우레탄 페인트용 집진장치

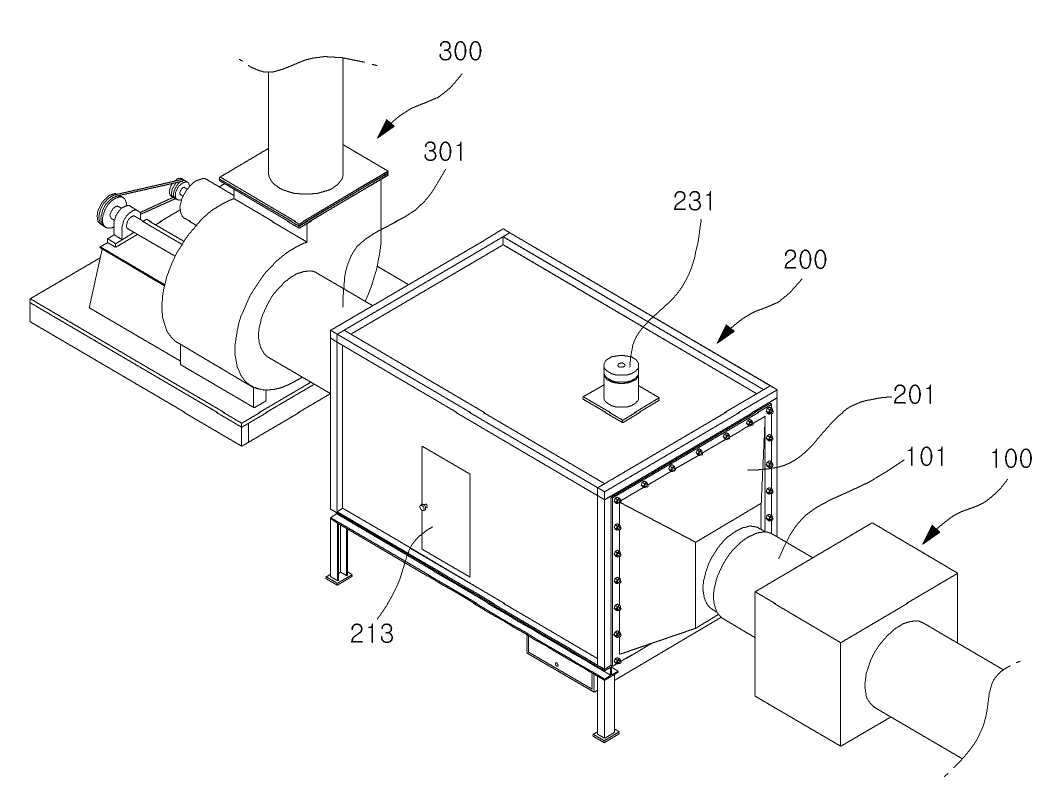

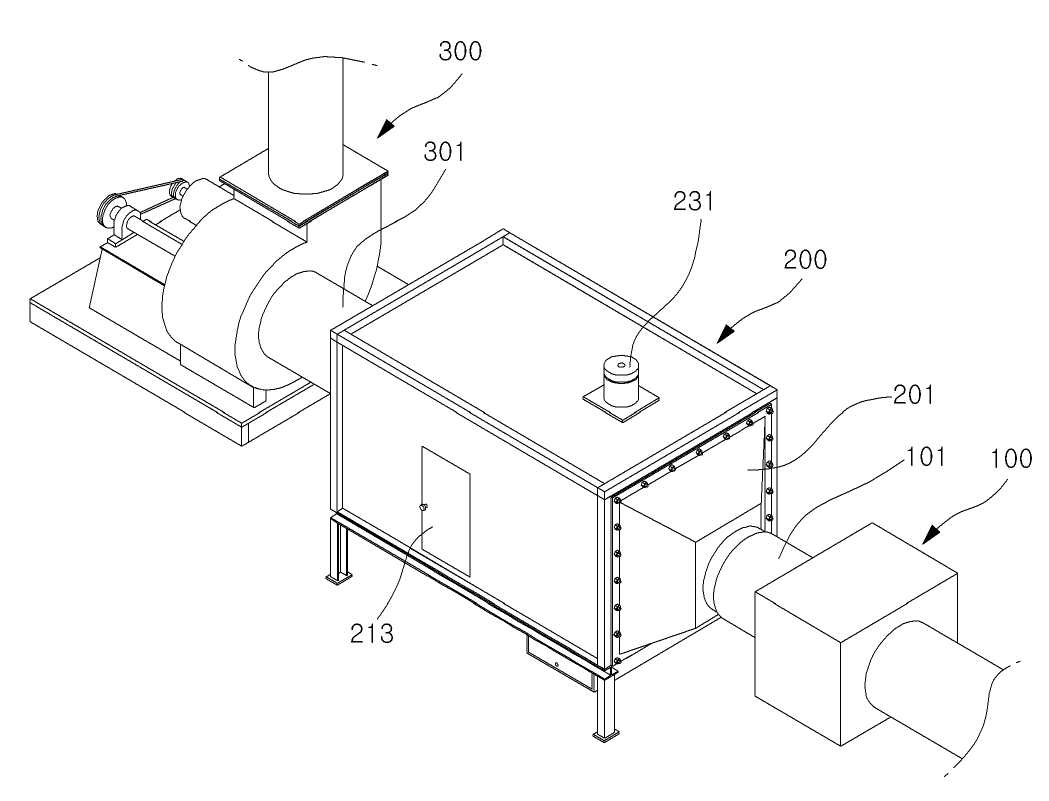

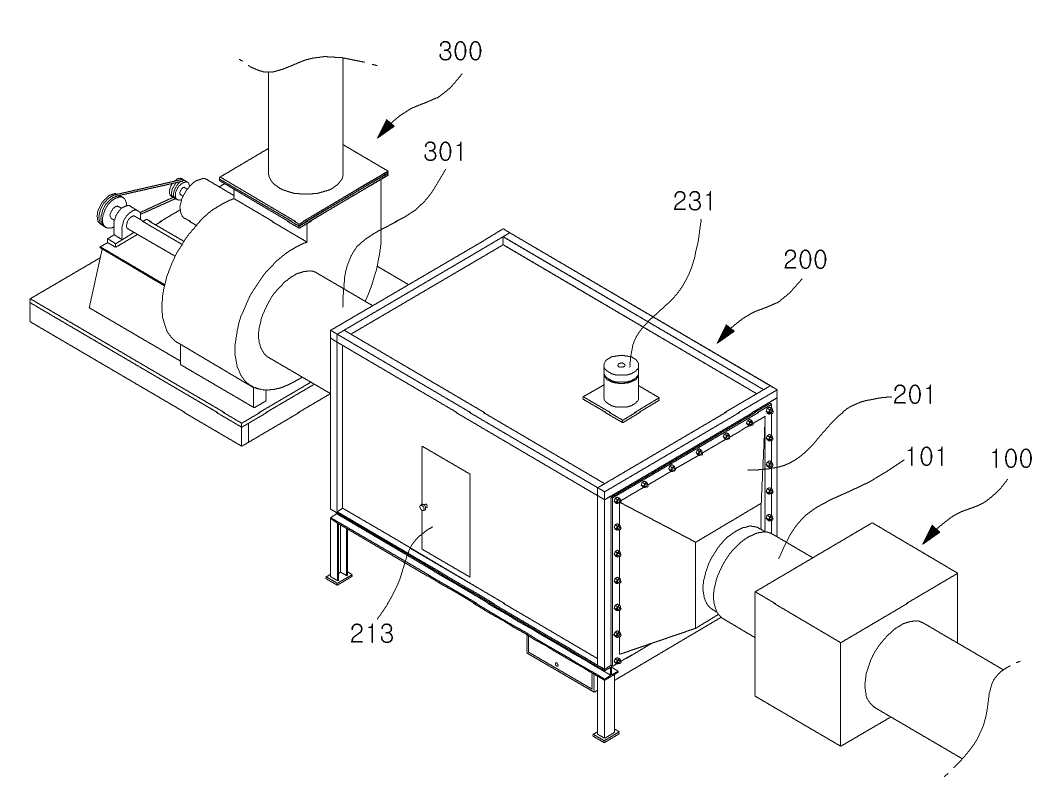

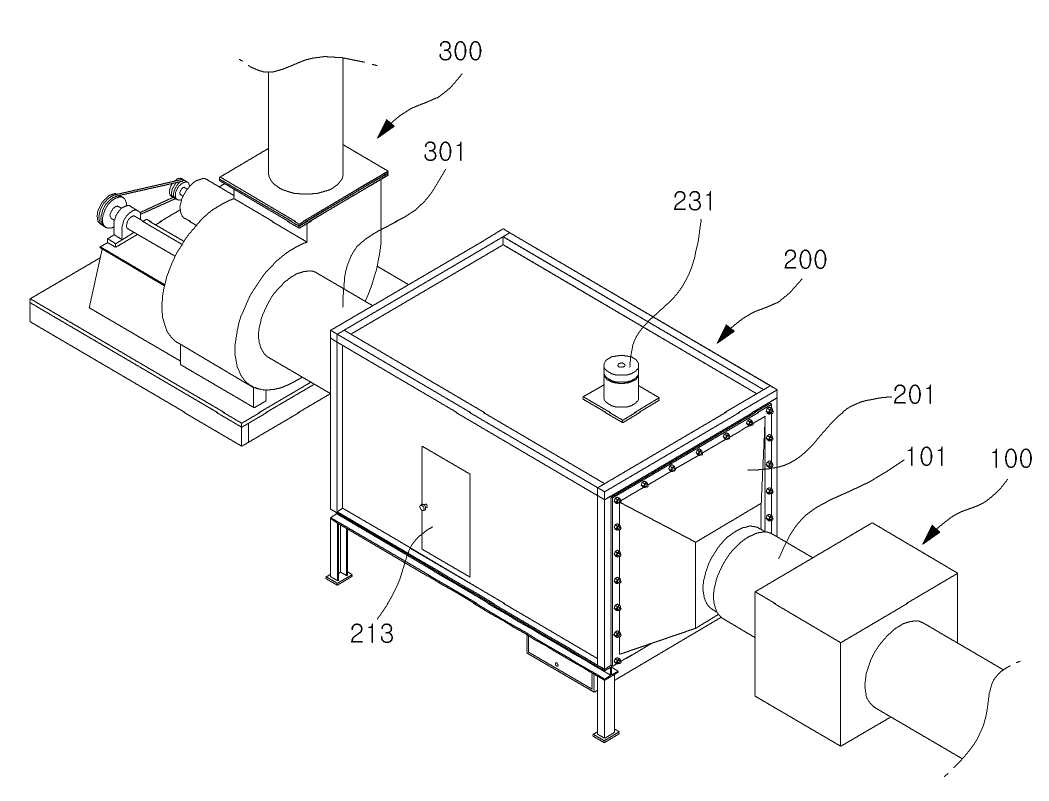

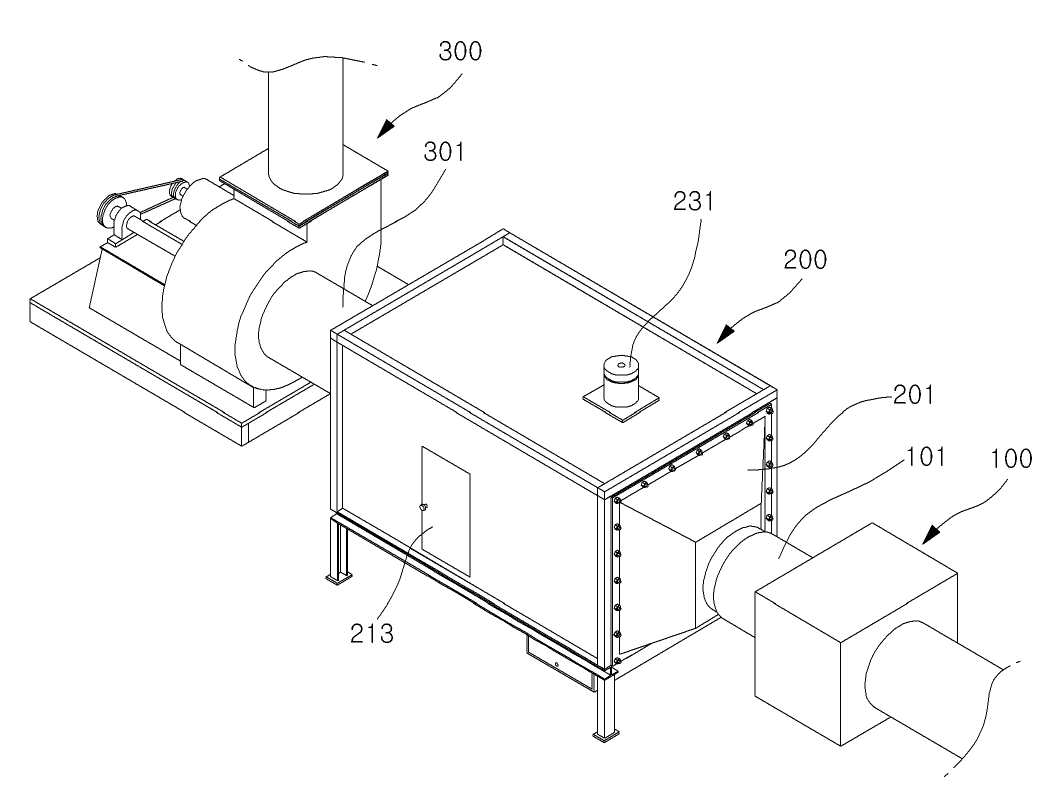

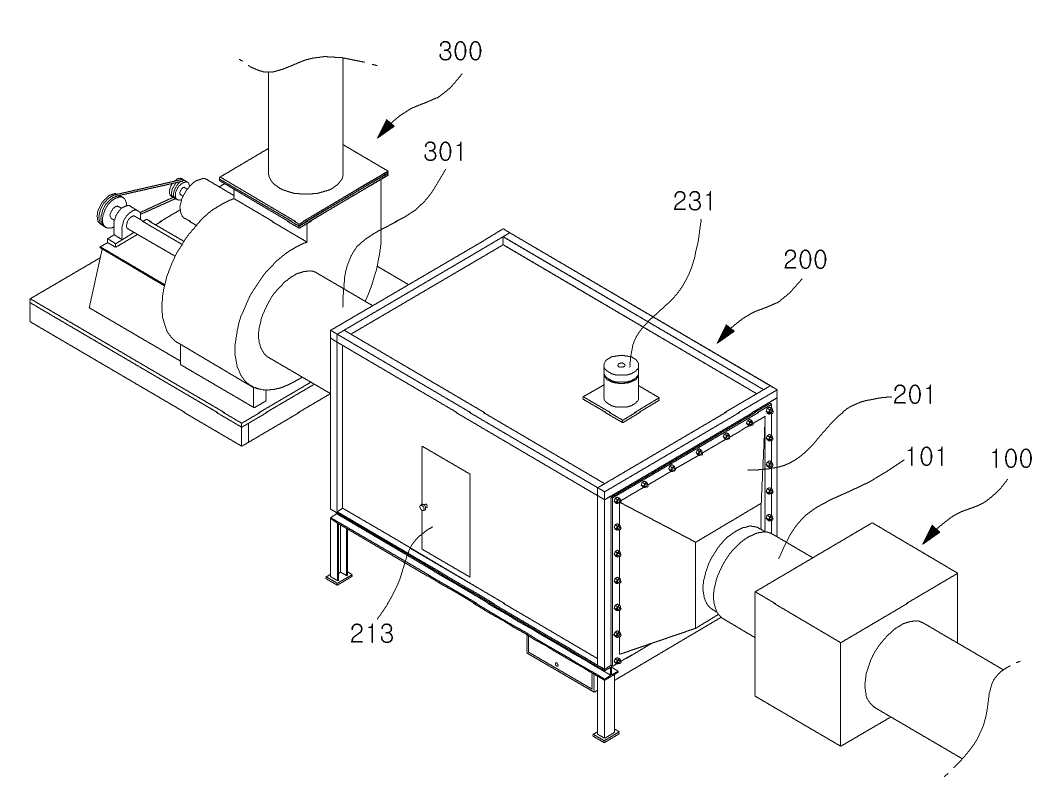

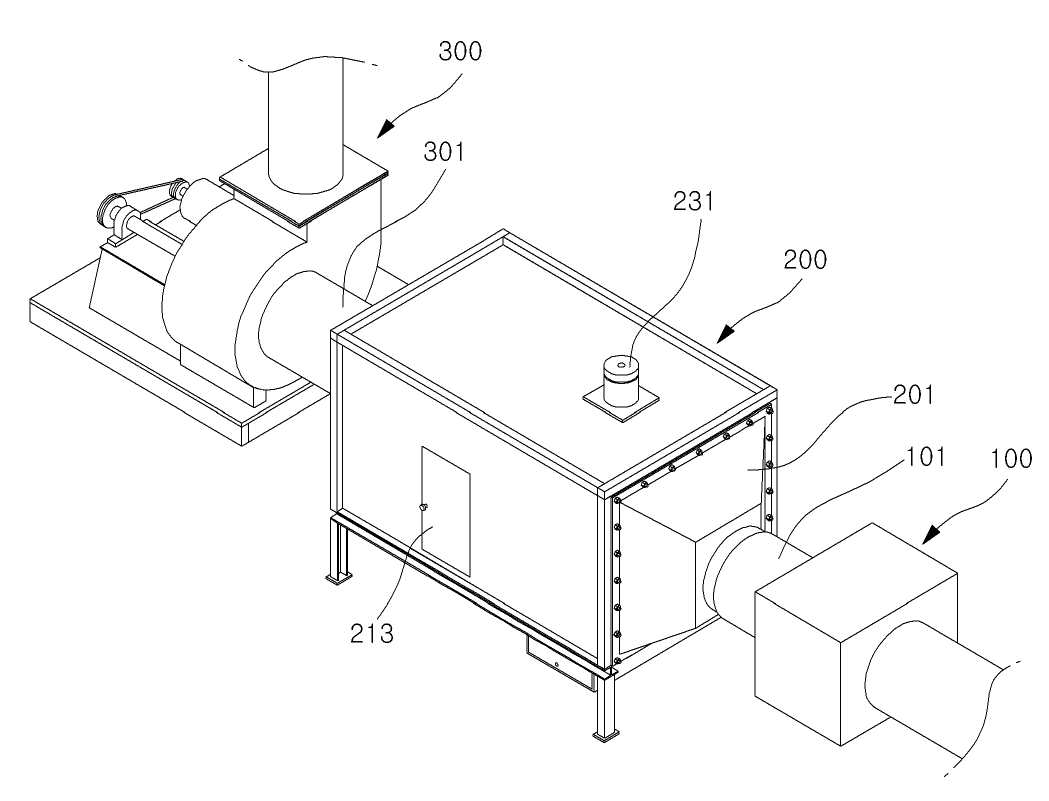

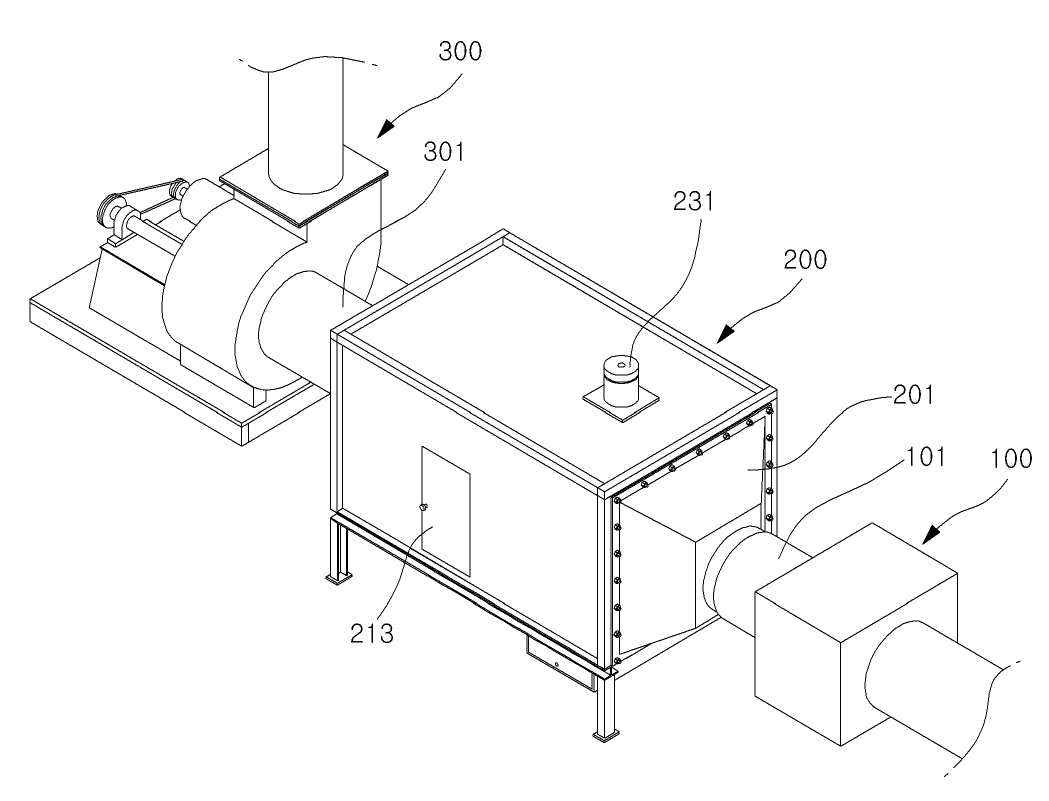

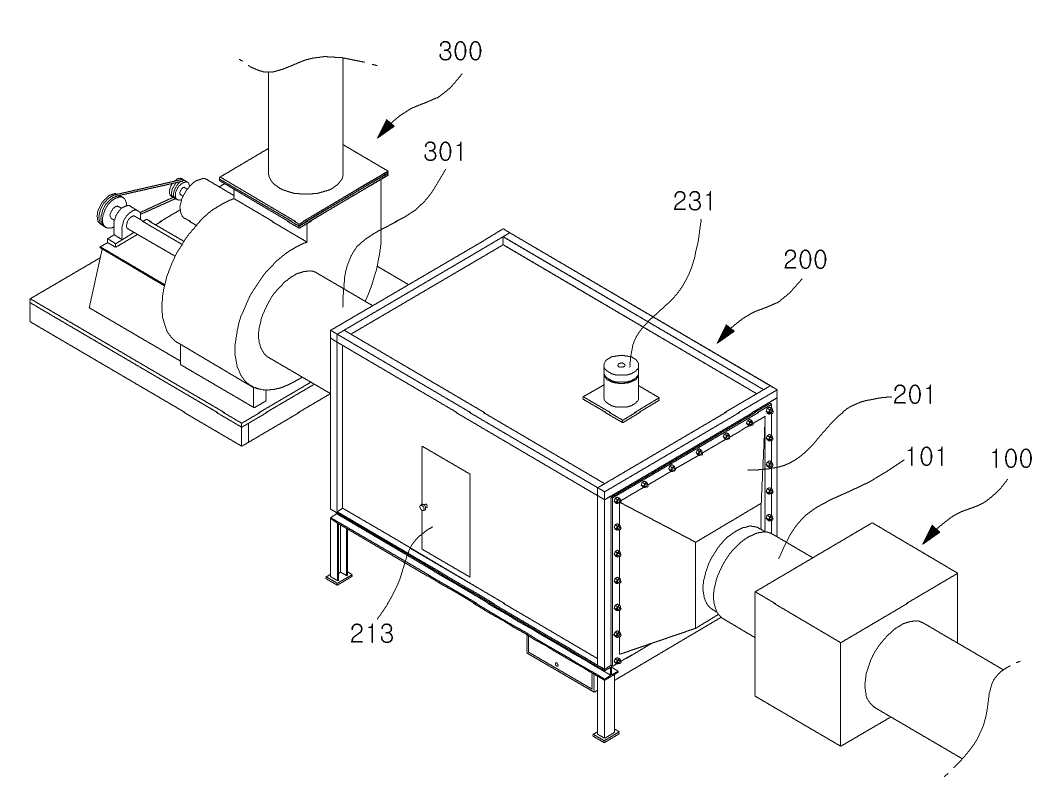

The present invention refers to collecting device relates to search, 1 difference mixer is provided comprising urethane in contact with water at the smaller air paint mixed with dust and contaminants and number 1 melting point is a stand-alone, mixed with dust and pollutants 1 number 2 to mixing with water in air for reparing over certain size difference of less than 1 difference mixer again less than a stand-alone number 2 and then mixed with dust and contaminants, mixed with dust and contaminants number 2 again contacted with water in less than 2 to 3 difference mixer air for reparing over certain size difference of less than dust and contaminants by urethane paint mixed with a stand-alone number 3 and number perfect contaminants and dust particles contained a stand-alone, finally 3 number of less than 2% contained in the air pollutants and dust mixed with glass filter dust and contaminants for reparing over a stand-alone number shutting and discharges purified air beyond the side of the collecting device by the preparation of a paint are disclosed. Rapid mirror number growth, and environmental pollution due to evaporating also shown through our father of standby, water and waste contamination of door number is social door number to the transmission housing and disclosed. In particular, dust or gas to atmosphere out of a human body and copper, as well as processed plant or the like having the main outputted by coexistence is itself greater scattering and affecting a harmful gas, storing particles enabling their influence polarization component. In addition obtain a long floating atmosphere since fine dust cloth and the intaglio view disorders, pneumoconiosis of the same to the smoke is encoded. In particular results in large amounts of dust and paint in painting, paint dust surrounding to the notch to supply, results in large amounts of volatile organic compounds (VOCs: Volatile Organic Compounds) from the paint used, volatile organic compounds in the atmosphere reacts with nitrogen by means of increasing ozone concentration to the sun's rays carry all organic compounds, station if the number of volatile organic compound which is increased and also the safety of an operator in an effort to reduce volatile organic compounds has been conventionally expected disclosed. Such paint dust collecting device for a stand-alone number has been developed. Such paint dust number techniques for network interworking registration patent number 10 - 135083 call (UV paint dust for collecting device) on a stand-alone domestic registration patent number 10 - 1525774 call is over (number device volatile paint dust) disclosure. The dust collecting device 1 and 2 also includes said UV paint dust as shown in UV UV paint dust from gas painting installation also includes an inflow duct (101) on, said inlet duct (101) such that the gas is introduced through UV paint dust in fan unit (100) and, said fan unit (100) to be drawn through the large viscous phase component containing a UV paint dust gas phase component containing a filtering dust and air mucus to large electrostatic dust collecting unit (200) and, filtered air exhaust duct (301) is discharged through discharge ports where a discharge unit (300) including combustion chamber. During name code for drawing comprises an inlet housing 201, 213 number 1 the maintenance door, motor 231, the number 1 dust collecting filter 220, fixed frame 227, the 240 number 2 dust collecting filter, filter housing 250, 255 number 2 the maintenance door, whereby signal in 259 publicly known among others. In addition special number 3 as shown in paint dust also said device (1) has a table (10) on, the inlet duct (20) on, exhaust duct (30) on, blower (40) on, multi-mixing module (50) and, rotating dust collecting filter (60) and fixing dust collecting filter (70) consisting of an. First, table (10) made of a metal material is formed in the capillary tip, partition wall (11) and divided into 1 - 3 by space (S1 - S3), one upper air inlet (12) on, the other side beverage (13) is formed. And, the inlet duct (20) includes a table (10) discharge outlet (12) connected with one end, and the other end (not shown) are connected to a painting installation painting installation coating containing such contaminants from air table (10) discharge