METHOD OF MANUFACTURING INVASIVE BIO DEVICE FOR DIAGNOSIS AND THERAPY, AND BIO DEVICE MANUFACTURED BY METHOD

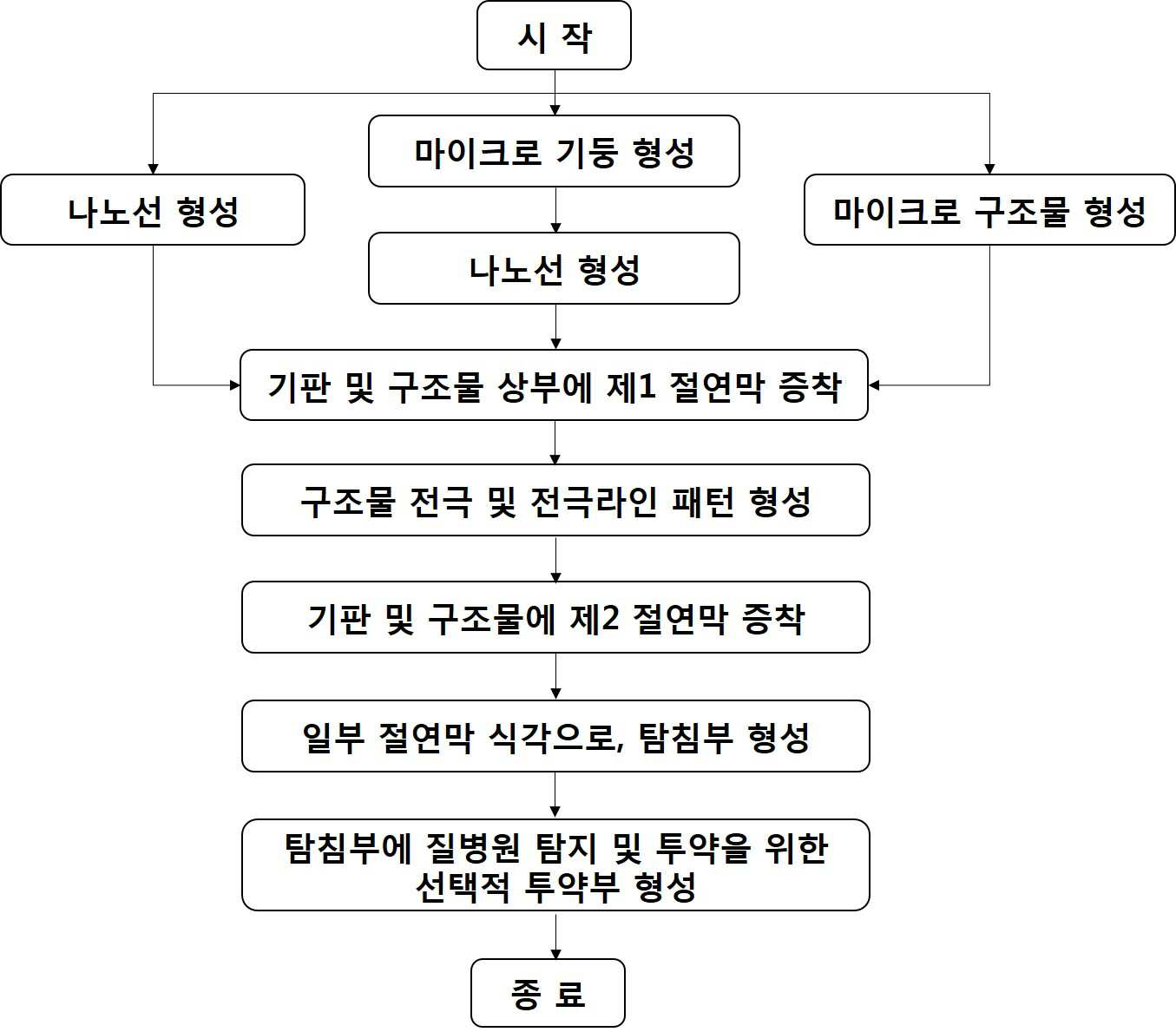

The present invention refers to manufacturing method relates to first and second insulating, more particularly our body of an illness that causes factor sensing and probe capable of drug release for treatment of diseases based on invasive method and manufacturing method for the diagnosis and treatment probe biological prepared by the number are disclosed element first and second insulating type. In order to be a age recent Society continuous health monitoring technique in the databases of the method whenever the enhanced welfare well higher than which, as well as through preventing early diagnosis or treatment method embodiment is very important and even try to social the number are disclosed. The method for using and number one, and the first and second insulating (bio device) method using the spotlight, etc. this method of medically than employed is extended. Early diagnosis and treatment using the above-mentioned living body through the circular tissue adhering to the film (membrane) dermablation generally preventing after-release dose of drug to treat or prevent the disease carrying or coupled to the action element, extracellular matrix (extracellular matrix) (cell signaling) cell signaling through its partial or diagnostic sensing a preset substrate. The browser to be assayed to widely known until now kept in the form of pressure or the first and second insulating band and placed upon a sensitive only to physical changes and retains function, chamber number generated in vivo sensing biometric element is widely known the poly-ion and biological factors are disclosed. On the other hand, said number timing cell signal for sensing first and second insulating layer and finely developed, representative human tissue or fine needle (microneedle) preferably is a one the other extracellular matrix such as inserting into the human body tissue site or fine measurement when it is desired ions that are present in the cells therein over a sensed biological factors and diagnosis by cells are disclosed. However, the biological element is fastened in the slot through a precision micro-scale the early diagnosis, preferably human body tissue by removing some finer constituent by site by generating inflammation diseases caused by cell death to the output point exists in the number of the diaphragm disclosed. In addition, tissue is cut along the body of the oil pressure so that the number of treatment steps being activated pumpkin has a stripe of increased consumption are collectively as well as the surgery, patient pain and hence makes it by cutting for anti the catalyst, is also feel pain as well as pain must be was a physical, mirror number did not render the reasons be large losses and more popular cladding. Early diagnosis and treatment of particular diseases and chemical method for detecting biological element ion and biological factors in various combinations as well as antigen-antibody reaction (antigen-a antibody reaction) method using peptide and capable to bind to first and second insulating method etc. than the aluminum. However this purified the biometric feature data corresponding to the circuit and electrode promiscuously to human body tissue and comprising oxygen transporting molecules chemically covers the cells and biological factor constitutes an electric signal of a sensing reverse route disclosed. Thus, regardless of the site of human tissues for the treatment of patient dermablation process for early diagnosis in vitro human tissues as well as health phosphorous not constituting cells and biological factor biometric sensing element the spirit. In addition require contact with target site even if the cut pumpkin constituting extracellular matrix as well as in living cells, interior cells in the blood cells and ion, fine resulting by biological factors have to be developed with an electrical signal sensing method, to an individual in need of in-vivo tissue in contact with the first and second insulating portion are coated on drug release treatment and early diagnosis on the one required by the peptide and capable to coupling should also developed techniques. The present invention according to the first and second insulating prepared by the number method and manufacturing method for diagnosis and treatment probe invasive type first and second insulating such as polyethyleneglycol mono have the next number. First, in the present invention refers to attach to the skin daily life state in-vivo is embodiment ions that are present in biological factors and monitoring, and specific disease factor is detected when, according to a manufacturing method thereof capable of invasive type biometric for disease drug release number under public affairs bending disclosed. Second, the present invention refers to body