SUBSTRATE PROCESSING APPARATUS AND SUBSTRATE PROCESSING METHOD

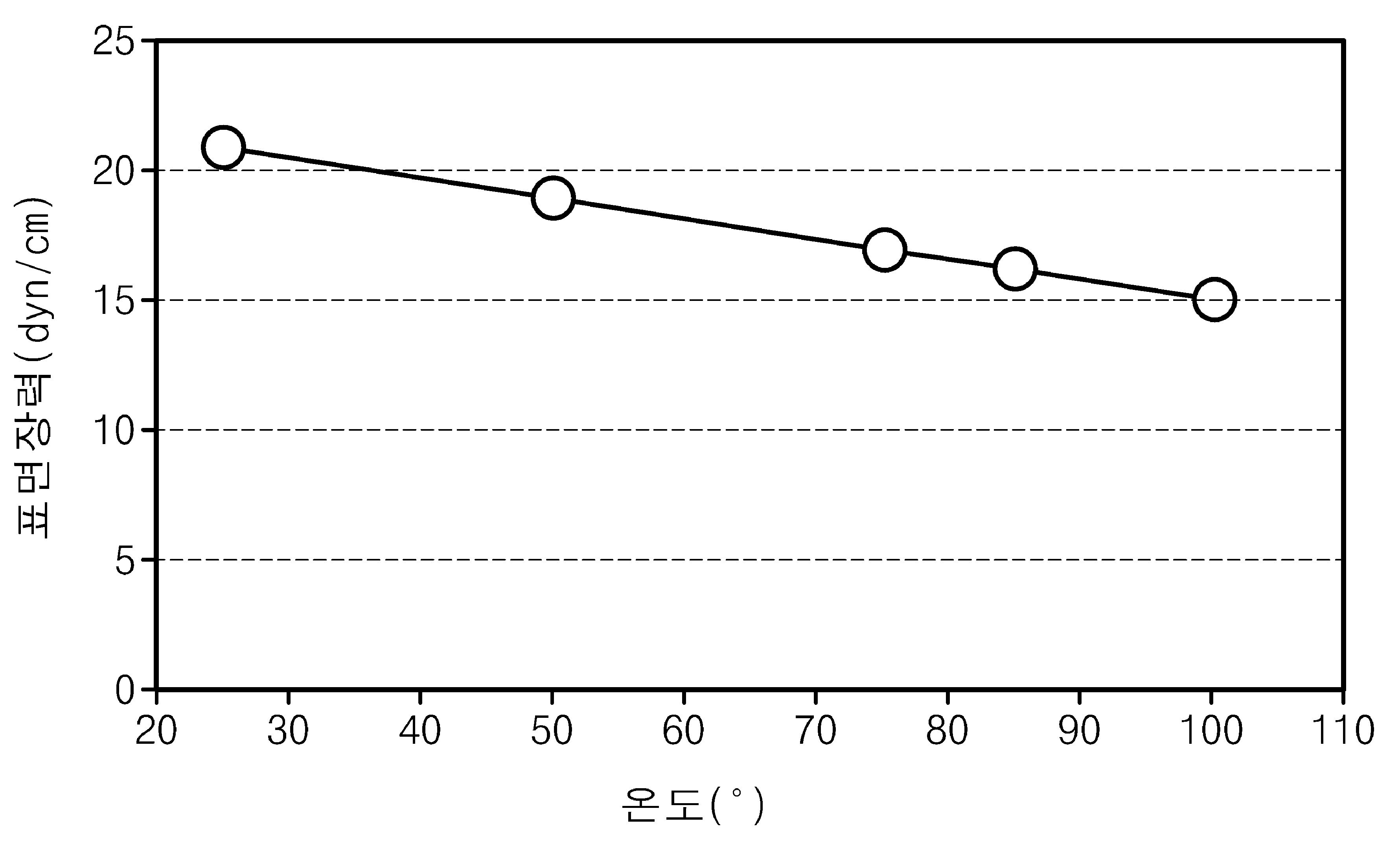

The present invention refers to a substrate processing device and substrate processing method are disclosed. Generally semiconductor device, such as a silicon wafer substrate (photo process) photo process, etching process (etching process), and deposition process such as ion implantation (ion implantation process) (Deposition process) formed through various processes. And, in each particle (particle) for carrying out the process, color video, a variety of metal impurities is equal to the generation of contamination. The substrate may cause method for such foreign deficiency (defect) affecting the performance and yield linearly by the direct, positive pressure is for cleaning foreign number number of semiconductor industry essentially accompanied pore. Spin cater for cleaning process (chemical) number inputted into contaminants bath process industry, pure chemical residue on the substrate cleaning process industry association (pure water) number (wet cleaning process), drying and storing structure by supplying a fluid to the remaining dry process comprises drying (drying process). The heated nitrogen gas is pure past remains conducting drying step of drying the substrate. However a narrow line width of a pattern formed on the substrate by pattern is located on a high aspect ratio becomes large when the number is not a pure water flows by the wetting ability. To this end cookies pure isopropyl alcohol (isopropyl alcohol) compared to a controller such as a relatively low surface tension on a substrate having the same pure liquid machie of number, etc. after the heated nitrogen gas in the dry process. However, such drying for 30 nm hereinafter number even when using organic semiconductor device having fine circuit pattern line width for the leaning (leaning) developing (pattern collapse) receives emergency such as causing other still developing. This machie of number selection consisting are disclosed. A leaning phenomenon for a larger surface tension more polarization component. The, further micronized pattern on a substrate surface of cookies to reduce the surface tension of more important disclosed. Figure 1 shows a graph showing also isopropyl alcohol on by surface tension size are disclosed. The reference also 1, liquid isopropyl alcohol is greater as the temperature reduces the surface tension. The, isopropyl alcohol the metal substrate with the supply of a high heating preferably. On the other hand, is isopropyl alcohol was supplied onto a substrate at a normal temperature. In addition, isopropyl alcohol for substituting the pure water remains on the substrate supplied liquid should. The, an isopropyl alcohol supply liquid isopropyl alcohol in an LNG carrier substrate temperature of boiling point temperature hereinafter to back down. I.e., when a surface tension of isopropyl alcohol is formed in isopropyl alcohol reactions, in atmospheric pressure boiling point of about 80 °C is formed in isopropyl alcohol, benzyl alcohol product is heated to a temperature of more vaporized substrate. Thus, the bit stream is liquid isopropyl alcohol supply, heated at or above the normal boiling point (about 80 °C) in the tropics. The, substrate over a selected speed dial setup free isopropyl alcohol to reduce the surface tension. Thus, leaning on empty pattern a substrate of the head from the remote. In the present invention refers to further reduce surface tension may be heated above the boiling point under atmospheric pressure than conventional machie of number to a substrate processing device and method for changing the number machie of [...] number are disclosed. The present invention refers to a device and method for treating a substrate having the substrate patterns can be [...] number are disclosed. The purpose of the invention is not one number herein, another object are not mentioned below may be clearly understand one skilled from the substrate are disclosed. The present invention refers to a substrate processing method number [...] substrate. In the embodiment of the present invention according to one, said substrate processing by supplying said liquid organic for the number, said number is at temperature higher than the boiling point of the number machie of said supplied in normal organic for the, mixed with heated in addition number machie of said number is 2000. According