Purifying wire from a Gold-Legierung, procedure for its production and its use.

The invention concerns a purifying wire from a Gold-Legierung for contacting semiconductor components, a procedure for the production of the purifying wire and its Verwendung.

For contacting - bonding - semiconductor components suitable Drãhte - also called Bonddrãhte - must possess good electrical characteristics and exhibit good mechanical mechanical properties. The diameter of the wires can amount to about 10-200 micrometers and lies usually with approximately 20-60 micrometers; it becomes the application purpose accordingly gewählt.

The bond wires consist hãufig of gold of high purity or of Gold-Legierungen. The latters possess the advantage of a hõheren firmness and, if they contain only a small quantity of Legierungsbildnem, one that of the gold similar electrical Leiffãhigkeit.

So for example,608,161 C are the use of an alloy from gold and 0.001-0.1% one or several rare-earth metals, particularly in the form of cerium Mischmetali from DE 1, or yttrium for the production of Zufûhrungsdrähten in integrated circuits well-known. This alloy of the gold with small quantities of rare-earth metals or yttrium possesses stretch behavior with Erwãrmungstemperaturen up to 50OeC substantially improved Festigkeitsund, without chemical Bestãndigkeit or electrical resistance, substantially affects other characteristics of the gold, like hardness, werden.

Gold SeitenerdmetalI alloys for bond wires become also in DE 3 237385 A (US 4885 135), DE 3936281 A (US 4938923), JP 5-179375 A, JP 5-179376 A, JP 6-112258 A, EP 0743679 A and EP 0,761,831 A beschrieben.

DE 3,237,385 A concerns a fine gold alloy wire with high tensile strength from a Gold-Legierung with 0,0003-0,01 weight % SE] tenerdmetall, particularly cerium, and if necessary zusåtzlich still germanium, beryllium and/or Calcium.

DE 3,936,261 A describes a gold lead fûr connecting a Halbleitervorñchtung from gold of high purity, alloyed with geñngen quantities of lanthans, beryllium, calcium and elements of group of platinum, particularly platinum and/or Palladium.

JP 5-179375 A and JP 5-179376 A refer to fine gold alloy wires for bonding, from gold of high purity and 0.0003-0.005 weight % aluminum and/or gallium, 0.00030.003 weight % calcium and 0.0003-0.003 weight % the yttrium, lanthan, cerium, neodymium, dysprosium and/or Beryl] ium bestehen.

From JP 6-112 258 A, refeñert in Chemical Abstracts Voi. 121, 89 287m, admitted bonding wire consists of a Gold-Legierung with 1-30% platinum and 0.0001-0.05% scandium, Yttdum and] or of Seltenerdmetal] and if necessary 0.0001-0.05% beryllium, calcium, germanium, nickel, iron, cobalt and/or Silber.

In EP 0,743,679 A a bonding wire from a platinhaltigen gold SeltenerdmetalI alloy is likewise suggested. The alloy consists cerium in a quantity of 0,0001-0,02 weight % of gold and small quantities platinum (0.0001-0.005 weight %), silver, magnesium and europium and knows for example still enthalten.

In EP 0,761,831 A a fine wire from a platinum and] or palladium a containing gold SeitenerdmetalI alloy is described. The alloy consists weight % platinum and/or palladium, 0.0001-0.005 weight % beryllium, germanium, calcium, lanthan, yttrium and/or europium, remainder of gold of 0,1-2,2. The wire is manufactured by melts the alloy of forming elements in a crucible, from bottom to top progressive Kûhlung of the alloy melt in the crucible to a casting ingot and following rollers, pulling and glowing. Proves a stretch of 38% and a Young module of 6800-9000 kgf/mm2 auf.

EP 0,288,776 a2 refers to contacting metallizations from aluminum, which are endowed with copper to the improvement of Hãrte and firmness, so that the one smaller hardness exhibiting standard gold bond wires with beryllium doping are less well suitable. Connecting from Kontaktierungspads with copper endowed aluminum from there a bonding wire becomes from an alloy from gold and 0.01-1 weight % copper with one that of endowed aluminum adapted hardness vorgeschlagen.