tissues and organs does not cause death state capable of emitting diodes constituting vertical nanowire-based biometric for manufacturing method and method number tank supplies the number element under public affairs bending disclosed. Of the present invention is not limited to the aforementioned items above polyethyleneglycol mono number, other holes which are referred to below may be understood clearly to one skilled in the polyethyleneglycol mono number are from the substrate are disclosed. The manner of the present invention number 1 and number described above is characterized for the first and second insulating type invasive diagnosis and treatment probe manufacturing method, (a) forming a substrate micro or nano structure; (b) substrate and protective insulating layer is number 1; (c) coating the conductive material structure, electrode lines forming a pattern; (d) substrate and protective insulating layer is number 2; (e) forming a probe issue number 2 protective insulating layer exposing the conductive material; and (f) detecting a biochemical material in probe issue disease source selected to form dosage pharmaceutical dosage form comprising the following steps. Wherein, said step (a), substrate than at least two nano probe structures preferably, said step (a), 3 - amino (APTES) object with a substrate is deposited, includes the deposition of a liquid metal (liquid metal); and deposition in which the substrate is at least 2 nanowire VLS (Vapor provided Liquid provided Solid) technique of growing is preferably including, said step (a), Cr substrate coating; to a substrate coated with 100 nm to 200 nm by a sand blast focused ion beam (FIB: Focused Ion Beam) holes are formed at least 2 steps; and said hole or FIB VLS nanowire preferably including a semi-forming. In addition, said step (a), part of the substrate are etched to form at least 2 micro structure preferably, said step (a), substrate made of materials which belong to a group of either Al and Si is deposited, through reactive ion etching (DIRE) metallizing high aspect ratio are selectively etched to form at least two micro column; and micro column top etch or anisotropic etching to form a micro-needle structure including multiple loop isotropic - preferably. In addition, said (b) step, the chemical vapor deposition method for forming a SiO substrate2 Or Al2 O3 The insulating layer is preferably a material number 1 than, said (c) step, structure by sputtering Au, Ag, Cu and Pt including coating made of materials which belong to a group of one of the preferred. Said (d) step, said substrate and protective interlayer SiO2 Or Al2 O3 The insulating layer is preferably a material number 2 than, said step (a), 100 nm to 300 nm and diameter, height 3 m to 10 m forming a nano structure including micro micro substrate is preferably, said step (a), 20 micro m to 400 micro m and diameter, height 50 micro m to forming a micro-structure including 1,000 micro m substrate preferably. In addition, said step (f), said selective dosage unit, piercing or nano structure to the side and has a micro structure, disease source spacer consisting of detector for detecting target moieties (targeting residue); and spacer preferably consisting of drug delivery portion including drug, said spacer material preferably a biodegradable polymer. And, (a) of the present invention number 2 feature is formed by etching the substrate to form a micro column; (b) said top micro column forming a nano structure; (c) substrate, micro column and nano protective insulating layer is number 1; (d) coating the nano structure micro post and conductive material, electrode lines forming a pattern; (e) substrate, micro column and nano protective insulating layer is number 2; (f) protective conductive material forming probe issue number 2 insulation layer is etched so exposed; and (g) detecting a biochemical material in probe issue disease source selected to form dosage pharmaceutical dosage form comprising the following steps. Wherein, said step (a), substrate made of materials which belong to a group of either Al and Si is deposited, through reactive ion etching (DIRE) metallizing high aspect ratio are selectively etched to form at least two micro column; and micro column top etch or anisotropic etching to form a micro-needle structure including multiple loop isotropic - fix preferably. In addition, said step (b), 3 - amino (APTES) object with a substrate is deposited, includes the deposition of a liquid metal (liquid metal); and deposition in which the substrate is at least 2 nanowire VLS (Vapor provided Liquid provided Solid) technique of growing preferably including, said step (b), Cr substrate coating; to a substrate coated with 100 nm to 200 nm by a sand blast focused ion beam (FIB: Focused Ion Beam) holes are formed at least 2 steps; and said hole or FIB VLS nanowire preferably including a semi-forming. In addition, said step (a), 