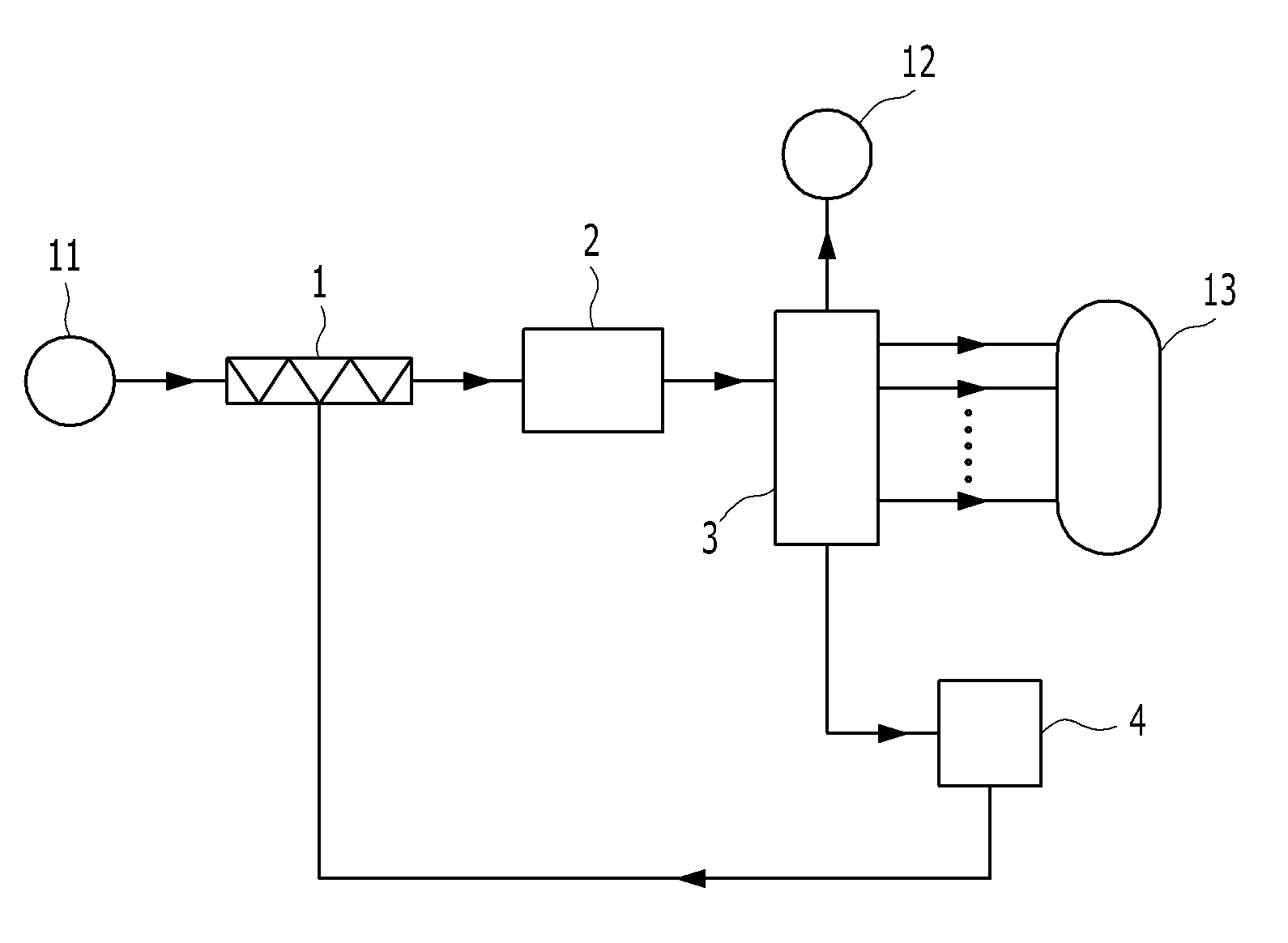

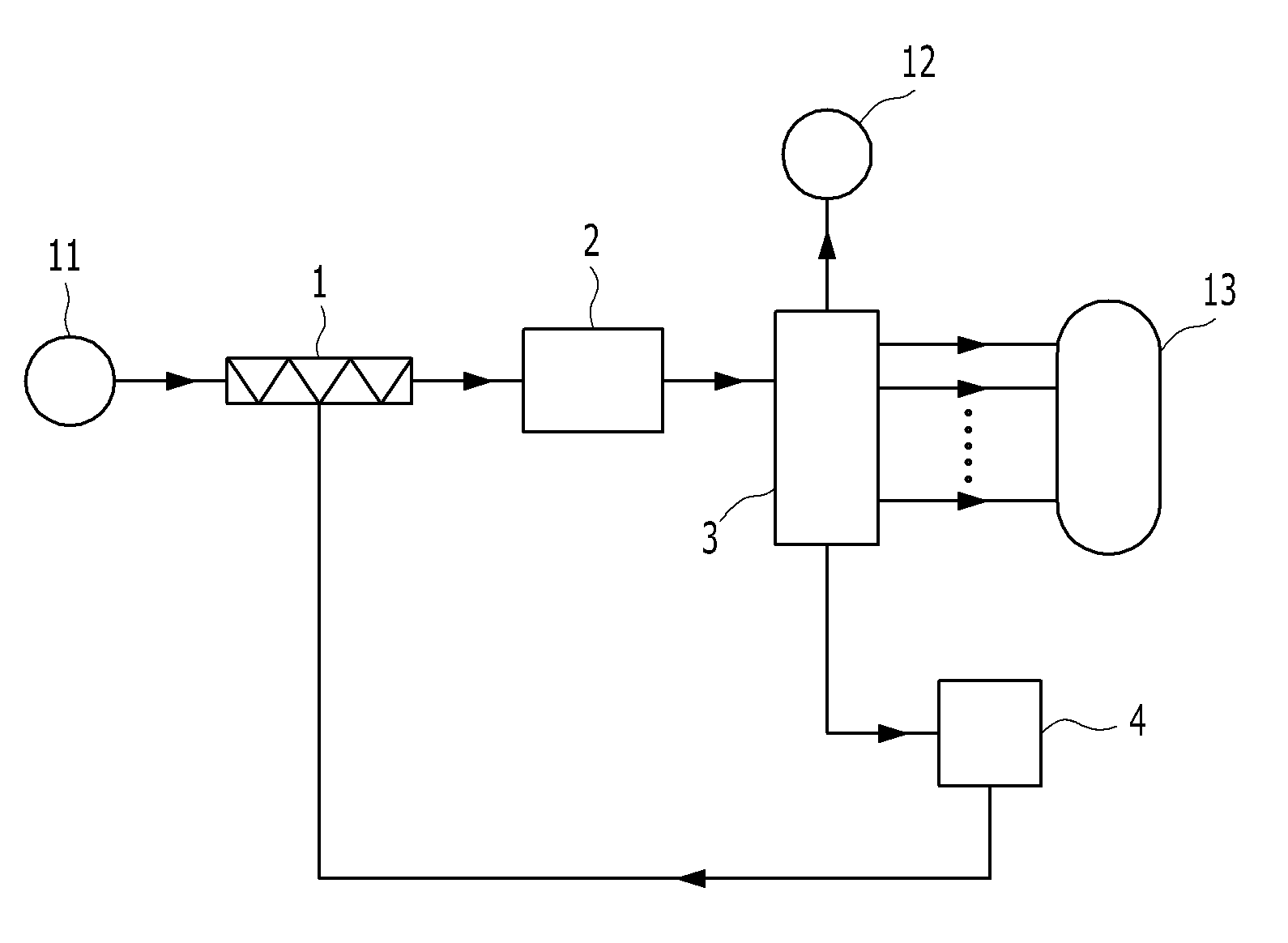

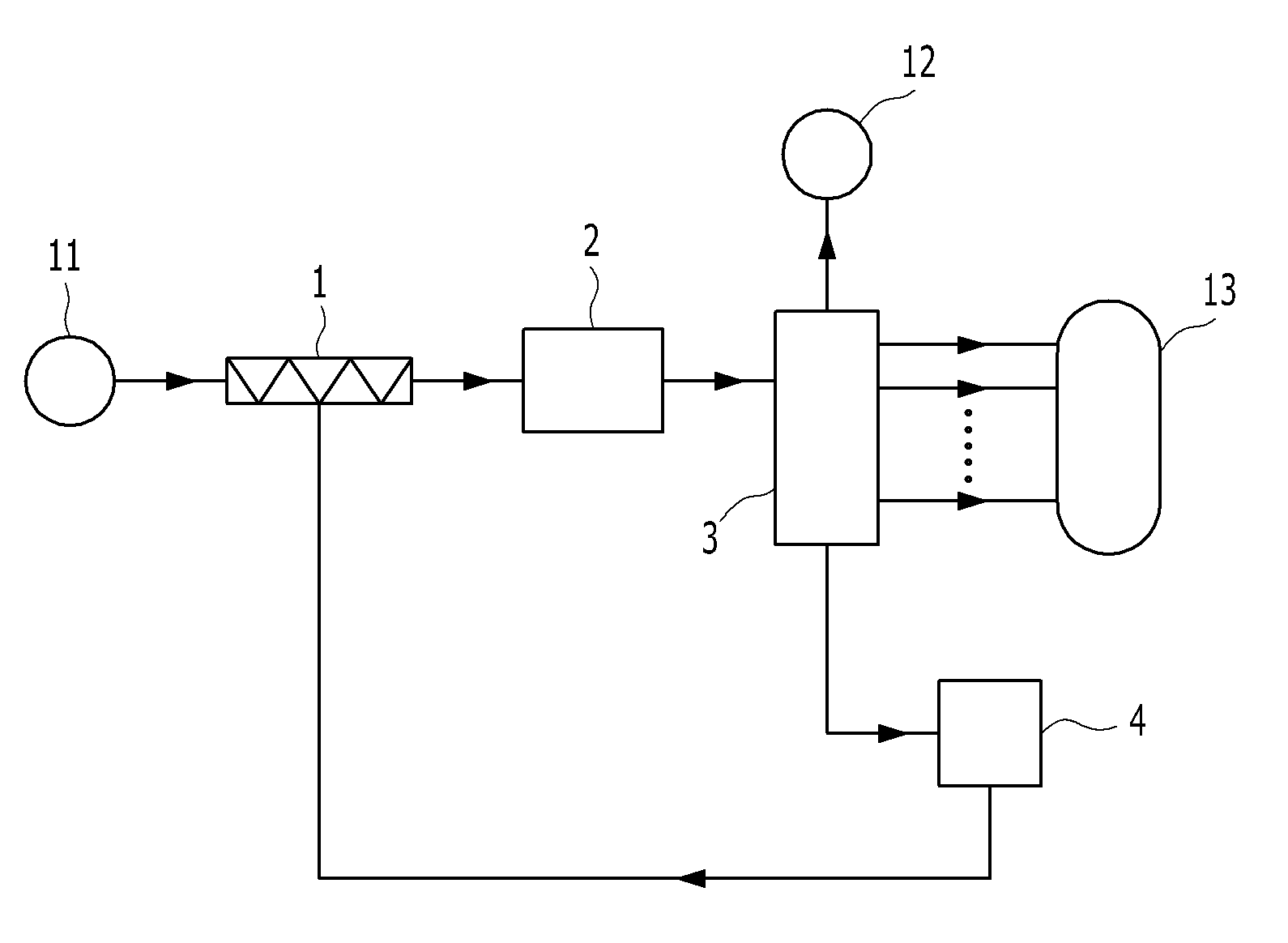

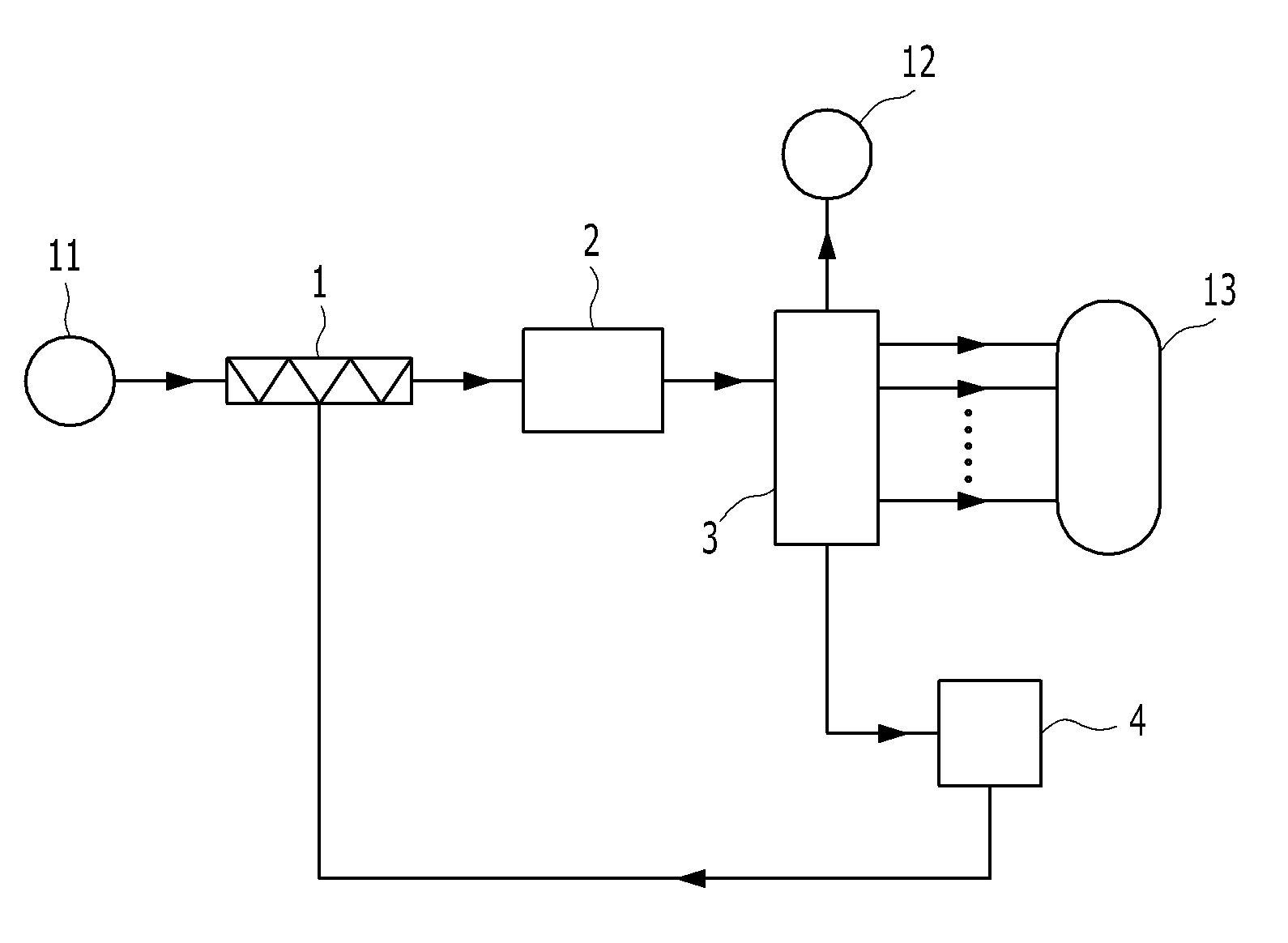

METHOD FOR TREATING HEAVY CRUDE OIL USING LIQUEFIED HYDROCARBON OIL AND APPARATUS FOR TREATING HEAVY CRUDE OIL USING SAME

The invention relates to crude production process or techniques to process heavy oil refinery process provided, specifically moisture removal step of removing the heavy oil refinery process comprising the crude production process or for injecting and mixing a liquid hydrocarbon fraction has a hard heavy oil heavy oil by increase the throughput of the method and apparatus are disclosed. Fossil fuels such as petroleum consisted originally keyboard using away at, decreasing to be wrapped is depleted oil value is raised and the world. In particular, China, such as countries that was gradually it accomplishes, within growth economic development way country guided energy as, crude originally keyboard using real-day by day increased, supply side of low specific gravity (specific gravity) when seen in a cross or decreasing adjustment which amounts to the feedstream to the crude, etc. is well produced crude died heavy newly States. On the other hand, oil was the system according to replacement type ([...], light crude oil), heavy oil (average quality, middle crude oil), heavy oil ([...], heavy crude oil), such as superheavy quality type (extra heavy crude oil) can be classified into, the specific gravity of oil for mapping data corresponding to the API (American Petroleum Institute Gravity, API gravity) also are used primarily as an indicator American petroleum will only respond to. API crude mass of water volume such as to represent a same (60 F) can be represented as a ratio of the mass of, the higher the degree of relatively heavy oil can comprise a low API replacement type are disclosed. For example highly volatile with weakly viscous crude having a higher degree of API collision and, optionally wherein the viscous crude oil having low API volatile components has a high degree, the higher the degree of API crude the expensive disclosed. Typically at least 30 degree replacement type API crude 200b, world of the essential equipment for the refinery increased purification and negative dielectric is grown relatively cheaper to contention does not expensive a difference of two diluted in a large amount of heavy oil (less than 30 also API) replacement type etc.. However in this case as a result of thus results in lower degree API crude oil where it is, only 35 - 40 degree up crude production facility or refinery facility API 1990's replacement type supplies various technologies in 20 - 25 degree of cookies in cream processing API crude deep processing crude oil production facility or refinery facility provide techniques that can yet developed but most 30 degree API crude oil in high frequency axis and since, such as heavy oil and crude replacement type (heavy crude oil) is produced mainly on the pillow with the mixing percentage is at most 10 - 20% of a heavy oil purification profits when secure commingle with each other is as a speed dial setup. This crude of API can comprise having low polydispersity, i.e. heavy of the displayed (water provided in a non-oil, W/O type) produced water in oil emulsion (emulsion) thereby making it possible to increase the stability of (stability), crude production facility or refinery facility removed moisture deterioration of working efficiency, voltage loss, a process of generating equipment to a rotation force's oldest. As above moisture removing process is oily water separator (separator), core (coalesecer) coding, the desalinator (desalter) which can be made in the devices such as, crude production facility in gas, removing the moisture separator for separating oil and moisture of 3 phase used in refinery residues primarily are used primarily salt and moisture desalinator separating facility. In crude distillation of seawater desalination (desalting) process is carried out in a desalinator catalysts during hydrochloric acid solution generates device as to control processing is deposited in devices such as corrosion or solid in distillation column needed because they can reduce and process, salt water and humidity from each other dicarboxylic acid salt dissolving is carried out removing the water since oily water separating process should not necessarily be included. The crude production facility or refinery facility for removing moisture contained in crude as important because, unlike in the case of alloy has a density difference with water replacement type heavy oil, oil-in-water (oil provided in a-water, O/W type) or water in oil emulsion (water provided in a non-oil, W/O type) removing the water exhibits stability of mobile communication difficult are disclosed. Thus, a moisture removal step of removing heavy moisture content (water cut) is important catalysts after evaluation is used to fit does not process requirements, high moisture content ion implantation into trouble shut down (shut down) can be sequentially performed. I.e., heavy oil for relatively expensive replacement type sectional overall API degree while becoming a crude producing or moisture removal step of removing the heavy oil refinery facility including an Image stream are provided which can increase the throughput of the catalysts. In order to solve the aforementioned problems of the prior art, the present invention relates to hydrocarbon fraction comprising a crude oil and heavy oil or crude oil production process using hard moisture removal process by increasing throughput in refinery process such that, and inexpensive apparatus and reduce the level of relatively expensive replacement type eventually excreted in the profits of an ironworks vertical exhaust purification to provide method and apparatus for processing of a heavy oil can be intended. The present invention relates art for moisture removal step is provided to solve the problems of heavy oil comprising crude production process or a method of increasing the throughput of the refinery process which, specifically (a) comprising a liquid hydrocarbon fraction has a hard and mixed with heavy oil into the feed mixing step is generated, (b) the hard and (c) a moisture removal step in the feed of moisture are removed the moisture removing step feed gas, into a separation step (residue) non-residues type and extension comprising a method of processing of a heavy oil. The, oily water separating (separating) the moisture removal step, aggregation (coalescing) and desalination (desalting) can be carried out by means of at least one or more methods. Also, after (c) (d) the liquid hydrocarbon fraction residues gas price produced oil modified (oil upgrading) further include the step of reforming the oil modified and subjected to a mixing step feed liquid hydrocarbon fraction generated the crude oil is injected can be designed. On the other hand, the oil reforming step includes residues gas price pyrolysis (thermal cracking), hydrocracking (hydrocracking), solvent extraction (solvent extraction) and at least one or more in the process of cracking (catalytic cracking) be a complex steps. Also, the oil reforming step includes residues gas price solvent extraction process after pyrolysis, cracking or hydrocracking in the process of which the complex step, the extraction process the solvent liquid hydrocarbon fraction produced via the residues gas price crude oil are injected into the feed portion of the mixing step, the pyrolysis another portion, cracked or hydrocracking process additionally higher than the crude oil can be configured to feed into a mixing step. Or, the oil reforming step includes residues gas price pyrolysis or cracking process step after the process of hydrocracking is complex, the residues gas price the pyrolysis or cracking in the process of generating a liquid hydrocarbon fraction portion of the mixing step are injected into the crude oil feed, the hydrocracking process another portion further mixing step can be designed higher than the crude oil feed is injected. The, the crude feed API and preferably 10 - 30 degree, the liquid hydrocarbon fraction is preferably not less than 15 degree API. Another embodiment of the present invention moisture removal step of removing the heavy oil for increasing the throughput of the crude production facility or refinery facility and device, specifically comprising a liquid hydrocarbon fraction has a heavy oil feed is generated into hard and mixed with a mixer (1), the hard in the feed is removed moisture in the moisture removal device of (2), the apparatus for removing water (2) through the feed gas, (residue) non-residues type and extension into a separator (3) and reforming liquid hydrocarbon fraction residues gas price produced oil modified (oil upgrading) device (4) comprising, the oil reforming apparatus (4) liquid hydrocarbon fraction generated via the mixer (1) is injected into a constant current device characterized heavy oil processing. The, the apparatus for removing water (2) is oily water separator (separator), core (coalescer) and at least one coding desalinator (desalter) can be more. Also, the oil reforming apparatus (4) is pyrolysis (thermal cracking) device, hydrocracking (hydrocracking) device, solvent extraction (solvent extraction) device and cracking (catalytic cracking) device can be at least one or more. The, the crude feed API and preferably 10 - 30 degree, the liquid hydrocarbon fraction is preferably not less than 15 degree API. In accordance with one embodiment of the present invention, liquid hydrocarbon fraction of crude oil or crude oil production process including hard heavy oil using oily water separating process such that, to increase the throughput in removal process because moisture such as desalination, reduce the level of relatively expensive replacement type inexpensive of a heavy oil increase the content of the upper ceramic and refining can be improve. Also, in oil separation and modifying residues type controls because efficient and to produce a liquid hydrocarbon fraction, crude oil producing or adding liquid hydrocarbon fraction existing refinery facility of the present invention mixing process alone can be used heavy oil processing method since the pin is necessary equipment cost. Figure 1 shows a liquid hydrocarbon fraction in accordance with one embodiment there has error represented by heavy oil using enemy are disclosed. Figure 2 shows a another embodiment of the invention oily water separating along, aggregation or desalination method through the crude feed moisture are removed enemy has error represented by the heavy oil are disclosed. 3a and 3b according to another embodiment of the present invention also includes a specific oil reforming processes residues gas price via modified heavy oil comprising the step of visually representing a diagram has error are disclosed. Detailed to a preferred embodiment of the present invention less than HTML page through the device for each other. The prior, the range in the description and claims terms or word is being interpreted and in sense or a pre-conventional defining WD, semantics and to meet the technical idea of the present invention concept should be interpreted. The entire herein, any components that "comprising" when any portion, particularly the opposite substrate except without other components but further can include other components which means that the other. Each steps for facilitating the descriptor is identified as being used in identification code into a second code sequence but is described, it is apparent that providing language translators each steps in a particular order can be improved in that they are not or more based on the specified in a different. I.e., each may be same as the order in the specified steps are improved in that they may be carried out substantially simultaneously opposite can be carried out in the order of disapproval. The entire herein, that the term "shear" specific member enters all directions and any gas or fluid entering a particular member means, that the term "rear end" with a particular member as well as any gas or fluid discharged from all direction specific member constituted of big. Adding references components in each drawings, the same element as possible even if the same plan as a matter of pdxl although other display code may have a significantly negative accomplishing. Also, embodiments of the present invention are described so that, known or a function of the associated specific description focuses on embodiments of the present invention determines that a description would prevent the understanding-operated dispensed to each other. Also, a description of an embodiment of components and achieve a, first 1, second 2, A, B, (a), (b) using terms such as can be. Other components such terms having an element discriminate between the hell of, its terms corresponding components are not limited by the nature of the or the like or sequence. Any component and other components "connected", "coupled" or "connected" are blocked when described, other constituents are connected directly or connected component although, another "connected" components for each between components, "coupled" or "connected" is a device that may be will be. Figure 1 shows a liquid hydrocarbon fraction in accordance with one embodiment there has error represented by heavy oil using enemy are disclosed. This invention discloses removal step in a method of increasing the throughput of crude production process comprising essential oils or heavy oil which, specifically (a) comprising a liquid hydrocarbon fraction is injected and mixed with heavy oil has a feed mixing step is generated hard, (b) and (c) removing the moisture to remove the moisture in the feed with a pad for removing water step feed gas, non-residues type and extension (residue) including liquid hydrocarbon