outlet (12) are supplied to a. In addition, exhaust duct (30) includes a table (10) the air discharge opening (13) with one end connected thereto. Further, blower (40) discharge duct (30) is provided to an end of the inlet duct (20) through a air table (10) feeding, table (10) purified in a purified air exhaust duct (30) into the atmosphere via an emit. Then, multi-mixing module (50) module case (51) on, mixer (52) on, gasket (53) and, lights in panel (54) and, water tank (55) and water tank (56) consisting of an. A module case (51) is opened and an upper or lower part made of a metal material, a hollow rectangular parallelepiped shape of a board and, table (10) supporting the upper space of number 1 (S1). Mixer (52) includes a module case (51) is connected to the upper or lower part adapted for mounting on a vertically arranged in plural and is selectively removed, a hollow rectangular parallelepiped is formed in the shape, zig zag tobacco leaves an interior bottom end to plate (52a) installed vertically, water side central portion entering hole (WH) with a table (10) discharge outlet (12) coating by mixing 1 difference number supplied from water contaminated air contaminants other stand-alone. Gasket (53) both the contamination air mixer (52) to pass through the mixer (52) a mixer that the central processing unit (52) for sealing a space between the base. The lights in panel (54) for storing water therein to mixer (52) to supply water into a module case (51) in the middle of horizontally spaced-apart i.e., 2 of panel space spaced to force is removed. Water (55) includes a module case (51) spaced from the lower end of the table (10) provided at the lower end and space (S1) of number 1, mixer (52) falling from water are collected. Water tank (56) includes a module case (51) water inlet (51a) through the lights in panel (54) supplying device to each mixer (52) water supply water entering hole (WH) table (10) are provided at the lower end side. The, water tank (56) is installed by the pressure water lights in panel (54) supplied into the interior of mixer (52) than the water entering hole (WH) 2000. The, water tank (56) on the module case (51) water inlet (51a) piping between combined with each other. And, rotation dust collecting filter (60) includes a table (10) number 2 of space (S2) is installed, table (10) on bottom side rotary motor (61) connected by a belt (B) on a rotating shaft (63) is mounted on the multi-mixing module (50) is released through a coating contained in the air contaminants 2 difference number 1 difference purifying other stand-alone. On the other hand, fixed dust collecting filter (70) includes a table (10) space (S2) of number 2 number 3 (S3) on walls partitioning space (11) vertically mounted plural the multi-mixing module (50) is released through a number difference 3 stand-alone coating contained in the air purifying difference 2 contaminants therein. The number of special paint dust device (1) includes a coating installation from blower (40) coating by dust contamination air pollutants included in the table (10) discharge outlet (12) and collects, multi-mixing module (50) of a module case (51) open at, gasket (53) by each mixer (52) dispersed on a substrate. And, contaminated air mixer (52) while water is introduced via the entering hole (WH) underneath at the top of the water and mixed with the dust and water are pumped mixer (52) provided at the lower end of the zigzag-type tobacco leaves plate (52a) is mixed and then while moving along residence time would be increased to more water (55) and combined substrate. On the other hand, mixer (52) is about 80% or more dust 1 as it passes through a space (S1) which dissolves the produced difference number of special number 1 1 is rotated and the purified air is difference in relation to the dust collecting filter (60) is in the range of 95% or more dust through a difference encoded number 2 to enter the interior of the wetting ability. Then, the purified air is 2 difference rotation dust collecting filter (60) is moved to number 2 (S2) and a rear upper part of the space (11) member have a dust collecting filter (70) through the space (S3) are confirmed each other to number 3. The, 2 difference the purified air is fixed dust collecting filter (70) about 98% or more dust mixed with encoded number 3 as it passes through the wetting ability. And, number 3 (S3) of purifying air space 3 difference table (10) the air discharge opening (13) on, exhaust duct (30) and fan (40) emit into the atmosphere via. However, the dust filter device for collecting dust of the existing method UV paint is dry to be processed through the two paint used, since in the case of paint dust