusion implant 200 is similar to the spinal fusion implant i00 except that the openings 228 are bisected by the bone engaging edge 222 of the plurality of ratchetings 220. In t] 1 is manner, the bone engaging edges are interrupted by the openings 228 to provide a "tooth-like" edge that engages the bone of the vertebrae V and creates an interference fit to prevent the backing out of the implant 200 once inserted. It is appreciated that the number of openings 228 and the number of bone engaging edges 222 may be varied and that the opening 228 call be placed in any orientation relative to the ratchetings 220 or other surface roughening without departing from the scope of the present invention. Referring to Figures 15-19, an alternative embodiment of the spinal fusion implant of the present invention generally referred to by the numeral 300 is shown. The spinal fusion implant 300 has a substantially cylindrical configuration having surface roughenings for stabilizing the implant 300 within the intervertebral space D. As shown in Figure 18, the surface roughenings comprise a surface knurling 320 such as, but not limited to, the diamond-shaped bone engaging patterll shown. The spinal fusion implant 300 may have surface knurling 320 throughout the entire external surface of the spizlal fusio 11 implant 300, throughout only a portion of the external surface, or any combination thereof, without departing from the scope of the present invention. In those circumstances where there is llo undrilled bone in the disc space D forward of the spinal fusion implant 300 to resist further forward advancement of the implant, surface knurling 320 is preferred as it produces an exceedingly high interference fit with the bone of the vertebrae v and resists motion equally in all directions and without the tendency to urge itself forward. Referring to Figure 17, two spinal fusion implants 300a and 300b may be placed side-by-side across tile disc space D havizlg the same dimensions of the disc space D shown in Figure 2, such that the two spinal fusion implants 300a and 300b are touching each other and thus reducing the overall combined width of the two spinal implants 300a and 300b to the minimum distance possible with a substantially cylindrical implant having a roughened surface. In this manner, two cylindrical spinal fusion implants 300a and 300b having a sufficient diameter to cross the height H of the disc space D can be placed across s the disc space D without exceeding the transverse width W of s the spinal column S. The spinal fusion implants 300a and 300b are inserted by linear advancement as described above for spina! fusion implant i00. Therefore, as no threading is reguired for the insertion of spinal fusion implants 300a and 300b, little or no space need be present between the spinal fusion implants 300a and 300b, as compared to the space that would be required for a thread when using threaded implants. Thus, the spinal fusion implants 300a and 300b may be placed closer together to substantially reduce the overall combined width of two such implants. Referring to Figures 23-30, an alternative embodimezlt of the spinal fusion implant of the present invention is shown and is generally referred to by the numeral 400. The spinal fusion implant 400 has a similar configuration to that of the spinal fusion implant 200, except that it comprises a partially cylindrical member having arcuate portiolls 402 and 404 which are arcs of the same circle with portions of its outer wall 405 that are flattened so as to present a first flat side 406 and a second flat side 408. Referring to Figure 28, the spinal fusion imp].ant 400 has a major diameter M equal to the distance between two diametrically opposite non-flattened segmellts, such as arcuate portions 402 and 404 which are arcs of tile same circle. The width W. of the spinal fusion imp].ant 400 is equal to tile distance between a flattened segment and a point diametrically opposite the flattened segment, such as the distance between the first and second flat sides 406 and 408. Referring to Figure 25, a diagrammatic representation of a segment of a spinal column S comprising several vertebrae V is shown having two spinal fusion implants 400a and 400b inse 1 -ted across the disc space D between the two adjacent vertebrae V. The spinal fusion implants 400a and 400b are identical and each has a first arcuate portion 402a and 402b, respectively; a second arcuate portion 404a and 404b, respectively; a first flat side 406a and 406b, respectively; and a second flat side 408a and 408b, respectively. The spinal fusion implants 400a and 400b are implanted across the disc space D wit], the second flat side 408a of spinal fusion implant 400a facing and adjacent to the first flat side 408b of spinal fusion implant 400b such that the combined overall width of the two spinal fusion implants 400a and 400b is less