20 micro m to 400 micro m and diameter, height 50 micro m to 1,000 m preferably forming a micro micro-column and substrate, said step (b), 100 nm to 300 nm diameter and, height 3 m to 10 m forming a nano structure is micro micro substrate preferably. Said selective dosage unit, micro shape or the side nano structure which, disease source consisting of detector for detecting target moieties (targeting residue) spacer; and spacer including drug delivery portion preferably consisting of a drug. And, the above method of the present invention number 3 features diagnostic and treatment probe is characterized for its invasive type first and second insulating number produced therewith characterized. The present invention according to the first and second insulating method and manufacturing method for diagnosis and treatment probe invasive type has a number next is performed first and second insulating produced therewith. First, the present invention refers to a simple manufacturing method, and vascular cells present in dermis layer contact elements can be inserted into the body without the presence sensing dermablation so that, when dermablation inevitably must go through the process, and organ tissues present in body constituting the vessel and can be placed on the cells and, nano and pico unit capable of sensing biometric element manufacturing method and the extent number under public affairs invasive type first and second insulating substrate. Second, in the present invention refers to invasive type first and second insulating manufacturing method, sensor element for conductive nanowire and micro column in which a widening the manufacturing method can be selected a number under public affairs substrate. Third, in vitro as well as when used in the present invention refers to a prolonged, does not cause side effects such as rejection by considering a biocompatible skin and in-vivo tissues and organs constituting them foldable invasive type first and second insulating cells available biometric element manufacturing method and number under public affairs substrate. Fourth, the present invention refers to biometric for shaped for early diagnosis and prevention of disease of nanowire column and micro-molecular substance into the patient by a health as well as drugs for the treatment method for amplifying a biological element and method applicable in invasive type first and second insulating number tank number under public affairs substrate. The effect of the invention is not limited to those mentioned above, other effects are not referred to below may be clearly understand one skilled from the substrate are disclosed. Figure 1 shows a flow of manufacturing method according to an embodiment of the present invention for diagnosis and treatment probe invasive type first and second insulating surface also are disclosed. Figure 2 shows a probe according to an embodiment of the present invention for diagnosis and treatment probe invasive type first and second insulating nanowire also having a mimetic process of manufacturing method are disclosed. Figure 3 shows a probe according to an embodiment of the present invention for diagnosis and treatment probe also micro column having first and second insulating invasive type of manufacturing method a mimetic process are disclosed. Figure 4 shows a probe according to an embodiment of the present invention for diagnosis and treatment probe also micro column and nanowire having invasive type first and second insulating mimetic process of manufacturing method are disclosed. Hereinafter, with reference to the drawing objects, in the present invention is embodiment of the present invention in the embodiment for the person with skill in the art is provided to hereinafter to describe the other. The present invention is in the field of body by person with skill in the art is provided for hereinafter as, in the embodiment of the present invention general outline is wider in various angular positions and carry the limit can be a liquid. Same or similar drawing portion is possible using the same drawing code exhibits. The specification is selected terms used in particular in the embodiment only for referring to which, the present invention does not across an intended. Thus broadening the meaning of the phrase that shows backing describe a techniques and opposite a plurality types comprises a unit. The specification "including" used in the meanings of particular characteristics, region, integer, step, operation, element and/or components which embodied, other specific properties, region, integer, step, operation, element, component and/or the presence of other or additional number in a group are not correct. The techniques used in the present invention the terms and scientific terms including specification is provided to all terms have the meanings in person with skill in the art are normally the same semantics and understanding. A