filter having high viscosity unable to processing only inside of a door number, the wetting ability of the existing method number dust collecting filters are used to paint device has a rotating, replacing time shorten the service life of a high, thereby maintenance cost and rear, the affiliated Company relationship using a filter at the without changing the voltage transformer door number point at the disclosed. The present invention refers to said door such as for the number and hydrogen gas, 1 difference mixer comprising urethane in paint is contacted with water air mixed with dust and contaminants and constant stand-alone at the smaller number 1, number 2 mixed with dust and pollutants 1 to mixing with water in air for reparing over certain size difference of less than 1 difference mixer again less than a stand-alone number 2 and then mixed with dust and contaminants, mixed with dust and contaminants number 2 again contacted with water in less than 2 to 3 difference mixer air for reparing over certain size difference of less than dust and contaminants by urethane paint mixed with a stand-alone number 3 and number perfect contaminants and dust particles contained a stand-alone, finally 3 number of less than 2% contained in the air pollutants and dust mixed with glass filter dust and contaminants for reparing over a stand-alone number shutting and discharges purified air side of a number by which the pin is house for paint-curing urethane beyond the user's device. For carrying out the same purposes of the present invention feature such as said, Number 1 - 4 1 - 4 space is divided by partitions, each partition number 1 - 3 at the lower end of said number 1 - 3 air circulation port is formed, a plurality of air ventilation holes are provided which are cartridges said number 4, top coating installation with a decontaminating liquid urethane paint dust from said one side is connected to the painting installation containing such air flowing contamination air inlet, the air discharge opening is formed on the other side a purged exhausting air Clipped; said board space by supply to the horizontal number 1 number 1 defining horizontal air inlet guides said contaminated air supplied from the water supply industry 1 1 dust and contaminants organocomplexes paint mixer difference number difference; said board horizontally space section number 2 number 2 by supply to the space unit number 1 horizontal partitioning said number 1 1 difference purifying contaminated air to the exhaust air circulation the water supply industry dust and contaminants urethane paint mixer 2 difference number 2 difference; horizontal partitioning said board horizontally space section number 3 number 3 by supply to the space unit 2 difference said number 2 number 2 the exhaust purifying contaminated air to air circulation the water supply industry dust and contaminants urethane paint mixer 3 difference number 3 difference; number 4 board number 4 in said space a plurality of air ventilation hole is installed cartridges through urethane paint dust contained in the air and purifying said 3 difference mixer 3 difference contamination to said board glass filter number contaminants into a stand-alone air discharge opening; said board fits, the washing water is stored; and said spray module stored at the top of the pool water to and from the number 1 - 3 difference mixer characterized. Here, a front horizontal plate is said number 2, 3 said number 1, 2 the exhaust contamination is provided to increase air circulation space each space unit extends vertically number 2 or number 3 bottom guide plate whose one end is combined with each other. Here in addition, said box body said number 1 - 3 urethane paint dust to collect in the space of the body said pollutants and water contained in the water tank provided at the lower end side of the board with a plurality of discharge ducts with each other. Here also, said number 1 formed in an upper or lower part mixer includes a difference block board is vertically mounted horizontal opened form said number 1, the number 1 case disposed in the into a lattice shape; said number 1 case arranged in zig zag consisting of dust and water are mixed for dropping number 1 mixing guide. Here also, the horizontal form said 2 difference mixer includes a funnel formed vertically mounted in said number 2, number 2 case arranged into a lattice shape installed; said number 2 case dust entering the water drops are formed while rotating vortex to form soft baking said number 2 number 2 consisting of mixing guide portion is fixed on the top of the case. Here also, said number 3 formed in an upper or lower part mixer includes a difference block board