A cupreous bonding wire is also from DE 3,990,432 C2 (= US 5,491,034 A) well-known. The bonding wire serves weight % copper for connecting electrodes of a semiconductor element with ãusseren Anschlûssen and consists of a Gold-Legierung with at least 1 and less than 5. Zusãtzlich knows the bonding wire 0.0003-0.01 weight % calcium, germanium, Beryliium, lanthan and] or Indium and at least 1 of weight % and hõchstens 5 weight % platinum contain. The production of the bonding wire takes place via Erschmelzen of the Gold-Legierung in a vacuum melting furnace, a wire drawing and a following Wãrmebehandlung (Glûhung) with 200-600°C. The Wårmebehandlung is usual and has the purpose to improve the Vefformbarkeit or stretch bad due to pulling (“elongation”). Since with the improvement of the ductility a decrease of the firmness is connected, the firmness affecting Legierungsbildner regarding kind to wãhlen and quantity and the conditions of the thermal treatment are in such a way, dess both - ductility and firmness - which corresponds to respective requirements. The firmness of the bonding wire becomes larger with a Erhõhung of the Kupfer-Anteils.

From JP 01-87 734 A (patent Abtracts OF Japan) a purifying wire from gold and 0.05-0.3 weight % at least one of the elements copper, aluminum, Yttñum, nickel, cobalt, titanium, tungsten, silicon, zirconium, calcium, palladium, ruthenium, iridium, platinum, silver and osmium is well-known. The purifying wire points a good Ziehfãhigkeit and very good mechanical characteristics auf.

ó JP 08-199 261 A (Japanese patent Office - patent Abstracts OF Japan) describes a bonding wire from highly pure gold, 0.1-2 weight % copper, 0.01-0.1 weight % palladium and if necessary 0.0001-0.01 weight % tin and/or 0.0001-0.01 weight % at least one of the metals calcium, Beryllíum, Germaníum, rare-earth metal, strontium, Bañum, Indium and titanium. The firmness of the bonding wire is sufficient, around contact errors between neighbouring bond loops in plastic-Inge-bedded semiconductor components too vermeiden.

With the selection from Bonddrãhten in particular also as high a firmness as possible becomes with given stretch gefordert. apart from special chemical and physical characteristics

From there the task is appropriate for the invention to reason to find a purifying wire of the initially charakteñsierten kind from a Gold-Legierung which good firmness/stretch Verhãltnis mõglichst possesses and whose elektñsche Leitfãhigkeit mõglichst itself few of the one pure gold purifying wire differentiates. In addition soli a procedure to be indicated, kontinuierfiche production of the purifying wire in economically favourable way ermõglicht. The purifying wire soli both to the Drahlbonden and for the production of so-called BalI Bumps fût those Flip CH p-TechnJk, as it is described for example in DE 4,442,960 C, suitably sein.

The task is gelõst by a purifying wire from a Gold-Legierung, which erfindungsgemãss by the fact it is characterized that the Gold-Legierung from 0,5-0,9 weight % copper, 0.05-0.95 weight % platinum, remainder of gold besteht.

The task is gelõst also by a purifying wire from a Gold-Legierung, which erfindungsgemåss by the fact it is characterized that the Gold-Legierung from 0,5--0,9 weight % copper, 0.0001-0.1 weight % at least one element from the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold besteht.

In the sense of the invention under “alkaline earth metal” beryllium, magnesium, calcium, and strontium, are called Badum under “rare-earth metal” lanthan (ordinal number 57) and the 14 elements cerium ordinal number 58 following on the lanthan) to lutetium (ordinal number 71), in the technical literature also “elements of the lanthan row”, verstanden.

Gûnstigerweise is Erdalkalimetallund/or to rare-earth metal content about 0,001--0,01 weight % and, if platinum is present, the platinum content with 0,1-0,9 Gewichts-%.

The alkaline earth metal consists preferentially of beryllium, magnesium, calcium or a mixture of at least two of these alkaline earth metals. If mixtures from beryllium and calcium are used, then to have itself such from in each case 50 weight % beryllium and calcium as particularly suitable erwiesen.

The rare-earth metal consists preferentially of cerium or a mixture of Ger and or several of the rare-earth metals with the ordinal numbers 57 and 59 to 71. As particularly been suitable cerium mixture metal proved. Cerium mixture metal a ûblicherweise mixture with 50-60% cerium, 2530% lanthan, 10-15% neodymium, 4-6% praseodymium and 1% iron is called as well as small portions of further side earth metals (Rõmpp chemistry encyclopedia, George Thieme Vedag Stuttgart - New York, volume 1,10. Edition (1996), 647).