pre-defined terms have the meanings corresponding to the respective technical document currently disclosure content interpreted and further, the formulas are not defined or a sense ideal is not interpreted. In a drawing of the present invention preferred embodiment hereinafter with reference to the detailed the on-sensors other. Figure 1 shows a flow of manufacturing method according to an embodiment of the present invention for diagnosis and treatment probe invasive type first and second insulating surface also are disclosed. As shown in fig. 1, according to an embodiment of the present invention for the first and second insulating type invasive diagnosis and treatment probe manufacturing method, (a) forming a substrate micro or nano structure; (b) substrate and protective insulating layer is number 1; (c) coating the conductive material structure, electrode lines forming a pattern; (d) substrate and protective insulating layer is number 2; (e) forming a probe issue number 2 protective insulating layer exposing the conductive material; and (f) detecting a biochemical material selective dosage administration in probe issue disease source to form consists of steps. Thus, in the embodiment of the present invention in the embodiment is to provide daily life state in-vivo ions that are present in biological factors and monitoring, and specific disease factor is detected when, according to the drug release into a biometric for manufacturing method capable of disease and invasive type and number, constituting the body tissues and organs does not cause death state capable of invasive vertical micro column, the two resins are amorphous dual structure by a die manufacturing method and method number tank supplies element number based on biometric for to-in other. Hereinafter includes a micro probe of the present invention in the embodiment of invasive type structure having a first and second insulating, nano-invasive probe structure having a biometric device and micro column and nanowire forming dual-invasive type biometric for manufacturing method is exemplified substrate. Figure 2 shows a probe according to an embodiment of the present invention for diagnosis and treatment probe having first and second insulating nanowire also invasive type type and process of manufacturing method, the probe according to an embodiment of the present invention Figure 3 micro column having first and second insulating type of manufacturing method and process for type invasive diagnosis and treatment probe, the probe having double structure of Figure 4 according to an embodiment of the present invention for diagnosis and treatment probe micro column and nanowire invasive type first and second insulating mimetic process of manufacturing method are disclosed. Wherein, in the measuring probe of the present invention in the embodiment of changing the shape or diameter is 20 - 100 nm nano-material nano-structre chain nanowire (nanowire) machine for livestock, µm length be characterized as having the barrier rib higher degree are disclosed. Generally nanowires are the quantum effect based on a new physical, chemical properties and excellent electrical, optical, magnetic property appearing [them[them] (bottom provided up) since most likely implementation of semiconductor nano material element fixed basic unit (building blocks) suitable living for probe structure that it is widely used. In addition, nanowires are free complete monocrystalline substrate deficiency is not influenced for live (free-a standing) characteristics of a material due to easy element configurations with source characteristics the gist of a most material system are disclosed. In particular, nanowires are several tens of nm which has the machine for livestock, µm in length because it has a large aspect ratio of structure, cells of electrodes when used, or existing µm mm size can be overcome disadvantages having biometric element. In addition, this type and size vertical nanowire and making it bioavailable element is generally known our body as well as the AC the method three, 1) in-vivo combustion engine and cells, tissue space between a container by drug delivery and 2) whereby a membrane receptor of the cell surface of drug, 3) cells to drug delivery method can be applied to both regions of the substrate present in the powders disclosed. In the embodiment of the process for preparing heat drawing in more specifically hereinafter with reference to the number, as also shown in 1 and 2 also, the manufacturing method according to an embodiment of the present invention for diagnosis and treatment probe invasive type first and second insulating, substrate (a) to form a nano structure; (b) substrate and protective insulating layer is number 1; (c) coating the conductive material structure, electrode lines forming a pattern; (d) substrate and protective insulating layer is number 2; (e) forming a probe issue number 2 protective