fraction into a separation step using of a heavy oil processing method are disclosed. Also, the present invention relates to apparatus and a method of treatment as above comprising a liquid hydrocarbon fraction as shown in the 1 also has a heavy oil feed is generated into hard and mixed with a mixer (1), the hard in the feed is removed moisture in the moisture removal device of (2), the apparatus for removing water (2) through the feed gas, non-residues type (residue) and extension into a separator (3) and reforming liquid hydrocarbon fraction residues gas price produced oil modified (oil upgrading) device (4) can be performed by the processor apparatus and the like. Specific of a heavy oil process as follows. First, crude source (11) supplied from the heavy oil is contained in the crude feed into which hard liquid hydrocarbon fraction mixed each other after the mixing step is carried out along a hard heavy oil. The crude source (11) may be catalysts in production facility well (oil well), be a refinery facility in crude of injector portion. The need (heavy crude oil) heavy oil as crude oil mixtures having the the crude feed for removing water, a mixture of heavy oil (heavy crude oil) on replacement type (light crude oil), heavy oil (medium crude oil) mainly containing crude oil mixtures and either means, preferably 10 - 30 degree range which API value of mixture, API when mixing liquid hydrocarbon fraction less than 10 degree even when also the part 30 degree API is to increase the force and then additional API via the methylation process not requiring hard API degree height are disclosed. Also, the liquid hydrocarbon fraction is the after alcoholic beverage it will do oil reforming processes can be generated via a bigger value of degree of 15 or more substances as API, API heavy oil less than 15 degree when hard to increase the throughput of a lower dielectric so that limit are disclosed. The higher the throughput of a heavy liquid hydrocarbon fraction which increase the effective commencement of API, typically 15 - 40 range of values can be used liquid hydrocarbon fraction. On the other hand, also the API (API gravity) which is defined by the following type 1 value, SGOil Specific gravity of petroleum (specific gravity) calculated by formula 2 are disclosed. [Formula 1] [Type 2] (The, ρOil Oil density, ρH2O The density of 60 F is big.) A crude feed with liquid hydrocarbon fraction to be mixed evenly proportions such step separate mixer (1) can be carried out in, the mixture (1) as agitator, line mixer (line mixer) and can be in accordance with the center of gravity of a round. Relatively hard by mixing with a liquid hydrocarbon fraction contains API with a pad having an increased supply of moisture are removed in the feed subjected to moisture removal step which, as oily water separator (separator) preferably comprises 2 on a (21) oily water separating in, core coding (coalescer) (22) or the desalinator (desalter) aggregation in in (23) in the feed used in the desalination in through the moisture removed therefrom. The means by which oily water separating (separating) crude gas, by separating the crude oil and moisture onto of 3 contained in large amounts, and the detaching process for removing small or minor amounts of water, through oil-in-water (oil provided in a-water, O/W type) or water in oil emulsion (emulsion) is removed (water provided in a non-oil, W/O type) value of equal to or higher than proper B&SW to suit. Conventional crude in manufacturing process-based water-containing conditions (water cut) is 0. Less than 5%. Such oily water separator (21) oily water separating method using catalysts which are not limited but preferably incorporated on the production process, can be used without limit even refinery. Aggregation (coalescing) with oil and water by using a density difference in the buoyancy of the oil by using the principle of moisture removing a method, performed by a coding is preferably electrically core (electric coalecer) but not the limited to. Desalination (desalting) prior to removing said crude RM included among the inorganic salt distillation operation, these inorganic salt water are always the established suspension must be performed because the emulsion to comprise with demineralization dehydrated together, provide the means by which such desalination and dehydration step to desalination process which contains both desalination herein are disclosed concept. Also, the desalinator (23) is carried out in a desalination step calcium (Ca), nickel (Ni), vanadium (V) can be also removed with the metal (metal). In the designated content is typically 10 - 3000 ppm