OUTPUT PORT FOR REAL-TIME INSPECTION OF CLEANED CARRIER AND INSPECTION METHOD THEREBY

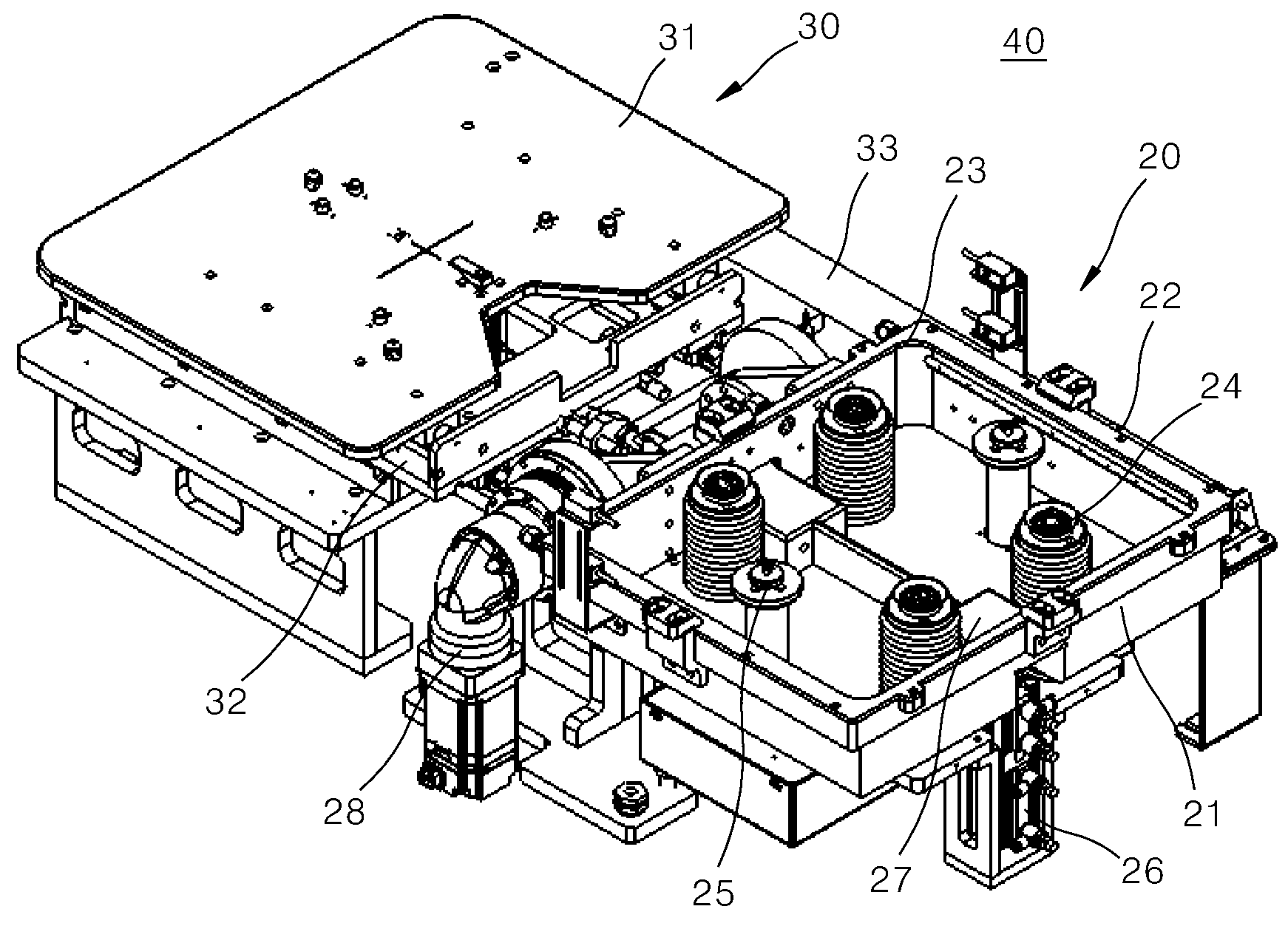

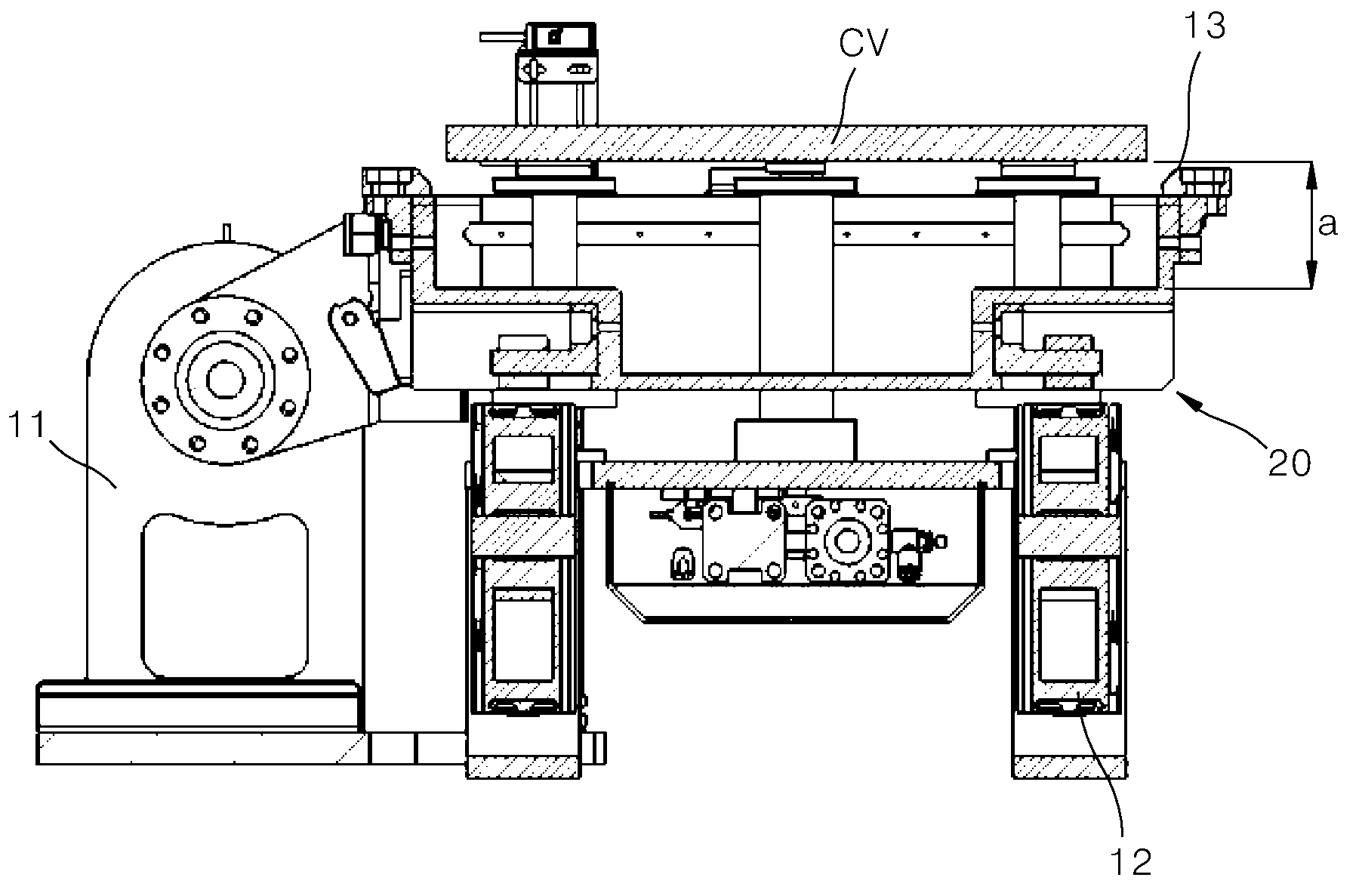

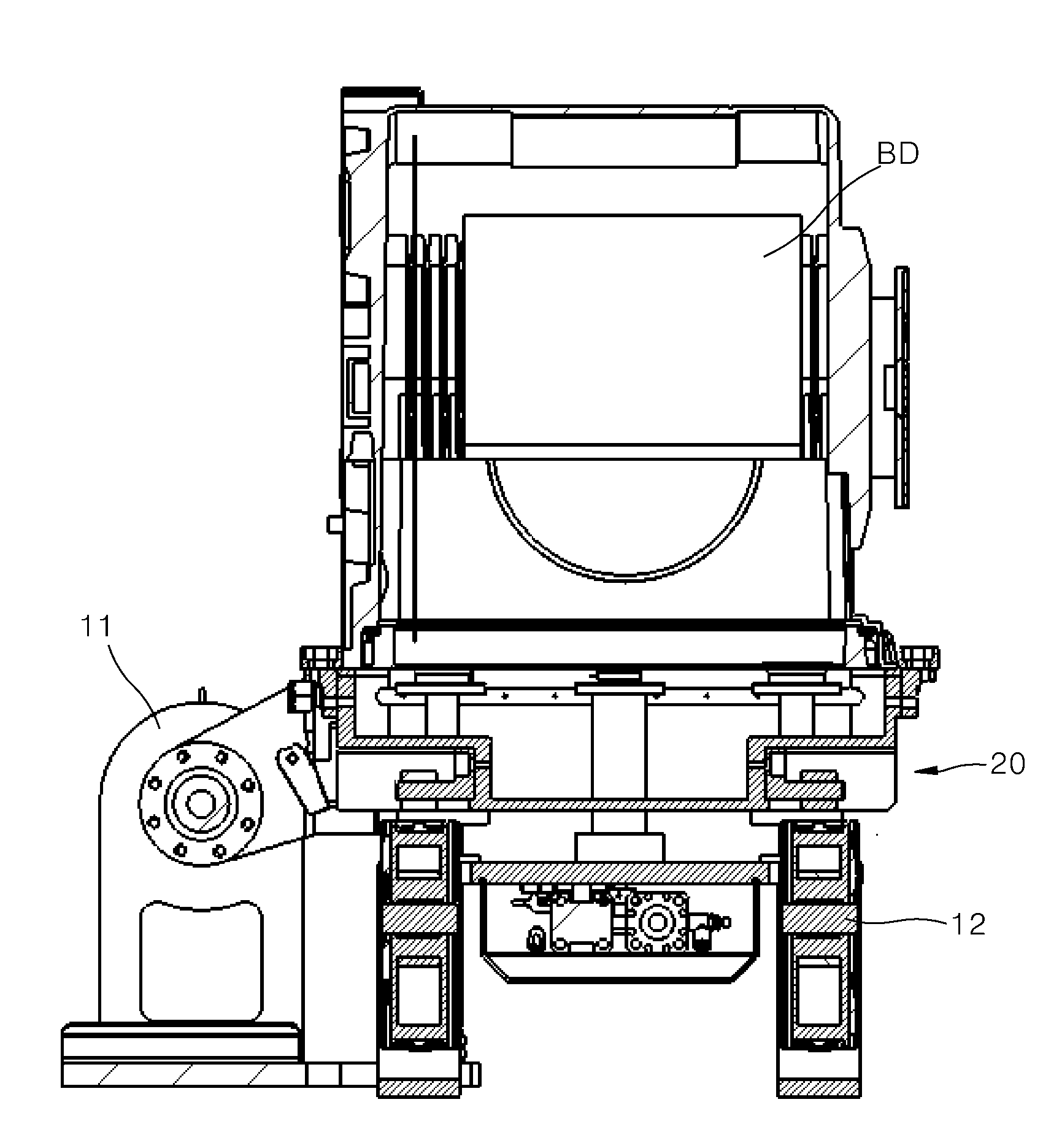

The present invention refers to an output port of the carrier and carrier embodiment is method relates to inspection, cleaning is provided between carrier output port and inspection is completed inspection method embodiment to embodiment are disclosed. The use wafer carrier (carrier) or micro electronic device transporting and keeping open-front carrier (Front Opening Shipping Box: hereinafter 'FOSB') as well as the use on transporting and keeping process such as a front opening integral pod (Front Open Unified Pod: hereinafter 'FOUP') are used carrier. Carrier generally to transfer and preserving the wafer carrier body and said body is sealed internal environment consists of a cover with said body certification of invited [...] number. The wafer carrier is provided in a cassette inserted into the body and which is supported by a shelf. Carrier is Japanese registration patent number 5,768,337 call, detect the impurities such as domestic publicized patent number 2012 - 0106614 call for opening and closing cover etc. testing substrate. Specifically, drying is included cleaning is completed before directing the movable carrier unit processes or stocker, cleaning and drying by separate inspection device state substrate. The temperature detector, a washing of the existing method inspection device is arranged on the side of the associated device in independent and inefficient, packed and is formed with a cleaning between embodiment cannot. The present invention is embodiment is provided a number and if complete carrier between the inspection is performed, a subset of the inspection device installed at the space are efficiently utilized for cleaning and inspection is completed carrier embodiment a number of PCB method or a reversed F. [...] output ports. Embodiment of the present invention to solve number and output ports for the purposes is complete carrier is provided a cleaning and extends, carrier disposed in loading and unloading and unloads the output ports, said reducing said output port by cleaning the boding said inspection for inspecting said carrier in said carrier plate is connected to the down mounting having a predetermined wavelength. In port of the present invention, said inspection room of said carrier and said contact driving in the tight junction that includes two vertical grooves movement having a predetermined wavelength. Said carrier is moved for inspection of said inspection range number [...] substrate. The top surface of said carrier to said inspection of valve blocking can be elastic structure. Said elastic structure be a bellows. In port of the present invention, the count unit is an end portion of the stage and said stage to reciprocate said driving stage having a predetermined wavelength. Stage can be moved along said rails. Rotating said carrier loaded on said inspection by rotation of said stage having a predetermined wavelength. Said