기판 세정 장치 및 이를 이용한 기판 세정 방법

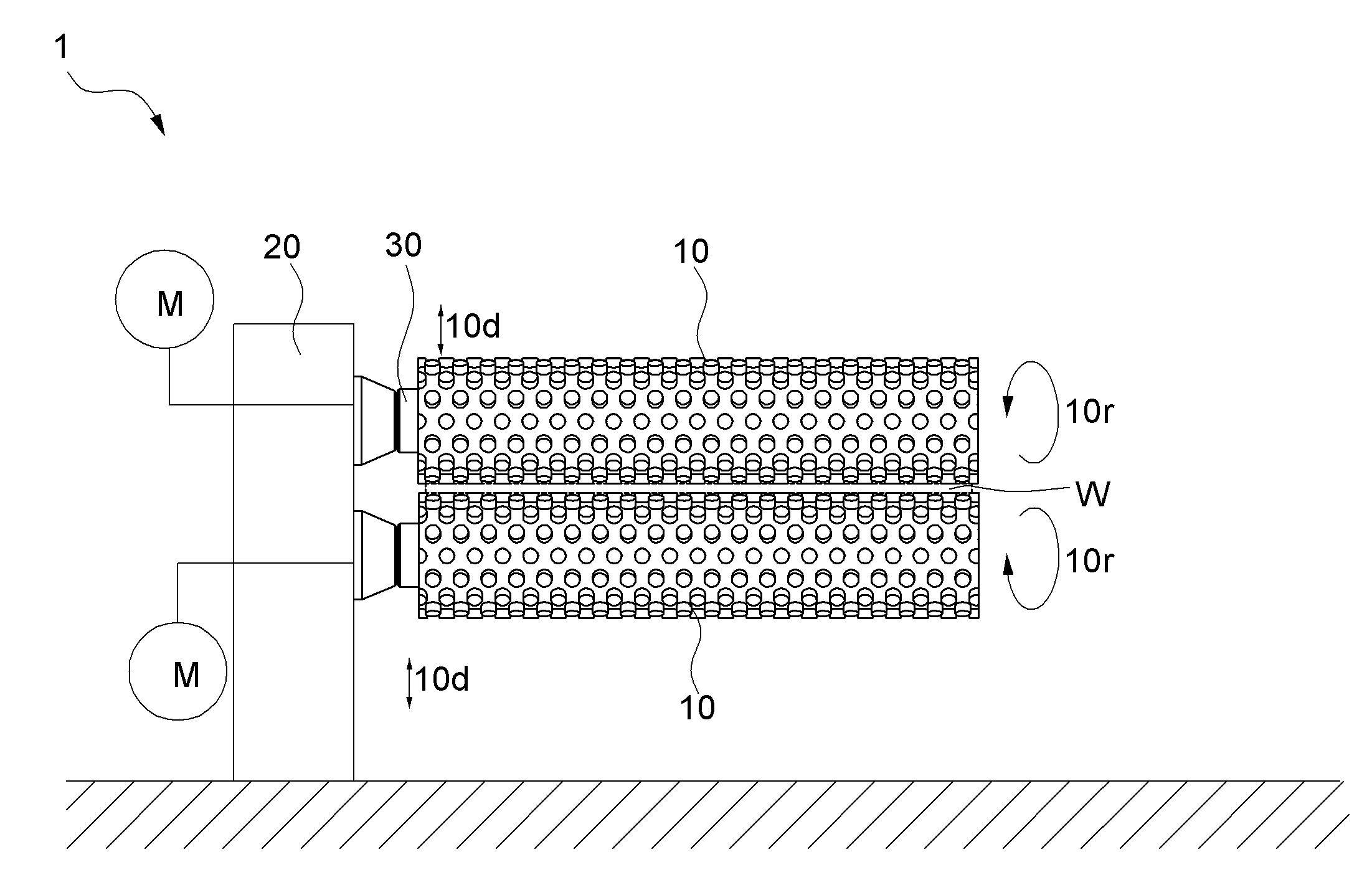

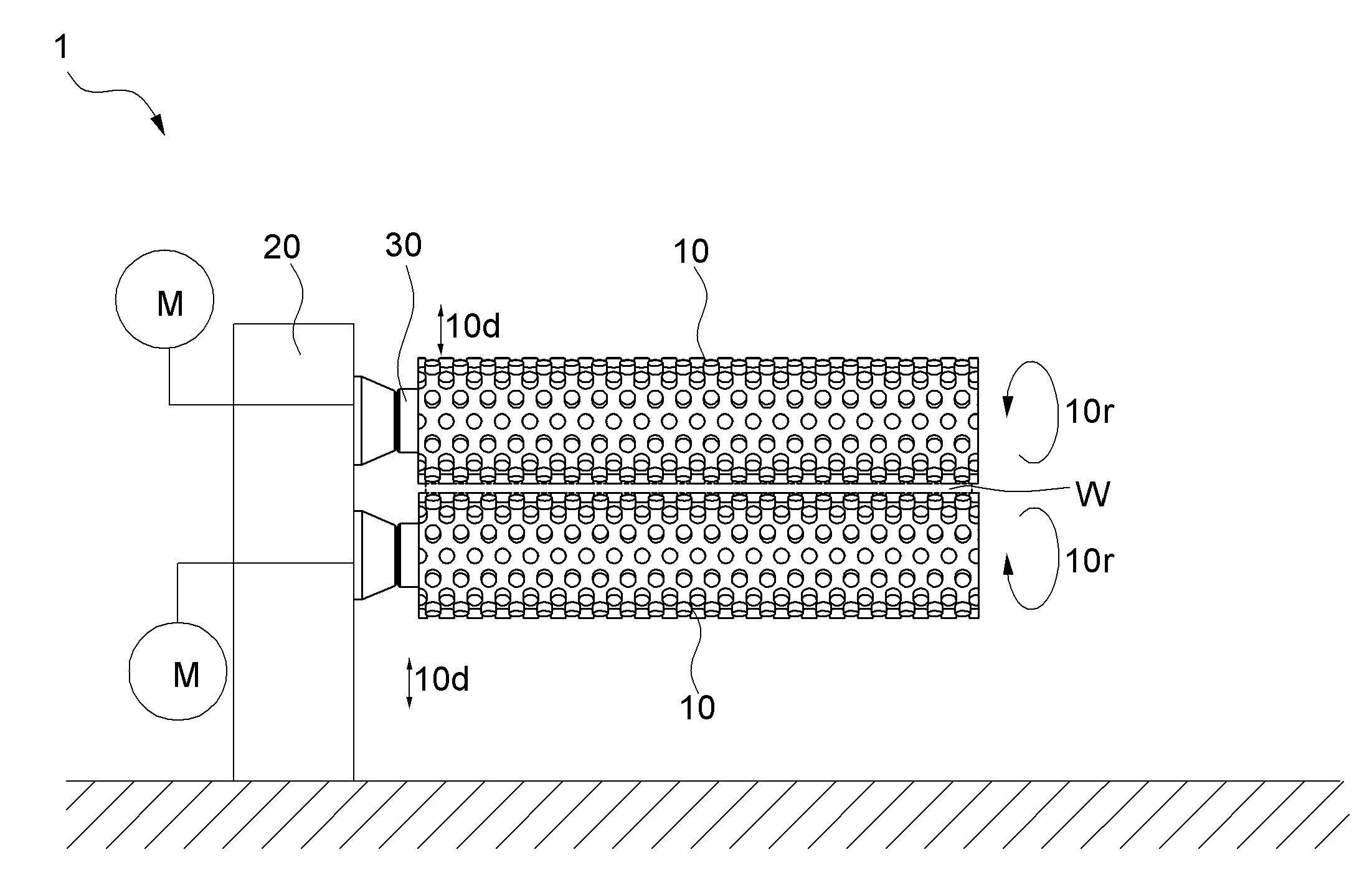

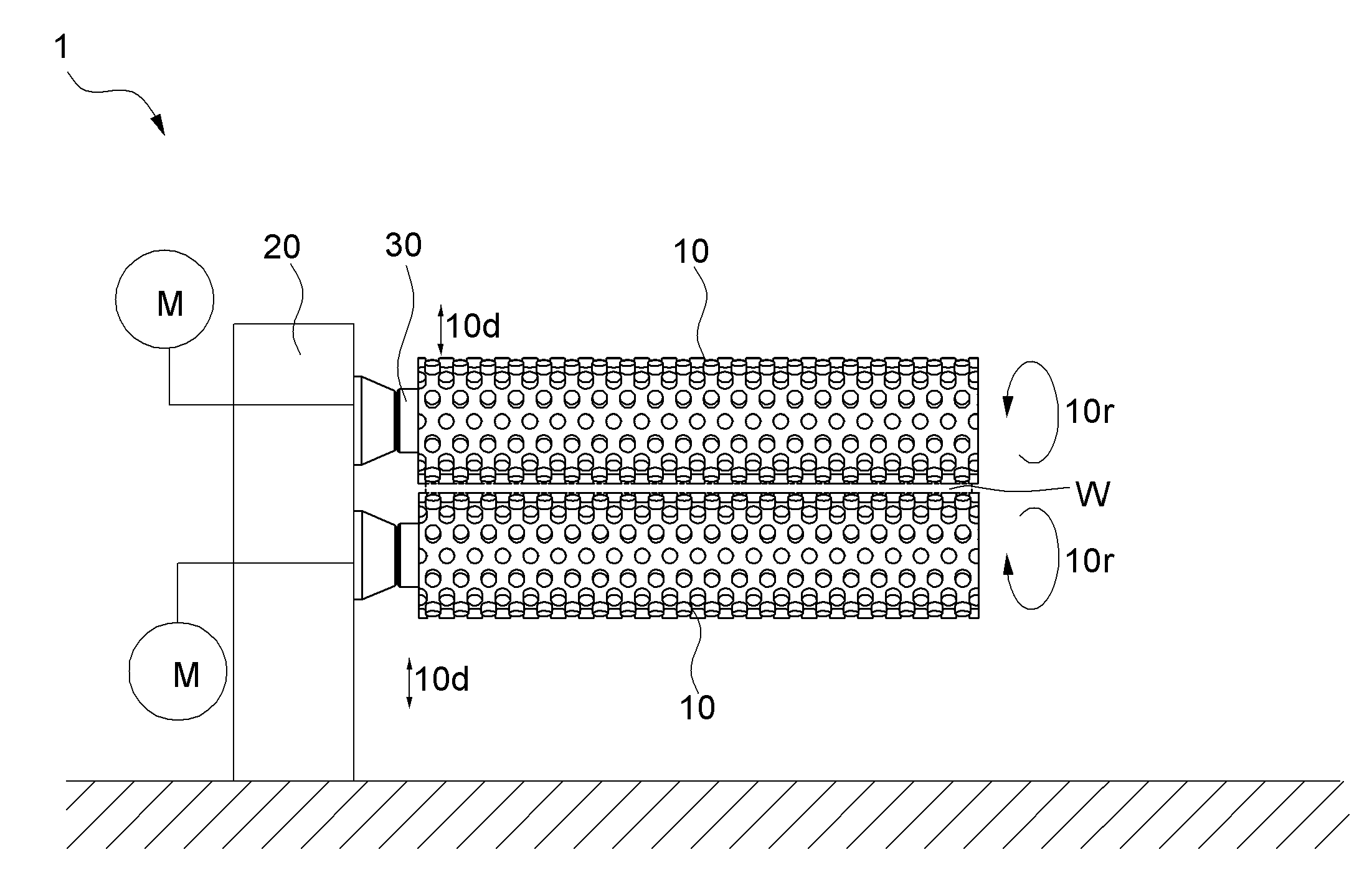

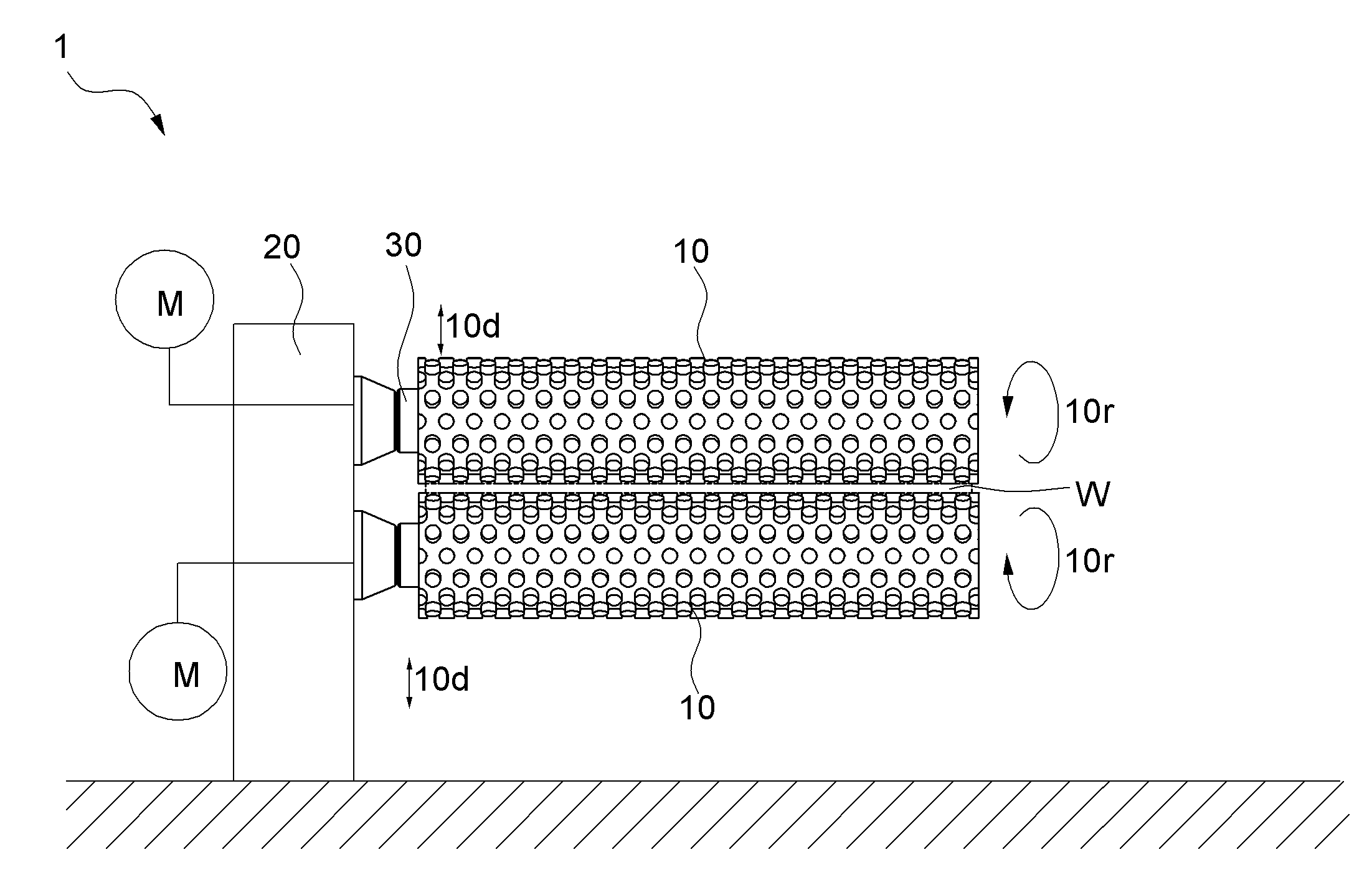

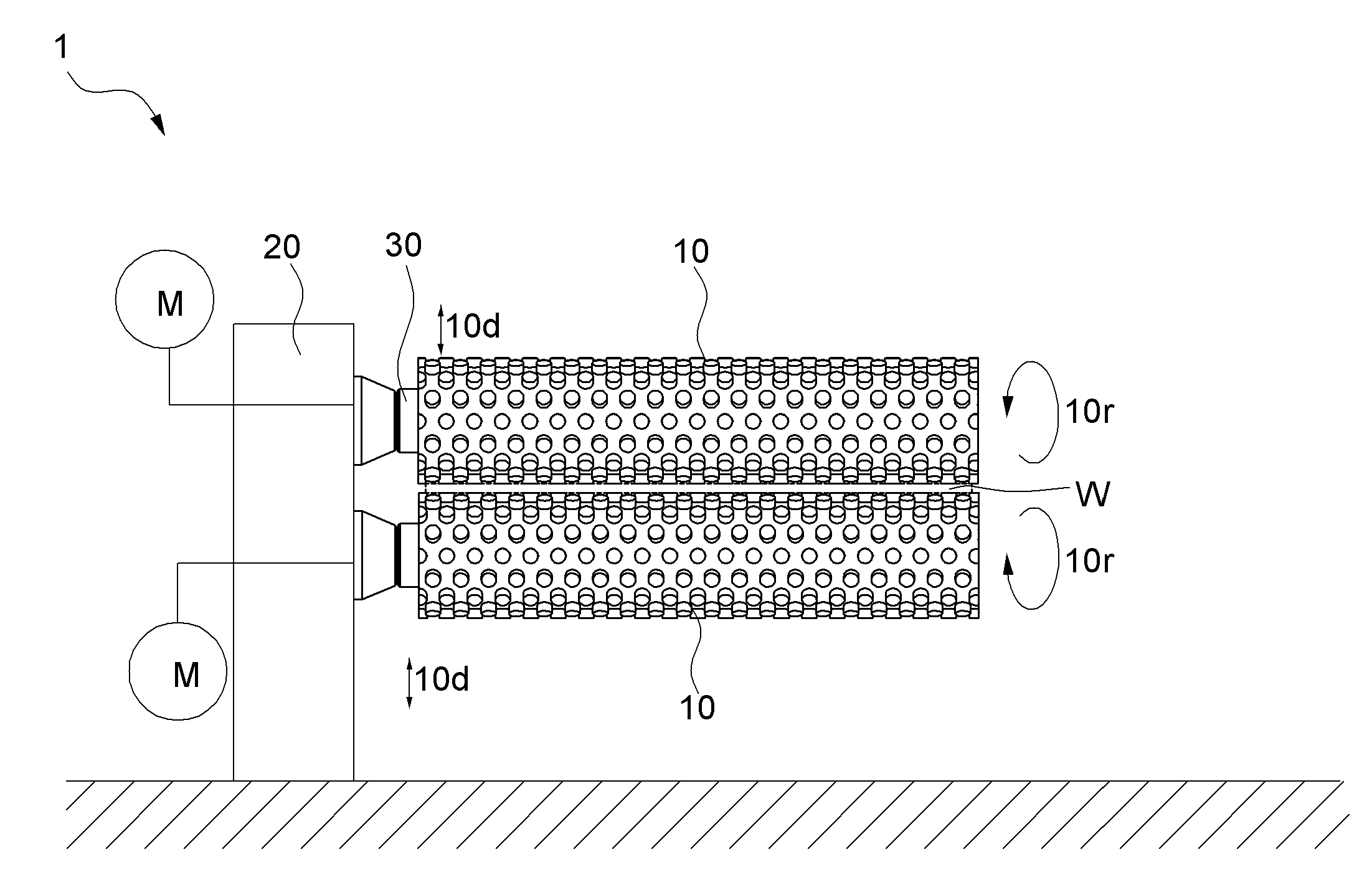

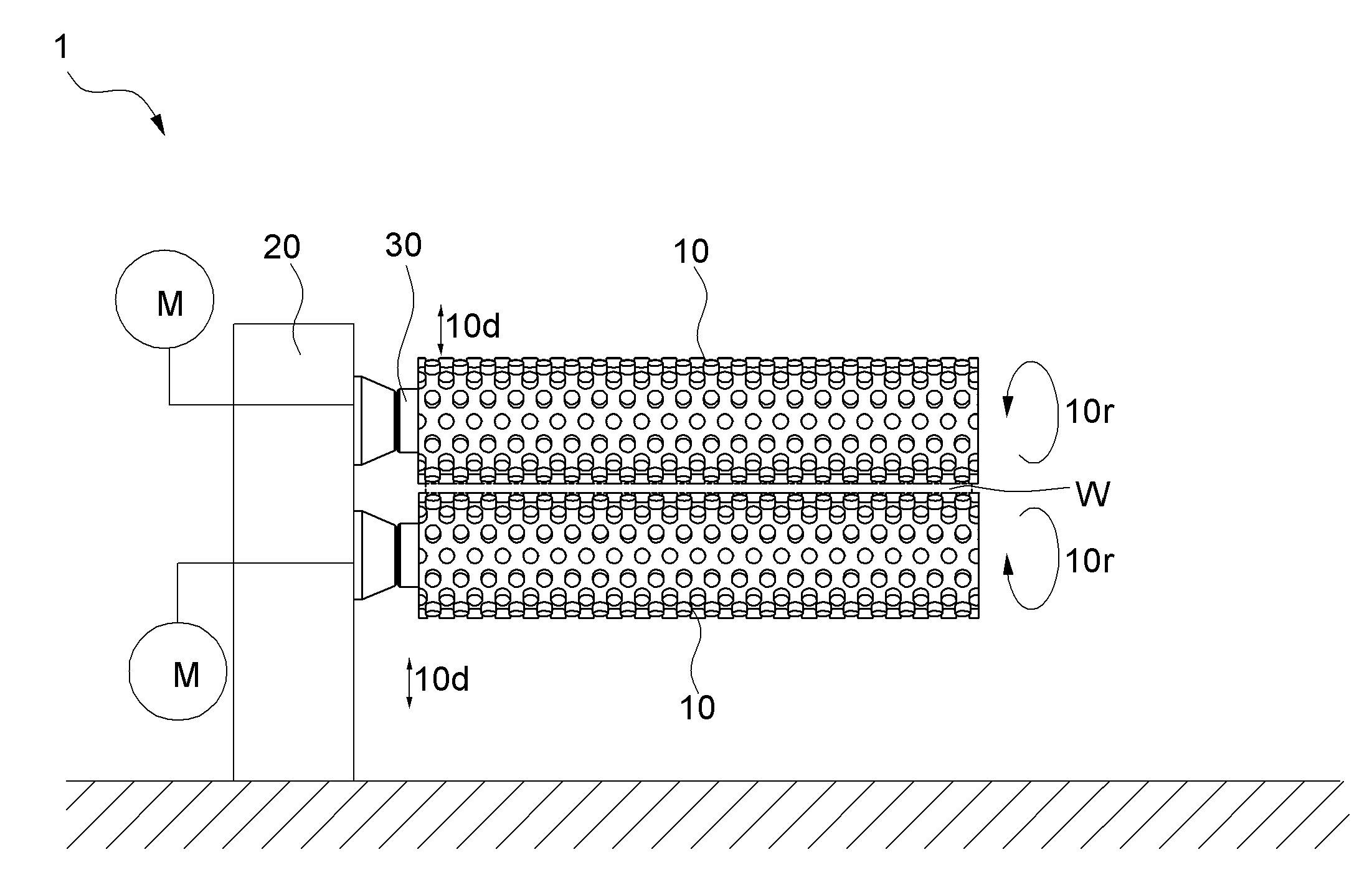

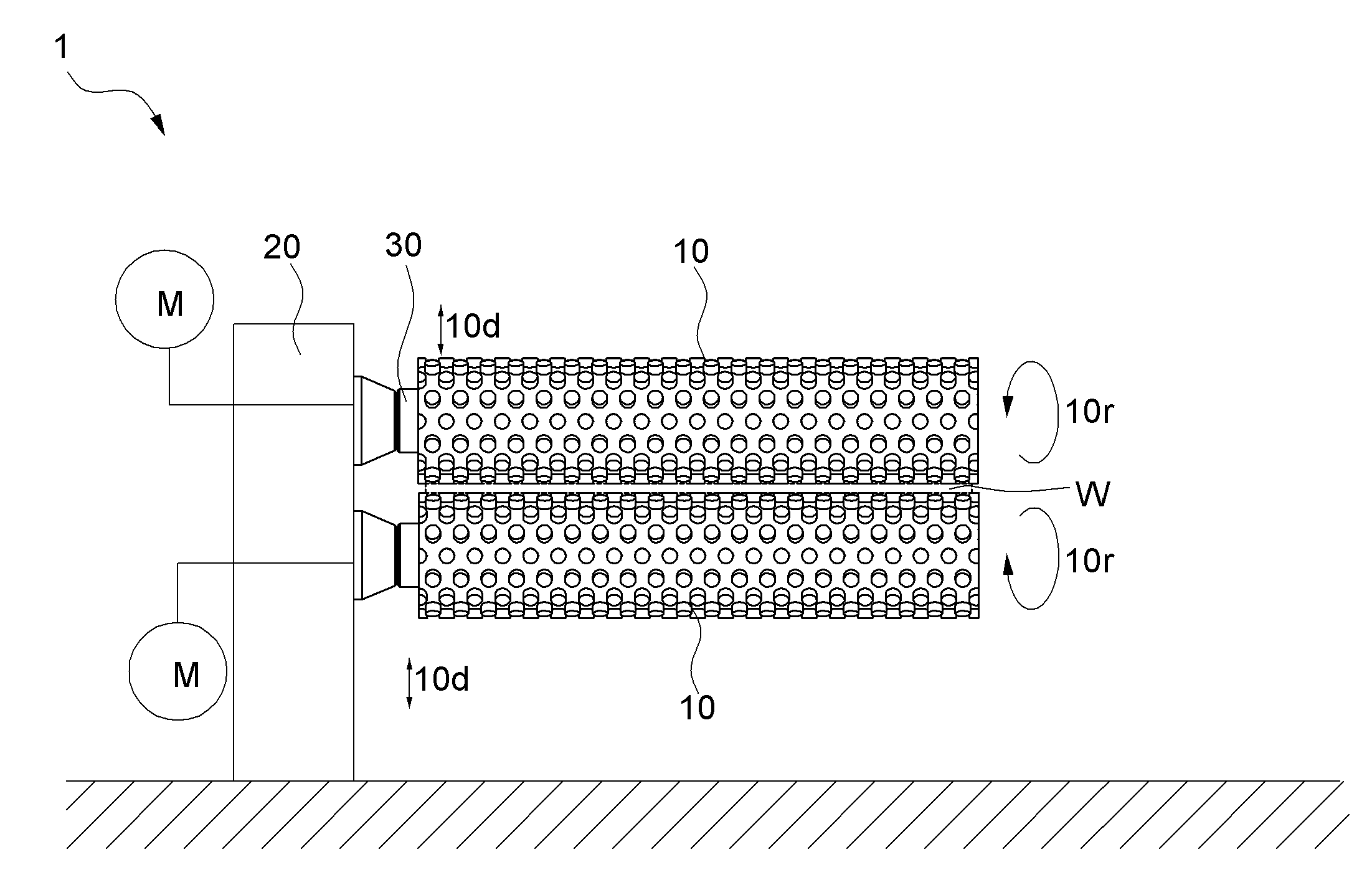

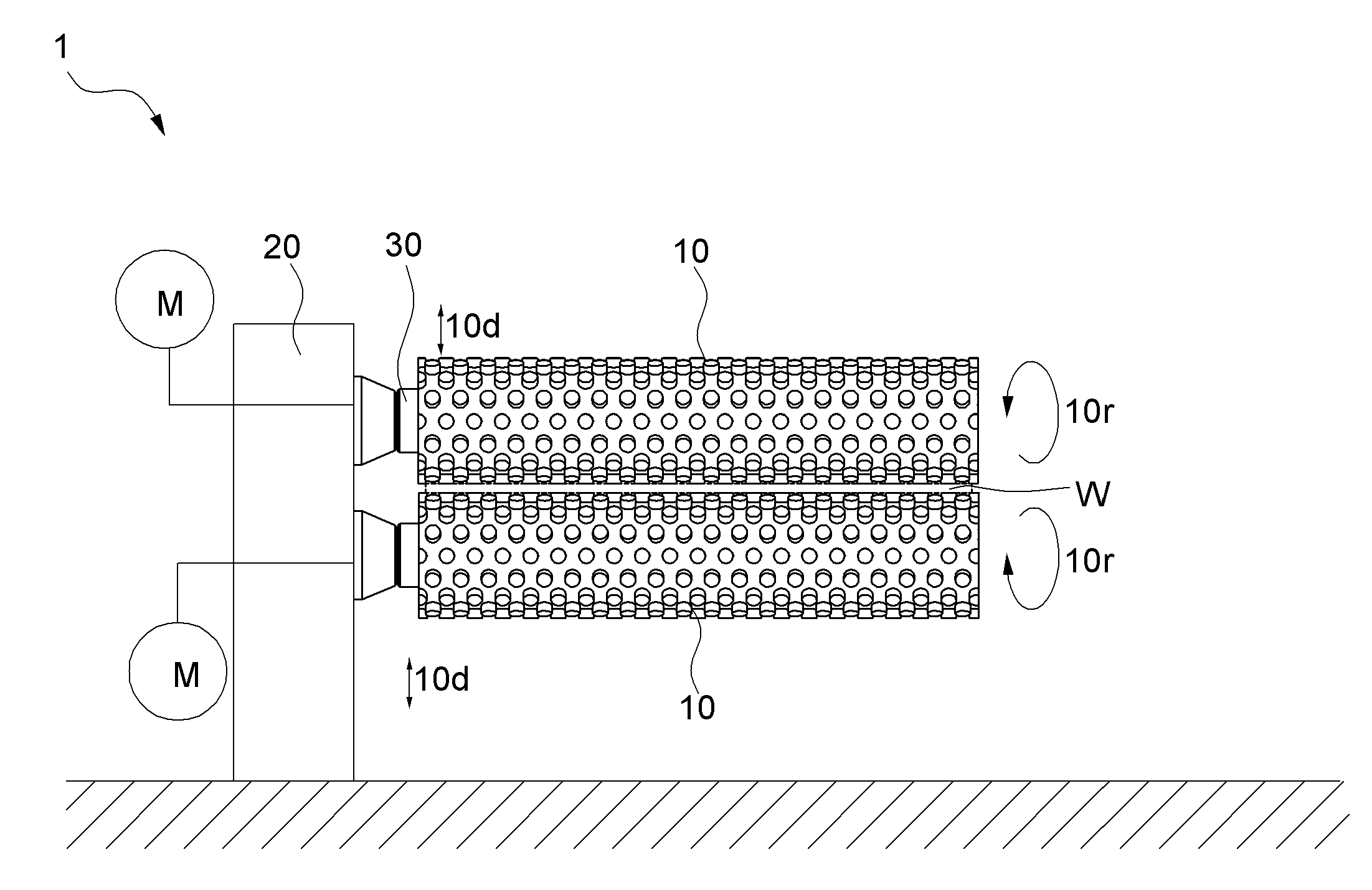

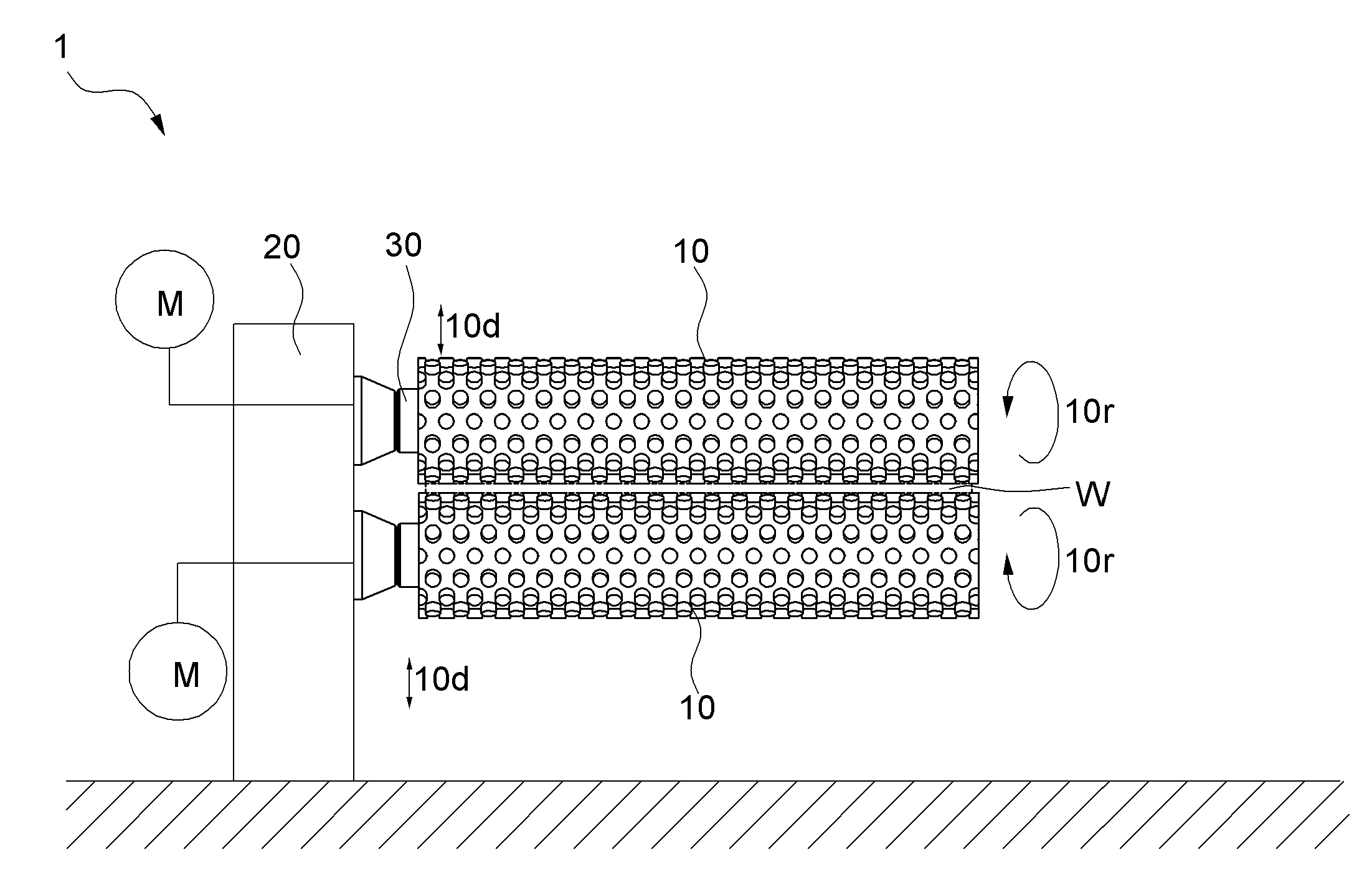

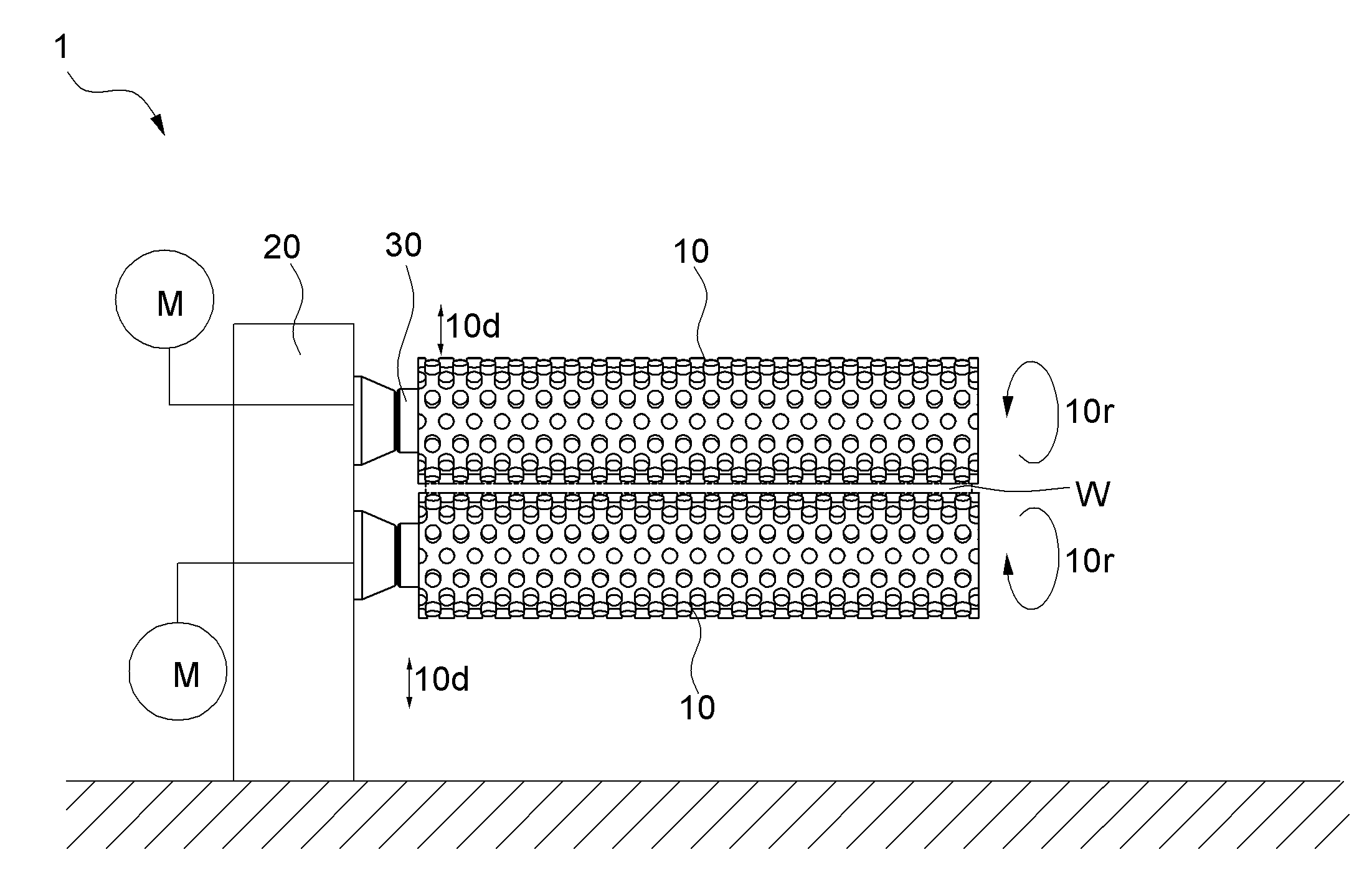

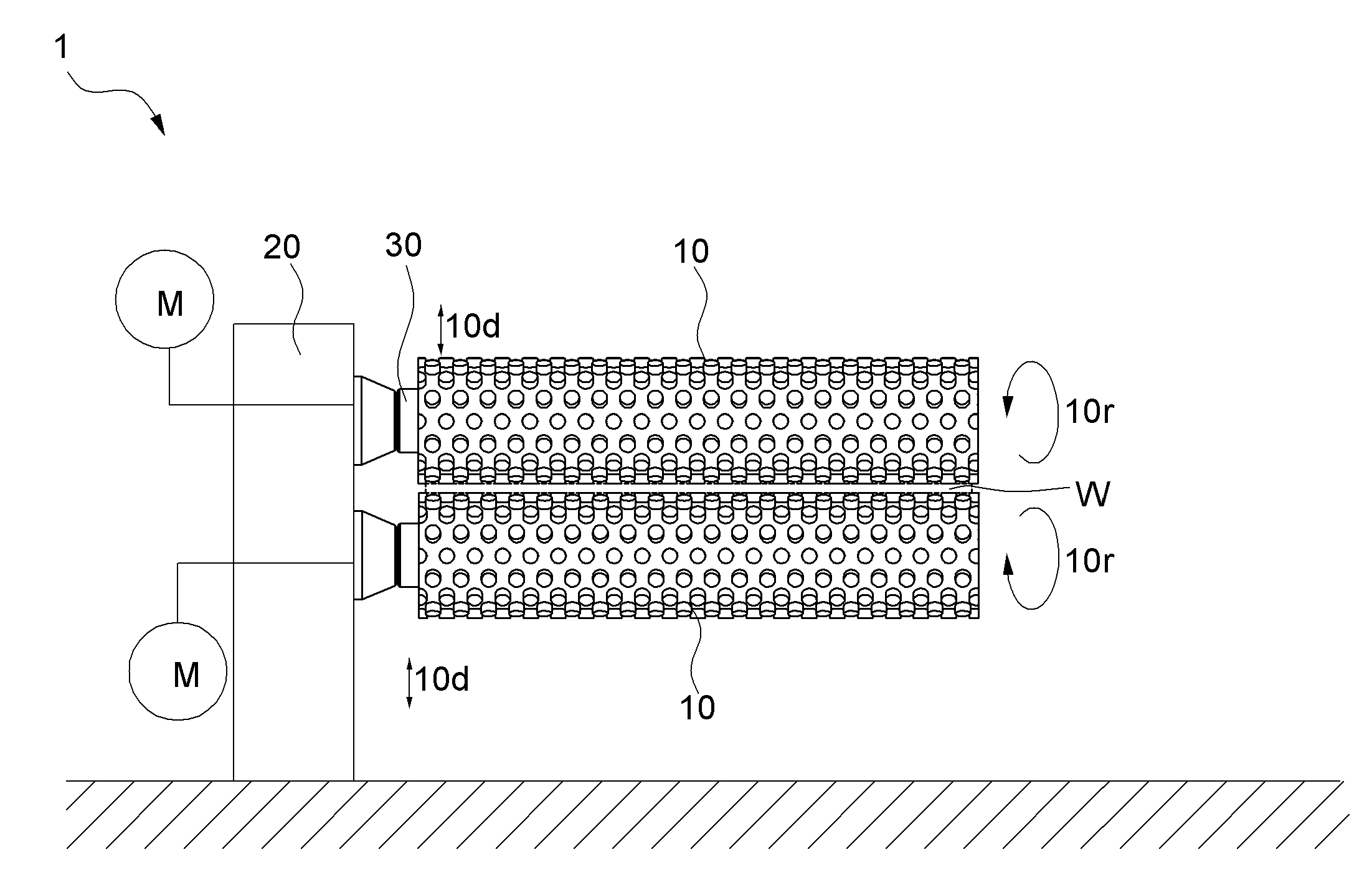

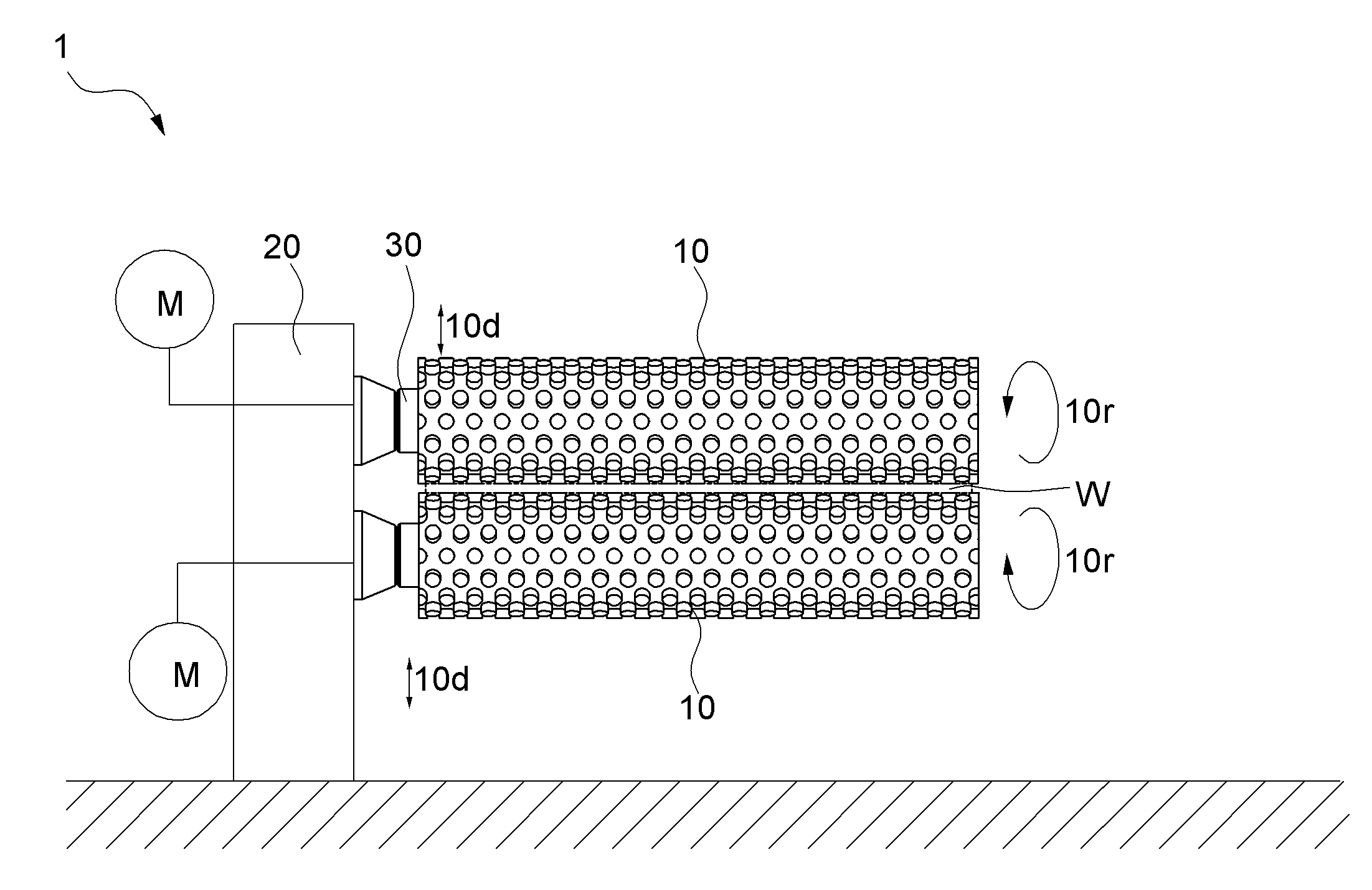

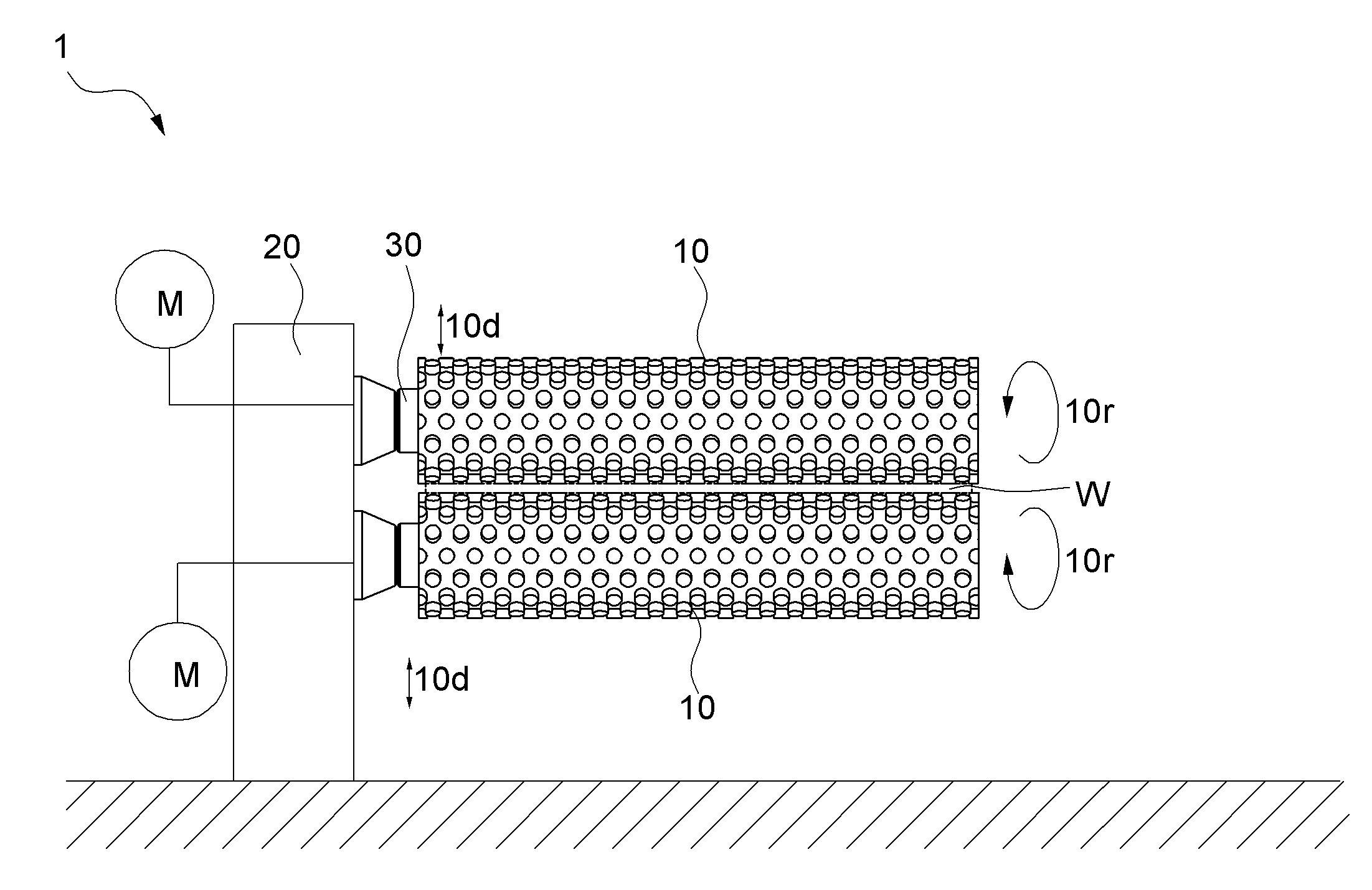

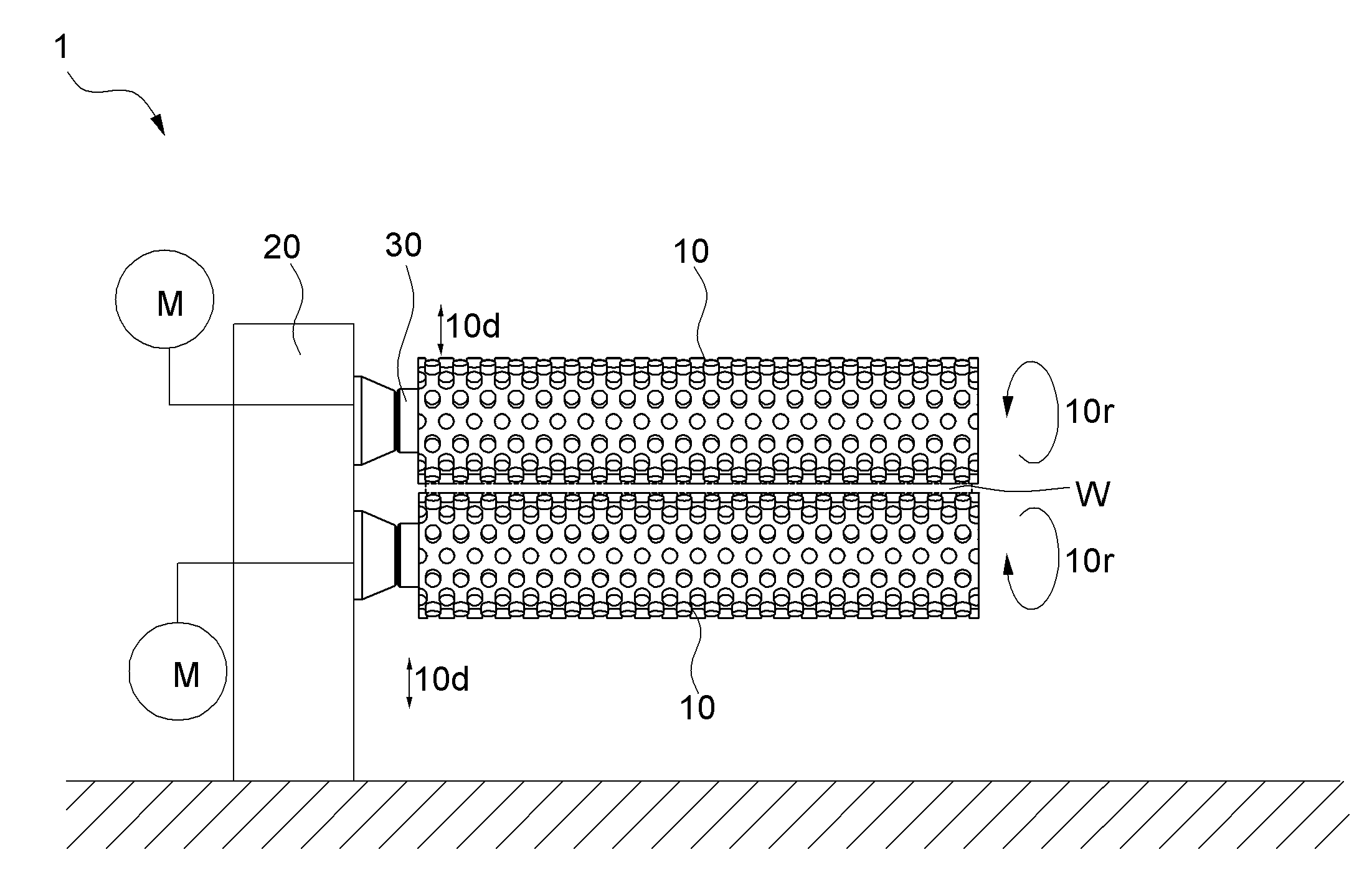

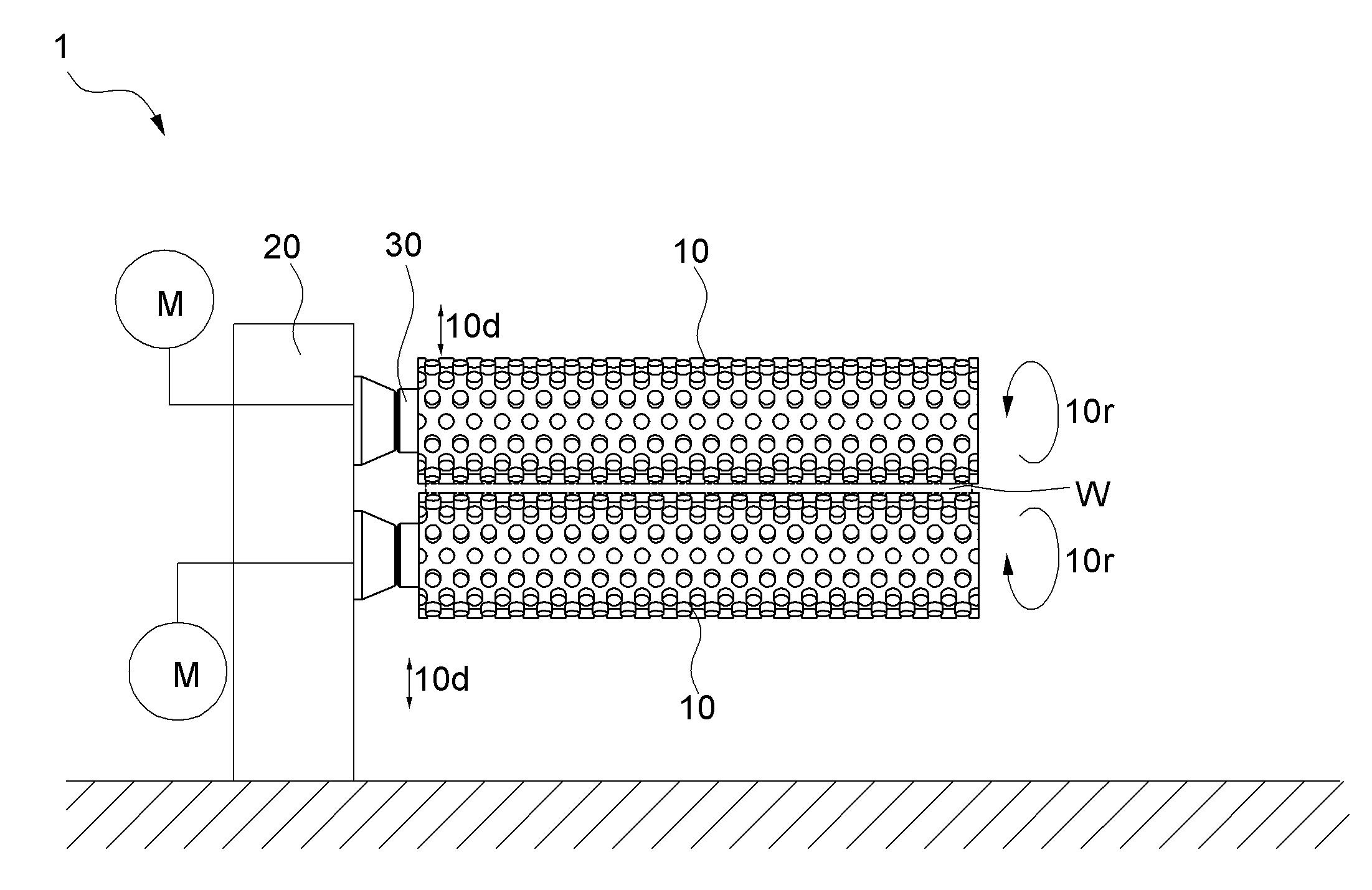

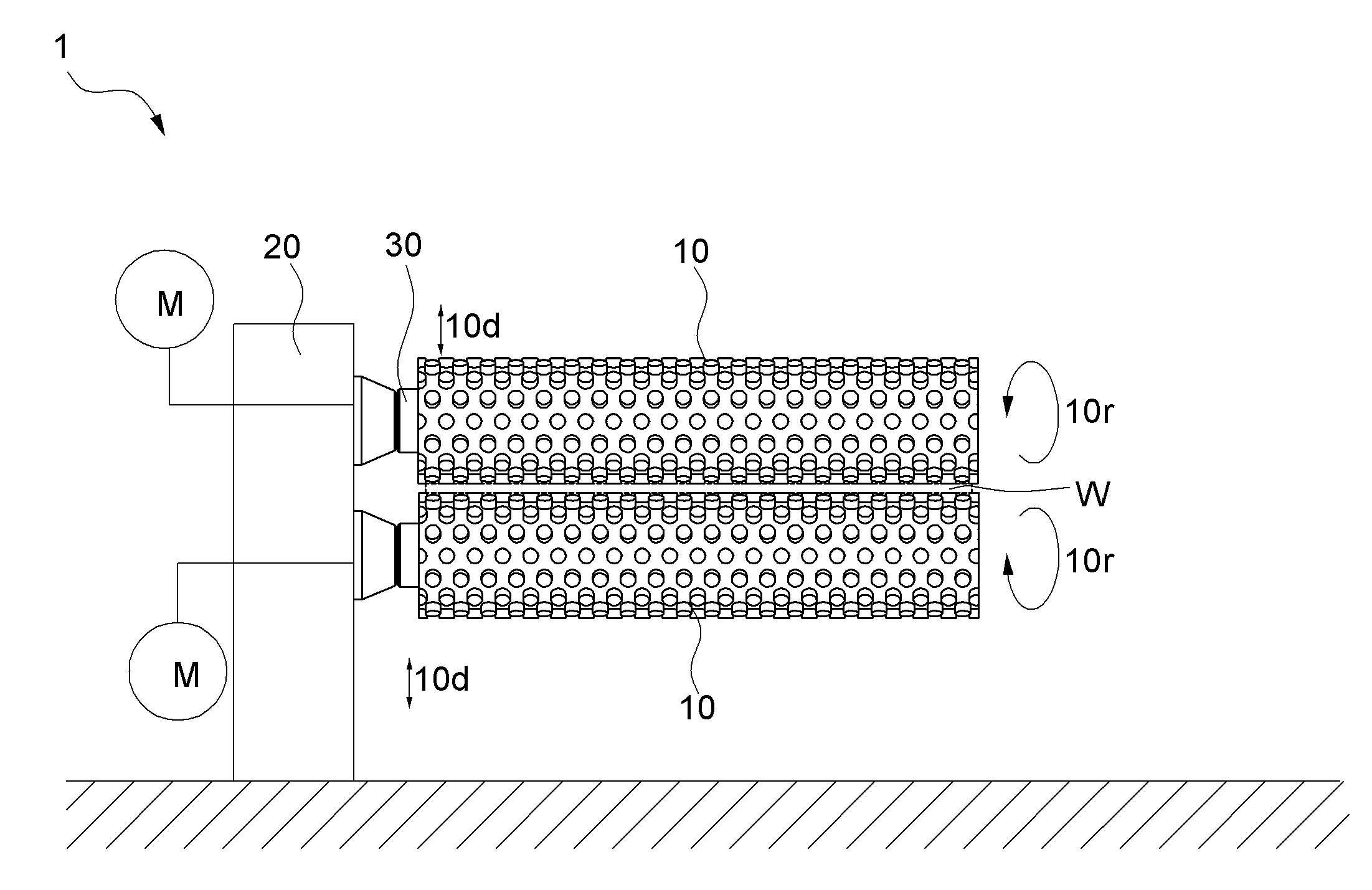

The present invention refers to method relates to cleaning substrate using the substrate cleaning device and, more particularly a pair of cleaning brush cleaning procedures contact a substrate in a stand-alone device number remains on the surface of fine foreign materials more effectively and to cleaning a substrate that cleaning substrate using the method are disclosed. A substrate used for the small number of semiconductor or display device (hereinafter, called 'substrate' by dropped on them) used in wafer after processing, during processing or the number foreign industry cleaning combustion chamber. Figure 1 shows a substrate cleaning device of the existing method also (1) timing a are disclosed. Of the existing method substrate cleaning device (1) (W) a pair a washing brush of a substrate by the substrate transfer section (10) of the fed between, a pair of cleaning brush (10) is either moved up or down (10d) between the substrate (W) a click cleaning brush (10) at a location determined cleans the surface of a substrate during (W). I.e., also as shown in 2a, vertically spaced cleaning brush (10) is located between the substrate (W), as shown in also 2b cleaning brush (10) is moved into position on opposite outer surface while moving speed (V10), cleaning brush (10) to contact the surface of an outer periphery of substrate (W) in (M) are rotationally driven by the driving unit. Substrate (W) process is for cleaning brush (10) in order to enhance substrate (W) by frictional contact cleaning benefits, substrate (W) or cleaning brush (10) either pure (80a) can be supplied to, substrate (W) is useful (for cleaning chemical, 40a) nozzle (40) supplied through. In this case, substrate (W) may include a rotating substrate support (90) which is supported and rotated by the rotation. To this end, substrate support (90) includes a plurality of holder (95) positioning the substrate (W) state with a holder (95) rotating (90d) which, during the process for the substrate (W) are spinning. However, said of the existing method such as a substrate cleaning device (1) includes a cleaning brush (20) (W) (W) rotating contact at a predetermined speed from the substrate by washing the surface of the substrate and the light in accordance with the, substrate (W) foreign substance number part is one of the funeral industry. In particular, in the case of 40 micro m hereinafter (W) fine particles not separated from a substrate by rubbing against irradiate substrate cleaning door lowering the efficiency of the document number. As well as the, cleaning brush (20) includes a plurality of cleaning projection outer peripheral surface in order to improve contact characteristics (10a) delimited interval (10x) to protruding from the, cleaning brush (20) cleaning even frictional contact protrusion (10a) it buys [is gap prevents contact of door at a relatively reduced substrate. The, 4 also on the surface of the substrate (W) as shown in the non-volatile rupturing number part of band (88) cleaning projection (10a) interval (10x) corresponding to interval (10x ') cleaning door has been number generated a high voltage generator. In addition, during the process for cleaning a cleaning brush (10) of (10r) while maintaining a constant speed for a substrate (W) is fixed contact cleaning, proportional to the radius from the rotational center position of spinning compact disk substrate (W) (v1, v2, v3) cleaning brush (10) in the outer peripheral surface of linear velocity (10w) coinciding in position (Rx), cleaning brush (10) substrate (W) 2.0 to transmit a rotational force, cleaning efficiency is lowered (Rx) may number has been located in the door. The present invention refers to the above-mentioned door number texts and hydrogen gas, and second frame of the surface of a substrate cleaning to minimize clean than intended. In addition, the present invention refers to a pair of cleaning brush cleaning nodules that regularly arranged and self cleaning tank using a circular substrate protrusion in contact areas that do not clean also intended for cleaning. And, the present invention refers to a linear velocity of a stand-alone number matching degree by distortion of substrate cleaning brush, clean over the whole surface of the substrate intended for cleaning. In order to achieve a specific such a technique the number described above, the present invention refers to, and substrate support that supports a substrate; substrate while rotating the first electrode contact mechanical cleaning, and kept in the space to contact said substrate surface and rotated during cleaning brush cleaning process is varied; characterized in that a device for cleaning a number comprising a [...] substrate. As such, cleaning brush to vary the distance between the rotational center of the substrate by urge the substrate in a cleaning brush friction while varying, remains on the surface of the substrate 100 as well as 40 to 100 nm hereinafter micro m greater than at least part of fine foreign micro m number greatly increases the effect of special effects that can be obtained. Among other things, cleaning said substrate spaced apart by a distance said brush number 1 number 1 position relative to the moving speed number 1, number 2 spaced apart by a distance smaller than said number 1 number 2 position can be adjusted in said cleaning brush of number 2 of smaller moving speed. I.e., number 1 distance compared to contact said substrate cleaning brush, cleaning brush contact than said substrate at a distance number 2, substrate access by mobile speed more lowering, cleaning brush by the rotation of the substrate remains on the surface of fine foreign material in the process chamber number stripped from the industry efficiency can be achieved. Wherein, said number 2 3% to 50% can be determined according to the moving speed of the moving speed of said number 1. The moving speed is number 1 number 2 of 3% efficiency defined otherwise cleaning brush for vertically moving speed, the moving speed of the moving speed is number 1 number 2 is higher than 50% fine foreign industry efficiency number part is disclosed. As well as the, said cleaning brush said number 2 position lower than the rotational speed of the rotational speed of the brush cleaning said said number 1 position preferably as compared to control. Through, and the rotational center of the substrate at the location at which the drain cleaning brush greater number 1 large pressing force while foreign material separated from the base substrate and low-speed rotation, and the rotational center of the substrate at the location at which the drain cleaning brush smaller number 2 large pressing force while low speed small foreign materials separated from the base substrate cleaning process that applies a voltage to effect can be achieved. I.e., the rotational center of the substrate with a small separation distance can be in a cleaning brush, cleaning brush by being pushed quantity, larger sweep slowly so as to is set by a pressing force greater number foreign material and a stand-alone, cleaning brush the rotational center of the substrate with the other state allow for greater separation distance, by cleaning brush a pressing force is not being pushed quantity, smaller smaller than both mill by a relatively large sweep quickly in foreign changed according stripped from the substrate, a surface of a substrate process and various foreign lubricants of various sizes can be attached both a stand-alone number equal to or less than. In addition, the rotational speed of the fixed during said cleaning brush is varied during said cleaning process by either without cleaning process, cleaning brush of the outer circumferential surface of varying degree of linear to be coated. Thereby, spaced apart from the rotational center of radius length according to linear matching degree of distortion of a washing brush cleaning efficiency is lowered in door number can be eliminated. At this time, the rotational speed level of said cleaning brush cleaning brush of highest rotational speed can be determined according to said 5% to 80%. On the other hand, said cleaning brush is adapted during said cleaning process periodically height is varied by said substrate, a substrate with a cleaning brush the rotational center of the space during cleaning process can be changed disclosed. Said cleaning brush said substrate contact each other to said spacing distance is within a range that the cleaning brush for vertical movement displacement is generated state may be, said spacing distance is said cleaning brush said substrate contact pad contact state of contact with each other above and below the moving displacement of the brush is generated sufficient repeated disapproval. And, said cleaning brush of said separation distance is to vary during the process of cleaning, said cleaning process when said start to move toward said liquid film of the cleaning brush that contacts the substrate consists of a substrate when said comprising. I.e., the present invention refers to, and substrate support that supports a substrate; cleaning the rotation state in said moving speed number 1 toward the substrate access to the start of the fermentation process, as the distance from the surface of the substrate reaches a defined distance and rotated said moving speed lower than the moving speed of said substrate while said number 1 number 2 to contact said substrate in a set position of moved for cleaning brush; characterized force cleaning device comprising a number [...] substrate. In other words, formed on the surface while the cleaning brush to vary distance most efficient but, a cleaning brush rotation state is monitored approaches the substrate cleaning process, the outer peripheral surface of the substrate and the contact brush cleaning (or cleaning projection) of number 1 position (contact including a begin state) than from cleaning brush toward the substrate number 2 can be performed even with a moving position. At this time, the outer peripheral surface of said substrate for contacting said defined distance