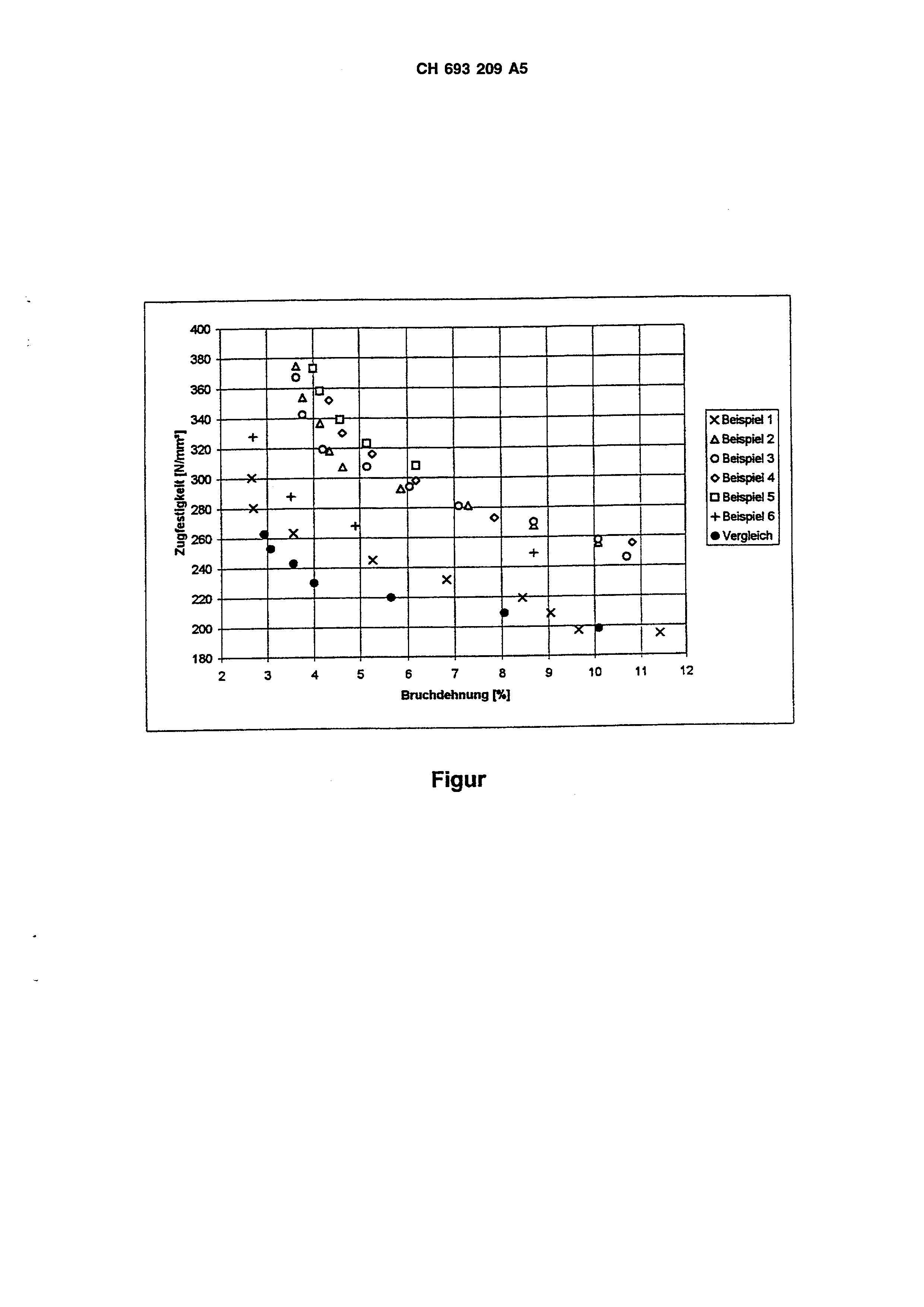

The purifying wire according to invention with fûr Bonddrãhte ûblichem diameter possesses all fûr the employment for bonding necessary characteristics. It is characterised particularly by its high elektñsche conductivity, measured as specific elektñscher resistance (see table Vili), and its - related to the stretch - very good firmness (see figure). Ûberraschenderweise fûhrt the eñindungsgemåsse selection from kind and quantity of the Legierungsbildner copper and alkaline earth metal and/or rare-earth metal to a Verñngerung of the firmness loss by the Glûhung (see table IX).