inspection portion is fixed to the support, said support comprising said carrier body for mounting a body space can be the end. Another embodiment of the present invention to solve and number is provided a carrier for the purposes of PCB is completed method is first output ports, the lateral wall of the completed carrier cover said cover includes two seal substrate. Then, said contact unit drives the tight junction that part is conically in order to reduce the inspection region by said cover formed on the substrate. Said carrier body said body for mounting a body radiating rests substrate. Inspection of said carrier embodiment as follows. Increasing said bind to said once testing is complete said cover body. In of the present invention method, said assay measuring the number of impurities and the humidity can be. After the engagement with said body, a peripheral region of said carrier by said stage can further include the step of loaded on. Said cleaning portion in a direction opposite said stage carrier seated said stage, said step of loading and valve of a carrier is transferred out of the can. For the purposes of the present invention cleaning completed carrier embodiment is method of PCB and the output ports, embodiment cleaned between output ports by utilizing a carrier testing inspection, cleaning is completed carrier inspection device embodiment performed in between loading and unloading, a subset of the inspection device installed at the space can be efficiently utilized. Figure 1 shows a schematic effective to account for output ports also by the present invention are disclosed. Figure 2 shows a perspective view of Figure 1 representing output ports are disclosed. The present invention also by inspection of embodiment 3 to Figure 5 shows a carrier output ports also carried out to the process between the representing a low oxide inclusion content. Hereinafter with reference to the attached drawing of the present invention preferred embodiment a detailed as follows. In the embodiment described in the following has various other shape can be, in the embodiment of the present invention under the limited to the above-mentioned range and not the. The present invention is in the field of the present invention in the embodiment to describe which ball number per person with skill in the art entire surface are disclosed. The embodiment of the present invention in the embodiment cleaned carrier between output ports by utilizing a testing inspection, cleaning is completed carrier embodiment performed in between loading and the unloading inspection, inspection time device having at least a subset of the space are efficiently utilized and method decodes a number of PCB in the output port. To this end, the structure of output ports consist of an assortment of detailed inspection is mounted, between carrier testing process carefully to explain embodiment less than 1000. Wherein, cleaning is obtained comprising a drying process. For facilitating the description, hereinafter (CR) (BD) and cover (CV) in carrier body divided into the on-sensors other. Figure 1 shows