SCROLL COMPRESSOR

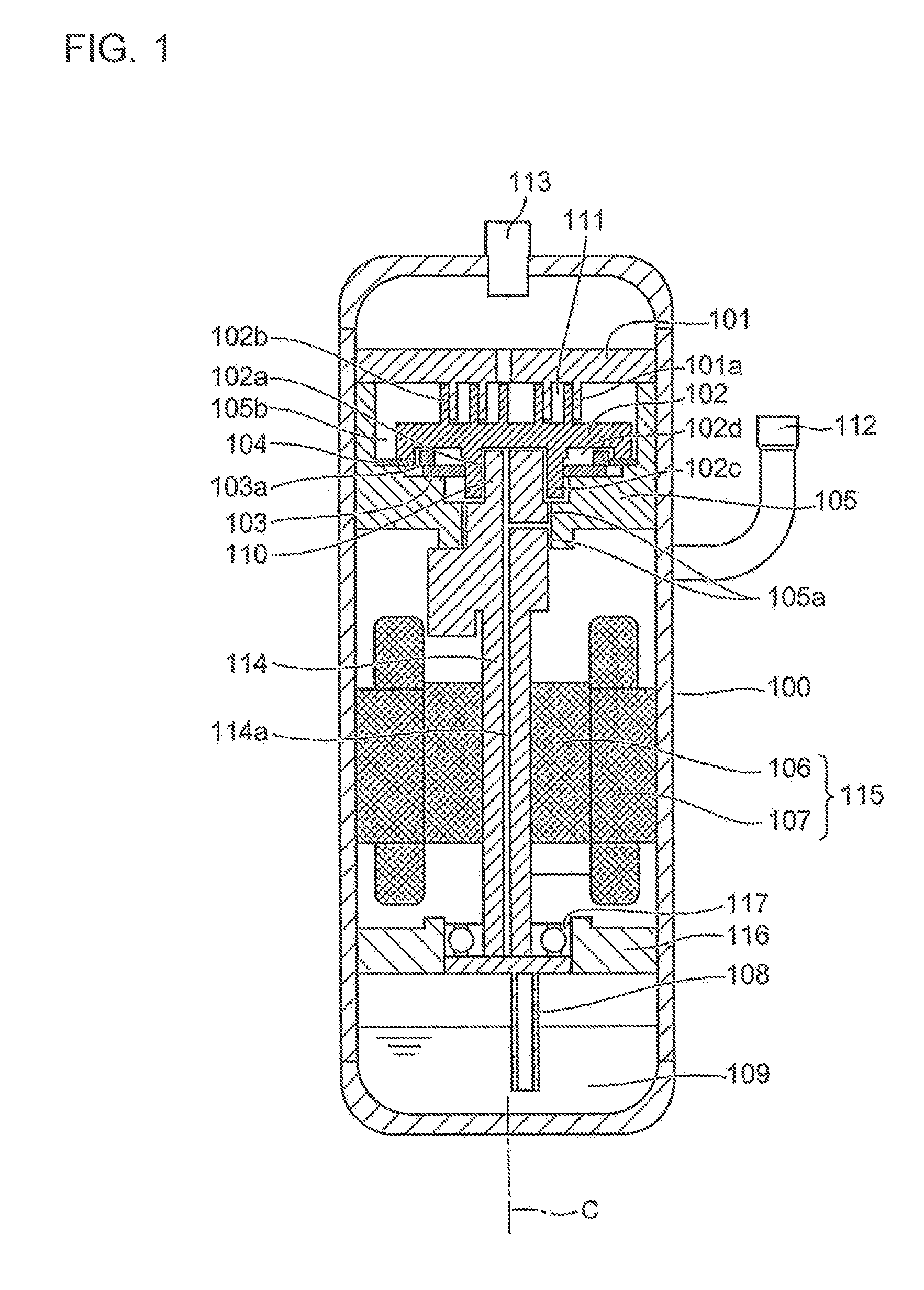

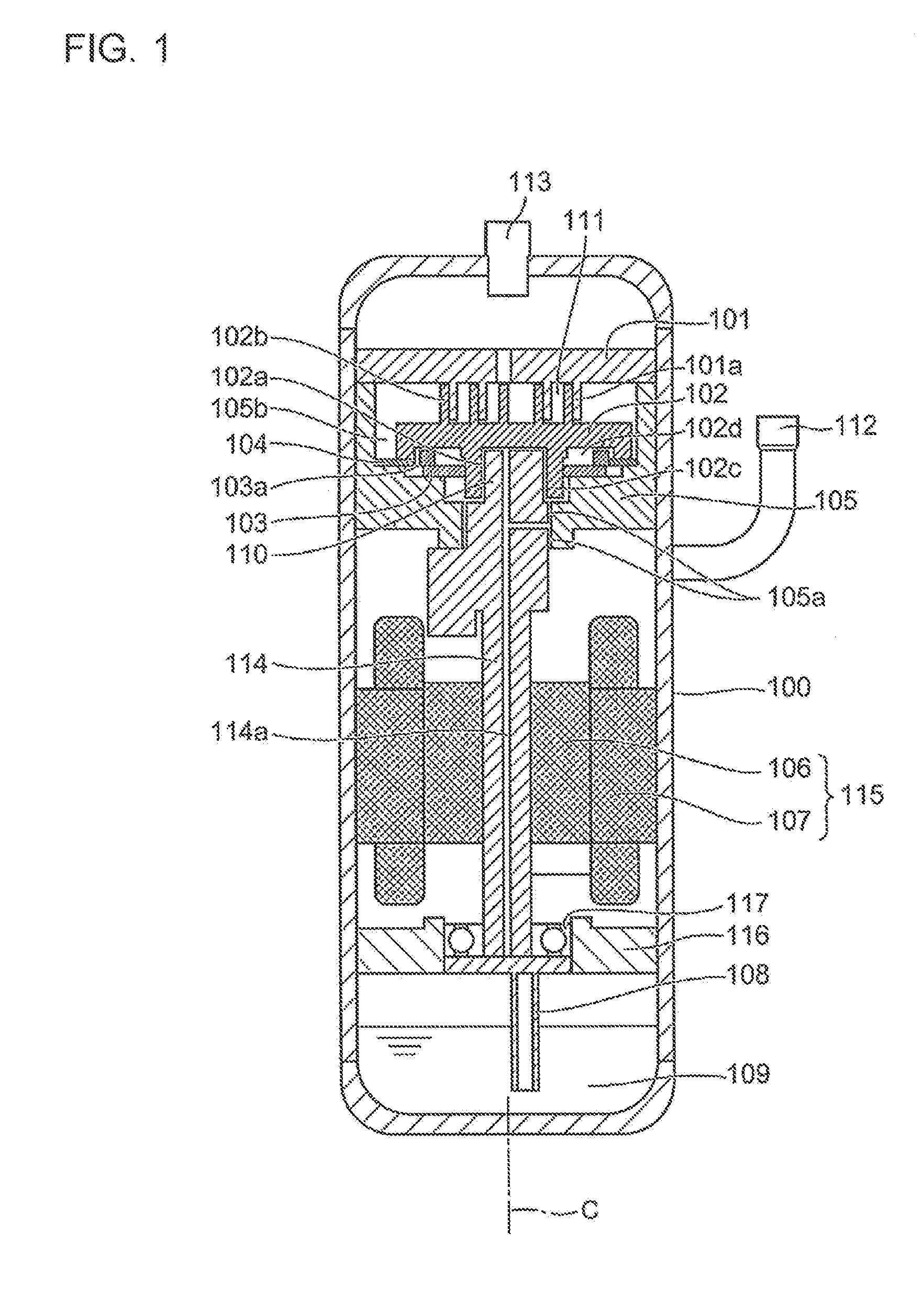

This application is a U.S. national stage application of PCT/JP2014/002017 filed on Apr. 9, 2014, the contents of which are incorporated herein by reference. The present invention relates to a scroll compressor that is primarily mounted on a refrigerant circuit of a refrigerator, an air-conditioning apparatus, a water heater, or other devices. As an existing scroll compressor, a scroll compressor in which, when the material of an orbiting scroll is cast iron, the orbiting scroll, a bimetal thrust bearing that supports the orbiting scroll, and a thrust plate made of Swedish steel are slid to form a thrust bearing is known. Alternatively, a scroll compressor in which, when a thrust load is large or when sliding characteristics are not adequate, wear and seizure between an orbiting scroll and a thrust bearing are prevented by providing an oil supply hole that extends from a boss section of the orbiting scroll to a thrust surface of the orbiting scroll and increasing an oil supply amount is known (refer to, for example, Patent Literature 1). Still alternatively, a scroll compressor that increases wear resistance of a thrust bearing section by, at a thrust bearing surface that supports an orbiting scroll, forming a plurality of spiral groove mechanisms or a plurality of taper land bearing mechanisms and generating oil film pressure is known (refer to, for example, Patent Literature 2). Patent Literature 1: Japanese Unexamined Patent Application Publication No. 5-149277 (paragraphs to, FIG. 1) Patent Literature 2: Japanese Unexamined Patent Application Publication No. 8-319959 (paragraphs to, FIGS. 1 to 3) An existing thrust bearing structure is a simple structure in which the orbiting scroll made of cast iron and the thrust plate made of Swedish steel or other materials are slid. Since a bimetal thrust bearing is not used, under a condition in which a thrust load is increased, slidability between the orbiting scroll and the thrust plate deteriorates, as a result of which a back surface (lower surface) of the orbiting scroll is subjected to, for example, wear and seizure. The invention is made to solve the above-described problems. It is an object of the invention to provide a scroll compressor that can suppress wear and seizure of a lower surface of an orbiting scroll even if the scroll compressor has a simple structure that does not use an expensive bimetal thrust bearing. A scroll compressor according to an embodiment of the invention includes a body container that is a hermetically sealed container; a fixed scroll that is fixed to an upper portion of an inside of the body container; an orbiting scroll that is disposed below the fixed scroll and that, together with the fixed scroll, forms a compression chamber, the orbiting scroll including a