than twice the maximum diameter M of the implants. The spinal fusion implants 400a and 400b are inserted by linear advancement as described above for spinal fusion implant i00. Prior to implantation, two partially overlapping cylindrical holes are drilled across the disc space D and into the adjacent vertebrae V. The holes are drilled sufficiently overlapping to allow the two spinal fusion impla]its 400a and 400b to be implanted with the flat sides perpendicular to the plane of the disc space D, the disc space D being in a plane perpendicular to the longitudinal vertical axis A of the spinal column S as shown in Figure The spinal fusion implants 400a and 400b may be inserted separately such that once a first spinal fusion implant 400a is inserted across the disc space D, a second spinal fusion implant 400b is driven across the disc space D so that the flat side 402 or 404 of each spinal fusion implant 400 are adjacent to each other and are touching. In this manner, t],e two spinal fusion implants 400a and 400b are implanted across the disc space D and engage the bone of the adjacent vertebrae v without exceeding tile transverse width W s of the spinal column S. Alternatively, the two spinal fusion implants 400a and 400b may be implanted across the disc space D simultaneously by placing tllem adjacent and facing each otller, in the orientation described above, prior to implantation. The two spinal fusion implants 400a and 400b are then linearly advanced into the drilled holes across the disc space D. Referring to Figure 28, the effect of having first and second flat sides 406 and 408 is that the overall width w. of the spinal fusion implant 400 is substantially reduced while the height of the spinal fusion implant 400 remains the maximum diameter M of the cylindrical portion of the spinal fusion implant 400. Referring to Figures 25 azld 26, as the height of each spinal fusion implant 400a and 400b is sufficient to cross the disc space D and into the two adjacent vertebrae V, each spizlal fusion implant 400a and 400b engages the bone of the adjacellt vertebrae V wl ile the combined width of the two spinal fusion implant i00 does not exceed the transverse width W of the s spinal column S. As a result, the advantages of placing two cylindrical implants side by side across the disc space D may be obtained without exceeding the width W of the spinal s column S. Thus, as shown in Figure 26, the two spinal fusion implants 400a and 400b can be inserted across the disc space D, having the same dimensions as the disc space D shown in Figure 2, and can be placed much closer together as a result of the first flat side 408b placed adjacent to the second flat side 408a while continuing to engage the adjacent vertebrae V. As shown in Figure 30, the spinal fusion implazlt 400 has a hollow internal central chamber 414 and has a series of openings 428 passing through the outer wall 405 and into the central chamber 414 of the spinal fusion implaJ,t 400. The openings 428 may also be present on the first and second flat sides 406 and 408. Said openings 428 while shown as round holes for example, may be any other workable configuration consistent with their purpose and may include, but is not limited to, ovals, slots, grooves and holes that are not round as is true for any of the cylindrical implants disclosed above. Referring to Figure 30A, it is appreciated that it is also within the scope of the present invention that the spinal fusion implant 400' could have only one flat side so as to provide only a first flat side 406' This configuration is appropriate where the width W. of the spinal fusion implant 400 need only be slightly reduced with respect to its maximum diameter M, to prevent the combined overall width of two such implants from exceeding the transverse width W of the spinal s column S. Referring to Figures 23, 24 and 29, the spinal fusion implant 400 of the present invention has a plurality of ratchetings 420 facing one direction, as described above for spinal fusion implant 100, along the outer surface of the cylindrical portion of the circumference of the spinal fusion implant 400. The ratchetings 420 have a bone engaging edges 422 and the angled configuration of the ratchetings 420 provide for a "one-way" insertion of the spinal fusion implant 400 as the movement of the spinal fusion implant 400 in the opposite way is prevented by the engagement or the engaging edges 422 with the vertebrae V. However, the flat sides 402 and 404 are preferably smooth and have a flat surface so as to allow placement in the closest possible proximity of the two spinal fusion implants 400a and 400b. The bone engaging edge 422 of each ratcheting 420 bisects the holes 428 to increase the stability of the spinal fusion implant 400 once implanted. The spinal fusion implants 100-600 each have an overall length in the range of 20ram to 30ram, with 25ram