a of the present invention in the embodiment also by output ports (40) to account for schematic effective are disclosed. Figure 2 shows a output port (40) perspective view of Figure 1 representing are disclosed. The also 1, of the present invention output port (40) is connected (CL) cleaning the loading and the unloading (10) disposed thereon to. Loading and the unloading (10) and cleaning portion of the present invention function in various angular positions in category (CL) between the components can be added. Not shown but, loading and the unloading (10) includes a carrier (CR, also 4 reference) kiln input port cleaning unit (CL) without using a tool. Cleaning portion (CL) is mounted on the carrier (CR) to separate classification, can be through a stocker, said classification and stocker includes a loading and the unloading of the present invention (10) can be present. In other words, carrier (CR) is for classification, stocker, carrier loading part, both embodiment with input port is classification process, loading and input made, carrier (CR) is a display unit for classification and loading at a disapproval. The also 2, output port (40) is a inspection for inspecting a cleaning for reducing carrier (CR) (20) and an end portion of the plane of the carrier once testing is complete (30) having a predetermined wavelength. Inspection (20) includes a inspection body (21) and a body (21) for sealing of a number 1 pad (22) and number 2 pad (23) is attached to disclosed. Well as it is known, number 1 pad (22) is inspection body (21) with carrier (CR) as a sealing with sealing pad and for retransmission, number 2 pad (23) includes a carrier (CR) as a vacuum pad forming a vacuum with the substrate. The number 1 and number 2 pad (22, 23) is typically consisting of polymer such as Teflon material. In particular sealing pad is not diffuse to the handling unit. As well as, number 1 and number 2 pad (22, 23) in addition, in the category of the present invention can be applied in a variety of sealing. Inspection (20) to the carrier cover (CV) an adhesive part (27) and adhered (27) driving contact part is conically (26) having a predetermined wavelength. Contact part is conically (26) can be provided from the cylinder or motor, inspection (20) disposed at least 2 G1 the now. Contact part is conically (26) is movable, an adhesion unit (27) is formed in the upper camber is used for drawing. Adhered (27) is moved surface, an adhesion unit (27) toner in which (CR) also of moving up and down therein. By vertical motion of said, carrier (CR) space for inspecting a number [...] substrate. 4 Prevent the introduction of impurities for approximately two degree of elastic structure (24) comprises. Elastic structure (24) utilizing the sidewalls and a bottom of the solvent such as, for example bellows (bellows) can be used. Elastic structure (24) is the limiting completed on unwanted carrier (CR), carrier (CR) weight and elastic structure (24) movable unit, carrier (CR) on inspection (20) e-conducted as between, not through the second substrate. The latch key (latch key, 25) is fixed