crude seawater, desalination method is considerably electric the demineralization law (electrical desalting process) can be classified into two methods of chemically the demineralization law (chemical desalting process). Used electric the demineralization law desalination method essentially, 440 volt high voltage current (emulsion) presence in combination with water in crude oil emulsion disruption desalination method are disclosed. In such a manner that the degree of water preheating and mixing mixing behind in demineralization trillionthe demineralization law crude 5 - 10 vol %, a temperature of at least minimum 90 °C, 4 - 20 kg/cm2 Conditions of the same emulsion pushes moisture and salt precipitated where high voltage outlet is polished manner combustion chamber. Chemical the demineralization lawclause emulsifier destroys the emulsion method applied to crude oil, crude to turn clause emulsifier and implanted behind 5 - 10 vol % water, then placed in water at a temperature of preheating and it agitatedreally the alveolus minimum 80 °C comprising precipitated into seawater, efflux recessed moisture and salt is polished manner carried out. This desalinator (23) using desalination method is preferably limited but has the refinery to be switched on, even crude production process can be used without limit. Moisture removal is also 2 on a crude feed as oily water separator (21) in oily water separating, core coding (22) in the aggregation and the desalinator (23) at least one or more methods can be carried out by means of a desalination in correction and but not limited to, crude production process is preferably performed in oily water separating next aggregation or demineralization preferably demineralization aggregation of essential oil is carried out before step. On the other hand, heavy crude oil emulsion stability (stability) of the displayed size of the object is disposed to pass a density difference with water since, such oily water separating, aggregation or desalination process is used crude by reducing the moisture loss during operation without voltage can increase a count. The cooking liquid hydrocarbon in which at least 15 degree API heavy oil is contained in the crude feed as impurity and mixed with hard changes generated by a hard since feed, water removal process is performed as above can be also meet API includes an automatic equipment to increase throughput of waste and recycling costs can be heavy oil, improving purification of crude oil that can be eventually excreted in completing a spatula. Moisture removing step the crude feed separator (3) gas, (residue) non-residues type and wired into a followed by a substrate. Gas H2 S, C1 - C3 Hydrocarbons and some C4 Comprising the hydrocarbons can be, non-residues type gasoline, via, with [khey[khey] scene, naphtha and the like can be, otherwise as extension material is typically separator (3) apart from each other at the bottom of. The, the separator (3) (distillation unit) can be used as distiller, the distiller (atmosphere distillation unit) production on an LNG production pressure (vaccum distillation unit) and the like, preferably atmospheric pressure can be connected sequentially distiller the rear end of the distiller. In the distiller feed oil boiling point (boiling point) of a wide variety of cosmetic contained in the separated, in addition membrane, adsorption or the like at a method can be also be used. Separated gas petroleum, products such as product supply sectionnon-residues type (12, 13) are subjected to either stored is transferred to an additional operation. On the other hand, huge carbon molecular size or the relatively high boiling point by receiving an residues type having a specific gravity (specific gravity) that it can be separated by using, such residues type too much by the increased amount of the pin is of a heavy oil throughput ratio of components varies or alumina. Utilizing such residues type oil reforming apparatus (oil upgrading unit) (4) to the oil reforming step can be. Oil modified (oil upgrading) RM extension such as producing process whereby a liquid hydrocarbon fraction from a catalytically superheavy qualitative type minutegeneral term, pyrolysis (thermal cracking), hydrocracking (hydrocracking), or a solvent extraction (solvent extraction) and cracking (catalytic cracking) such as can be. Also, more particularly when the pyrolysis of carbon rejection (carbon rejection), bis (visbreaking) roof, caulking (coking), such as coking (delayed coking) can be [til[til] RAID method, in the case of hydrogenation foul hydrotreating (hydro-a treating), and methods of hydrogenation (hydrogen addition) can