being preferred, and a maximum diameter M iu the range of 14ram to 24ram, with 18ram being preferred when inserted in the lumbar spine from the posterior approach, and 20ram being preferred when inserted in the lumbar spine from the anterior approach. The spinal fusion implant 400 is quite appropriate for use in the cervical and thoracic spine as well. In the cervical spine such implants would have a length in tlle range of 10-18ram preferred 12 mm and a maximum diameter M in the range of 12-20ram, with the preferred diameter being 16ram. In tile thoracic spine such implants would have a length iu the range of 16-26mm and a greatest diameter in the range of 14-20mm, with the preferred diameter being 16ram. In addition to the foregoing dimensiolls,' spinal fusion implants 400-600 have a width W. for use in the cervical spine in the range of 8-16ram, wit}, the preferred width w. being 10-14ram; for use in the lumbar spine in the range of 18-26mm, with the preferred width W being 18-20ram; and for s use in the lumbar spine in the range of 18-26mm, with the preferred width W. being 20-24mm. Referring to Figures 27 and 28, well viewed oll eud, the spinal fusion implant 400 of the present invention has externally the geometrical configuration of a circle with a portion of each side tangentially amputated vertically to form the first and second flat sides 406 and 408. The cap 430 extends beyond the narrowest diameter of the wall 412 along the first and second arcuate portions 402 and 404 at the end of the spinal fusion implant 400 and acts as an additional ratcheting 420 with an engaging edge 436. In this manner, the additional ratcheting 420 functions to further increase the stability of the spinal fusion implant 400 once inserted between the adjacent vertebrae V and to further prevent the dislodgement of the spinal fusion implant 400 from the disc space D. The cap 430 is flush with the flat sides 406 and 408 to preserve the flat surfaces of flat sides 406 arid 408. The cap 430 further has a sloping sides 438a and 438b corresponding position with the flat sides 406 and 408 to facilitate insertion of the spinal fusion implant 400 and to permit for close side by side placement of two spinal fusion implants 400. Alternatively, tlle cap 430 can be flush all the way around with the root diameter of the spinal fusion implant 400 to further facilitate insertion for a longer ramp length. The spinal fusion implant 400 has surface roughenings such as, but not limited to, ratchetings 420 such that the outer surface of the spinal fusion implant 400 may have a plurality of other surface roughenings to enhance to stability of the spinal fusion implant 400 and to resist dislodgement once implanted across the disc space D. For example, the spinal fusion implant 400 may have an irregular outer surface that may be created by blasting or rough casting and the like. Such an irregular surface may be used alone or in combination with other surface roughenings such as ratchetings and/or knurling and as already discussed, the openings 428 may be holes, grooves, slots or other. Referring to Figures 32-35, an alternative embodiment of the spinal fusion implant of the present invention is shown and generally referred to by the numeral 500. The spinal fusion implant 500 is substantially the same as the spinal fusion implant 400, except that the openings 528 are positioned on the ratcheting 520 such that the openings 528 are positioned between the bone engaging edges 522 and are not bisected by the bone engaging edges 522. In this manner the bone engaging edges 522 are continuous and uninterrupted to engage the bone of the vertebrae V and prevent the backing out of the implant 500 once inserted. Referring to Figures 36-40, an alternative embodiment of the spinal fusion implant of the present invention is shown and generally referred to by the numeral 600. The spinal fusion implant 600 is substantially identical to the spinal fusion implant 400 described above except that in place of ratchetings 420, it has surface knurling 620 such as, but not limited to, the diamond-shaped bone engaging pattern shown in Figure The surface knurling 620 assists in the retaining of the spinal fusion implant 600 once it is inserted across the disc space D between two adjacent vertebrae V. It is recognized that the surface knurling 620 of the implant 600 may be combined with any of a number of other surface roughenings such as, but not limited to, ratchetings to assist in retaining the spinal fusion implant 600 across the disc space D. As shown in Figure 36, the cap 630 of the spinal fusion implant 600 has sloping sides 660 and 662 corresponding with the first and second flat sides 606 and 608 to facilitate insertion of the spinal fusion implazlt 600 and to permit for close side by side placement of two spinal fusion implants 600. It is appreciated that the implant invention