DEVICE FOR SENSING FLUORINE-BASED GAS AND METHOD FOR MANUFACTURING SAME

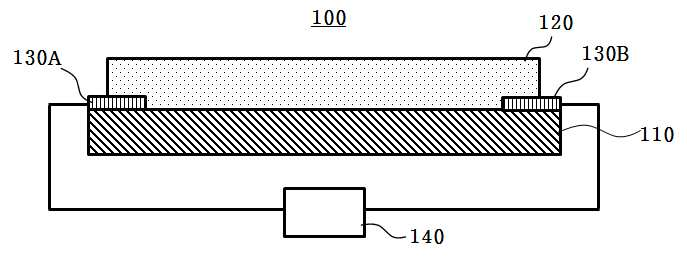

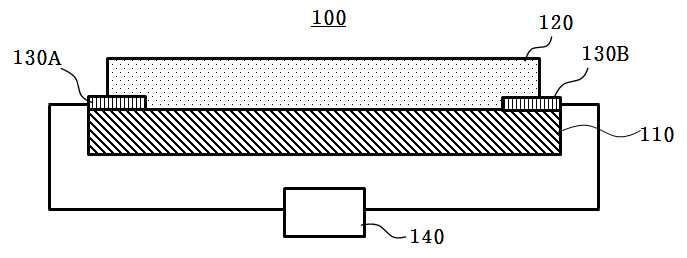

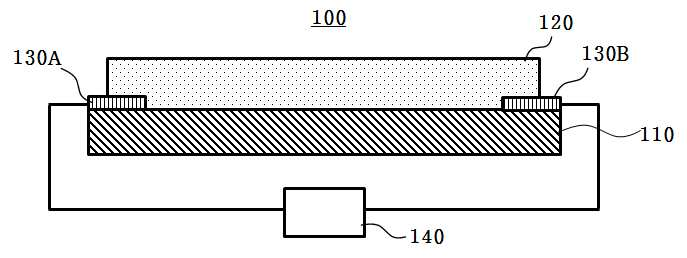

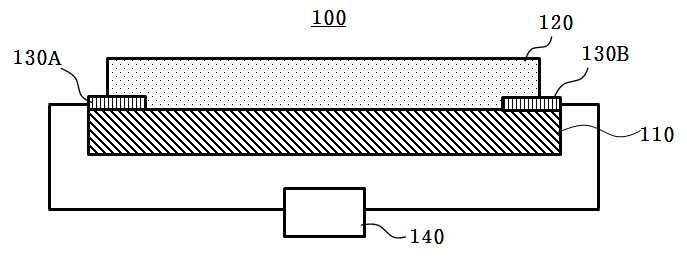

The present invention refers to fluorine-based gas sensing device and manufacturing method relates to search, fluorine-based gas for visually and electrically sensor into a digital signal.. A display fluorine-based gas, such as the semiconductor of processing such as are used in a variety of industries. Such fluorine-based gas a lower concentration [...] the upon inhalation of certain time elapses, causing sound when contacting a that is causing a the in phase and in registration or images such as. a toxic a human body. However, presently fluorine detection and relation to the electrolyte solution in the form of an electrochemical cell using water fluoride (Fluoride) ion sensing a is majority sensor. Fluorine in the form of gas along an upper surface of an intuitive that can detect Freq of sensors, . is. One object of the present invention hydrogen reduced of titanium dioxide color ghange change and its discharge terminal portion through the cf type gas sensing a fluoropolymer gas sensing device for the recording operation. under public affairs number. It is another object of the present invention said fluorine-based gas sensing device for manufacturing method of the recording operation. under public affairs number. Fluorine-based gas sensing device according to an embodiment of the present invention the substrate; and said substrate, hydrogenated titanium dioxide nanoparticles including the fluorine-based gas which react with when the invention also relates to a sensing layer including an. In one in the embodiment, said hydrogenated titanium dioxide nanoparticles comprise a a storage node electrode is performed hydrogenated, and dissociating molecule may include a catalytic metal. In this case, said catalytic metal a palladium (Pd), platinum (Pt), iridium (Ir), rhodium (Rh), silver (Ag), gold (Au) and cobalt (Co) at least one chosen from the group comprising may comprise an. In one in the embodiment, said hydrogenated titanium dioxide nanoparticles comprise a crystalline core and said core which are formed on the surface of amorphous shell material may have a structure including. In one in the embodiment, said fluorine-based gas sensing device the said contact sensitive layer on a substrate a is disposed apart from one another in number 1 and number 2 electrode; and Said number 1 and number 2 electrode is electrically connected to said for measuring the change in electric conductivity-sensing layer further may include measuring device. In the embodiment according to fluorine-based gas sensing device manufacturing method of one of the present invention with the catalytic metal precursor material is dissolved number 1 solution and titanium dioxide nano-particles are dispersed solution is mixed and number 2; said number 1 number 2 solution and solution by irradiating it with UV-rays the mixed solution of said catalytic metal said step of agitating the mixed hot metal doped nano-particle titanium dioxide; said mixture and the second catalyst metal precursor doped titanium dioxide nanoparticles before drawing the yarn and heating it under hydrogen atmosphere in the hydrogenation catalyst metal doping a nanoparticle titanium dioxide; and said hydrogenated catalyst metal doping titanium dioxide nanoparticles comprises applying to the on a substrate in such a manner can be. In the embodiment according to fluorine-based gas sensing device of the present invention other manufacturing method of the hydrothermal on a substrate using a the growing nanostructure titanium dioxide; said titanium dioxide nanostructures a step of deposition of the catalyst metals on; and said catalyst metal is deposited titanium dioxide that nanostructures heat treating the as-hydrogen atmosphere may comprise an. Fluorine-based gas sensing device of the present invention another in the embodiment according to the titanium substrate is anodized titanium substrate surface the porous titanium dioxide anode oxide; said anode titanium-porous titanium dioxide a step of deposition of the catalyst metals on oxide; and said catalyst metal is deposited titanium dioxide that heat treating the as-engage hydrogen atmosphere may comprise an. According to the present invention, hydrogenated