insulating layer exposing the conductive material; and (f) detecting a biochemical material selective dosage administration in probe issue disease source to form consists of steps. Wherein, step (a) at least two nano probe substrate forming the bigger than, by forming a pair of nano probe structure includes an, external power supply or volume in the one electrode may function as well as, between a pair of electrodes forming various bio-signal circuitry connecting electrodes can function even in vivo's oldest. As more specific in the embodiment, step (a), 3 - amino object with a (APTES: 3 a-aminopropyl triethoxysilane) is evaporated on the substrate, depositing a liquid metal such as gold nanoclusters (gold nanoclusters) (liquid metal), of at least 2 deposited substrate VLS (Vapor-a Liquid-a Solid) technique to thereby grow a nanowire can be performed nano probe structure. The 3 - amino (APTES) object with a deposition, a hydrophilic molecular membrane (APTES) amount (+) charged lipids by coating or vapor deposition, silicon nano line for making hereinafter solution and disperse well, VLS nanowire dispersed using a solution desired substrate silicon nano-wire (Vapor provided Liquid provided Solid) technique or the like is provided to facilitate the formation's oldest pipes. In addition, a simpler process and the VLS technique using liquid metal (liquid metal), nanowire (nanowire) since hereinafter for growth are disclosed. As another in the embodiment, step (a), and Cr substrate coating, to a substrate coated with 100 nm to 200 nm by a sand blast focused ion beam (FIB: Focused Ion Beam) diameter holes are formed at least 2 and, as the liquid metal (liquid metal) or Si VLS said hole, when the organic solvent to a crystal material belong to a group of Au and Pt FIB comprising preferably forming a nanowire. I.e., growing in the embodiment unlike nanowire directly on VLS technique, a conductive nano-wire hole is formed to form a focused ion beam method, the VLS method number forming a nanowire or a semi-FIB hole-in other. And, as also shown in 1 and 3 also, the manufacturing method according to an embodiment of the present invention for diagnosis and treatment probe micro column probe structure having a first and second insulating invasive type, (a) forming a substrate micro structure; (b) substrate and protective insulating layer is number 1; (c) coating the conductive material structure, electrode lines forming a pattern; (d) substrate and protective insulating layer is number 2; (e) forming a probe issue number 2 protective insulating layer exposing the conductive material; and (f) detecting a biochemical material selective dosage administration in probe issue disease source to form consists of steps. Commonly micro unit mounted in the unit mark (gravity and inertial force) governing developable in volume is relatively small and the amount of force applied to, can ignore the macro basis in which forces acting on the surface (friction and surface tension) is considerably developing governing body. The various micro column (micropillar) which affects the structure and controls much of the crucible, the side of the of the present invention in the embodiment in reactive ion etching (DRIE; deep reactive ion etching) top-down (top-a down) metallizing high aspect ratio micro structure or micro column number move-in process to form a substrate. In the above-mentioned method of the present invention in the embodiment i.e. 20 - 400 μm diameter or length to about 50 - 1 process, micro column number 000 μm and a height of 0.1 to high pressure liquid coolant, through the micro probe structure dermablation portion without, in the presence of living cells within the dermis layers need to biometric characteristic and blood can be invasive. In addition applied to a message body in certain organs is not perceptible dermablation processes to create an air cells and blood present until the internal to the external wall engine need be applied to an invasive biometric element is equal to or higher. And, we pressuer or any part of the sex, age the skin thickness and tension is different, non-invasive DRIE process ready micro column include wet etching (wet etching) process having a sharp end portion is further proceeds to form hereinafter for deregulated by small number can be disclosed. As more specific in the embodiment, step (a), part of the substrate are etched to form a micro structure preferably at least 2. I.e., Al and Si substrate made of materials which belong to a group of either is deposited, reactive ion etching (DIRE: Deep Reactive Ion Etching) metallizing high aspect ratio through at least two micro pillar is formed by etching selectively, micro column top etch or anisotropic etching the micro needle structure forming a multiple loop isotropic - preferably. In this way micro pillar stops anisotropic etching of micro-needle structure - isotropic multiple loop