may include any and all surface roughening collfiguration that either increase the surface area or interference fit of the implant and the vertebrae v. It is appreciated that the ratchetings described above for the various embodiments of the spinal fusion implants of the present invention may also comprise a knurled or other surface roughenings in combination with the ratchetings to further enhance the retention of the spinal fusion implant across the disc space D once inserted. referring to Figure 41, an alternative embodimel 1 t of tile spinal fusion implant of the present invention generally referred to by the ,lumeral 700 is shown. The spinal fusion implant 700 l]as surface roughenings comprising of a blasted external surface 701 to provide an engagement surface for the vertebrae V when inserted across the disc space D. The spinal fusioll implant has a plurality of openings 728, a removable cap 730 with a hex slot 734 for engaging a hex tool. Referring to Figure 42, an alternative embodiment of the spinal fusion implant of the present invention generally referred to by the numeral 800 is shown. The spinal fusion implant 800 is similar to spinal fusion implant 400 described above except that it has openings in the form of horizontal slots 828 on the flat side 806 and vertical slots 829 on the cylindrical portion of the spinal fusion implant 800. It is appreciated that the spinal implants of the present invention may have any configuration such that the combined overall width of the two such spinal fusion implants is less than twice the maximum diameter M of those implants without departing from the scope of the present invention. Referring to Figure 43, a segment of the spinal column S is shown with an alternative embodiment of two spinal fusion implants 900a and 900b inserted across disc space D 1 is shown. Spinal fusion implant 900a has a concave su[-face 902 which is correspondingly shaped for receiving the convex surface 904 of spinal fusion implant 900b. When the two spJ.nal fusion implants 900a and 900b are placed side by side, the concave surface 902 mates with the convex surface 904 such that the combined overall width of the two spinal fusion implants is less than twice the maxilnu,n diameter M of those implants. As a result, the advantages of placing two implants that are partially cylindrical, witl 1 respect to the portion engaging the vertebrae V, side by side across tile disc space D may be obtained without exceeding the width W of the spinal column s S. Referring still to Figure 43, an alternative embodiment of tile spinal fusion implant of the present invention comprising a single spinal fusion implant I000 inserted across the disc space D 2 of the spinal column S is shown. The spinal fusion implant i000 comprises a first cylindrical portion i010 and a second cylindrical portion 1012 and may have any of the suJ:face roughenings described above in reference to the embodiments set forth above. In the preferred embodiment, the spinal fusion impla,it i000 is inserted by linear advancement into two overlapping cylindrical l]oles drilled across the disc space D 2• While the present invention has been described in detail with regard to the preferred embodiments, it is appreciated that other variations of the present invention may be devised which do not depart from the inventive concept and scope of the present invention. The present invention discloses a spinal fusion implant (100) that is at least partially cylindrical, made of material appropriate for human implantation and having preferably, but not necessarily, one closed end and one end capable of being closed, such that an internal chamber (114) can be filled and hold any natural or artificial osteoconductive, osteoinductive, osteogenic or other fusion enhancing material. The partially cylindrical implant (100) directly participates and is incorporated in the ensuing fusion. In the preferred embodiment, the implant (100) of the present invention relies on surface roughenings (120) of the outer surface to enhance its stability and resist dislodgement from within the disc space between two adjacent vertebrae. The implant (100) of the present invention incorporates at its rear end, an engagement means (140) to facilitate insertion or extraction of the implant (100). The implant (100) may be filled with, coated with, and/or composed of, fusion promoting substances. Finally, the implant (100) of the present invention does not require rotation for its insertion and can be seated by linear advancement. 1. A spinal fusion implant made of a material appropriate for human implantation across a disc space between adjacent vertebral bodies, said implant comprising:

a non-threaded member having a leading end, a trailing end, and a length therebetween, said non-threaded member having a longitudinal axis and an exterior with at least in part opposed areuate portions adapted to penetrably engage the adjacent vertebral bodies when inserted between the vertebral bodies and across the disc space, said non-threaded member having a height passing perpendicularly through said opposed arcuate portions and the longitudinal axis of said non-threaded member, at least two portions of the length of said non-threaded member having the same height, each of said opposed arcuate portions having at least one opening passing therethrough to allow bone growth from adjacent vertebral body to adjacent vertebral body through said implant; and surface roughenings protruding from said exterior of said non-threaded member for engaging the vertebral bodies to maintain said implant in place, said surface roughenings configured to resist expulsion of said implant from between the vertebral bodies. 2. The spinal fusion implant of claim 1, in which said surface roughenings include knurling. 3. The spinal fusion implant of claim 1, in which said implant comprises a bone ingrowth material. 4. The spinal fusion implant of claim 1, wherein said non-threaded member has a hollow interior capable of retaining fusion promoting material. 5. The spinal fusion implant of claim 4, in which said implant has at least one removable cap for closing at least one end of said hollow interior. 6. The spinal fusion implant of claim 1, in which said at least one opening is capable of retaining fusion promoting material. 7. The spinal fusion implant of claim 1, in which said implant has a height larger than the disc space between the adjacent vertebral bodies to be fused. 8. The spinal fusion implant of claim 1, in which said implant comprises a fusion promoting material. 9. The spinal fusion implant of claim 1, in which said implant comprises a bone ingrowth material other than bone. 10. The spinal fusion implant of claim 1, in which said implant is made of an artificial material. 11. The spinal fusion implant of claim 10, in which said artificial material includes an implant quality metal. 12. A spinal fusion implant made of a material appropriate for human implantation between two adjacent vertebral bodies, said implant comprising:

a non-threaded member having a leading end, a trailing end, a length therebetween, and a hollow interior, at least one of said leading end and said trailing end having an access opening in communication with said hollow interior and being configured to cooperatively engage an end cap to at least in part close a portion of said access opening, said non-threaded member having a longitudinal axis and an exterior with opposed arcuate portions adapted to penetrably engage the two adjacent vertebral bodies, each of said opposed arcuate portions having at least one opening passing therethrough to allow bone growth from one of the adjacent vertebral bodies to another adjacent vertebral body through said implant; and surface roughenings protruding from said exterior of said non-threaded member for engaging the vertebral bodies to maintain said implant in place, said annular ratchetings being defined around the circumference of said non-threaded member to resist expulsion of said implant from between the adjacent vertebral bodies. 13. The spinal fusion implant of claim 12, in which said surface roughenings include a plurality of annular ratchetings. 14. The spinal fusion implant of claim 12, in which said implant comprises a bone ingrowth material. 15. The spinal fusion implant of claim 12, in which said implant has a height larger than the disc space between the adjacent vertebral bodies to be fused. 16. The spinal fusion implant of claim 1, wherein said surface roughenings include a plurality of annular ratchetings. 17. The spinal fusion implant of claim 12, further comprising at least one removable end cap for cooperatively engaging and closing said access opening in at least one of said ends. 18. The spinal fusion implant of claim 12, in which said implant comprises a fusion promoting material. 19. The spinal fusion implant of claim 13, in which said ratchetings include an angled segment terminating in a bone engaging edge defined around the circumference of said non-threaded member. 20. The spinal fusion implant of claim 19, in which said at least one opening interrupts said ratchetings. 21. The spinal fusion implant of claim 19, further comprising a plurality of openings located at least in part between said ratchetings. 22. The spinal fusion implant of claim 12, in which said implant comprises a bone ingrowth material other than bone. 23. The spinal fusion implant of claim 12, in which said implant is made of an artificial material. 24. The spinal fusion implant of claim 23, in which said artificial material includes an implant quality metal. 25. A spinal fusion implant, substantially as herein described with reference to any one of the embodiments of the invention shown in the accompanying drawings.