include, in the case of solvent extracting the mask power law solvent (solvent deasphalting) can be like. As above specific residues type oil reforming processes can be modified via one or more, the feed liquid hydrocarbon fraction produced reformed to crude oil injected can be exploited by mixing step. As such, the apparatus and method and device for processing using liquid hydrocarbon fraction and heavy oil by increasing throughput in hard water by removing process to have a spatula eventually excreted in improving purification, more than compensated by increased amount of heavy oil throughput of the distillation step and controls the liquid hydrocarbon fraction residues type oil and modifying device are provided to produce or thirty disapproval. Also, the present invention relates to apparatus and method is provided for processing as above existing refinery crude oil producing or facility has a mixing process alone can be a liquid hydrocarbon fraction to an additional equipment necessary since it would cost disapproval. 3a and 3b according to another embodiment of the present invention also includes a specific oil reforming processes residues gas price via modified heavy oil comprising the step of visually representing a diagram has error are disclosed. Method and apparatus for treating heavy oil of the present invention as shown in the fig. 3a and 3b, pyrolysis, hydrocracking, solvent extraction and at least two or more in the process of cracking may be modified disclosed. Also, as also 3a on a separator (3) separated in step residues gas price separate solvent extraction device (4a) solvent extraction process after pyrolysis apparatus (4b) can be designed to be modified in the process of pyrolysis, the extraction process the solvent liquid hydrocarbon fraction produced via residues gas price crude oil are injected into the feed mixing step portion of the, the pyrolysis process via the crude feed another portion additionally can be injected into the disclosed. The pyrolysis process may be carried out pyrolysis apparatus (4b) cracking process instead of cracking or hydrocracking process performed performed hydrocracking apparatus are used disapproval. residues gas price pyrolysis or cracking the paraffin (paraffin) generated in the process of liquid hydrocarbon fraction (aromatics) olefin (olefin) aromatic compound as a main component included 28 - 35 degree range value while the API is partially characterized as having, only liquid hydrocarbon fraction produced via solvent extraction process based on API 13 - 20 degree range value includes paraffins which have features. I.e., only liquid hydrocarbon fraction is generated via solvent extraction process despite the relatively low degree of API heavy paraffin as a main component having properties suited since hard and heavy oil etc.. Also, hydrocracking process 40 also have a high level API to create a rounded hydrocarbon fraction may be filled. The, such as on a solvent extraction apparatus (4a) in solvent extraction process and generates some liquid hydrocarbon fraction, the remaining part of the pyrolysis, cracking or hydrocracking device (4b) in pyrolysis, cracked or hydrocracking process additionally generated via liquid hydrocarbon together in such a way that heavy oil has as impurity and mixing even increases throughput by hard object of the present invention can be achieve, only the 2 liquid hydrocarbon fraction and solvent extraction solvent extraction process and the pyrolysis (or cracking, hydrocracking) process liquid hydrocarbon fraction in the 2 both hard degree by the clearance of the heavy oil pump capable of modulating unit to adjust the selected from the group is restrained disclosed. A process wherein the solvent extraction process integration of solvent deasphalting (solvent deasphalting) preferably. The invention also relates, in solvent extraction or contact residues gas price pyrolysis or cracking isolated from the separation step after hydrocracking in a hydrocracking in the process of the decomposition process can be designed to be modified, as well as the pyrolysis or cracking residues gas price generated in the process of crude oil are injected into the feed liquid hydrocarbon fraction portion of the mixing step, the hydrocracking process via the crude feed another portion additionally can be injected into the disclosed. On the other hand, the present invention also relates as 3b on a solvent extraction apparatus (4a) on pyrolysis or cracking device (4b) generated via a portion of the liquid hydrocarbon fraction again hydrocracking device (4c) designed in hydrocracking process may be filled. The, solvent