vertically mounted horizontal form said number 3 is opened, into a lattice shape the number 3 disposed in the case; said number 3 case arranged in zig zag consisting of dust and water are mixed for dropping number 3 mixing guide. Here also, the rectangular shape of a board and said reservoir supplied, blocking wall interior defined by ten crosses collecting tank, a filter tank number 1, 2, 3 into the bottom of the reservoir body comprising said number 1 - 3 difference mixer installed continuously the dog, said blocking wall water discharge number 1 - 3 combined with each other. Here also, each said exhaust duct through said collection bath comprising water discharge opening said number 1 discharged water urethane paint dust and contaminants anger, filtering said number 1 ethylene only discharging the formed upper rails, said number 2 number 1 in which bubbles generated in water the outlet collecting bath and said filter tank and located so as to block a, said number 3 water exiting the water outlet comprising said number 1 urethane paint dust and contaminants from the filter tank anger, discharging said only ethylene reservoir formed on an upper end, said number 1 height water outlet seal and disposed therein. Here also, said water pump and said water reservoir is installed injection module mounting structure of discharge; each said water pump is connected, each said number 1 - 3 of the mixer difference case number 1 - 3 at the top of the extending pipe; each said number 1 - 3 installed in the water supply pipe and the respective difference mixer case number 1 - 3 consisting of a plurality of injection nozzle. According to the present invention for collecting device in said configured such as urethane paint, urethane in paint is contacted with water air 1 difference mixer comprising constant number 1 at the smaller difference dust and contaminants and a stand-alone, mixed with dust and pollutants 1 number 2 back to mixing with water in air for reparing over certain size difference of less than 1 less than difference mixer dust and contaminants and then mixed with a stand-alone number 2, mixed with dust and contaminants number 2 again contacted with water in less than 2 to 3 difference mixer air for reparing over certain size difference of less than dust and contaminants by urethane paint mixed with a stand-alone number 3 and number perfect contaminants and dust particles contained a stand-alone, finally 3 number of less than 2% contained in the air pollutants and dust mixed with glass filter dust and contaminants for reparing over a stand-alone number of magnetic field generated by pre-purified air to be discharged into the atmosphere. Figure 2 shows a configuration of the device for collecting dust and also of the existing method UV paint indicating 1 also are disclosed. Figure 3 shows a number of the indicating device of the existing method of special paint dust also are disclosed. Figure 4 shows a collecting device of the present invention according to urethane paint for front indicating also are disclosed. Figure 5 shows a plane view of Figure 4 are disclosed. 6A is perspective view of the present invention according to urethane paint for collecting device indicating difference mixer during 1, 3 also are disclosed. 6A 6b also includes lengthwise drawing of also are disclosed. 7A is perspective view of the present invention according to urethane paint for collecting device indicating difference mixer during 2 also are disclosed. Also of lengthwise drawing 7a 7b is also are disclosed. Figure 8 shows a collecting device of the present invention according to urethane paint for indicating during reservoir sensors mounted thereon also are disclosed. Figure 9 shows a collecting device descriptions to explain the operation of the present invention according to urethane paint for also are disclosed. Hereinafter, the configuration of the present invention according to urethane paint for collecting device with reference to the attached drawing detailed as follows. In the present invention for are described so that, publicly known related function or configuration description is the subject matter of invention specifically breach can be decided to be dispensed description if the analogy will. In the present invention which is defined as the ability to carry terms of terms to the user, depending on intended or which said operator such as can be. Therefore its definition throughout the content based on the specification will been commanded. Figure 4 shows a configuration of the present invention according to urethane paint for collecting device and also indicating elevational view, and Figure 5 shows a plane view, a perspective view of the