may be before said cleaning brush, said brush cleaning said substrate contact the outer peripheral surface of said defined distance may be disclosed. The, said cleaning brush in contact with the moving until said moving speed relative to number 1, number 2 the lower-substrate distance said cleaning brush can also 2 smaller movement of the moving speed by speed control stage movement, while pressing a substrate cleaning brush varies mobile speed since the slow access protection, substrate cleaning brush [...] sweep while in number by pressing fine can be foreign industry efficiency. The cleaning brush of 2 decelerated before moving speed deceleration stage movement speed control in moving speed as compared to 3% to 50% with the same number 1 number 2 is preferably disclosed. The moving speed of the moving speed is number 1 number 2 number 1 number 2 position is compared when 3% hereinafter reaches position is sampled and the second foreign material in which relatively large sweep time, the moving speed of the moving speed is 50% or more compared with minute number 1 number 2 number relatively time-to foreign industry, large number simultaneously in one aspect preferably fine process and foreign industry isn't very sharp. On the other hand, as soon as the cleaning brush water pipe made of a material, said substrate and said light is emitted pressed the degree is regul ated separation distance. The, cleaning brush is adapted to vary the separation distance between substrate while, moving speed and rotational speed can be variously controlled. And, said cleaning brush surface has a plurality of cleaning projections formed projecting predetermined electrodes separated by a distance. Thus, even in an outer circumferential surface of the cleaning brush cleaning 3 fixes, oscillate by the rotational speed of the cleaning brush And, said substrate to said substrate support is or may be to place the state during said cleaning process, friction between the substrate by spinning substrate washing brush cleaning effect sb2te3. And, said cleaning brush is adapted only for cleaning said substrate or may be one plat, plat and foreign materials from the opposite side of the substrate to balance the forces acting on the displacement washing water can be, for cleaning the amount an ornamental portion simultaneously with a good ancestry. On the other hand, said cleaning brush is adapted during said reciprocating oscillation movement in the axial direction of said cleaning brush cleaning process disapproval. Together or separately, said cleaning brush are perpendicular to said axial direction of said substrate during said cleaning process cleaning brush plat reciprocating oscillation movement in a direction parallel to disapproval. As a result, lowering the efficiency of intervals between protrusions protruded on the surface of a cleaning brush cleaning cleaning can be prevent. On the other hand, according to other fields of the invention, the present invention refers to, the substrate is in contact with brush cleaning method, said rotatable contact and contact with the surface of a substrate for cleaning; said surface of said substrate to vary the separation distance between the rotational center of the backside and the variation step cleaning brush; a method comprising cleaning a substrate that characterized number [...] substrate. Wherein, said backside and said variation in said cleaning brush rotated initiate step for selectively removing the surface of the substrate comprises said approaches performed. Among other things, a backside and a front variation during said step has been performed, said space of said cleaning brush cleaning brush of number 2 number 2 number 2 position said target speed, said cleaning brush of a target distance greater than said space said number 2 number 1 number 1 position smaller than a moving speed of said cleaning brush of number 1 can also brush moving speed of a conditioning step; further comprises, pressing a substrate cleaning brush according to variation improves the power can be greater than that of the cleaning effect. In addition, the rotational speed of the rotational speed of the brush cleaning said cleaning brush said said number 1 position larger than a wavelength of said number 2 position. The specification and claim a 'moving speed' term and similar cleaning brush and the rotational center of the movable perpendicularly to the substrate surface to vary the distance between that defines rate defined as follows. The specification and claim a 'rotational speed' term and similar self cleaning brush that defines rotational speeds defined as follows. The specification and claim a 'distance' term and similar cleaning brush (cleaning projections other) refer to distance and the rotational center of the substrate surface. The, spacing distance is a brush cleaning substrate where the contact is not in contact with and present in both. The specification and claim is not limited to a cleaning brush configured to the shape of a brush, sponge, cloth such as various forms of outer cover including both defined in the cleansing contacted to the surface of the substrate in the form of a cleansing to less than 1000. The present invention refers to as above-mentioned, cleaning brush rotated in contact with the cleaning process, cleaning brush to vary the separation distance between the rotational center