The very gûnstige FestJgkeits/stretch Verhãltnis of the purifying wire trãgt substantially to the very good Qualitãt of the bonds bei.

In the figure the firmness becomes (tensile strength) [N/mm2] some Feinstdrãhte in accordance with the invention (of examples 1-6) and - to the comparison - a not erfindungsgemãssen purifying wire (example 7) in Abhãngigkeit of the stretch (elongation at rupture) [%] represented. The Feinstdrãhte gemãss the invention possesses a hõhere firmness with given stretch. In the table Vili become the chemical composition and the specific electrical resistance in the examples described of the erfJndungsgemässen and to the comparison of some effindungsgemãssen Feinstdrãhten angegeben.

The table IX shows the values fûr the firmness of the Feinstdrãhte beschnebenen in the examples 1-7 in the pull-hard condition and with a stretch of approximately 4% and eats the influence of the beryllium, Calciumund of cerium additive on the firmness recognizes. Beryllium, calcium and cerium decrease the Festigkeitsvedust. connected with annealing

The erfindungsgemãsse purifying wire knows in development which is the high frequency bonding due to its gûnstigen characteristics with special advantage for wire bonding, also fûr, and for the production of the Kontakthúgel of Flip chips assigned werden.

The solution of the task consists further in a procedure for the production of a purifying wire for contacting semiconductor components of a Gold-Legierung, which is characterized according to invention by the fact that a Gold-Legierung geglûht from a) 0.5-0.9 weight % copper, 0.05-0.95 weight % platinum, remainder of gold or pulled from b) 0.5-0.9 weight % copper, 0.0001-0.1 weight % at least one element from the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold erschmolzen, which strand-poured melted alloy the strand diameter ûblichem to a wire also for bond purposes and the wire wird.

The erfindungsgemãsse procedure particularly bewãhrt itself, if the melted alloy is poured to a strand with kreisfõrmigem cross section and the wire is geglûht with for instance 300-700oC. By the Glûhen the first ziehhañe wire the necessary stretch erhãlt. The Erschmelzen and pouring of the alloy know argon at air, under inert gas, for example, or in the vacuum erfolgen.

With the erfindungsgemãssen procedure the Erschmelzen of a Gold-Legierung with a content of alkaline earth metal and/or rare-earth metal of 0,001-0,01 weight % and a content of platinum - if available - of 0,1 - 0.9 Gewichts-%. is preferred

As alkaline earth metal can be used beryllium, magnesium, calcium, strontium, barium or a mixture from at least two of these elements. Particularly bewãhrt themselves Benjllium, magnesium, calcium or a mixture from at least two of these alkaline earth metals. If mixtures from beryllium and calcium are used, then such become from in each case 50 weight % beryllium and calcium bevorzugt.

As rare-earth metal cerium or a mixture from cerium is particularly used and one or more rare-earth metals with the ordinal numbers 57 and 59 to 71, the latters preferably in the form of handelsûblichem Cer-Mischmetall.

The eñindungsgemãsse procedure is characterised particularly by the fact that it is continuous to fûhren and procedure products - poured strand and pulled wire - with very gleichmãssiger and continuous Qualitåt liefert.

To the nãheren Edãuterung in the following examples 1-6 Feinstdrãhte and their production in accordance with the invention and - to the comparison - in example 7 a purifying wire gemãss from DE the 1,608,161 C admitted state of the art described. The Feinstdrãhte becomes by their stretch (elongation at rupture) [%], its firmness (tensile strength) [N/mrr and its specific electrical resistance [ohm of mm2/m] charakteñsiert.

Example 1 purifying wire from a Gold-Legierung with 0,8 weight % copper and 0.8 weight % Platin.

The melt of an alloy from 0,8 weight % copper, 0.8 Gewiehts % platinum and gold as remainder is poured in a continuous casting plant to a strand with kreisfõrmigem cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and the wire depending upon obtaining stretch with for instance 300-700°C at air is geglûht. The mechanical properties [N/mm2], measured as a function of the stretch [%], become in the table I angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, betrãgt 0.041 ohms mrr /m.