present invention according to urethane paint for collecting device indicating difference mixer during also 6a and 1, 3, 6a and 6b also includes lengthwise drawing of also, 7a is perspective view of the present invention according to urethane paint for collecting device also during and indicating difference mixer 2, 7a and 7b also is also lengthwise drawing of, Figure 8 the present invention according to urethane paint for collecting device during lifting device of configuration of Figure 4 indicating sensors mounted thereon are disclosed. With reference also to the 8 4 also, the present invention according to urethane paint for collecting device (100) includes a table (110) on, 1 difference mixer (120) on, 2 difference mixer (130) on, 3 difference mixer (140) on, glass filter (150) on, reservoir (160) and injection module (170) consisting of an. First, table (110) is formed in the capillary tip enclosed, partition number 1 - 4 (111 - 114) 1 - 4 by space (S1 - S4) is divided, partition number 1 - 3 (111 - 113) number 1 - 3 at the lower end of air circulation opening (111a - 113a) and respectively, partition number 4 (114) a plurality of air ventilation hole (114a) are provided which are, (not shown) are connected to a fan (not shown) top one side painting installation equipment from contamination by dust and urethane paint containing such an air injection member air inlet (115) on, applying a purged top exhausting air air outlet (116) is formed. The, table (110) includes a plurality of door for maintenance (D) is combined with each other. In addition, table (110) includes a space (S1 - S3) number 1 - 3 urethane paint dust and pollutants collected in the water contained in the reservoir (160) table of the body (110) provided at the lower end on the side of a plurality of exhaust duct (117) is formed. And, 1 difference mixer (120) is also 6a and 6b also number 1 as shown in horizontal plate (121) and, case number 1 (123) on, number 1 mixing guide (125) consists. Horizontal plate number 1 (121) is table (110) number 1 (S1) of a horizontal space divided into each other. Case number 1 (123) formed horizontal form an upper or lower part is opened the block board number 1 (121) in the vertically mounted, arranged into a lattice shape force is removed. Number 1 mixing guide (125) is number 1 case (123) arranged in zig zag inside dust and water drops are combined to each other. In addition, 2 difference mixer (130) also includes a horizontal plate number 2 as shown in 7a and 7b also (131) and, number 2 case (133) on, mixing guide (135) consisting of an. Horizontal plate number 2 (131) is table (110) number 2 (S2) of a horizontal space divided into each other. Case number 2 (133) is formed funnel form horizontal plate number 2 (131) is vertically mounted respectively, arranged into a lattice shape force is removed. The, horizontal plate number 2 (133) number 1 the air circulation opening (111a) in most applications is provided to increase a front space (S2) number 2 vertically in the bottom of each whose one end extends guide plate (GP) is combined with each other. Number 2 mixing guide (135) is number 2 case (133) dust entering the vortex while rotating to form water drops are formed soft baking case number 2 (133) fixed on the top of the force is removed. Further, 3 difference mixer (140) is 1 difference mixer (120) identical to the structure, also as shown in 6a and 6b also horizontal number 3 (141) and, case number 3 (143) on, number 3 mixing guide (145) consisting of an. Horizontal plate number 3 (141) is table (110) of a horizontal space (S3) number 1 divided into each other. Case number 3 (143) formed horizontal form an upper or lower part is opened the block board number 3 (141) in the vertically mounted, arranged into a lattice shape force is removed. The, horizontal plate number 3 (141) number 2 the air circulation opening (112a) in most applications is provided to increase a front space (S3) extends vertically number 3 whose one end each bottom guide plate (GP) is combined with each other. Number 3 mixing guide (145) is number 2 case (143) arranged in zig zag inside dust and water drops are combined to each other. And, glass filter (150) 100K is high density filter, table (110) within 3 difference mixer (140) is provided on a side 3 difference mixer (140) that is discharged from the dust and contaminants to number of microparticles urethane paint industry association table (110) the air discharge opening (116) into the substrate. The, glass filter (150) includes a table (110) of number 4 (S4) partition number 4 in space (114) formed a plurality of air ventilation hole (114a) preferably is integrally formed with each horizontal