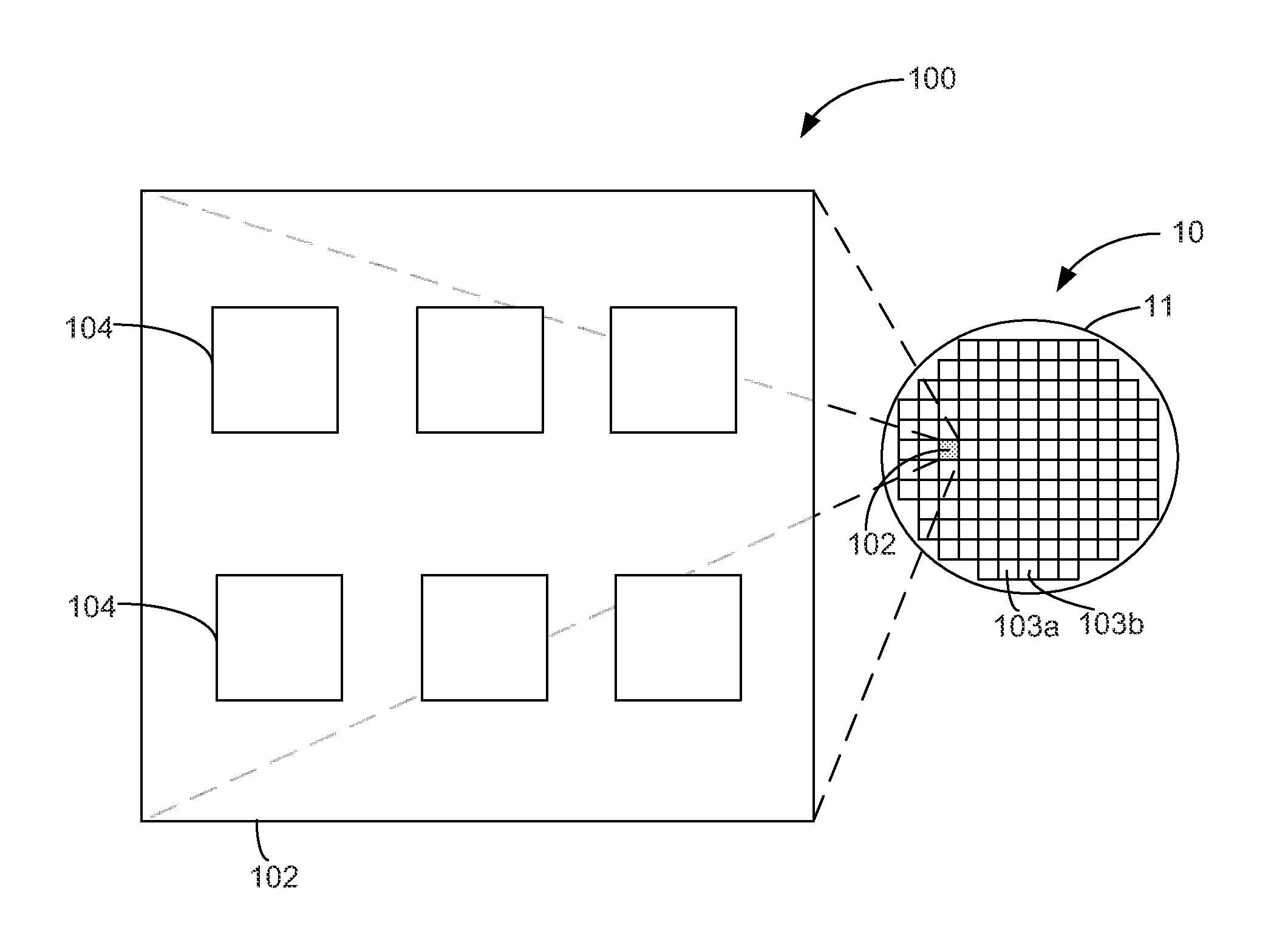