Table I stretch [%] [firmness [N/mm2] pull-hard 600,2.6,301,2.7,281,3.6,263,5.3,245,6.8,232,8.5,219,9.1,209,9.7,197 11.4 194 example 2 purifying wire from a Gold-Legierung with 0,8 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium and 0.8 weight % Platin.

The melt of an alloy from 0,8 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium, 0.8 weight % platinum and gold as remainder is poured in a continuous casting plant to a RST strand with kreisfõrmigem cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and the wire depending upon obtaining stretch with for instance 300-700oC at air is geglûht. The mechanical properties measured in Abhãngigkeit of the stretch [%] [n mm2] become in the table IL angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, betrãgt 0.041 ohms mn /m.

Table IL stretch [%] firmness [N/mm2] pull-hard 585,3.6,375,3.8,354,4.2,337,4.4,318,4.6,308,5.9,293,7.3,281,8.7,267 10.1 255 example 3 purifying wire from a Gold-Legierung with 0,8 weight % copper, 0.001 weight % beryllium, 0.001 weight % Calcìum and 0.3 weight % Platin.

The melt of an alloy from 0,8 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium, 0.3 weight % platinum and gold as remainder is poured in a continuous casting plant to a strand with kreisfõrrnigem cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and the wire depending upon obtaining stretch with for instance 300-700°C at air is geglûht. The mechanical properties measured in Abhãngigkeít of the stretch [%] [n mm2] become in the table [...] angegeben.

The specific elektñsche resistance at ambient temperature, based on eìnem wire with a diameter of 275 micrometers, amounts to 0.036 ohms of mm2/m.

Table [...] stretch [%] firmness IN/mm2] pull-hard 614,3.6,367,3.8,343,4.2,319,5.2,308,6.1,294,7.1,281,8.7,270 10.1 257 10.7 246 example 4 purifying wire from a Gold-Legierung with 0,9 weight % copper, 0.001 weight % beryllium and 0.001 weight % Calcium.

The melt of an alloy from 0,9 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium and gold as remainder is poured in a continuous casting plant to a strand with kreisfõrmigem cross section. Subsequently, from the strand a wire with a diameter of micrometer is pulled and the wire depending upon obtaining stretch with for instance 300-700°C at air is geglûht. The mechanical properties [N/mm2], measured in Abhãngigkeit of the stretch [%], become in the table IV angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, betrågt 0.034 ohms of mm2/m.

Table IV stretch [%] firmness [N/mm2] pull-hard 673,4.4,352,4.6,330,5.3,316,6.2,298,7.9,273 10.8 255 example purifying wire from a Gold-Legierung with 0,9 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium and 0.9 weight % Platin.

The melt of an alloy from 0,9 weight % copper, 0.001 weight % beryllium, 0.001 weight % calcium, 0.9 weight % platinum and gold as remainder is poured in a continuous casting plant to a strand with circular cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and depending upon obtaining stretch with for instance 300700°C at air glows. The mechanical properties [N/mn'ₜ], measured as a function of the stretch [%], become in the table V angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, amounts to 0.043 ohms of mm2/m.

Table V stretch [%] firmness [N/mm2] pull-hard 648,4.0,373,4.2,358,4.6,339,5.2,323,6.2,308 example 6 purifying wire from a Gold-Legierung with 0,8 weight % Kupter and 0.01 weight % Cer.

The melt of an alloy from 0,8 weight % copper, 0.01 weight % cerium and gold as remainder is poured in a continuous casting plant to a strand with circular cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and geglûht depending upon to er'zielender stretch with for instance 300-700oC at air. The mechanical properties [N/mm2], measured as a function of the stretch [%], become in the table VI angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, betrãgt 0.034 ohms mrr /m.

Table VI stretch [%] firmness IN/mm2] pull-hard 585,2.7,328,3.5,288,4.9,268,8.7,249 example 7 (comparison) purifying wire from a Gold-Legierung with cerium mixture metal gemãss DE 1,608,161 C.

The melt of an alloy made of gold and cerium mixture metal is poured in a continuous casting plant to a strand with kreisfõrmigem cross section. Subsequently, from the strand a wire with a diameter of 30 micrometers is pulled and the wire depending upon obtaining stretch with for instance 300-600°C at air is geglûht. The mechanical properties [N/mmz], measured in Abhãngigkeit of the stretch [%], become in the table Vil angegeben.