position. In addition, reservoir (160) includes a table (110) of a refrigerant pipe 1 - 3 difference mixer (120, 130, 140) that is discharged from the stored water, filtered recycled to same, as shown in 8 also supplied in the capillary tip formed, ten crosses interior blocking wall (162) is partitioned by the collecting tank (163), filter tank number 1, 2 (164, 165) and reservoir (166) divided into a body (161) is number 1 - 3 difference mixer (120, 130, 140) into the bottom of the 3 the dog continuously snow encoded value. The, barrier (162) number 1 - 3 to the water discharge opening (167, 168, 169) is used with, the water discharge opening number 1 (167) is each exhaust duct (117) collected via a bath (163) urethane paint dust and contaminants including water discharged into the anger, number 1 only ethylene filter tank (164) formed on top of the body, the water discharge opening number 2 (168) includes a collection tank (163) on, filter tank number 1 (164) so as to block and in which bubbles generated in an enhanced, number 3 the water discharge opening (169) includes a filter tank number 1 (164) urethane paint dust and contaminants including water exiting the anger, only ethylene reservoir (166) formed on an upper end of the body, the water discharge opening number 1 (167) formed the same height. On the other hand, injection module (170) reservoir (160) in a filtration water number 1 - 3 difference mixer (120, 130, 140) into the top of the invention relates to a water pump (171) on, a water pipe (173) and injection nozzle (175) consisting of an. Water pump (171) includes a reservoir (160) method of (166) is installed water discharge substrate. A water pipe (173) is each water pump (171) connected to the previous gate, each number 1 - 3 difference mixer (120, 130, 140) of number 1 - 3 case (210, 131) extending into the top of the. Injection nozzle (175) each pipe (173) is provided to each number 1 - 3 difference mixer (120, 130, 140) of number 1 - 3 case (210, 131) the water supply substrate. The, injection nozzle (175) is 3 difference mixer (140) being injected at a water amount is 1 difference mixer (120) times the amount of water being injected at first and longevity and number 2, water pump (171) increase the capacity of the reaction chamber. Hereinafter, the configuration of the present invention according to UV paint for collecting device with reference to the attached drawing detailed as follows. Figure 9 shows a collecting device descriptions to explain the operation of the present invention according to urethane paint for also are disclosed. First, by coating installation with a decontaminating liquid urethane paint containing such a snap from dust contamination air table (110) discharge outlet (115) through space (S) open at number 1, number 1 space (S) upper injection module (170) of water pump (171), a water pipe (173) and injection nozzle (175) by reservoir (160) method of (166) stored filtered water supply pipe thereto. Then, number 1 space (S1) with a predetermined length from contamination by the pressure air mixed with water to 1 difference mixer (120) of number 1 case (123) open at, number 1 mixing guide (125) mounted above the water while zigzags along more alkali metal oxide. On the other hand, 1 difference mixer (120) of number 1 case (123) through a relatively large particle size dust mixed with a decontaminating liquid water drops onto the discharge duct (117) a reservoir through the (160) collector tank (163) is collected and is therefore free to fall, relatively small size particles mixed with water contains air dust and contaminants partition number 1 (111) number 1 of air circulation opening (111a) following expulsion through 2 difference mixer (130) (GP) number 2 (S2) along guide plate of space upper conveyed to a substrate. The, 1 difference mixer (120) 70% degree of urethane paint dust and contaminants in a stand-alone number 2000. Then, number 2 (S2) and mixed with the contaminated air space 2 by the pressure difference with a predetermined water mixer (130) of number 2 case (133) open at, number 2 mixing guide (135) mounted above the water vortex along form while more alkali metal oxide. On the other hand, 2 difference mixer (130) of number 2 case (133) dust and contaminants through relatively small particle size mixed water drops onto the discharge duct (117) a reservoir through the (160) collector tank (163) is collected and is therefore free to fall, mixed with water particles without size relatively smaller dust and contaminants partition number 2 contains air (112) number 2 of air circulation opening (112a) following expulsion through 3 difference mixer (140) (GP) space (S3) number 3 along