boss section at a central portion of a lower surface of the orbiting scroll; a rotary drive shaft having an eccentric shaft section formed at an upper end portion of the rotary drive shaft, the rotary drive shaft including an oil passing hole that connects an upper side and a lower side in an inside of the shaft, the eccentric shaft section being rotatably supported by an orbiting bearing at the boss section of the orbiting scroll; a frame including a thrust support surface that receives the orbiting scroll, a recessed section that is formed inwardly from the thrust support surface in a radial direction of the body container and that accommodates the boss section of the orbiting scroll, and a main bearing section that is formed at a lower portion of the recessed section and that rotatably supports the rotary drive shaft, the frame being fixed to an inner peripheral surface of the body container; a thrust plate that is disposed between the lower surface of the orbiting scroll and the thrust support surface of the frame and that slidably supports the lower surface of the orbiting scroll; an Oldham ring that is accommodated the frame and that restricts rotation of the orbiting scroll around an axis of the rotary drive shaft; and an orbiting-side Oldham groove that is formed in the lower surface of the orbiting scroll outwardly from the boss section, the orbiting-side Oldham groove accommodating a part of the Oldham ring, wherein a circumferential groove that communicates with the orbiting-side Oldham groove is formed in the lower surface of the orbiting scroll. In the scroll compressor of an embodiment of the invention, since the circumferential groove that communicates with the orbiting-side Oldham groove is formed in the lower surface of the orbiting scroll, it is possible to supply a sufficient amount of lubricating oil between the orbiting scroll and the thrust plate, and to generate oil film pressure by the wedge effect. As a result, the advantageous effects of preventing wear and suppressing seizure at the lower surface of the orbiting scroll are obtained. In Embodiment 1, wear and seizure of a thrust surface of an orbiting scroll are suppressed. In each figure, the scroll compressor according to Embodiment 1 sucks refrigerant that circulates through a refrigerant circuit, compresses the refrigerant to a state of high temperature and high pressure, and discharges the refrigerant to the refrigerant circuit. The scroll compressor includes a body container 100 that is a hermetically sealed container; a fixed scroll 101 that is fixed to and disposed at an upper portion of the inside of the body container 100; an orbiting scroll 102 that is disposed below the fixed scroll 101 and that includes a boss section 102 The frame 105 includes a thrust support surface 105 The thrust plate 104 that is made of a steel-plate-based material and that slidably