extraction process generates the liquid hydrocarbon fraction portion of the mixing step are injected into the crude oil feed, the pyrolysis or contact another portion of the decomposition process some further after the hydrocracking process via the remaining part of the catalysts for injection feed once more crude feed are apart from each other. Also, solvent extraction device (4a) on pyrolysis (or cracking, hydrocracking) device (4b) and hydrogenation decomposition device (4c) includes a separator (3) not connected in parallel process is sequentially performed as above may be filled. <Liquid hydrocarbon Changes Mixed crude Feed The water removal efficiency measuring experiments for> Heavy oil processing capabilities of the present invention assess demineralization as follows using crude mixed liquid hydrocarbon fraction for removing moisture surveying efficiency experiments for commercial implementation. Heavy oil, and liquid hydrocarbon fraction included in the crude 90 vol % replacement type, 10 vol % water, 10 minutes after mixing to a blender clause emulsifier (demulsifier) 100 ppm, 15 minutes in line by using electric demineralization base batch compartments 90 °C obtained a crude supernatant (oil a-rich phase/layer). The water content of crude supernatant obtained in centrifugal separating method for measuring moisture removing Karl-a Fisher sampled evaluating the efficiency of a transparent conductive layer, a bottom surface of lower moisture content for removing the moisture can comprise removing big. The, the crude contained in heavy oil, the blending ratio of the apatitic hydrocarbons and liquid hydrocarbon fraction replacement type generated in different experiments when the blowing method, a table as shown in the experiment result yet. Experiment example 1: replacement type (API also: 32. 8) on heavy oil (API also: 18. 2) is contained in the crude to a coking (delayed coking) generated through pyrolysis process from extension [til[til] RAID liquid hydrocarbon fraction (API also: 30. 2) when mixing Experiment example 2: replacement type (API also: 32. 8) on heavy oil (API also: 18. 2) is contained in the liquid hydrocarbon fraction generated through the use of contact from the extension of the decomposition process catalysts (also API: 28. 1) when mixing In this way a heavy hydrocarbon fraction containing crude liquid for removing the moisture by mixing one of the desalination process conducting, 15% to 20% of a heavy oil content is mixed replacement typereplacement type reduces overall increased over even if moisture content 0. 03% degree of difference occurs only through his car with the result of the fact that experiments of example 1. Also, the result of the blending ratio of the experiment of example 2 you will liquid hydrocarbon fraction content of 5% by increasing replacement type overall moisture content by the control signal from the difference 0. 04% generating only the fact that his car. The ferroelectric layer as above, oil reforming process can be generated from liquid hydrocarbon fraction treatment of heavy oil by mixing relatively expensive replacement type cost of a heavy oil can be dried while reducing the content of increasing the throughput of a heavy oil may be his car. The present invention relates to particular embodiments and description without defined, in the claims claim the subject matter of the present invention made without deviating from this invention is knowledge of the NaOCl in consultation with various modifications and is anyone, such modifications are in a range that enables protection of the present invention are disclosed. 1: mixer 2: apparatus for removing water 3: separator 4: oil reforming apparatus 4a: solvent extraction device 4b: pyrolysis apparatus 4c: hydrocracking apparatus 11: crude source 12, 13: product supply section 21: oily water separator 22:23 core coding: the desalinator The present invention relates to a technology of treating heavy crude oil in a crude oil production process or an oil refinery process and, more specifically, to a method and an apparatus for hardening heavy crude oil by injecting and mixing liquefied hydrocarbon oil to crude oil supplies including heavy crude oil in a crude oil production process or an oil refinery process including a moisture removing process, thereby increasing the treating amount of heavy crude oil. COPYRIGHT KIPO 2017 Moisture removal step in a method to increase the throughput of essential oils comprising crude production process or in heavy oil, comprising (a) a liquid hydrocarbon fraction has a heavy oil feed into a hard and mixed with generated mixing step; (b) a moisture removal step