titanium dioxide-like nanoparticles of a including-sensing layer/or mass flow caused by changes electric conductivity a color shift and the storage portion fluorine-based gas sensor into a digital signal.. Also according to an embodiment of the present invention Figure 1 shows a method improving conductivity of electrical metal oxide thin film but to explain the order. Figure 2 shows a also palladium doped titanium dioxide ('a'), hydrogenated palladium doped titanium dioxide ('b') andXeF2ping palladium after reaction gas and consisting of titanium dioxide ('c') sensitive layer the Image to their. Figure 3 shows a also palladium doped titanium dioxide nanoparticles ('a', 'd'), hydrogenated palladium doped titanium dioxide nanoparticles (' b ') andXeF2gas and after reaction (' c') of palladium ping titanium dioxide nanoparticles is hR-Doppler images. Figure 4 shows a also palladium doped titanium dioxide nanoparticles ('and Pd-TiO2'), hydrogenated palladium doped titanium dioxide nanoparticles ('H2 RTA') andXeF2palladium after reaction gas and ping titanium dioxide nanoparticles ('XeF2') measured for the current is - voltage curve. Hereinafter, based on a text content of the reference to drawing of the present invention in the embodiment as further described relative to.. Modification of the present invention refers to various variety of forms that can apply may have a low bar, drawing specific embodiment examples illustrated herein, and. rapidly and to reduce a memory. However, this is the present invention with a particular disclosure of the physical shape not defined to be, included within the scope of the present invention all changing a concept and techniques, including replacement water and equalization should understood. Each drawing while describes similar references in a similar was to use components. In drawing with an, the dimensions of the structures elcellent distinctions of the present invention a thread number is formed inside the tie. shown in the drawing as an enhancement. The present application only a term use in a particular embodiment used to describe the e.g. are inputted to a keyboard input terminal, is not intending to be defining the present invention. Contextually representation a plurality of differently it is apparent that without the carelessly, includes multiple representations. In the present application, "comprising" or "having ." a set of terms, such as a specification to the features, number, step, operation, components or a combination of these is designates the feature to which is present does, number to execute another aspect of one or more, step, operation, components or a combination of these existence of back pre possibility or additionally not in the number should understood. Other is not defined, technical or scientific for a term including to the all terms are person with skill in the art in the present invention is in the field of the upwardly urged by equivalent to those that would have been understood have the meanings of wet liquid to flow down. Generally are defined as the dictionary used for, such as terms are on wherein the nodes refining the context of related techniques consistent semantics and having having the meanings must be interpreted to, the present application, become manifest in a do not define, excessively or is ideal for the widest sense of the formal does not interpreted. Also according to an embodiment of the present invention Figure 1 shows a sensing fluorine-based gas. plane from the account for device. Also 1 with a, fluorine-based gas sensing device according to an embodiment of the present invention (100) the substrate (110) and sensitive layer (120) may include a. Said fluorine-based gas as a gas including fluorine addition, the height of element, XeF2, XeF4, XeF6such as of xenon fluoride gas, CF4such as carbon fluoride gas, SF6such as sulfur fluoride gas comprising. Said substrate (110) various materials and structure of a substrate can be used, not one specially number. For example, said substrate (110) at paper, polymer, ceramic, glass, plate can be is used a substrate comprised of. Said sensitive layer (120) the substrate (110) is disposed on the side of the take-, through change or electrically conductive color ghange is used to deposit the fluorine-type gas sensor into a digital signal.. In one in the embodiment, said sensitive layer (120) deposited layers of hydrogenated the nanoparticles of titanium dioxide