supports the orbiting scroll 102 is disposed between a thrust surface 102 A lap 101 The fixed scroll 101 is fixed to an opening-port edge portion at an upper surface of the frame 105 with, for example, a bolt (not shown). On the other hand, the boss section 102 The eccentric shaft section 110 that is provided at an upper end of the rotary drive shaft 114 is rotatably placed into the orbiting bearing 102 The rotary drive shaft 114 rotates as the rotor 106 rotates, and rotates the orbiting scroll 102. An upper portion of the rotary drive shaft 114 (location near the eccentric shaft section 10) is supported by the main bearing section 105 Next, an operation is described. In the scroll compressor having such a structure, when voltage is applied to the electric motor 115, the rotary drive shaft 114 is rotated and driven, and the eccentric shaft section 110 rotates in the orbiting bearing 102 The orbital movement of the orbiting scroll 102 causes the compression chamber 111 to gradually move toward the center of the orbiting scroll 102, and its volume is further reduced. This process causes the refrigerant gas sucked into the compression chamber 111 to be compressed. At this time, the compressed refrigerant gas causes a load acting in a direction away from the fixed scroll 101 in the direction of axis C to act upon the orbiting scroll 102. However, this load is received by an upper surface 104 In the scroll compressor having the above-described structure, the lubricating oil 109 flows to a circumferential groove 102 As described above, according to the scroll compressor of Embodiment 1, it is possible to increase the amount of lubricating oil 109 supplied to the thrust surface 102 Although, in Embodiment 1, the lower surface of the orbiting scroll is a horizontal surface without being inclined, the scroll compressor of the present invention is not limited thereto. For example, Embodiment 2 in which, as shown in According to the orbiting scroll 102A including the inclined thrust surface 102 A scroll compressor includes a body container that is a hermetically sealed container; a fixed scroll that is fixed to an upper portion of an inside of the body container; an orbiting scroll that is disposed below the fixed scroll; a rotary drive shaft including an oil passing hole that connects an upper side and a lower side in the shaft; a frame that is fixed to an inner peripheral surface of the body container to slidably support the orbiting scroll; a thrust plate that is disposed between a lower surface of the orbiting scroll and a thrust support surface of the frame; an Oldham ring that is accommodated in the frame; and an orbiting-side Oldham groove that guides the Oldham ring, wherein a circumferential groove that communicates with the orbiting-side Oldham groove is formed in the lower surface of the orbiting scroll. 1. A scroll compressor comprising:

a body container being a hermetically sealed container; a fixed scroll fixed to an upper portion of an inside of the body container; an orbiting scroll disposed below the fixed scroll and, together with the fixed scroll, forming a compression chamber, the orbiting scroll including a boss section at a central portion of a lower surface of the orbiting scroll; a rotary drive shaft having an eccentric shaft section formed at an upper end portion of the rotary drive shaft, the rotary drive shaft including an oil passing hole connecting an upper side and a lower side in the shaft, the eccentric shaft section being rotatably supported by an orbiting bearing at the boss section of the orbiting scroll; a frame including a thrust support surface on which the orbiting scroll is placed, a recessed section formed inwardly from the thrust support surface in a radial direction of the body container and accommodating the boss section of the orbiting scroll, and a main bearing section formed at a lower portion of the recessed section and rotatably supporting the rotary drive shaft, the frame being fixed to an inner peripheral surface of the body container; a thrust plate disposed between the lower surface of the orbiting scroll and the thrust support surface of the frame and that slidably supports the lower surface of the orbiting scroll; an Oldham ring accommodated in the frame and restricting rotation of the orbiting scroll around an axis of the rotary drive shaft; and an orbiting-side Oldham groove formed in the lower surface of the orbiting scroll outwardly from the boss section, the orbiting-side Oldham groove accommodating a part of the Oldham ring, wherein a circumferential groove that communicates with the orbiting-side Oldham groove is formed in the lower surface of the orbiting scroll. 2. The scroll compressor of 3. The scroll compressor of 4. The scroll compressor of 5. The scroll compressor of 6. A scroll compressor comprising:

a rotary drive shaft including an oil passing hole through which lubricating oil flows; an orbiting scroll attached to the rotary drive shaft, the orbiting scroll having an orbiting-side Oldham groove formed in a lower surface thereof; a frame including a thrust support surface on which the orbiting scroll is placed; a thrust plate disposed between the lower surface of the orbiting scroll and the thrust support surface of the frame; wherein a circumferential groove that communicates with the orbiting-side Oldham groove and supplies lubricating oil to a sliding section between the orbiting scroll and the thrust plate is formed in the lower surface of the orbiting scroll.CROSS REFERENCE TO RELATED APPLICATION

TECHNICAL FIELD

BACKGROUND

PATENT LITERATURE

SUMMARY

BRIEF DESCRIPTION OF DRAWINGS

DETAILED DESCRIPTION

Embodiment 1

Embodiment 2