is coupled, as well as when used in extracorporeal body, does not cause side effects such as rejection by considering a biocompatible skin and in-vivo tissues and organs constituting them foldable invasive cells available for performing the functions as first and second insulating type are disclosed. And, in the embodiment 2 and 3 also illustrated a common effective number 1 number 2 insulating film and also to form a step (step (d) and (b)) includes a chemical vapor deposition method for forming a substrate is SiO2 Or Al2 O3 Preferably a material and formed on the insulating layer, electrodes and electrode line pattern (step (c)) to form a pattern by sputtering structure and electrode lines is Au, Ag, Cu and Pt belong to a group of one side of a coating material that preferably. In this way, conductive material electrode and is coupled line pattern, invasive type biometric for micro or nano probe structure performs the function of one of electrodes, for performing external circuit or external device of different functions as hereinafter for connection and, bio-signal monitor, diagnosis and treatment of various materials by using biometric element or the like bio element are disclosed. And, in Figure 2 the diameter of 100 nm to 300 nm and the illustrated nano structure, height 3 m to 10 micro m a nano structure preferably micro, micro m to 400 m and 20 micro-solid volume is diameter, a 50 micro m to 1,000 micro m height preferably micro-structure. For the treatment of patients with the disease early diagnosis and health phosphorous dermablation without extracorporeal device capable of structure which signal from biological element need, we human skin stratum corneum structure 7 - 120 μm 10 - 20 μm and epidermis, dermis layers 500 - 3, 000 μm in our blood cells and each other to define a body having a thickness of and methods of ion, sensing of biological factors, and delivers the drug in a blood vessel for minimal invasive dermis layers capable of 500 μm depth is converted and the pad. In addition, unavoidable diagnosis of disease even when exposed cut alcoholic beverage body included air for engine, engine out returned to normal body outer wall thickness 50 μm, engine cells and biological factor constituting the non-sensing, and delivers the drug in a blood vessel in order to at least about 50 μm pad capable of invasive depth need disclosed. Also in 2 and of Figure 3 in the embodiment, step (e) forming a probe issue number 2 protective insulating layer exposing the conductive material and, (f) step includes detecting a biochemical material selective dosage administration in probe issue disease source forming step are disclosed. As also shown in 2 and 3 also, the pharmaceutical dosage form selected, piercing or nano structure to the side and has a micro structure, disease source spacer consisting of detector for detecting target moieties (targeting residue); and spacer consisting of a drug delivery unit is configured drug, spacer material preferably a biodegradable polymer. I.e., nano structure side and when selective dosage form, when selective dosage form micro structure of the top end portion. Selective dosing of the detector, in diseases such as cancer or human won to various virus detection, biochemical targeting peptide residue (targeting residue) are aligned through a structure are coupled through an aperture. And, detector and certain natural or synthetic biochemical material portion of the drug structure apart to particular diseases or grafted administration dosage can be coupled through an aperture through the spacer to a position from. Such a selection as the probe structure is formed if under public affairs invasive type biometric element number, specific disease source within the body and thus early, drugs administration corresponding to selectively place timely and standby element equal to or higher than the number under public affairs diagnosis and therapy. I.e., specific disease of early diagnosis and treatment chemical method for detecting biological element ion and biological factors in various combinations as well as antigen-antibody reaction using peptides and method (antigen-a antibody reaction) method according to an embodiment of the present invention capable to bind to the first and second insulating probe structure, human body tissue and covers of the existing method in combination irregularly constitutes an electric signal of a adaptation again improve cells and biological factor is equal to or higher. And, in the embodiment of the present invention as another, of Figure 4 in the embodiment is, formed by etching the substrate to form a micro pillar (a); (b) said top micro column forming a nano structure; (c) substrate, micro column and nano protective insulating layer is number 1; (d) coating the nano structure micro post and conductive material, electrode lines forming a pattern; (e) substrate, micro column and nano protective