The specific electrical resistance at ambient temperature, based on a wire with a diameter of 275 micrometers, betrãgt 0.023 ohms of mm2/m.

Table Vil stretch [%J firmness [N/mrn2 pull-hard 375,2.9,263,3.1,253,3.6,243,4.0,230,5.7 22O 8.1,209 10.1 198 table Vili composition [weight %] example outer fuel element approx. remainder remainder remainder remainder remainder remainder 100 remainder remainder remainder remainder of 1 2 3 4 6 7 (see) * 8 (see) 9 (see) lo (VgL) 1 (see) 12 (see) Ce cu Pt 0.8,0.8,0.3,0.8 0.001 0.001 0.8 0.001 0.001 0.8 0.001 0.001 0.9 specific electrical resistance 0.041 0.041 0.036 0.034 0.001 0.001 0.9 0.01 0.8,2.0,2.0 *Gold-Legierung with cerium mixture metal in accordance with DE 1,608,161 C 0.9,2.0,5.0,2.0 0.043 0,034 0,023 0.023 0.048 0.043 0.073 0.068 table IX composition [weight %] firmness [N/mm2] example outer fuel element approx. Ce cu Pt pull-hard 4% stretch 1 remainder 0.8,0.8,600,260 2 remainder 0.001 0.001 0.8,0.8,585,335 3 remainder 0.001 0.001 0.8,0.3,614,330 4 remainder 0.001 0.001 0.9,673,365 remainder 0.001 0.001 0.9,0.9,648,373 6 remainder of 0.01 0.8,585,280 7 (see) * 375,230 *Gold-Legierung marked by cerium mixture metal in accordance with DE 1,608,161 C Patentansprü¢he 1st purifying wire from a Gold-Legierung for contacting semiconductor components, by the fact that the Gold-Legierung from 0,5-0,9 weight % copper, 0.05-0.95 weight % platinum, remainder of gold besteht.

2. Purifying wire from a Gold-Legierung for contacting semiconductor components, by the fact characterized that the Gold-Legierung from 0,5-0,9 weight % copper, 0.0001-0.1 weight % at least one element from the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold besteht.

3. Purifying wire according to requirement 2, by the fact characterized that Erdalkalimetallund/or SeltenerdmetalI content of the Gold-Legierung 0.001-0.01 weight % betrãgt.

4. Purifying wire after one the Ansprûche 1 to 3, by the fact characterized that the platinum content of the Gold-Legierung 0.1-0.9 weight % betrãgt.

Purifying wire after one the Ansprûche 2 to 4, by the fact characterized that the alkaline earth metal beryllium, magnesium and/or calcium ist.

6. Purifying wire after one the Ansprûche 2 to 5, by the fact characterized that the rare-earth metal cerium ist.

7. Procedure for the production of a purifying wire from a Gold-Legierung for contacting from semiconductor components to one of the requirements 1 to 6, by the fact characterized that a GoldLegierung from a) 0.5-0.9 weight % copper, 0.05-0.95 platinum, remainder of gold or from b) 0.5-0.9 weight % copper, 0.0001-0.1 weight % at least one element from the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold erschmolzen, which strand-poured melted alloy the strand diameter usual to a wire with fûr bond purpose pulled and the wire glowed wird.

8. Procedure according to requirement 7, by the fact characterized that to a strand with circular cross section poured the melted alloy wird.

9. Procedure according to requirement 7 or 8, by the fact characterized that a Gold-Legierung with Erdalkalimetallund/or SeltenerdmetalI content of 0,001-0,01 weight % erschmolzen wird.

Procedure after one the Ansprûche 7 to 9, by the fact characterized that a Gold-Legierung with a content of platinum of 0,1-0,9 weight % erschmolzen wird.

11. Procedures after one requirements 7 to 10, thereby characterized that a Gold-Legierung, which enthãlt as alkaline earth metal beryllium, magnesium and/or calcium it erschmolzen wird.

12. Procedure after one of the requirements 7 to 11, by the fact characterized that a Gold-Legierung with cerium as rare-earth metal erschmolzen wird.

13. Procedure after one of the requirements 7 to 12, by the fact characterized that the wire with 300700°C glowed wird.

14. Use of the purifying wire after one the Ansprûche 1 to 6 to the Drahtbonden.

Use according to requirement 14 for wire bonding under Hochfrequenz-Anwendung.