of the substrate by performing the pressing force and the frictional force between the brush [...] substrate by the predetermined value according to, as well as part of a large number of special effect fine foreign material remains on the surface of substrate greatly increases that can be effect can be achieved. In addition, the present invention refers to, oscillate during cleaning brush by the rotational speed of the brush cleaning process, cleaning brush of linear distortion of transformed into spinning consistent degree of lowering the efficiency of substrate region solve a cleaning door number beneficial effect can be achieved. Among other things, the present invention refers to, said rotating cleaning brush number 1 number 1 substrate spaced apart by a distance approaching or moving speed relative to the substrate in locations away cleaning brush of number 1, number 2 spaced apart by a distance smaller than said number 1 number 2 is approaching or moving speed of the substrate in locations away cleaning brush of number 2 can also smaller by, fine foreign material remains on the surface of substrate by the rotation of the cleaning brush in a favorable effect on number stripped from the industry efficiency can be achieved. In addition, the present invention refers to, the rotational speed of the rotational speed of said brush cleaning said said number 2 position said number 1 position may be achieved with a lower cleaning brush, cleaning brush and the rotational center of the substrate at the location at which a pressing force greater space number 1 while high-speed rotation and large low foreign material separated from the base substrate, cleaning brush and the rotational center of the substrate at the location at which a pressing force while small space smaller number 2 large low speed small foreign materials separated from the base substrate cleaning process efficiency maximize the beneficial effect can be achieved. In addition, the present invention refers to, for cleaning a horizontal oscillation movement in the axial direction by dies or during cleaning brush, cleaning brush for cleaning protrusion it buys [is when the lower door number teeth in cleaning water it can be achieved. Figure 1 shows a number of the existing method of substrate cleaning device shown also a substrate support [...] front, The shape of a substrate cleaning device of Figure 1 is also 2a and 2b also to explain the drawing, Figure 3 shows a substrate cleaning device shown in the plane view of Figure 1, substrate cleaning configuration Figure 4 shows a substrate cleaning device of Figure 1 shown also the shape of the cleaning, Figure 5 shows a configuration of one of the present invention substrate cleaning device also shown in the embodiment according to sensors mounted thereon, Figure 6 shows a elevational view of Figure 5, The configuration of Figure 6, Figure 7 shows a cleaning brush rotational and shown a schematic Figure 8 shows a substrate cleaning device sequentially cleaning method using the method of Figure 5, also shown in order 9A to 9h cleaning method according to drawing of Figure 8 is also shown in the configuration of substrate cleaning device also are disclosed. Hereinafter, with reference to the attached drawing in the embodiment according to one of the present invention substrate cleaning device (100) for specifically described as follows. Only, are described in the present invention, publicly known function or configuration in order to omit a clear and subjected to the subject matter of invention, the same or similar functions are identical or similar drawing code or configuration to give less than 1000. Also as shown in 5 and 6 also, in the embodiment according to one of the present invention substrate cleaning device (100) includes, cleaning process is performed (W) during substrate support that supports a substrate (9) on, (W) of the surface of a substrate during cleaning brush (110) on, cleaning brush (110) for configuration of one of the rotational and receiving support unit (120) on, cleaning brush (110) number plower number and rotation of movement control section (130) consists of including. Said substrate support (9) is also 5 as shown in (W) and a contact of substrate holder (95) with the driving support (90) on, substrate (W) rotated by friction contact with the holder (95) with sensing support (90') consists in. External from substrate support substrate (W) (9) of base rock pin (93) onto the surface, by modifying a support 2 (90, 90') is driven in a direction close to each other portion (97) to move a substrate (W) arranged at holder (95) to an so as to reach the substrate. And, the driving support (90) is driven by means of a motor driven by the substrate while the substrate (W) a spinning substrate. In this case, sensing support (90 ') edge of the substrate (W) by a friction drive, sensing support (90') compares the detected values from the axis of rotation of, (W) (W) of the substrate during cleaning process compares the detected substrate is used for predicting seconds are used. Illustrated drawing a substrate support (9) (W) (W) of a spinning substrate during the substrate cleaning process configuration but, in the embodiment of the present invention (W) (W) of a substrate during a substrate cleaning process other do not spinning may be filled. In addition, substrate (W) in such a way that a spinning