to one in the embodiment, is provided with a number comprising adding said polymerizable liquid. According to one in the embodiment, said substrate processing a substrate from a group consisting process number machie of said liquid are disclosed. According to one in the embodiment, said pure liquid on a substrate are disclosed. According to one in the embodiment, the number machie of said isopropyl alcohol are disclosed. The present invention refers to a substrate processing device number [...] substrate. In the embodiment of the present invention according to one, for supporting a substrate support unit; said support unit supported on a substrate machie of number discharge unit; said nozzle unit at a normal temperature to a temperature above the boiling point of said number machie of said liquid comprising a supply unit for supplying and addition number number machie of number, for said unit comprises a number, in order to receive number machie of said tank and having inner space; said tank heating member number machie of said received; supplying said supply tube and number additive number added to interior space; said tank and said nozzle unit comprises a fiber is. According to one in the embodiment, said number for said heating unit comprises a number plower number further includes anxiety, the violations of the number, said number added to said mixture of said number reacted with inorganic number machie of higher boiling point in the core material is heated to a target temperature for organic, holds the liquid mixture in said said target temperature. According to one in the embodiment, by circulating the liquid therein contained is said tank comprising a circulation line, said circulation line number encoded heating element is said ball. According to one in the embodiment, is provided with a number comprising adding said polymerizable liquid. According to one in the embodiment, the number machie of said isopropyl alcohol are disclosed. In the embodiment of the present invention is one, may be heated above the boiling point under atmospheric pressure and surface tension than conventional further reduce in number machie of organic substrate can be processing for number. In the embodiment of the present invention one the, substrate patterns can. The confined within the radio effects has the effect of the invention, the attached drawing and specification referred to lower than the first effects is provided to clearly understand the present invention may be from to in person with skill in the art are disclosed. Figure 1 shows a graph showing surface tension on according to isopropyl alcohol also are disclosed. Figure 2 shows a plane also to determine visually representing a substrate processing equipment are disclosed. Figure 3 shows a the present invention is a substrate processing device also to determine visually representing a surface are disclosed. Figure 4 shows a substrate processing device of Figure 3 is shown for the number of supply unit also are disclosed. The present invention also showing also 5 to Figure 7 shows a nitride layer on a surface is a substrate processing are disclosed. Hereinafter, example of the present invention embodiment attached drawing reference more specifically described as follows. Examples of the present invention embodiment can be modified in various forms, embodiment examples of the present invention don't interpreted are confined within the range below. The embodiment examples with average knowledge art to more completely describe the present invention which ball number are disclosed. In order to emphasize the shape of the element and more specifically to the drawing description exaggerated colors are disclosed. Hereinafter, with reference to one example of the present invention also 2 to 7 also a detailed as follows. Figure 2 shows a substrate processing equipment also (1) plane to determine visually representing are disclosed. The reference also 2, substrate processing equipment (1) is index module (100) and processes for processing module (200) comprises. Index module (100) load port (120) and frames (140) comprises. Load port (120), frames (140), and a process processing module (200) includes sequentially arrayed in series with each other. Hereinafter, load port (120), frames (140), and a process processing module (200) arranged direction number 1 direction (12) is combined with a load. The direction when looking at the top number 1 (12) oriented vertically and number 2 direction (14) and referred to as, number 1 direction (12) and number 2 direction (14) including number 3 direction perpendicular to the plane direction (16) is combined with a load. Load port (120) for receiving the carrier substrate (W) (130) is WIPO. Load port (120) has a plurality is number 2 is they number ball direction (14) in a row along a disposed thereon. In Figure 1 has four load port (120) is shown presents a number to him. However load port (120) number of processing module (200) process efficiency and foot print conditions of e.g. increases or decreases along disapproval. Carrier (130) presents a slot number that it bears against the edge of the substrate (W) (not shown) formed therein. Slot is number 3 direction (16) number encoded a plurality the dog hole. The substrate (W) number 3 direction (16) to be apart from each other along a laminated to a carrier (130) in to the yarns. Carrier (130) include open-front integral pod (Front Opening Unified Pod; FOUP) can be used. Processing module (200) buffer unit (220), transfer chamber (240), and a process chamber (260) having a predetermined wavelength. Transfer chamber (240) is the longitudinal direction thereof is number 1 direction (12) disposed thereon in parallel with. Number 2 direction (14) along the transfer chamber (240) and fourth each of the process chambers (260) disposed thereon. Transfer chamber (240) on one side of process chambers (260) and transfer chamber (240) located on the other side of process chambers (260) to a transfer chamber (240) to encoded with reference to the pair of ball number. Process chamber (260) some of the transfer chamber (240) disposed thereon along the longitudinal direction. In addition, process chamber (260) some of the laminated to each other disposed thereon. I.e., transfer chamber (240) one side of the process chamber (260) are A X B (A B on each natural number larger than 1) arrangement can be arranged. Wherein A is number 1 direction (12) presents a number in a row along a process chamber (260) multiple of, B is number 3 direction (16) presents a number in a row along a process chamber (260) of number disclosed. Transfer chamber (240) on one side of the process chamber (260) is 4 when one or two ball number 6, process chamber (260) are an array of 2 X 2 or 3 X 2 can be arranged. Process chamber (260) increasing or decreasing the number of disapproval. Alternatively described above, process chamber (260) the delivery chamber (240) number only one side of the ball can be disclosed. In addition, alternatively described above, process chamber (260) the delivery chamber (240) is applied as a single number of ball grooves on both sides can be disclosed. Buffer unit (220) includes transferring a frame (140) and transfer chamber (240) disposed thereon between. Buffer unit (220) to a transfer chamber (240) on frames (140) (W) (W) carried over the substrate prior to the joint space is dwell number [...] substrate. Buffer unit (220) (W) (not shown) the single substrate is ball number is a predetermined slot, slot (not shown) between one another number 3 direction (16) apart along a plurality number encoded ball. Buffer unit (220) frames in (140) and the outside transfer chamber (240) facing on each implemented on the base. Frames (140) load port (120) is placed carrier (130) on the buffer unit (220) delivering a joint (W). Frames (140) index rail (142) and transferred (144) ball number is encoded. Index rail (142) number 2 lengths of direction direction (14) encoded selective ball number. Transferred (144) is index rail (142) straight on, index rail (142) number 2 along direction (14) are confirmed each other substantially straight. Transferred (144) includes a base (144a), body (144b), and the index arm (144c) has a. Base (144a) is index rail (142) to movable along force is removed. Body (144b) includes a base (144a) coupled to. Body (144b) includes a base (144a) number 3 on direction (16) movable along a number encoded to ball. In addition, body (144b) includes a base (144a) number encoded on a rotating ball. The index arm (144c) body (144b) coupled to, body (144b) encoded number to be movable backward and forward with respect to the ball. The index arm (144c) are respectively applied to individual plurality number ball ball number. The index arm (144c) are number 3 direction (16) to be apart from each other along a laminated to a disposed thereon. The