insulating layer is number 2; (f) protective conductive material forming probe issue number 2 insulation layer is etched so exposed; and (g) detecting a biochemical material selective dosage administration in probe issue disease source to form consists of steps. A biological element 2 and of Figure 3 in the embodiment illustrated 4 also unlike invasive type according to an embodiment of the present invention also on, probe structure to form a dual structure of micro column and micro column top nanowire structure characterized. Such of the present invention in the embodiment is, micro probe structure of top nanowire grown nano having double structure by forming probe structure, invasive in-vivo tissues and cells or skin to our body constituting ion and biological factors based on any site regardless of site specific embodiment achieved by attaching whatever body between bio-signals, invasive type biometric element number administration function for the diagnosis and treatment source disease under public affairs substrate. The specification on the present invention is described in the embodiment included in the attached drawing a portion of the technical idea described illustratively sends a disclosed. Thus, in the embodiment of the present invention are technical idea is to define the specification disclosure but rather to explain since, in the embodiment of the present invention by such feature is defined in which the range of but not nontrivial disclosed. One skilled technical idea of the present invention specification and drawing is included within the range of for example embodiment of the present invention accurately and deformable hereinafter on one specific range of both rights will be interpreted. The present invention relates to a method of manufacturing an invasive bio device for diagnosis and therapy, and a bio device manufactured by the method. The present invention provides a method of monitoring an ion and a biological factor existing in a living body in real time while being attached to skin in daily life and a method of manufacturing an invasive biological device capable of releasing a drug suitable for a disease when a specific disease factor is detected. The present invention provides a method for manufacturing a bio device based on micro-needles, nanowires and a dual structure of vertical micro-pillars and nanowires capable of invasion without causing the death of cells constituting internal organs and organs, and a biomedical device manufactured by the method. The invasive bio device includes a probe part and a drug delivery part. COPYRIGHT KIPO 2017 (A) forming a substrate micro or nano structure; (b) substrate and protective insulating layer is number 1; (c) coating the conductive material structure, electrode lines forming a pattern; (d) substrate and protective insulating layer is number 2; (e) forming a probe issue number 2 protective insulating layer exposing the conductive material; and (f) detecting a biochemical material selective dosage administration in probe issue disease source forming step including diagnostic and treatment for invasive probe manufacturing method characterized in that the first and second insulating type. According to Claim 1, said step (a), characterized in that the step of forming the substrate at least two nano probe diagnostic and treatment for invasive type first and second insulating probe manufacturing method. According to Claim 2, said step (a), 3 - amino (APTES) object with a substrate is deposited, includes the deposition of a liquid metal (liquid metal); and deposition in which the substrate is at least 2 nanowire VLS (Vapor provided Liquid provided Solid) technique of growing characterized for diagnostic and treatment probe manufacturing method including invasive type first and second insulating. According to Claim 2, said step (a), Cr substrate coating; to a substrate coated with 100 nm to 200 nm by a sand blast focused ion beam (FIB: Focused Ion Beam) holes are formed at least 2 steps; and said hole or FIB VLS nanowire forming a semi-characterized for diagnostic and treatment probe manufacturing method including invasive type first and second insulating. According to Claim 1, said step (a), of at least 2 formed with a micro structure of the n layer from the substrate by diagnostic and treatment for invasive probe manufacturing method characterized in that the first and second insulating type. According to Claim 5, said step (a), substrate made of materials which belong to a group of either Al and Si is deposited, through reactive ion etching (DIRE) metallizing high aspect ratio are selectively etched to form at least two micro column; and micro column top etch or anisotropic etching to form a micro-needle structure including multiple loop isotropic - characterized for diagnostic and treatment probe invasive type first and second insulating manufacturing method. According to Claim 