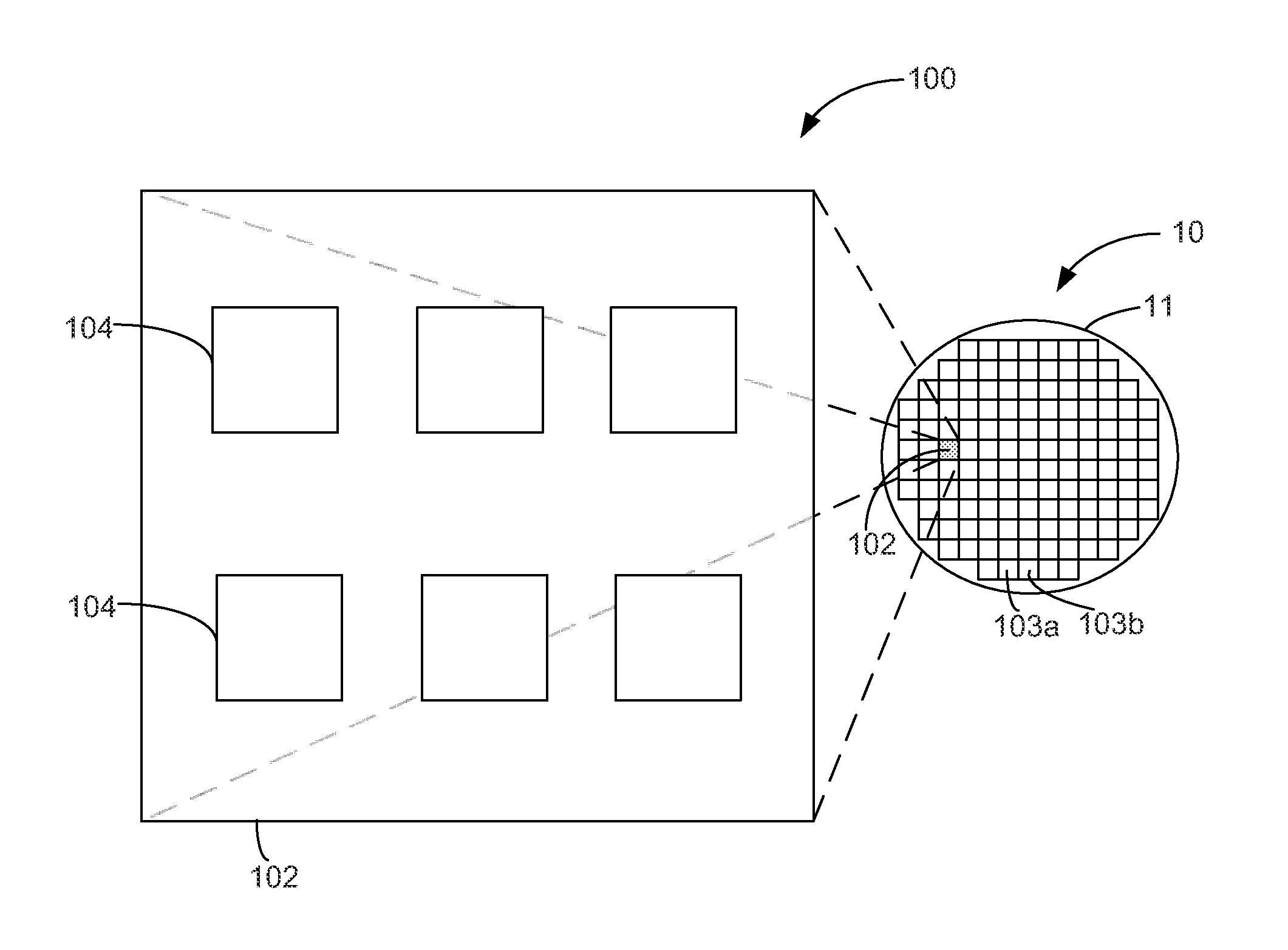

TSV들을 이용하는 통합된 마이크로폰 디바이스를 가진 다이