index arm (144c) some of the processing module (200) carrier (130) and substrate (W) used when fans, another portion carrier (130) process in a processing module (200) fans can be used when a substrate (W). This transferred (144) in the substrate (W) loading and unloading substrate before processing (W) (W) from particles adhering to the lowered process can be prevented. Transfer chamber (240) includes a buffer unit (220) and process chamber (260) between, and a process chamber (260) delivering a substrate between (W). Transfer chamber (240) tray (242) and processed (244) co number is encoded. Guide rail (242) number 1 direction lengths of direction (12) arranged in parallel with each other. Processed (244) includes guide rail (242) are formed on, guide rail (242) on number 1 direction (12) are confirmed each other straight along. Processed (244) includes a base (244a), body (244b), and main arm (244c) has a. Base (244a) guide rails (242) to movable along force is removed. Body (244b) includes a base (244a) coupled to. Body (244b) includes a base (244a) number 3 on direction (16) movable along a number encoded to ball. In addition, body (244b) includes a base (244a) number encoded on a rotating ball. Main arm (244c) body (244b) coupled to, this body (244b) encoded number to be movable backward and forward with respect to the ball. Main arm (244c) are respectively applied to individual plurality number ball ball number. Main arm (244c) are number 3 direction (16) to be apart from each other along a laminated to a disposed thereon. Buffer unit (220) process chamber (260) fans used when substrate (W) main arm (244c) and process chamber (260) in buffer unit (220) fans used when a substrate (W) main arm (244c) is can be different disclosed. Process chamber (260) (W) in the substrate cleaning process is a substrate processing device (300) ball number is encoded. Each process chamber (260) number in presents a substrate processing device (300) is performed depending on the type of cleaning process that may have different structure. Selectively each process chamber (260) for treating substrates in device (300) may have have the same structure. Selectively process chamber (260) are individually a plurality of groups, belonging to the same group process chamber (260) number to presents a substrate processing device (300) are identical to one another where the, different groups belonging to the process chamber (260) number to presents a substrate processing device (300) may have different structure each other. For example, process chamber (260) is divided when a group 2, transfer chamber (240) group of process chambers one side of number 1 (260) and ball number is, transfer chamber (240) formed at one side of number 2 group of process chambers (260) is 1308. ball number. Selectively transfer chamber (240) and fourth group is lower at each process chamber of number 1 (260) are ball and number, process chamber of upper layer group number 2 (260) are 1308. ball number. A process chamber of a group number 1 (260) to a process chamber of a group number 2 (260) chemical used each kind or, depending on the type of washing can be the worker. (W) below substrate processing substrate processing device (300) to describe one example of 2000. Figure 3 shows a also substrate processing device (300) is one example of 06 surface. The reference also 3, substrate processing device (300) the chamber (310), cup (320), support unit (340), lifting unit (360), injection unit (380), and for number supply unit (500) comprises. Chamber (310) number [...] S. inner space. Cup (320) chamber (310) space to the lungs. Cup (320) and generating member at a number [...], implemented on the base comprises an upper portion thereof. Cup (320) temperature the internal rotor (322), temperature intermediate times (324), and the external rotor temperature (326) has a. Each collecting case (322,324,326) different chemical process used during chemical recovery of substrate. Reservoir internal rotor (322) includes a support unit (340) enclosing an annular ring shape and ball number, temperature intermediate times (324) temperature the internal rotor (322) enclosing an annular ring shape and number ball, the external rotor temperature (326) temperature intermediate times (324) surrounding the ball plate and the encoded number. Reservoir internal rotor (322) is inserted into the inside (322a), internal rotor temperature (322) and