16. Use of the purifying wire after one of the requirements 1 to 6 for connecting semiconductor components in Flip chip technology An ultra-fine wire, for semiconductor component bonding, consists of a gold alloy which contains platinum and/or palladium, optionally together with one or more alkaline earth and/or rare earth metals. An ultra-fine gold alloy wire, for contacting semiconductor components, consists of a gold alloy of composition (by wt.) (a) 0.05-0.95% Cu, 0.05-0.95% Pt and/or Pd and balance Au or (b) 0.05-0.95% Cu, 0.0001-0.1% one or more alkaline earth and/or rare earth metals, 0-1% Pt and/or Pd and balance Au. An Independent claim is also included for production of the above ultra-fine wire by subjecting the continuously cast alloy to drawing to the usual diameter and then annealing. Table IX composition [weight %] firmness [N/mm2] example outer fuel element approx. Ce cu Pt pull-hard 4% stretch 1 remainder 0.8,0.8,600,260 2 remainder 0.001 0.001 0.8,0.8,585,335 3 remainder 0.001 0.001 0.8,0.3,614,330 4 remainder 0.001 0.001 0.9,673,365 remainder 0.001 0.001 0.9,0.9,648,373 6 remainder of 0.01 0.8,585,280 7 (see) * 375,230 *Gold-Legierung with cerium mixture metal in accordance with DE 1,608,161 C Patentansprü¢he 1. Purifying wire from a Gold-Legierung for contacting semiconductor components, by the fact characterized that the Gold-Legierung consists weight % copper, 0.05-0.95 weight % platinum, remainder of gold of 0,5-0,9. 2. Purifying wire from a Gold-Legierung for contacting semiconductor components, by the fact characterized that the Gold-Legierung consists weight % copper, 0.0001-0.1 weight % of 0,5-0,9 at least one element of the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold. 3. Purifying wire according to requirement 2, by the fact characterized that Erdalkalimetallund betrãgt/or SeltenerdmetalI content of the Gold-Legierung 0.001-0.01 weight %. 4. Purifying wire after one the Ansprûche 1 to 3, by the fact characterized that the platinum content of the Gold-Legierung 0.1-0.9 weight % betrãgt. purifying wire after one the Ansprûche 2 to 4, by the fact characterized that the alkaline earth metal is beryllium, magnesium and/or calcium. 6. Purifying wire after one the Ansprûche 2 to 5, by the fact characterized that the rare-earth metal is cerium. 7. Procedure for the production of a purifying wire from a Gold-Legierung for contacting from semiconductor components to one of the requirements 1 to 6, by the fact characterized that a GoldLegierung from a) 0.5-0.9 weight % copper, 0.05-0.95 platinum, remainder of gold or from b) 0.5-0.9 is pulled to weight % copper, 0.0001-0.1 weight % at least one element from the group alkaline earth metal and rare-earth metal, 0-1 weight % platinum, remainder of gold erschmolzen, which melted alloy strand-poured the strand diameter usual to a wire with fûr bond purpose and the wire is glowed. 8. Procedure according to requirement 7, by the fact characterized that the melted alloy is poured to a strand with circular cross section. 9. Procedure according to requirement 7 or 8, by the fact characterized that a Gold-Legierung with Erdalkalimetallund/or SeltenerdmetalI content of 0,001-0,01 weight % erschmolzen wird.

Procedure after one the Ansprûche 7 to 9, by the fact characterized that a Gold-Legierung with a content of platinum of 0,1-0,9 weight % will erschmolzen. 11. Procedure after one requirements 7 to 10, thereby characterized that a Gold-Legierung, which enthãlt as alkaline earth metal beryllium, magnesium and/or calcium will erschmolzen. 12. Procedure after one of the requirements 7 to 11, by the fact characterized that a Gold-Legierung with cerium will erschmolzen as rare-earth metal. 13. Procedure after one of the requirements 7 to 12, by the fact characterized that the wire with 300700°C one glows. 14. Use of the purifying wire after one the Ansprûche 1 to 6 to the Drahtbonden. use according to requirement 14 for wire bonding with application of high frequencies. 16. Use of the purifying wire after one of the requirements 1 to 6 for connecting semiconductor components in Flip chip technology