of moisture are removed the hard in the feed; (c) the moisture removing step feed gas, non-residues type and extension into a separation step (residue); and (d) reforming the residues gas price produced oil modified (oil upgrading) wherein liquid hydrocarbon fraction, the oil modified and subjected to a liquid hydrocarbon fraction generated the crude oil feed into the mixing step characterized using liquid hydrocarbon fraction of a heavy oil processing method. According to Claim 1, the moisture removal step, oily water separating (separating), aggregation (coalescing) and desalination (desalting) characterized in that at least one or more methods using liquid hydrocarbon fraction is carried out by means of a heavy oil processing method. Deletion According to Claim 1, the oil reforming step, the residues gas price pyrolysis (thermal cracking), hydrocracking (hydrocracking), solvent extraction (solvent extraction) and cracking (catalytic cracking) than the complex process of at least one or more characterized using liquid hydrocarbon fraction of a heavy oil processing method. According to Claim 1, the oil reforming step includes residues gas price solvent extraction process after pyrolysis, cracking or hydrocracking in the process of which the complex step, the extraction process the solvent liquid hydrocarbon fraction produced via the residues gas price crude oil are injected into the feed portion of the mixing step, the pyrolysis another portion, cracked or hydrocracking process than the crude oil feed into the mixing step further characterized using liquid hydrocarbon fraction of a heavy oil processing method. According to Claim 1, the oil reforming step includes residues gas price pyrolysis or cracking process step after the process of hydrocracking is complex, the residues gas price the pyrolysis or cracking in the process of generating a liquid hydrocarbon fraction portion of the mixing step are injected into the crude oil feed, the hydrocracking process another portion higher than the crude oil feed into the mixing step further characterized using liquid hydrocarbon fraction of a heavy oil processing method. According to Claim 1, the crude feed API 10 - 30 degree characterized in using a liquid hydrocarbon fraction of a heavy oil processing method. According to Claim 1, the liquid hydrocarbon fraction of not more than 15 degree API is characterized using liquid hydrocarbon fraction of a heavy oil processing method. A moisture removal step of removing the heavy oil refinery crude production facility or facility for increasing the throughput of the device, comprising a liquid hydrocarbon fraction has a heavy oil feed is generated into a hard and mixed with a mixer (1); the hard to remove the moisture in the moisture removal device of a feed (2); the apparatus for removing water (2) through the feed gas, non-residues type (residue) and extension into a separator (3); and reforming liquid hydrocarbon fraction residues gas price produced oil modified (oil upgrading) device (4); wherein, the oil reforming apparatus (4) liquid hydrocarbon fraction generated via the mixer (1) characterized using liquid hydrocarbon fraction is injected into the injection of heavy oil processing apparatus. According to Claim 9, the apparatus for removing water (2) is, oily water separator (separator), core (coalescer) and at least one coding desalinator (desalter) characterized in comprising at least a liquid process for injection for heavy oil processing apparatus. According to Claim 9, the oil reforming apparatus (4) is, pyrolysis (thermal cracking) device, hydrocracking (hydrocracking) device, solvent extraction (solvent extraction) device and cracking (catalytic cracking) characterized by at least one device comprising at least a liquid process for injection for heavy oil processing apparatus. According to Claim 9, characterized in the the crude feed API 10 - 30 degree liquid process for injection for heavy oil processing apparatus. According to Claim 9, the liquid hydrocarbon fraction of not more than 15 degree API is characterized liquid process for injection for heavy oil processing apparatus. Mixing ratio (%) Water content (%) replacement type Heavy oil Liquid hydrocarbon fraction Experimental example 1 - 1 85 15 0 0. 10 Experiment example 1 - 2 75 25 0 0. 25 Experiment example 1 - 3 75 15 10 0. 12 Experiment example 1 - 4 70 15 15 0. 13 Mixing ratio (%) Water content (%) replacement type Heavy oil Liquid hydrocarbon fraction Experimental example 2 - 1 85 15 0 0. 10 Experimental example 2 - 2 75 25 0 0. 25 Experimental example 2 - 3 75 12. 5 12. 5 0. 11 Experimental example 2 - 4 70 12. 5 17. 5 0. 15