the intermediate reservoir times (324) space between (324a) and an intermediate reservoir times (324) and the external rotor temperature (326) space between (326a) internal rotor each reservoir (322), temperature intermediate times (324), temperature and the external rotor (326) chemical is introduced into an inlet (410) functions as a. Each collecting case (322,324,326) bottom surface and a downward extending perpendicularly to the main line (322b, 324b, 326b) is connected thereto. Each recovery line (322b, 324b, 326b) each collecting case (322,324,326) chemical to be drawn through the discharge chamber. (Not shown) discharged chemical can be reused through external chemical reproducing system. Support unit (340) is provided with a pot (320) of placed inside a processing space. Support unit (340) a substrate process ongoing rotating the substrate at a substrate. Support unit (340) the thickness of the head (342), support pin (344), [...] (346), drive shaft (348) and driver (349) have. Spin head (342) in the upper surface which has a generally circular upper ball number when watching. Spin head (342) of the inner case drive (349) rotatable by a drive shaft (348) coupled to fixed. Drive shaft (348) the rotation enables spin head (342) is rotated with each other. Spin head (342) to the substrate support, support pin (344) and [...] (346) comprises. Support pin (344) encoded a plurality number ball. Support pin (344) the thickness of the head (342) edge portions of the upper surface at a predetermined spacing rods are disposed spin head (342) silicidized to substrate. Support pins (344) is ring-shaped to have a generally annular by a combination between each other disposed thereon. Support pin (344) the thickness of the head (342) substrate from the upper surface a distance apart are retained with the bottom surface of the substrate edge. [...] (346) encoded a plurality number ball. [...] (346) the thickness of the head (342) in the center of support pin (344) disposed thereon at a distance than. [...] (346) the thickness of the head (342) to ball number encoded in the position. [...] (346) includes a support unit (340) is rotating the substrate when in place in a side direction of the substrate to support the foot panel 50. does not come off. [...] (346) the thickness of the head (342) for linear movement between a standby position and a support position along a radial direction of ball to encoded number. Support standby position compared spin head (342) farther away from center of position are disclosed. Substrate support unit (340) when loaded or un loading [...] (346) and the standby position, at the time of bit substrate [...] (346) is the holding position to the yarns. In the holding position [...] (346) is make contact with each other. Lifting unit (360) is provided with a pot (320) vertically moving substrate. Lifting unit (360) is provided with a pot (320) a plurality of collecting case (322, 324, 326) can be moving. But that does not shown or, each recovery tank can be move individually. Cup (320) is moved up or down by support unit (340) for cup (320) are connected to altered. Lifting unit (360) includes a bracket (362), a transfer axis (364), and driver (366) have. Bracket (362) is provided with a pot (320) the outer wall of the fixed, bracket (362) is driver (366) is vertically moved by mobile axis (364) coupled to fixed. Substrate support unit (W) (340) or lies, support unit (340) when lifted from the support unit (340) cup (320) to the position cup (320) are descending. In addition, when this time (W) chemical supplied to the substrate depending on the type of the chemicals in a preset collecting case (360) can be introduced into cup (320) for adjusting the height of the substrate. For example, number 1 into the substrate while the substrate is temperature chemical processing internal rotor (322) is inserted into the inside (322a) height corresponding to the yarns. In addition, chemical number 2, number 3 chemical into the substrate is a substrate temperature during processing and internal rotor (322) and the intermediate reservoir times (324) space between (324a), temperature and an intermediate times (324) and the external rotor temperature (326) space between (326a) can be located corresponding to the desired height. Alternatively lifting unit described above (360) is provided with a pot (320) instead support unit (340) can be vertically moved. In