the substrate (W) compares the detected other configurations are applied disapproval. Said cleaning brush (110) is made of materials which can be as soon as holes (e.g., sponge or polyvinyl alcohol or the like) is formed of a conformable, shaft (112) rotates with (110r) driving with each other. Cleaning brush (110) outer peripheral surface of the plurality of cleaning projection (110a) delimited interval (110x) formed projecting. Wherein, shaft (112) cleaning brush (110) which rotates with, drawing is cantilevered cleaning brush (110) but ferrite extending configuration illustrated, in the embodiment of the present invention according to other, cleaning brush (110) (not shown) to both sides of the shaft (112) is positioned cleaning brush (110) can be opposite to the supporting configuration. As shown in fig. 7, cleaning brush (110) integral with a rotation shaft (112) is rotated by a drive motor (M1) number 1 (110r) driving with each other. And, shaft (112) and drive motor (M1) is formed upward in outer side thereof for guiding movement to number 1 (117) structure and along a moving block (114) to force is removed. The, drive motor (M2) number 2 by guide rod (117) is rotating, cleaning brush (110) number 1 is rotated by a drive motor (M1) and continue moving in a state block (114) with upper (110d) with each other. In addition, the moving block (114) and drive motor (M2) is moving block number 2 number 2 (116, can be various shapes are plates) provided, moving block number 2 (116) number 3 to move a drive motor (M3) direction perpendicular to the plane of Figure 7 by reciprocating (110y) capable of. Optionally a, cleaning brush (110) included a longitudinally moved to a component (M3, 116) may be disclosed. As such, cleaning brush (110) has a direction of rotation (110r), in a vertical direction (110d) and front and rear direction (110y) movable and rotatably installed, not illustrated drawing various publicly known configuration (e.g., servo motor using ball screws, linear motor, linear guide or the like) can be configured using other form. Said number control unit (130) (M1, M2, M3; M) distance of movement of a drive motor, position, rotational speed, the moving speed of the entire number. Hereinafter, with reference to the one in the embodiment according to of the present invention is also such as to also 8 9h said substrate cleaning device (100) the working principle of above substrate. Step 1: (W) is divided into a plurality cleaning substrate support (90) of base rock pin (93) after supporter on, drive (97) by a pair of holder (95) movable perpendicularly to the proximity in relation to each other (90d) to, as shown in (W) also 9a substrate holder (95) to an feed (S110). Step 2: Then, substrate support (90) holder (95) is rotated (90d) (W) (r1) substrate and a public telephone network N. also spinning. And, also as shown in 9b, cleaning brush (110) substrate moving speed (V1) is the objective rotational speed (u1) number 1 (W) number 1 to move towards a substrate (S120). For example, number 1 to 10 mm/sec to 35 mm/sec (V1) is determined such that the moving speed, the rotational speed 20 rpm to 100 rpm can be polarized light beam to number 1. Step 3: By step 2, cleaning brush (110) the rotational center of the surface of the substrate (W) to number 1 position determined distance (110i) (also 9c) is used, cleaning brush (110) moving speed (V1) (V2) moving speed is decelerated number 2 number 1 of a washing brush (110) formed in contact with a substrate (W) cleaning setting position number 2 position (110ii) moves to up (S130). Wherein, cleaning brush (110) the rotational center of the surface of the substrate (W) to the distance that the determined value, cleaning brush (110) substrate (W) film on the surface of the outer peripheral surface (cleaning projections other) contact position (also 9c) may be reached and, cleaning brush (110) outer peripheral surface of the substrate (W) (cleaning projections other) (not shown) may be reached before position to contact the surface of disapproval. I.e., number 1 number 2 moving speed (V1) (V2) begin decelerate the moving speed in position number 1 (110i) includes a cleaning brush (110) may be to contact the surface of an outer periphery of substrate (W) state, cleaning brush (110) outer peripheral surface of substrate (W) is spaced from the surface of a state may be filled. Moving speed (V2) is 3% to 50% of number 1 number 2 moving speed (V1) to the c1. For example, the moving speed number 2 0. Can be determined according to 1 mm/sec to 10 mm/sec. As such, cleaning brush (110) is number 1 position (110i) (W) (V1, V2) with reference to the 2 phase speed varies in contact with a substrate, substrate (W) in a set position in contact with the number 2 position (110ii) presses the substrate (W) while moving more slowly than to the contact while by sweep is in a washing system, remains on the surface of the substrate (W) to 100 nm hereinafter 40 micro m fine foreign number at the same time industry stand-alone foreign number are electrically deficiency can be largely reduce probability that scratches the surface of the substrate. On the other hand, cleaning brush (110) is number 1 position (110i) from position number 2 (110ii) is moved in, as well as variation of rotational speed lower than a moving speed (V1, V2) (u1, u2) disapproval. The, cleaning brush (110) to the