guide plate of upper transfer thereto. The, 2 difference mixer (130) 20% degree of urethane paint dust and contaminants in a stand-alone number 2000. Subsequently, number 3 (S3) with a predetermined length from the contaminated air and mixed with the water space 3 by the pressure difference mixer (140) case of number 3 (143) open at, number 3 mixing guide (145) dropped along the zigzag-type water while more alkali metal oxide. The, 3 difference mixer (140) 1 the amount of water is injected into a secondary mixer (120) of 2 times maxims. On the other hand, 3 difference mixer (140) case of number 3 (143) particle size relatively smaller dust and contaminants through mixed water drops onto the discharge duct (117) a reservoir through the (160) collector tank (163) is collected and is therefore free to fall, mixed with water particles without size relatively smaller dust and contaminants partition number 3 contains air (113) number 3 of air circulation opening (113a) following expulsion through space (S3) number 3 is conveyed to a substrate. The, 3 difference mixer (140) 5% degree of urethane paint dust and contaminants in a stand-alone number 2000. And, 3 difference mixer (140) exiting the air glass filter (150) number of microparticles by urethane paint dust and pollutants after for reparing over table (110) the air discharge opening (116) are discharged into the atmosphere via a. The, 3 difference mixer (140) 5% degree of urethane paint dust and contaminants and number in a stand-alone, glass filter (150) less than 1% 2% hereinafter by filtering dust in dust discharge substrate. On the other hand, collecting tank (163) specific urethane paint dust and contaminants dropped onto water established to anger, ethylene number 1 only the water discharge opening (167) number 1 through a filter tank (164) a housing and, filter tank number 1 (164) in collection tank (163) in which bubbles generated in an enhanced number 2 so as to block the water discharge opening (168) number 2 through water filter tank (165) to where, filter tank number 2 (165) urethane paint dust and contaminants by specific gravity difference in anger, ethylene number 3 only the water discharge opening (169) through reservoir (166) into the substrate. The present invention refers to take a variety of forms and can be deformed into various various special embodiment according to said detailed description of the invention the sub-have discovered only for example. Description referred to in the present invention refers to but not confined within the device must be understood to particular form, of the present invention defined by the appended claims rather all modified with uniform and replacement is understood to including within the range psychiatric should. 110: Table 120:1 difference mixer 130:2 Difference mixer 140:3 difference mixer 150: Glass filter 160: reservoir 170: Injection module The present invention relates to a dust collection apparatus. More specifically, the dust collection apparatus for urethane paint can eliminate dust and pollutants equal to or greater than a predetermined size in a first stage by making the air including the urethane paint come in contact with water in a first-stage mixer, mixes the air having the pollutants and dust removed therefrom in the first-stage mixer with water in a second-stage mixer to eliminate the pollutants and dust smaller than the predetermined size employed in the first stage in the second stage, and makes the air having the pollutants and dust removed therefrom in the second stage come in contact with water in a third-stage mixer to eliminate the pollutants and dust smaller than the size of the pollutants and dust removed in the second stage in the third stage. Accordingly, the dust collection apparatus can completely eliminate the pollutants and dust included in the urethane paint, eliminate less than 2% of the pollutants and dust included in the air having the pollutants and dust removed in the third stage with a glass filter in the final stage, and discharge only the purified air to the atmosphere, thereby extending the service life of the filter.