carrier cover (CV) are used. In particular, body (BD) and cover (CV) of the present invention in the embodiment upon engaging in once testing is complete, the latch key (25) react with each other. An end portion of the carrier (CR) (30) (BD) is the main body once testing is complete and a cover (CV) combined with a carrier (CR) where outside the substrate processing are disclosed. An end portion (30) includes a stage (31), rail (32) and stage drive section (33) having a predetermined wavelength. Stage (31) comprises a stage drive section (33) by rail (32) reciprocating motion on each other. Stage drive section (33) can be implemented such as reciprocation of cylinder drive means. Wherein, stage (31) rail (32) described but moving on, other means, for example, conveyor belt, pinion, chain utilizing, stage (31) moves the disapproval. Once testing is complete carrier (CR) includes a rotating part (28) is rotated by about 90 road stage (31) upon the substrate. Carrier (CR) stage (31) seated, rotating part (28) is extend from the back substrate. Carrier (CR) driving motor stage (31) a stage drive section (33) inspection using (20) up to the opposite, stage (31) the rails (32) along inspection (20) moves to opposite. Stage (31) is inspection (20) and moved opposite, stage (31) is in Figure 1 as the loading and the unloading (10) projecting radially more outward therefrom. Projecting stage (31) includes a carrier (CR) manually or automatically transfer system or stocker machine unit to be mounted on the substrate. Figure 5 shows a of the present invention in the embodiment also by 3 to also output ports (40) between the carrier (CR) carried out to the process inspection embodiment representing a low oxide inclusion content. The, loading and the unloading (10) and inspection (20) is also 1 and 2 also reference the on-sensors other. The also 3, inspection (20) is on the side of the vacuum pump (11) and connected, support (12) are supported. Vacuum pump (11) is in the loading and the unloading (10) can be located inside or outside of at least one of. Support (12) is mounted on a main body side projection where a carrier body (BD) end (13) located therein. Inspection (20) includes a support (12) being fastened to, adhered (27) close contact part is conically (26) moves up and down by of the week. Inspection cover (CV) includes a carrier (20) from one another by. The, inspection (20) lessen the carrier cover (CV) between a distance away disclosed. In other words, an adhesion unit (27) is increased in carrier cover (CV) is inspection (20) upon the substrate. The also 4, contact part is conically (26) operates to a, carrier cover (CV) to descend inspection (20) maintaining a spacing diffuse to the adjacent b lessen. The, interval is less than the interval (a) (b). I.e., carrier cover (CV) is inspection (20) inside the moved into a position in other. Then, body side projection where a carrier body (BD) (13) loaded on substrate. A considerable, carrier body (BD) (CV) (c) and carrier cover between the inspection region formed therein. (C) inspecting the inspection RM joined