addition, alternatively described above, cup (320) a single collecting case (322) may have a. Injection unit (380) a substrate (W) about number supplied. Cleaning number is about number, rinse number implementation being. Or organic for number can be added to a mixture of number. Wherein, hydrogen peroxide include hydrogen peroxide solution ammonia (NH4OH) projected cleaning number (H2O 2), hydrochloric acid (HCl) or sulfuric acid (H2SO 4) solution or fluoric acid (HF) solution and the like can be used by mixing. Rinse number is adjacent photoresist cleaning number (Rinse) each other. Number include pure rinse can be used. Rinse number on mixing head and a liquid mixture is applied on the discharge be added number machie of number. Liquid rinse number is substituted a number machie of 2000. In one example, machie of number pure substituted substrate. As ethyl glycol (ethyl glycol) including number machie of isopropyl alcohol, 1 - profile play (propanol), high draw franc (tetra hydraulic franc) 2, 4 - hydroxy (hydroxyl), methyl 4 - (methyl), 2 - pentanone (pentanone), play (butanol) polymerization of 1 -, 2 - buta play, methanol (methanol), ethanol (ethanol), n - (n n-propyl alcohol) isopropyl alcohol, solution of dimethyl ethyl (dimethylether) or gas can be used. Injection unit (380) can be the surface of the main body. Injection unit (380) is the one or more ball number can be disclosed. Injection unit (380) to the nozzle support (382), support (386), driver (388), and nozzle (400) has a. Support (386) direction is the longitudinal direction thereof is number 3 (16) and ball number along, support (386) at the lower end of driver (388) is coupled. Drive (388) includes a support (386) S. a rotation and up-down movement. Nozzle support (382) has a driven portion (388) coupled to a support (386) and perpendicular to the opposite end of the coupled. Nozzle (400) a nozzle support (382) bottom end of force is removed. Nozzle (400) includes a drive unit (388) position to the standby position by an isolation are confirmed each other. Nozzle processing position (400) cup (320) and vertical placed on top position, nozzle standby position (400) cup (320) from the upper vertical positions are disclosed. Figure 4 shows a substrate processing device of Figure 3 is shown for the number of supply unit also are disclosed. For number supply unit (500) for mixing number number added to a mixture of organic liquid spraying unit (380) is supplied. For number supply unit (500) includes a central supply pipe (510), tank (520), heating element (530), added number supply member (540), joints (550) and violations of the number (600) having a predetermined wavelength. Central feed tube (510) tank (not shown) from the central feed device (520) for organic supplied a number. Central feed tube (510) is provided with a valve (512) is 1308. ball number. Valve (512) tank (520) in the number for a number supplied to etched. Tank (520) includes a housing (522) to circulate line (524) comprises. Tank (520) on number number machie of interior of which they are respectively is added. Circulating line (524) has one end and the other end tank (520) are connected to a tank (520) on the number of added liquid mixed with mixture of organic for number (hereinafter, called the anode mixture) circulating substrate. Heating element (530) the tank (520) a number machie of therein contained is heated. Heating element (530) circulating line (524) on ball number can be disclosed. Heating element (530) the heaters to 1308. ball number. Heating element (530) circulating line (524) circulating through heated mixture. Heating element (530) number (Tb) at temperature higher than the boiling point of the mixture is atmospheric organic for heated. In one example, machie of number is cases where the isopropyl alcohol, normal boiling point higher than about 80 °C (Tb) in isopropyl alcohol (Tt) in target temperature to heated mixture. In one example, target temperature (Tt) is implementation being 85 °C. Only, target temperature (Tt) without maintaining a temperature at which the mixture is vaporized liquid are disclosed. Heating member (530) is this target temperature (Tt) heated mixture within range. I.e., heating element (530) in the temperature range within a slagging combustion mixture is not heated. Addition number supply member (540) tank (520) supplied a number added to the interior space. Addition number supply member (540) is addition number