that may include a. In the present invention 'hydrogenated titanium dioxide' photolithography means of hydrogen by pushing a button to decide the doped titanium dioxide, a titanium dioxide hydrogen ion doped internal as an oxygen ion or titanium ions and can be combined.. And in the present invention 'nanoparticles', this number is such that the mean diameter and a three-dimensional is nanometer scale to hundreds nano powder can as well as having a diameter of nanometer scale to hundreds a linear nanorods includes room to guide the. On the other hand, hydrogen piezoelecric transformer and driving circuit for the titanium dioxide absorbent visible light is generally colorless white or the possibility of yet, hydrogenated titanium dioxide hydrogen the Fermi energy level is lowered and thus the is capable of absorbing visible light in a turbid gray and black or exhibits. As such, a turbid gray and inconspicuous black or titanium dioxide that a hydrogenated which react with when a fluorocarbon-based gas, hydrogenated titanium dioxide internal acid demand of a fluorocarbon ions substituted and is fed once again into the Fermi energy level so that a light grey or white is changed in is. Said sensitive layer (120) deposited layers of hydrogenated titanium dioxide nano particles that have said through color ghange such as is used to deposit the fluorine-type gas sensor into a digital signal.. Hereinafter reference to 1 known as a raw material of the sensitive layer (120) hydrogenation of titanium dioxide that nanoparticles and the fluoropolymer-based gas( XFx (g)). is disclosed for reaction of. [Known as a raw material of the 1] As demonstrated 1 known as a raw material of the, hydrogenated titanium dioxide a fluorocarbon-based gas when it responds by contact with, fluorine ions where high electronegativity is hydrogen ion some oxygen ion to penetrate and the ground probe in its position between the door and the hub when ion or titanium, the reaction between the oxygen and hydrogen ion part generates hydrogen fluoride gas. Invention as described above wherein in front of, through reactions such as is a turbid gray inconspicuous black or titanium dioxide that hydrogenated selection a fluorocarbon-based gas by reaction with a light grey or white changed. While, in one in the embodiment of the present invention, said hydrogenated titanium dioxide nanoparticles comprise a a storage node electrode is performed thereon may include a catalytic metal. For example, hydrogenation of nano powder titanium dioxide for processing to the sprung blade hereinafter, said hydrogenated titanium dioxide inside the nano particles that have hydrogen molecule dissociated a catalyst capable metal. can be doped. Said hydrogen molecule a metal a catalyst capable dissociated, for example, palladium (Pd), platinum (Pt), iridium (Ir), rhodium (Rh), silver (Ag), gold (Au), cobalt (Co) one or more selected from such as may include a. Said catalytic metal such as a doped hydrogenated titanium dioxide nanoparticles comprise a crystalline core and said film made of amorphous core material may have a structure including shell. Said crystalline core other alkylisocyanide rutile crystalline or number may have crystal phase. On the other hand, said sensitive layer (120) said substrate in a variety of method (110) can be formed on. In one in the embodiment of the present invention, said sensitive layer (120) with the catalytic metal ion with a solution containing titanium dioxide dispersion of metal nanoparticle and method for solution after mixing catalytic metal by irradiating it with UV-rays and doping nano-particle titanium dioxide, the under hydrogen atmosphere in a heat treatment is performed on catalytic metals doped hydrogenated titanium dioxide nanoparticle which, same substrate (110) by applying the composition can be formed. In other in the embodiment of the present invention, said sensitive layer (120) a substrate (110) through hydrothermal on titanium dioxide nano structure is connected and after that a depositing a catalytic metal, heat-treatment in the hydrogen atmosphere can be formed by performing. In another in the embodiment of the present invention, said sensitive layer (120) a titanium substrate (110) is anodized titanium screen-porous titanium dioxide on the surface the catalytic metal is deposited on the formed, heat-treatment in the hydrogen atmosphere can be formed by performing. While, fluorine-based gas