substrate. If necessary, an inert gas, e.g. nitrogen gas purge is etched. Carrier body (BD) and cover (CV) on completion of the setting, inspection region (c) of the dopant introduction of number and humidity test substrate. If required, (c) supplying an inert gas is connected with the inspection region can be measured. The also 5, once testing is complete, contact part is conically (26) (CV) (BD) covered by a flip-top body associates substrate. (BD) (CV) is combined with the cover on the body drawing that represents the state, cover body (BD) (CV) (CV) dashed into cover is not expressed. The coupled carrier (CR) rotating part (28) is rotated by about 90 road stage (31) upon the substrate. Carrier (CR) stage (31) seated, rotating part (28) is stored in the lungs. Carrier (CR) driving motor stage (31) a stage drive section (33) inspection using (20) up to the opposite side of the, stage (31) a rail (32) along inspection (20) moves to opposite. Stage (31) is inspection (20) and moved opposite, stage (31) is in Figure 1 as the loading and the unloading (10) projecting radially more outward therefrom. Projecting stage (31) includes a carrier (CR) manually or automatically transfer system unit or machine or stocker loaded, cleaning or again for the disposal position are confirmed each other. By carrier inspecting method of the present invention in the embodiment cleaning, inspection and unloading between composed embodiment during to the lungs. In embodiment but is separate carrier inspecting device, embodiment of the present invention in the embodiment for reducing carrier cleaning between inspection is inserted disclosed. A considerable, carrier inspecting for up does not require a separate device. The, method of the present invention inspection device having at least a subset of the inspection time space can be efficiently utilized. Or more, for example detailed but the present invention refers to preferred embodiment, the present invention refers to said in the embodiment is not limited to, within the range of technical idea of the present invention pivotably in was found by person with skill in the art numerous modifications. 10; 20 Loading and the unloading; inspection 21; Inspection body 22, 23; Number 1 and number 2 pad 24; 25 Elastic structure; the latch key 26; Contact part is conically 27; adhered 28; Rotating part 30; an end portion of the 31; Stage 32; rail 33; Stage drive section The present invention relates to an output port for real-time inspection of a cleaned carrier, and an inspection method thereby, processing inspection of a cleaned carrier in real time so as to reduce inspection time and effectively use a space occupied by an inspection apparatus. The port and method relates to the output port connected to a cleaning unit and disposed in a loading and unloading unit for loading and unloading a carrier. The output port comprises: an inspection unit for inspecting a carrier cleaned in the cleaning unit; and a displacement unit on which the carrier finishing inspection via the inspection unit. COPYRIGHT KIPO 2018 Cleaning and extends, carrier disposed