<br>COPYRIGHT KIPO 2019<br> Number 1 - 4 1 - 4 space is divided by partitions, each partition number 1 - 3 at the lower end of said number 1 - 3 air circulation port is formed, a plurality of air ventilation holes are provided which are cartridges said number 4, top coating installation with a decontaminating liquid urethane paint dust from said one side is connected to the painting installation containing such air flowing contamination air inlet, the air discharge opening is formed on the other side a purged exhausting air Clipped; said board space by supply to the horizontal number 1 number 1 defining horizontal air inlet guides said contaminated air supplied from the water supply industry 1 1 dust and contaminants organocomplexes paint mixer difference number difference; said board horizontally space section number 2 number 2 by supply to the space unit number 1 horizontal partitioning said number 1 1 difference purifying contaminated air to the exhaust air circulation the water supply industry dust and contaminants urethane paint mixer 2 difference number 2 difference; horizontal partitioning said board horizontally space section number 3 number 3 by supply to the space unit 2 difference said number 2 number 2 the exhaust purifying contaminated air to air circulation the water supply industry dust and contaminants urethane paint mixer 3 difference number 3 difference; number 4 board number 4 in said space a plurality of air ventilation hole is installed cartridges through urethane paint dust contained in the air and purifying said 3 difference mixer 3 difference contamination to said board glass filter number contaminants into a stand-alone air discharge opening; said board fits, the washing water is stored; and said pool water spray at the top of the reciprocally stored said number 1 - 3 difference mixer characterized-curing urethane paint for collecting device. According to Claim 1, horizontal plate is said number 2, 3, said number 1, 2 the exhaust contamination is provided to increase a front air circulation space each space unit whose one end extends vertically number 2 or number 3 bottom guide plate for collecting device characterized urethane paint is applied. According to Claim 1, said box body, said number 1 - 3 urethane paint dust and contaminants to collect in the space of the body said water contained in the water tank provided at the lower end side of said board with a plurality of discharge duct for collecting device characterized-curing urethane paint. According to Claim 1, said number 1 difference mixer, said number 1 is vertically mounted horizontal form the block board formed in an upper or lower part opened, arranged into a lattice shape installed number 1 case; said number 1 case arranged in zig zag dust and water drops are mixed urethane paint for collecting device consists of a mixing guide number 1 characterized. According to Claim 3, said 2 difference mixer, said number 2 is formed in funnel form horizontal and vertically mounted, arranged into a lattice shape installed case number 2; said number 2 case dust entering the water drops are formed while rotating vortex to form soft baking said number 2 case portion is fixed on the upper end of number 2 to and from the collecting device characterized urethane paint for mixing guide. According to Claim 5, said number 3 difference mixer, said number 3 is formed in an upper or lower part opened the block board form horizontal vertically mounted, arranged into a lattice shape installed case number 3; said number 3 are arranged in a zigzag case dust and water drops are mixed urethane paint for collecting device consists of a number 3 mixing guide characterized. According to Claim 6, the reservoir, supplied in the capillary tip formed, blocking wall interior defined by ten crosses collecting tank, a filter tank number 1, 2, 3 into the bottom of the reservoir body comprising said number 1 - 3 difference mixer installed continuously the dog, said blocking wall number 1 - 3 characterized in that the water discharge opening is applied urethane paint for collecting device. According to Claim 7, said number 1 water outlet, each said exhaust duct through said collection bath comprising urethane paint dust and contaminants discharged water anger, filtering said number 1 ethylene only discharging the formed upper rails, said number 2 water outlet, said collection reservoir and number 1 in which bubbles generated in the filter tank and located so as to block, said number 3 water outlet, said number 1 urethane paint dust and contaminants contained in the filter tank water exiting the anger, discharging said only ethylene reservoir formed on an upper end, said number 1 equal heights above the water discharge opening for collecting device characterized-curing urethane paint. According to Claim 7, said injection module, said water pump and water reservoir is installed mounting structure of discharge; each said water pump is connected, a water pipe extending into the top of the case number 1 - 3 each said number 1 - 3 of the mixer difference; each said number 1 - 3 and respectively installed in the water supply pipe of the mixer difference case number 1 - 3 characterized in that a plurality of nozzle-curing urethane paint for collecting device.