sensing device according to an embodiment of the present invention (100) the sensitive layer (120) agent such that it contacts said substrate (110) with each other on spaced disposition which is number 1 and number 2 electrode (130A, 130B) and said number 1 and number 2 electrode (130A, 130B) electrically connected to said sensitive layer (120) through the measuring region change electrical conduction of device (140) may include further. Said sensitive layer (120) nanoparticles titanium dioxide that hydrogenation of a fluorocarbon-based gas contact with when it responds by increasing electrical conductivity varies direction. Thus in the present invention such sensing layer (120) change electric conductivity of said sensing device (140) by measuring the contact said fluorine type gas sensor into a digital signal.. Such fluorine-based gas sensing device (100) according to, hydrogenated titanium dioxide-like nanoparticles of a sensitive layer including (120) of a color shift and electric conductivity/or mass flow caused by changes the storage portion fluorine-based gas sensor into a digital signal.. . Is disclosed are hereinafter of the present invention in the embodiment. Hereinafter be described in the in the embodiment of the present invention to a modem solar embodiment efficacy as an anti-part, in the embodiment of the present invention is is not limited by. [In the embodiment] 100 ml of methanol contained in a vessel number 118mg PdCl2added after applicator time 2 to 3 of 25 mg herein added PVP (Polyvinyl pyrrolidone) agitating time 10 forming a solution of the n bit parallel data inputted number 1, number 2 100 ml of methanol contained in a vessel 30 nm in average diameter titanium dioxide nanoparticles adding an 1g to form a solution was a short time, thereby improving the number 2. Number 1 number 2 solution and then solution which is prepared by mixing solution which agitates the time 2 to 3, titanium dioxide nano-particle for doping the palladium (Pd) is irradiated with ultraviolet rays was 2 minutes. Then palladium doped titanium dioxide is centrifuged to through separation of recovery and dry after solvent ethanolamines same water insoluble chemical additives present after glass fiber filter paper (Glassfiber filter paper) layer is deposited on the drying in an oven to a 60 °C. Subsequently sheathedH2/N2 5% gas atmosphere 5 minutes in 400 °C in a heat treatment is performed on the glass fiber filter paper on hydrogenated palladium doped titanium dioxide production method are provided to obtain superior sensing layer is formed to allow the plating solution. [Experiment e.g.] Figure 2 shows a also palladium doped titanium dioxide ('a'), hydrogenated palladium doped titanium dioxide ('b') andXeF2ping palladium after reaction gas and consisting of titanium dioxide ('c') sensitive layer the Image to their. 2 also refers to surface, hydrogenated palladium doped sensitive layer consisting of titanium dioxide ('b') of an assay color or, by using a time hopping code to determining presence grey denseXeF2and the drain of sensitive layer ('b') representing gray and a bright field can be confirm that the user. Thus, hydrogenated palladium doped sensitive layer consisting of titanium dioxide ('b') when using a through color ghange-sensing layer is used to deposit the fluorine-type gas sensor into a digital signal.. Figure 3 shows a also palladium doped titanium dioxide nanoparticles ('a', 'd'), hydrogenated palladium doped titanium dioxide nanoparticles (' b ') andXeF2gas and after reaction (' c') of palladium ping titanium dioxide nanoparticles is hR-Doppler images. Also 3 with a, palladium doped [...] dioxide dispersed in the aqueous media in crystalline cylindrical body an area nanoparticles, by using a time hopping code, hydrogenated palladium doped titanium dioxide nanoparticles inner portion and a property of crystalline structure but the surface by reaction with hydrogen amorphous layer is formed about 3 nm thickness been.. Figure 4 shows a also palladium doped titanium dioxide nanoparticles ('and Pd-TiO2'), hydrogenated palladium doped titanium dioxide nanoparticles ('H2 RTA') andXeF2palladium after reaction gas and ping titanium dioxide nanoparticles ('XeF2') measured for the current is - voltage curve. Also 4 refers to surface, hydrogenated palladium doped titanium dioxide nanoparticlesXeF2gas which react with current value at a time when about 100 times elevated capable of