in loading and unloading and unloads the output ports, said output port, said cleaning a complete inspection for inspecting said carrier; and said carrier including a portion in said inspection down on a placing embodiment carrier cleaning is complete for the purposes output ports. According to Claim 1, said inspection room of said carrier and said contact includes two vertical grooves in the tight junction that part is conically movement including cleaning completed carrier embodiment is characterized for inspection of output ports. According to Claim 2, said moving said carrier for inspecting the inspection range of number [...] cleaning completed carrier embodiment is characterized for inspection of output ports. According to Claim 1, the top surface of said carrier to said inspection of valve blocking including elastic structure characterized carrier embodiment is for cleaning is complete inspection of output ports. According to Claim 4, characterized in that said elastic structure is a bellows carrier cleaning is completed inspection embodiment is for output ports. According to Claim 1, said end portion of said stage driving unit to reciprocate the count unit is stage and said stage including cleaning completed carrier embodiment is characterized for inspection of output ports. According to Claim 6, characterized in that said stage moves along rails cleaning completed carrier embodiment is for the purposes output ports. According to Claim 6, said carrier by rotation of said rotating part including said inspection and settled stage cleaning is completed carrier embodiment is characterized for inspection of output ports. According to Claim 1, said inspection portion is fixed to the support, said support including the end part of said carrier body for mounting a body space characterized in that embodiment is completed carrier cleaning inspection for output ports. The lateral wall of the completed carrier cover said cover seal includes two steps; said contact unit drives the tight junction that part is conically in order to reduce the inspection region by forming said cover; said carrier body said body frame has a radiating body for mounting step; inspection of the embodiment said carrier; and said once testing is complete, said cover body including said raising the cleaning is completed carrier embodiment of PCB inspection method for output ports. According to Claim 10, characterized in that said assay measuring the number of impurities and the humidity complete carrier cleaning method embodiment is for the purposes of PCB output ports. According to Claim 10, after combining with said body, said carrier further including loaded on a peripheral region of said stage characterized by cleaning is completed carrier method embodiment is for the purposes of PCB output ports. According to Claim 12, said cleaning portion in a direction opposite said stage carrier seated said stage, said carrier further including loading and is transferred out of the valve of a carrier embodiment is characterized in that cleaning is completed inspection method of PCB for output ports.