Dated 21 December, 1999 Sofamor Danek Group, Inc.

Patent Attorneys for the Applicant/Nominated Person SPRUSON & FERGUSON

CPC - классификация

AA6A61A61BA61B1A61B17A61B17/A61B17/1A61B17/16A61B17/167A61B17/1671A61B17/17A61B17/175A61B17/1757A61B17/8A61B17/88A61B17/888A61B17/8888A61B2A61B20A61B201A61B2017A61B2017/A61B2017/0A61B2017/02A61B2017/025A61B2017/0256A61B2017/9A61B2017/92A61B2017/922A61B209A61B2090A61B2090/A61B2090/0A61B2090/03A61B2090/036A61FA61F2A61F2/A61F2/3A61F2/30A61F2/307A61F2/3074A61F2/30744A61F2/3076A61F2/30767A61F2/3077A61F2/30771A61F2/4A61F2/44A61F2/442A61F2/446A61F2/46A61F2/460A61F2/4603A61F2/461A61F2/4611A61F2/465A61F2/4657A61F20A61F200A61F2002A61F2002/A61F2002/2A61F2002/28A61F2002/283A61F2002/2835A61F2002/3A61F2002/30A61F2002/301A61F2002/3013A61F2002/30131A61F2002/3014A61F2002/30143A61F2002/30148A61F2002/302A61F2002/3023A61F2002/30235A61F2002/304A61F2002/3040A61F2002/30405A61F2002/305A61F2002/3059A61F2002/30593A61F2002/306A61F2002/3060A61F2002/30604A61F2002/307A61F2002/3077A61F2002/30774A61F2002/30777A61F2002/3078A61F2002/30785A61F2002/30787A61F2002/3079A61F2002/30795A61F2002/30797A61F2002/308A61F2002/3083A61F2002/30836A61F2002/3085A61F2002/3087A61F2002/30879A61F2002/309A61F2002/3090A61F2002/30904A61F2002/30906A61F2002/4A61F2002/44A61F2002/448A61F2002/449A61F2002/46A61F2002/461A61F2002/4619A61F2002/462A61F2002/4627A61F2002/4629A61F2002/468A61F2002/4681A61F22A61F222A61F2220A61F2220/A61F2220/0A61F2220/00A61F2220/002A61F2220/0025A61F223A61F2230A61F2230/A61F2230/0A61F2230/00A61F2230/001A61F2230/0013A61F2230/0017A61F2230/006A61F2230/0069A61F225A61F2250A61F2250/A61F2250/0A61F2250/00A61F2250/006A61F2250/0063A61F23A61F231A61F2310A61F2310/A61F2310/0A61F2310/00A61F2310/000A61F2310/0002A61F2310/00023A61F2310/002A61F2310/0029A61F2310/00293A61F2310/007A61F2310/0079A61F2310/00796IPC - классификация

AA6A61A61BA61B1A61B17A61B17/A61B17/0A61B17/02A61B17/1A61B17/16A61B17/17A61B17/2A61B17/22A61B17/8A61B17/88A61B19A61B19/A61B19/0A61B19/00A61FA61F2A61F2/A61F2/0A61F2/00A61F2/2A61F2/28A61F2/3A61F2/30A61F2/4A61F2/44A61F2/46Цитирование НПИ

EP 637440WO 89/12431

WO 91/06266