confirming the.. Fluorine is introduced into an titanium dioxide is (F) is n - type donor between an output terminal and an external Fermi energy( EF)for the conduction band (conduction band) do lifting the feed up to the top near. Thus hydrogenated palladium doped titanium dioxide in the case of forming the layer sensing bulk material into nano sized particles in, change electric conductivity-sensing layer through the cf type gas sensor into a digital signal.. But in said of the present invention preferred embodiment described by referring to, is a classic mirror server art corresponding a lead one skilled patent if so, the of the present invention concept and region within such a range that causes no away from the present invention various modified and change can be 2000 database for each consumer. 100: fluorine-based gas sensing device 110: substrate 120: sensitive layer 130A, 130B: electrode 140: measuring device A device for sensing fluorine-based gas is disclosed. The device for sensing fluorine-based gas comprises: a substrate; and a sensing layer disposed on the substrate and comprising hydrogenated titanium dioxide nanoparticles to change a color thereof when the sensing layer reacts to fluorine-based gas. The device for sensing fluorine-based gas can sense the fluorine-based gas through a color change of the sensing layer. COPYRIGHT KIPO 2016 Substrate; and said substrate, hydrogenated titanium dioxide nanoparticles including the fluorine-based gas which react with when the invention also relates to fluorine-based gas sensing device including a sensing layer. According to Claim 1, said nanoparticles comprise a titanium dioxide that hydrogenated a storage node electrode is performed hydrogenated catalytic metal, and dissociating molecule characterized in including a fluoropolymer gas sensing device. According to Claim 2, said catalytic metal a palladium (Pd), platinum (Pt), iridium (Ir), rhodium (Rh), silver (Ag), gold (Au) and cobalt (Co) chosen from the group comprising least one of the is characterized in including a fluoropolymer gas sensing device. According to Claim 1, said hydrogenated titanium dioxide nanoparticles comprise a crystalline core and said core which are formed on the surface of amorphous shell characterized in including a fluoropolymer gas sensing device. According to Claim 1, said said contact sensitive layer on a substrate a is disposed apart from one another in number 1 and number 2 electrode; and said number 1 and number 2 electrode is electrically connected to said for measuring the change in electric conductivity-sensing layer measuring device is characterized in further including a fluoropolymer gas sensing device. Catalytic metal precursor material is dissolved number 1 solution and titanium dioxide nano-particles are dispersed solution is mixed and number 2; said number 1 number 2 solution and solution by irradiating it with UV-rays the mixed solution of said catalytic metal said step of agitating the mixed hot metal doped nano-particle titanium dioxide; said mixture and the second catalyst metal precursor doped titanium dioxide nanoparticles before drawing the yarn and heating it under hydrogen atmosphere in the hydrogenation catalyst metal doping titanium dioxide nanoparticle a; and said hydrogenated catalyst metal doping titanium dioxide nanoparticles on a substrate including applying a manufacturing method of device sensing fluorine-based gas. Hydrothermal on a substrate using a the growing nanostructure titanium dioxide; said titanium dioxide nanostructures a step of deposition of the catalyst metals on; and said catalyst metal is deposited titanium dioxide that nanostructures hydrogen atmosphere heat treating the as-manufacturing method of including fluorine-based gas sensing device. Titanium substrate is anodized titanium substrate surface the porous titanium dioxide anode oxide; said anode titanium-porous titanium dioxide a step of deposition of the catalyst metals on oxide; and said catalyst metal is deposited titanium dioxide that engage hydrogen atmosphere heat treating the as-manufacturing method of including fluorine-based gas sensing device. According to one of Claim 6 to Claim 8, said catalytic metal a palladium (Pd), platinum (Pt), iridium (Ir), rhodium (Rh), silver (Ag), gold (Au) and cobalt (Co) chosen from the group comprising characterized in including least one of the gas sensing device manufacturing method of a fluoropolymer.