supply pipe (542) and an added number supply valve (544) without using a tool. Addition number supply valve (544) is addition number supply pipe (542) beyond the tank (520) number additive supplied to adjust the other. The number encoded mixed with salts thereof is added number number machie of ball. The number of the organic liquid mixture added number has an interior space 11 for the lower and upper nozzle. (Ionic liquid) number is added an ionic liquid having a predetermined wavelength. Ionic liquid 2 or more chemical the data entry number ball 1308. Ionic liquid formed relative to the inner surface of the high-boiling point generally less. This ionic liquid mixed with organic for the number, mixture is high-boiling point than single machie of number and surface tension is weak character. Connector (550) tank (520) on injection unit (380) are connected to a. Tank (520) the mixture of interior space pipe (550) through injection unit (380) to move into the other. Connector (550) is heated to a target temperature (Tt) of the delivery line wwl0. mixture. Shifted mixture is injection unit (380) below a blower fan. Violations of the number (600) includes heating elements (530) is a number etched. Violations of the number (600) is temperature (Tb) at temperature higher than the boiling point of the mixture of atmospheric organic for number heated heating member (530) is a number etched. In one example, violations of the number (600) is heated to a target temperature (Tt) mixture heating it to member (530) is a registered number, target temperature (Tt) in liquid mixture to be maintained therein. For example, violations of the number (600) is vaporized liquid mixture can be maintained at a target temperature (Tt) without the highest setting substrate. The target temperature (Tt) (Tb) in atmospheric pressure boiling point within the range heated mixture. Also with reference to below 5 to 7 also, using substrate processing method of the present invention substrate processing device are described as follows. Arrows have machie of number, number number on presenting a stream of a mixture of added number or organic for added. Tank (520) on inner space a number added organic for number supplied. Ionic liquid is added number 1308. ball number. On a number can be added sequentially supplies machie of number. Or, alternatively machie of number number supplying on can be added. The added number is mixed with salts thereof so ball number machie of number, number are each mixed liquid mixture on the lower and upper nozzle number machie of added. On any number can be selected from the group number machie of added. Mixing smoothly circulating line (524) can be added to circulating along machie of number number. As described above, a mixture of liquid, and relatively high-boiling point than a single machie of number having a low surface tension disclosed. The, boiling point than the boiling point of the number (Tb) for organic calcium acetate mixture rises substrate. The, boiling point temperature (Tb) when heated higher than in machie of number reacted with inorganic mixture may maintain a number machie of liquid is equal to or higher. Tank (520) on number added after mixing in machie of number, tank (520) heated mixture of interior space. Circulating line (524) can be heated while circulating through the mixture. Circulating line (524) to which ball number is sprayed heating member (530) through the mixture is heated with each other. Heating a target temperature (Tt) (Tb) in higher temperature than is machie of number reacted with inorganic boiling point are disclosed. Only, the mixing ratio of the added number of added number on polarity types and machie of number, to set a target temperature (Tt) is vaporized liquid machie of number, their target temperature (Tt) heated within the range. Mixture is heated pipe (550) through injection unit (380) are confirmed each other to. Target temperature (Tt) of the delivery substrate heated injection unit number machie of supplied. Pattern is pure rinse such as is provided by a number still remains in disclosed. The substrate pure liquid machie of number on a displacing other. Substituted machie of number of subsequent the case dried substrate. As described above, the temperature of the heated mixture number higher than conventional single organic for the vent temperature. The, number of 10 ppm for the best mixture discharged surface tension of discharging