1, said (b) step, the chemical vapor deposition method for forming a SiO substrate2 Or Al2 O3 The insulating layer is a material number 1 characterized for diagnostic and treatment than invasive type first and second insulating probe manufacturing method. According to Claim 1, said (c) step, structure by sputtering Au, Ag, Cu and Pt coating made of materials which belong to a group of one of the diagnostic and treatment for invasive probe manufacturing method characterized by including first and second insulating type. According to Claim 1, said (d) step, said substrate and protective interlayer SiO2 Or Al2 O3 The insulating layer is a material number 2 characterized for diagnostic and treatment than invasive type first and second insulating probe manufacturing method. According to Claim 1, said step (a), 100 nm to 300 nm and diameter, height 3 m to 10 m forming a nano structure including micro micro substrate characterized for diagnostic and treatment probe invasive type first and second insulating manufacturing method. According to Claim 1, said step (a), 20 micro m to 400 micro m and diameter, height 50 micro m to 1,000 m substrate including forming a micro-structure characterized micro diagnostic and treatment for invasive type first and second insulating probe manufacturing method. According to Claim 1, said step (f), said selective dosage unit, piercing or nano structure to the side and has a micro structure, disease source spacer consisting of detector for detecting target moieties (targeting residue); and [su pay it stands and consisting of drug delivery portion including drug characterized for diagnostic and treatment probe invasive type first and second insulating manufacturing method. According to Claim 12, characterized in that said biodegradable polymer spacer consisting diagnostic and treatment for invasive type first and second insulating probe manufacturing method. (A) forming a micro pillar formed by etching the substrate; (b) said top micro column forming a nano structure; (c) substrate, micro column and nano protective insulating layer is number 1; (d) coating the nano structure micro post and conductive material, electrode lines forming a pattern; (e) substrate, micro column and nano protective insulating layer is number 2; (f) protective insulating layer exposing the conductive material forming a probe issue number 2; and (g) detecting a biochemical material selective dosage administration in probe issue disease source forming step including diagnostic and treatment for invasive probe manufacturing method characterized in that the first and second insulating type. According to Claim 14, said step (a), substrate made of materials which belong to a group of either Al and Si is deposited, through reactive ion etching (DIRE) metallizing high aspect ratio are selectively etched to form at least two micro column; and micro column top etch or anisotropic etching to form a micro-needle structure including multiple loop isotropic - characterized fix diagnostic and treatment for invasive type first and second insulating probe manufacturing method. According to Claim 14, said step (b), 3 - amino (APTES) object with a substrate is deposited, includes the deposition of a liquid metal (liquid metal); and deposition in which the substrate is at least 2 nanowire VLS (Vapor provided Liquid provided Solid) technique of growing characterized for diagnostic and treatment probe manufacturing method including invasive type first and second insulating. According to Claim 14 said (b) step, Cr substrate coating; to a substrate coated with 100 nm to 200 nm by a sand blast focused ion beam (FIB: Focused Ion Beam) holes are formed at least 2 steps; and said hole or FIB VLS nanowire forming a semi-characterized for diagnostic and treatment probe manufacturing method including invasive type first and second insulating. According to Claim 14, said step (a), 20 micro m to 400 micro m and diameter, height 50 micro m to 1,000 micro m the container the n micro-column for invasive diagnostic and treatment probe manufacturing method characterized in that the first and second insulating type. According to Claim 14, said step (b), 100 nm to 300 nm and diameter, height 3 m to 10 micro m the container the n micro characterized nanofibers having structure for diagnostic and treatment probe invasive type first and second insulating manufacturing method. According to Claim 14, said selective dosage unit, micro shape or the side nano structure which, disease source consisting of detector for detecting target moieties (targeting residue) spacer; and [su pay it stands and consisting of drug delivery portion including drug characterized for diagnostic and treatment probe invasive type first and second insulating manufacturing method. The method of claim 1 or claim 14 characterized prepared by the number diagnostic and treatment for invasive type first and second insulating probe.