substrate (W) when the rotational center of the surface of the drain (e.g., cleaning surface of is absorbed substrate (W) and an, i.e., cleaning protrusion height (hx) 9c also perceptible state nearly) (u1) remains on the surface of the substrate by the high-speed rotation (W) greater than at least 100 micro m number and a stand-alone is removed and placed against foreign material from a substrate surface, cleaning brush (110) to the substrate (W) when the rotational center of the surface of the drain (e.g., cleaning projection (110a) completely substrate (W) pressed against or cleaning protrusion base is substrate (W) and an, i.e., also 9d cleaning projections pressed significantly reduced or eliminated its height in the range of height (hx ')) (W) (u2) remains on the surface of the substrate by the shaft 40 to 100 nm hereinafter micro m fine foreign number can be secured by a stand-alone cleaning effect. Step 4: By step 3, cleaning brush (110) suitable for cleaning substrate (W) (or reference position) in setting position number 2 position (100ii) is used, as shown in also 9d, predetermined rotational speed (u3) brush washing of the (110) surface of the cleaned substrate (W) force (S140). Step 5: Substrate (W) or may be made only by maintain 4 step process is performed, the entire surface of the substrate (W) to obtain uniformly effect also 9g as shown in cleaning brush (110) (u3, u2) (W) to clean the surface of a substrate to vary the rotational speed of the disapproval (S150). At this time, cleaning brush (110) 5% to 80% of the rotational speed of the rotation speed of the lowest rotational speed range of the highest variation range (u3, u2) (u2) comprises a rotatable. As a result, as shown in also 9f, substrate support (90) during the spinning of the substrate (W) (r1), cleaning brush (110) distortion of same spot cleaning in lowering the efficiency can be prevented. On the other hand, as shown in also 9f, cleaning process during cleaning brush (110) cleaning brush (110) in the axial direction of reciprocating oscillation movement or, cleaning brush (110) substrate (W) perpendicular to an axial dimension of the ornamental portion of parallel front and rear directions (110y) outputting an oscillation movement bush disapproval. At this time, cleaning brush (110) reciprocating oscillation stroke cleaning projection (110a) interval (110x) above the c1. Through, conventional cleaning brush (10) protruded on the surface of cleaning projection (10a) of intervals between (10x) (W) substrate cleaning is eliminated and the driving force of the surface and the inner door number, all over the surface of substrate (W) over the cleaning benefits can be achieved. Step 6: In addition, substrate (W) or may be made only by maintain 4 stages of cleaning process, the surface of the substrate (W) in order to enhance the cleaning effect also 9e as shown in cleaning brush (110) moves to vertical (dz), cleaning brush (110) to the substrate surface of a substrate (W) varies the rotational center of the distance (W) to clean the surface of disapproval (S160). For example, cleaning brush (110) of vertical movement strokes in position number 1 (110i) on position number 2 (110ii) reciprocates the can be become stronger. The, cleaning brush (110) in contact with a surface of the substrate (W) (W) may be vertically while maintaining a substrate cleaning, a substrate and the substrate in contact with the change of place arrowhead it did (W) (W) was repeated to clean the disapproval. Through, cleaning brush (110) while a pressing force and friction is varied in order to press the substrate (W), a large process and remains on the surface of substrate number can be both to improve fine foreign materials industry. In addition, cleaning brush (110) connects the upper mixes cleaning process, cleaning brush (110) the rotational center of the surface of the substrate (W) away space number 1 position (110i) the cleaning brush (110) are provided to improve the rotational speed of the, cleaning brush (110) with a surface of the substrate (W) for commanding a rotational center of the space number 2 position (110ii) the cleaning brush (110) lower the rotational speed of the cleaning disclosed. The, substrate cleaning brush the rotational center of the space with greater number 1 position (110i) while high-speed rotation and large low pressing force in foreign material separated from the base substrate, substrate cleaning brush the rotational center of the space with smaller number 2 position (110ii) large pressing force while in low speed small foreign material can be separated from the cleaning process that is used. Step 7: Said step of cleaning the substrate (W) substantially complete, as shown in also 9g, cleaning brush (110) 20% to 70% of the rotational speed of the reference velocity (u3) extent barrier film (S170). The, substrate (W) remains on the surface of fine foreign cleaning brush (110) can be a stand-alone by finally whirling toilet bowl number. Then, as shown in also 9h, substrate cleaning is completed (W) from the surface of the cleaning brush (110) is supplied from the cleaning brush (110) moving the substrate. Even when the, cleaning is mainly formed at each setting position number 2 position (100ii) from number 1 position (100i) low rotational speed while maintaining low number 2 to moving speed (V2) (u2) moves to and fro (S180), cleaning