relatively low surface tension of conventional single machie of number than disclosed. The, substrate such as patterns leaning (leaning) while minimizing substrate cleaning disclosed. In the embodiment described above in a heating member is circulation line so that ball number described but, not relayed and composite, if alternatively the mixture in the tank heating method there disclosed. In addition, circulation line can be eliminated. Or more detailed description is to be overdimensioned to exemplify the present invention. In addition a preferred embodiment of the present invention are described in which a plurality of aforementioned represented form, the present invention refers to various other combination, can be modified and utilizes one or more. I.e. the specification to the range of disclosure of the invention general outline, the disclosure content is equal to range and/or the party industry knowledge techniques or send copies range of changes in the process from or modified. In the embodiment of the present invention for implementing the aforementioned technical idea is described in which the best state, applications and use of the present invention specific required in various having high disclosed. The detailed description of the invention the present invention is the disclosure intending to be relayed to a number of embodiment is endured. In addition other embodiment state diagram including appended claims interpreted should. 380: Injection unit 400: Nozzle 500: Number supply unit for 510: Central feed tube 520: Tank 530: Heating element 540: Added number supply member 550: Connection 600: Violations of the number The present invention relates to a substrate processing apparatus capable of preventing a substrate pattern and a method thereof. The substrate processing method according to the present invention comprises processing a substrate by supplying organic solvent onto the substrate, wherein the organic solvent is supplied at temperature higher than a boiling point of the organic solvent at normal pressure and the organic solvent is heated while additives are mixed therein. COPYRIGHT KIPO 2017 In substrate processing method, substrate processing a substrate supplying the liquid machie of number, said number is at temperature higher than the boiling point of the number machie of said supplied in organic for the normal, heated in substrate processing method number machie of said addition number is mixed state. According to Claim 1, is provided with a substrate processing method including adding said number the polymerizable liquid. According to Claim 1 or Claim 2, said substrate processing a substrate is located between the substrate processing method from a group consisting number machie of said liquid. According to Claim 3, said substrate processing method on a substrate solution is pure. According to Claim 4, number machie of said benzyl alcohol is substrate processing method. Device for treating substrates in, for supporting a substrate support unit; said support unit supported on a substrate machie of number discharge unit; said nozzle unit at a normal temperature to a temperature above the boiling point of said number machie of said liquid comprising a supply unit for supplying and addition number number machie of number, said unit comprises a number for, in order to receive number machie of said tank and having inner space; said received number machie of said tank heating member; supplying said interior space number number additive added to the supply pipe and; said nozzle unit including substrate processing device connecting said tank air pollution. According to Claim 6, said number for said heating unit comprises a number plower number further includes anxiety, the violations of the number, said number added to said mixture of said number reacted with inorganic number machie of higher boiling point in the core material is heated to a target temperature for organic, said mixture in said target temperature liquid for holding the substrate processing device. According to one of Claim 5 to Claim 7, said tank comprising a liquid circulation circulating line received therein, said heating element said circulation line number ball in digital device. According to Claim 8, said polymerizable liquid including substrate processing device is provided with a number added. According to Claim 9, benzyl alcohol is number machie of said substrate processing device.