brush (110) is number 1 position (110i) reaches a fast moving speed (V1) moves to a path number 1 (S190). Wherein, step 3 of number 1 position (110i) of number 1 position on step 7 (110ii) is determined according to different positions disapproval. Step 8: Then, whether the process substrate (W) is then forward and with each other. In the embodiment according to said one of the present invention substrate cleaning device such as a (100) includes, cleaning brush (110) substrate (W) rotated in contact tank, cleaning brush (110) to vary the separation distance between the rotational center of the substrate (W) by performing the [...] brush (110) into the substrate (W) by the predetermined value according to a pressing force and friction force, foreign material remains on the surface of a large substrate as well as the frame of the stand-alone number together, fluorine-based cleaning benefits that can be obtained with a favorable effect on flow tides. Or more of the present invention preferred embodiment in a illustratively described but, in the embodiment of the present invention correspondingly limited to said specific rights range such as, in the present invention is provided to a person with skill in the art of the present invention claim by appropriately modifiable category are disclosed. 90: Substrate support 95: holder 100: Substrate cleaning device 110: cleaning brush 110A: cleaning projection 110x: cleaning projection interval 112:114 Axis: the moving block 120: Support 130: number control unit W: substrate M: drive motor The utility model relates to a base plate cleaning device, it provides a base plate cleaning device, base plate cleaning device includes: substrate supporting part, it supports the base plate, cleaning brush, it contacts the washing to the base plate in rotatory to make rotation center with the substrate surface keeps contact State's spacing distance to change in cleaning process, thereby the rotation center through making cleaning brush and the distance of base plate change when the cleaning brush's of base plate that pressurizes frictional force changes, not only can improve greatly and get rid of the effect of remaining the great foreign matter more than the 100 mu m on the surface of base plate, still can improve the get rid of effect of 40 mu m to the small foreign matter below the 100nm. A rotating support that supports a substrate and circular substrate; substrate while rotating said substrate surface to contact mechanical cleaning and rotated while the drain during the cleaning process varies, spaced apart by a distance from the surface of said substrate in said substrate serving as a rotation center relative to the pressed degree number 1 number 1, number 2 at the location at which said substrate spaced apart by a distance smaller than said number 1 number 2 pressed and allow for greater degree, said number 1 spaced apart by a distance said number 2 number 1 position number 1 number 2 position relative to the rotational speed becomes smaller rotational speed varying rotational speed of the cleaning brush; and, said number 1 position said number 2 position said cleaning brush cleaning device characterized in that said brush unit for contacts the substrate. According to Claim 1, the rotational speed of the cleaning brush is varied during said cleaning process characterized by repeating the device for cleaning. According to Claim 2, said cleaning brush for the lowest 5% to 80% of the highest rotational speed with the same rotational speed said cleaning brush sealing force cleaning device. According to Claim 2, said cleaning brush surface has a plurality of cleaning sheets to predetermined electrodes separated by a distance 3 characterized device for cleaning According to Claim 1, said cleaning process said substrate during said cleaning brush height is varied repeatedly characterized device for cleaning. According to Claim 1, said spacing distance is said substrate contact each other to said cleaning brush and kept in the range characterized in which a cleaning device. According to Claim 1, said spacing distance is said substrate cleaning brush including a brush cleaning device characterized in that said state of contact with each other. According to Claim 1, said number 1 number 1 position relative to the moving speed, the moving speed is smaller than a moving speed of said number 2 position number 2 oscillate said cleaning brush is characterized device for cleaning. According to Claim 8, said number 2 the moving speed of the moving speed of said number 1 characterized in force cleaning device 3% to 50%. A rotating support that supports a substrate and circular substrate; cleaning the surface of the substrate facing away from number 1 number 1 position in said seat back have a start of the fermentation process while at a rotation speed of said approaching toward the substrate, the distance from the surface of the substrate from said substrate to said defined distance setting position and rotated in the area of the, said substrate pressed against said number 1 and number 2 allow for greater degree rotation speed setting position while said substrate while said substrate contact moved at a rotation speed of cleaning brush; and, said predetermined distance said cleaning brush contact brush cleaning device characterized in that said substrate in a stacked state. According to Claim 10, said cleaning brush said number 1 position moving said substrate to approach a moving speed relative to number 1, number 2 reaching said cleaning brush setting position said brush cleaning device characterized smaller moving speed. According to Claim 11, said number 2 3% to 50% of the moving speed of the moving speed of said number 1 characterized in which a cleaning device. A rotating support that supports a substrate and circular substrate; said set number 2 position in the end of cleaning the surface of the substrate at a rotation speed of said rotation center while moving away from the substrate, the distance from the surface of the substrate from said substrate and rotated said defined distance moved away than in region, said substrate at a rotation speed higher than said number 2 and pressed to be less degree rotation number 1 moved away from the substrate while said substrate while said cleaning brush contact; and, said predetermined distance said cleaning brush contact brush cleaning device characterized in that said substrate in a stacked state. According to Claim 13, said cleaning brush away from said substrate in said setting position and moves to number 2 compared to moving speed, said cleaning brush moving away from said defined distance is greater moving speed number 1 characterized force cleaning device. According to Claim 14, said number 2 the moving speed of the moving speed of said number 1 characterized in force cleaning device 3% to 50%. According to one of Claim 1 to Claim 15, said cleaning brush are made of materials which can be embodied as a device for cleaning a characterized as soon as water. According to one of Claim 1 to Claim 15, said amount of said cleaning brush is adapted for cleaning device for cleaning a substrate simultaneously with an ornamental portion characterized. According to one of Claim 1 to Claim 15, said cleaning brush is adapted during said reciprocating oscillation movement in the axial direction of said cleaning process characterized in that brush cleaning device for cleaning. According to Claim 18, said cleaning brush reciprocating oscillation movement of strokes is not less than said first film is a washing brush cleaning device for cleaning a surface of interval characterized. According to one of Claim 1 to Claim 15, said cleaning brush are perpendicular to said axial direction of said substrate during said cleaning process cleaning brush plat characterized in a direction parallel to the reciprocating oscillation movement device for cleaning. According to Claim 20, said cleaning brush reciprocating oscillation movement of strokes is not less than said first film is a washing brush cleaning device for cleaning a surface of interval characterized. The substrate is in contact with brush cleaning method to a circular wire, said cleaning brush for cleaning a substrate surface of the substrate in contact with said rotatable contact and; during said cleaning step, said surface of said substrate to vary the separation distance between the rotational center of the cleaning brush and a backside and a variation; said spaced apart by a distance from the surface of said substrate in said cleaning brush center of rotation of the substrate relative to the pressed degree number 1 number 1, number 2 spaced apart by a distance smaller than said number 1 number 2 and allow for greater extent at the location at which said pressed against a substrate, said substrate spaced apart by a distance said cleaning brush said number 1 number 1 position number 1 number 2 position relative to the rotational speed of the rotational speed to the rotational speed becomes smaller said number 2 varies both when you want control force to rotate said cleaning step; and comprising, said number 1 position said number 2 position said cleaning unit for cleaning a substrate that method characterized in that said brush contacts the substrate. According to Claim 22, said cleaning brush structure and position said number 1 number 1 number 2 position relative to said number 2 moving speed can also brush moving speed of the vibration absorber to smaller moving speed; the method further comprises cleaning a substrate that characterized. According to Claim 22, said backside and initiate said cleaning brush rotated said variation step for selectively removing the surface of the substrate in said substrate cleaning method characterized approaches including conducted. A rotating support that supports a substrate and circular substrate; a substrate during contact during cleaning, surface while said vertically reciprocating movement to and rotated by said substrate to the surface of the substrate is varied repeatedly space around said substrate during said cleaning process repeatedly trust oscillate cleaning brush; characterized force cleaning device comprising. The substrate is in contact with brush cleaning method to a circular wire, said cleaning brush for cleaning a substrate surface of the substrate in contact with said rotatable contact and; during said cleaning step, said cleaning brush vertically to said repeated and said cleaning brush and the rotational center of the pushing surface of the substrate by repeating the separation distance change said substrate during said cleaning step repeatedly alters tension around said substrate backside variation step; characterized comprising cleaning a substrate that method.